Bredel Equipment We Distribute

Bredel, a leading manufacturer in the fluid handling industry, specializes in the production of an extensive range of pumping solutions that cater to various industrial applications. Their product lineup includes Industrial Hose Pumps, designed for handling high-viscosity fluids, abrasive slurries, and corrosive chemicals with exceptional reliability and efficiency. Bredel’s Heavy-Duty Hose Pumps are engineered to withstand the toughest industrial environments, offering long-lasting performance and low maintenance requirements. The APEX™ Hose Pump Series is a versatile and cost-effective pumping solution that combines reliability, efficiency, and ease of use for a wide range of applications, including chemical dosing, wastewater treatment, and food processing. Additionally, Bredel offers an array of Hose Pump Accessories designed to enhance the performance, adaptability, and usability of their pumps, ensuring that customers can tailor their pumping solutions to meet specific operational needs and requirements.

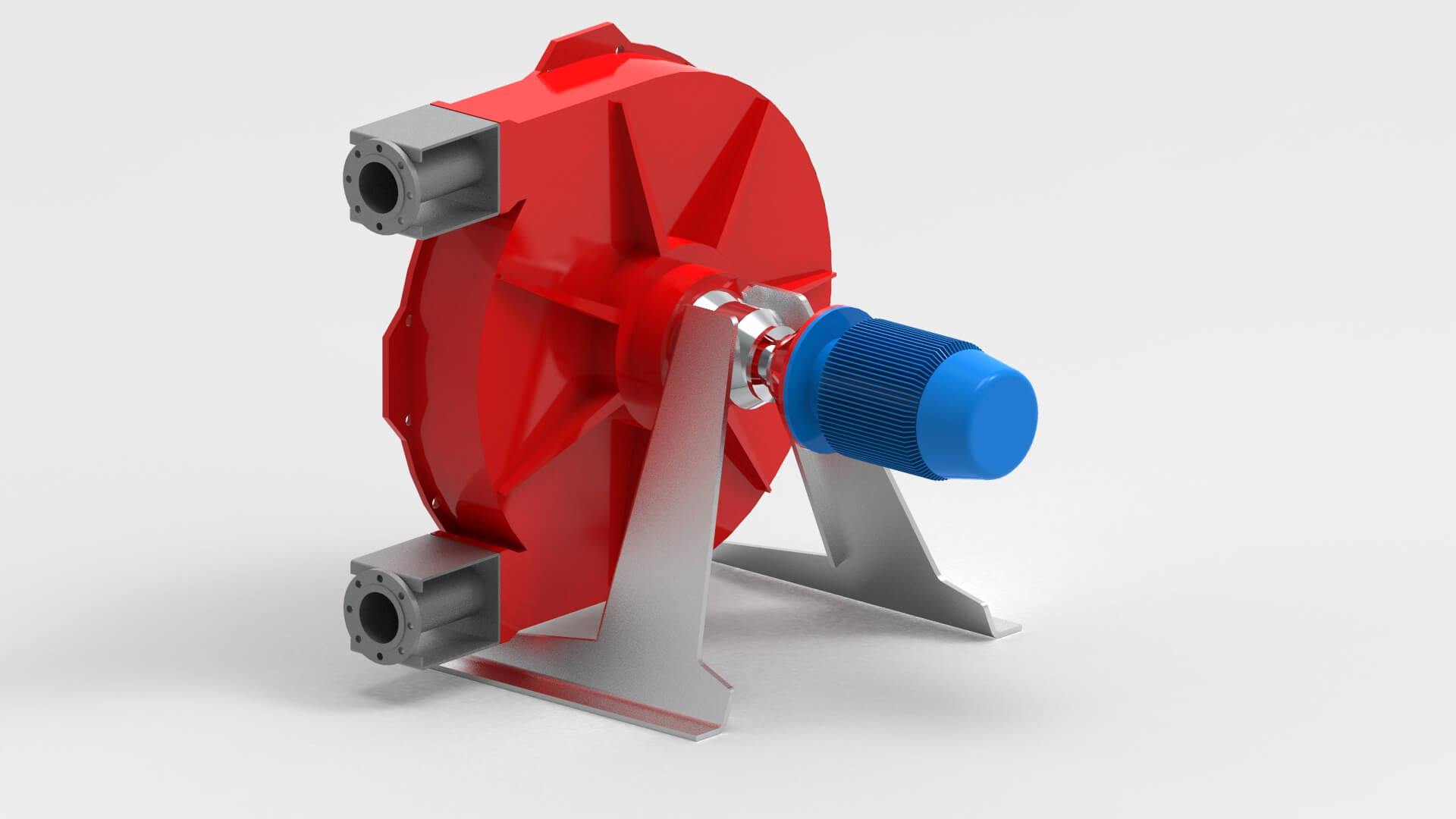

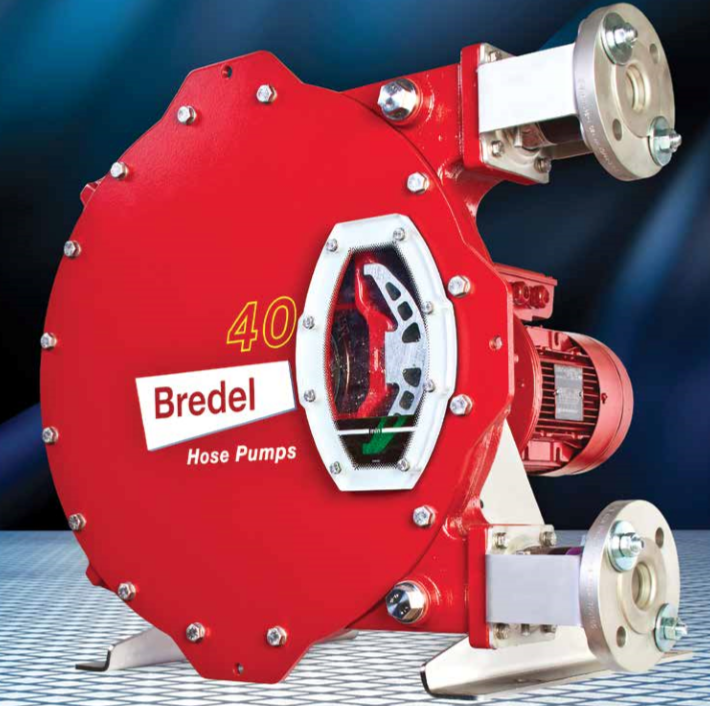

Industrial Hose Pumps

Bredel’s Industrial Hose Pumps are designed to provide reliable and efficient fluid handling solutions in a wide range of industries and applications, including chemical processing, water and wastewater treatment, and food and beverage production. These peristaltic pumps are known for their ability to handle high-viscosity fluids, abrasive slurries, and corrosive chemicals with ease and precision. By utilizing a unique pumping mechanism that involves compressing a hose to generate flow, the Industrial Hose Pumps eliminate the need for valves, seals, or glands, reducing maintenance requirements and the risk of contamination or leakage.

One of the key advantages of Bredel’s Industrial Hose Pumps is their ability to deliver consistent performance across a broad spectrum of operational conditions. The pumps offer accurate and repeatable flow rates, making them ideal for applications requiring precise dosing or metering of fluids. Additionally, the pumps are capable of operating at high pressures, enabling them to efficiently transfer fluids over long distances or against significant head pressures. The gentle pumping action of Bredel’s Industrial Hose Pumps also ensures that shear-sensitive fluids or fluids containing delicate solids can be handled without causing damage or degradation.

Bredel’s commitment to quality and innovation is evident in the design and construction of their Industrial Hose Pumps. Manufactured using high-quality materials and state-of-the-art engineering techniques, these pumps are built to withstand the rigors of demanding industrial environments. The pumps feature rugged, abrasion-resistant hoses and durable pump casings that ensure long-lasting performance with minimal maintenance requirements. Furthermore, Bredel’s Industrial Hose Pumps are designed with ease of use and maintenance in mind, offering user-friendly controls and straightforward access to internal components, thereby minimizing downtime and enhancing operational efficiency.

Heavy-Duty Hose Pumps

Bredel’s Heavy-Duty Hose Pumps are engineered to provide robust and dependable fluid handling solutions for the most demanding industrial environments. These high-performance pumps are specifically designed to handle aggressive chemicals, abrasive materials, and high-pressure applications, making them ideal for sectors such as mining, chemical processing, and heavy manufacturing. Bredel offers a range of heavy-duty hose pump series to cater to different needs, including the CIP (Clean-In-Place) and DuCoNite series, each offering unique features and advantages to address specific challenges in various industries.

The CIP series of Bredel’s Heavy-Duty Hose Pumps are designed with hygiene and cleanliness in mind. These pumps are particularly well-suited for applications in the food, beverage, and pharmaceutical industries, where maintaining strict hygiene standards is paramount. The CIP series offers easy-to-clean components and a streamlined design that allows for efficient cleaning-in-place processes, ensuring that pumps meet stringent sanitation requirements without compromising performance or reliability. The gentle pumping action of the CIP series also preserves the integrity of shear-sensitive fluids and solids, making them ideal for handling delicate products such as sauces, yogurts, and pharmaceutical formulations.

Bredel’s DuCoNite series of Heavy-Duty Hose Pumps are specifically designed to withstand the corrosive and abrasive environments commonly encountered in chemical processing and mining applications. These pumps feature a unique surface treatment technology called DuCoNite, which provides exceptional resistance to chemical attack, wear, and corrosion. This innovative treatment extends the service life of the pumps, reducing maintenance requirements and minimizing the risk of pump failure. The DuCoNite series is capable of handling aggressive fluids, such as acids, alkalis, and solvents, as well as abrasive slurries and particulate-laden materials, making them an invaluable asset in industries that demand high levels of durability and performance in fluid handling equipment.

APEX™ Hose Pump Series

Bredel’s APEX™ Hose Pump Series is a versatile and cost-effective pumping solution designed to cater to a diverse array of industries and applications. Combining reliability, efficiency, and ease of use, these pumps offer an excellent alternative for fluid handling tasks in sectors such as chemical processing, water and wastewater treatment, food and beverage production, and mining. With their precise and consistent flow control, the APEX™ series is well-suited for dosing and metering applications, ensuring optimal performance even in challenging conditions.

The APEX™ Hose Pump Series boasts a number of advanced features that enhance its performance and adaptability. One of the key advantages of these pumps is their ability to handle a wide range of fluid types, including high-viscosity fluids, abrasive slurries, and corrosive chemicals. The peristaltic pumping action eliminates the need for valves, seals, or glands, reducing the risk of contamination, leakage, or clogging while ensuring minimal maintenance requirements. The pumps can also operate in either direction, allowing for reversible flow, which is particularly useful for processes that require the transfer of fluids in multiple directions or for emptying lines and containers.

Bredel’s commitment to quality and innovation is reflected in the design and construction of the APEX™ Hose Pump Series. Manufactured using high-quality materials and state-of-the-art engineering techniques, these pumps deliver long-lasting performance with minimal wear and tear. The pumps feature rugged, abrasion-resistant hoses, durable pump casings, and advanced sealing systems to extend service life and reduce maintenance costs. Furthermore, the APEX™ series is designed with user-friendliness and ease of maintenance in mind, offering straightforward access to internal components and intuitive controls that minimize downtime and enhance operational efficiency.

Hose Pump Accessories

Bredel offers a comprehensive range of Hose Pump Accessories designed to enhance the performance, versatility, and usability of their pumping solutions. These accessories enable customers to tailor their pumping systems to meet specific operational needs and requirements, ensuring optimal efficiency and reliability across diverse industrial applications. From hoses and connectors to flow meters and control systems, Bredel’s Hose Pump Accessories provide the necessary components to optimize fluid handling processes and maximize the benefits of their industry-leading pump technology.

One of the key components of Bredel’s Hose Pump Accessories is their selection of high-quality hoses. These hoses are available in various materials, sizes, and designs to accommodate different types of fluids, pressure requirements, and operating conditions. Bredel hoses are engineered to provide exceptional durability, resistance to wear and abrasion, and compatibility with a wide range of fluids, including corrosive chemicals, abrasive slurries, and high-viscosity materials. By offering hoses in various materials, such as natural rubber, EPDM, and nitrile, Bredel ensures that customers can select the most suitable hose for their specific application, ensuring maximum performance and service life.

In addition to hoses, Bredel’s Hose Pump Accessories also include a range of connectors, flow meters, and control systems designed to facilitate seamless integration with existing process infrastructure and enhance the overall functionality of the pumping system. The connectors are available in various configurations and materials, enabling secure and leak-free connections between the pump, hoses, and other system components. Flow meters and control systems provide precise and real-time monitoring of pump performance, allowing for accurate flow control, efficient dosing, and timely detection of potential issues. By offering a comprehensive selection of Hose Pump Accessories, Bredel empowers customers to customize their fluid handling solutions, ensuring optimal performance, reliability, and efficiency in a wide array of industrial applications.

Applications of Bredel Equipment

Bredel equipment caters to a wide range of industries, providing versatile and reliable fluid handling solutions that address the unique challenges and requirements of each sector. In the Industrial domain, Bredel pumps excel at handling abrasive, corrosive, and high-viscosity fluids, ensuring smooth operation in industries such as chemical processing, ceramics, and pulp and paper. Within the Water and Wastewater sector, Bredel pumps play an essential role in the accurate dosing and transfer of chemicals for treatment processes, as well as sludge and waste handling. In the Food and Beverage industry, Bredel’s hygienic pumps, such as the CIP series, offer easy-to-clean components and gentle pumping action, making them ideal for handling shear-sensitive fluids and maintaining strict sanitation standards. Lastly, in the Mining sector, Bredel equipment is known for its durability and efficiency in managing abrasive slurries, tailings disposal, and mineral processing. With its diverse product portfolio and commitment to engineering excellence, Bredel continues to set the standard for fluid handling solutions across various industries.

Industrial

Bredel equipment is widely employed in various industrial sectors, offering reliable and efficient fluid handling solutions for a diverse range of applications. Bredel’s Industrial Hose Pumps, Heavy-Duty Hose Pumps, APEX™ Hose Pump Series, and associated accessories have been designed to meet the unique challenges and requirements of the industrial sector, delivering consistent performance, durability, and adaptability in demanding conditions. Industries such as chemical processing, mining, pulp and paper, and ceramics rely on Bredel equipment to handle abrasive, corrosive, and high-viscosity fluids, ensuring the smooth and uninterrupted operation of critical processes.

In the chemical processing industry, Bredel pumps play a vital role in the accurate dosing and transfer of aggressive chemicals, such as acids, alkalis, and solvents. The peristaltic pumping action of Bredel equipment eliminates the need for valves, seals, or glands, reducing the risk of contamination, leakage, or clogging, and ensuring the safe and efficient handling of hazardous materials. Additionally, Bredel pumps’ ability to maintain precise flow control and operate at high pressures makes them an invaluable asset in chemical transfer, blending, and reaction processes, where accuracy and reliability are of paramount importance.

The mining industry also benefits significantly from the use of Bredel equipment, particularly in applications that involve the handling of abrasive slurries and particulate-laden materials. Bredel’s Heavy-Duty Hose Pumps, such as the DuCoNite series, are designed to withstand the corrosive and abrasive environments commonly encountered in mining operations, offering exceptional resistance to wear, corrosion, and chemical attack. Furthermore, Bredel pumps’ capability to handle high-viscosity fluids and solids without causing damage or degradation ensures the efficient and reliable transfer of materials in various mining processes, including tailings disposal, mineral processing, and dewatering. Bredel’s commitment to engineering excellence, innovation, and customer satisfaction makes its equipment a preferred choice for fluid handling applications in the industrial sector.

Water and Wastewater

Bredel equipment plays a critical role in the Water and Wastewater industry, offering dependable and efficient fluid handling solutions for a variety of treatment processes. These pumps are known for their ability to handle aggressive chemicals, abrasive materials, and high-viscosity fluids with precision and reliability. Bredel pumps, such as the APEX™ Hose Pump Series and the Heavy-Duty Hose Pumps, are widely employed in water treatment plants, municipal wastewater facilities, and industrial wastewater management systems, where they contribute to ensuring the safe and effective treatment of water and wastewater streams.

One of the primary applications of Bredel equipment in the Water and Wastewater industry is chemical dosing and transfer. Accurate dosing and metering of chemicals such as coagulants, flocculants, disinfectants, and pH adjustment agents are essential for the efficient operation of water and wastewater treatment processes. Bredel’s peristaltic pumps offer precise flow control and repeatability, ensuring that the correct amounts of chemicals are added to the treatment process at the appropriate times. The pumps’ valveless design and ability to handle corrosive and abrasive chemicals make them an ideal choice for this application, reducing the risk of contamination, leakage, or clogging, and minimizing maintenance requirements.

Another significant application of Bredel equipment in the Water and Wastewater industry is sludge handling and transfer. The pumps’ ability to handle high-viscosity fluids, solids-laden materials, and abrasive slurries makes them well-suited for transferring dewatered sludge, primary sludge, and other waste materials throughout the treatment process. Bredel pumps can also manage varying flow rates and pressures, allowing them to efficiently transfer sludge over long distances or against significant head pressures. The reliable performance and durability of Bredel equipment ensure that water and wastewater treatment facilities can operate smoothly, optimizing resource recovery and reducing the environmental impact of waste disposal.

Food and Beverage

Bredel equipment is extensively utilized in the Food and Beverage industry, providing hygienic and efficient fluid handling solutions that cater to the unique needs of this sector. The gentle pumping action of Bredel’s hose pumps, such as the CIP (Clean-In-Place) series, makes them ideal for transferring shear-sensitive fluids and solids without causing damage or degradation. Bredel pumps are widely employed in various food and beverage applications, including the transfer of sauces, dairy products, fruit purees, beverages, and other process fluids. With their precise flow control, reliability, and low maintenance requirements, Bredel pumps contribute to enhancing the quality and efficiency of food and beverage production processes.

One of the key features that make Bredel equipment well-suited for the Food and Beverage industry is its hygienic design. Bredel’s CIP series of pumps, for example, are specifically designed with cleanliness and sanitation in mind. These pumps feature easy-to-clean components and a streamlined design that allows for efficient cleaning-in-place processes, ensuring that they meet stringent sanitation requirements without compromising performance or reliability. The valveless design and absence of seals or glands in Bredel pumps also help reduce the risk of contamination, making them an ideal choice for food and beverage applications where product quality and safety are paramount.

Another crucial aspect of Bredel equipment in the Food and Beverage industry is its ability to handle a wide range of fluid types and viscosities. Bredel pumps can efficiently transfer high-viscosity fluids, such as fruit concentrates, chocolate, and dough, as well as materials containing soft solids, like fruit pieces and vegetable chunks, without causing damage to the product. This versatility enables food and beverage manufacturers to utilize Bredel pumps for a variety of applications, from ingredient transfer and blending to filling and packaging processes. With their commitment to engineering excellence and innovation, Bredel continues to offer fluid handling solutions that meet the evolving needs of the Food and Beverage industry.

Mining

Bredel equipment is highly valued in the Mining industry, where it offers robust and efficient fluid handling solutions for a wide range of demanding applications. Bredel’s Industrial Hose Pumps, Heavy-Duty Hose Pumps, and APEX™ Hose Pump Series are designed to withstand the harsh and abrasive environments commonly encountered in mining operations. Their ability to handle abrasive slurries, corrosive chemicals, and high-viscosity fluids makes them an ideal choice for various mining processes, including mineral processing, tailings disposal, and dewatering. Bredel pumps deliver consistent performance and durability, ensuring the smooth operation of essential mining processes and contributing to the overall efficiency of mining operations.

In mineral processing applications, Bredel pumps excel at transferring abrasive slurries and particulate-laden materials, such as ore concentrates, leach solutions, and process water. The peristaltic pumping action of Bredel equipment ensures that these fluids are handled gently and with minimal wear, extending the service life of the pump and reducing maintenance costs. Bredel’s Heavy-Duty Hose Pumps, such as the DuCoNite series, is specifically designed to resist wear and corrosion, making them ideal for applications involving the transfer of abrasive and corrosive materials. Additionally, Bredel pumps can handle varying flow rates and pressures, allowing them to efficiently transfer materials over long distances or against significant head pressures.

Tailings disposal and dewatering are other critical applications of Bredel equipment in the Mining industry. Bredel pumps are capable of handling high-viscosity fluids and solids-laden materials without causing damage or degradation, ensuring the efficient and reliable transfer of tailings and dewatered materials to storage facilities or disposal sites. The pumps’ ability to manage varying flow rates and pressures also enables them to effectively handle fluctuations in the volume and composition of tailings streams, ensuring that the disposal process operates smoothly and with minimal environmental impact. Bredel’s commitment to engineering excellence, innovation, and customer satisfaction makes its equipment a preferred choice for fluid handling applications in the mining sector.

Factors to Consider When Buying Bredel

As a trusted manufacturer of high-quality peristaltic hose pumps and associated accessories, Bredel has established itself as a leader in fluid handling solutions across various industries. From mining to food and beverage, Bredel equipment provides reliable and efficient fluid transfer, meeting the unique needs and requirements of each sector. However, before making a purchase, professionals should consider several key factors to ensure that they select the right equipment for their specific applications. In this article, we will discuss essential aspects to consider before buying Bredel equipment.

Fluid Characteristics

The first and foremost consideration when selecting Bredel equipment is the fluid characteristics of the materials to be handled. Professionals need to assess the viscosity, abrasiveness, corrosiveness, and shear sensitivity of the fluid to determine the most suitable pump type and hose material. By understanding the fluid characteristics, professionals can choose equipment that can efficiently handle the fluid without causing damage, degradation, or excessive wear, thereby ensuring optimal performance and longevity.

Flow Rate and Pressure Requirements

Another crucial factor to consider is the flow rate and pressure requirements of the application. Bredel pumps are available in various sizes and capacities, with different models designed to handle different flow rates and pressures. It is essential to accurately determine the desired flow rate and pressure to select a pump that can efficiently meet these requirements while operating within its optimal performance range. Oversizing or under-sizing the pump can lead to inefficient operation, increased energy consumption, and reduced service life.

Hygiene and Sanitation Requirements

For professionals in the food, beverage, and pharmaceutical industries, hygiene and sanitation requirements are of paramount importance. Bredel offers pumps with hygienic designs, such as the CIP series, which are specifically engineered for easy cleaning and compliance with strict sanitation standards. When selecting Bredel equipment for applications with high hygiene requirements, professionals should ensure that the chosen pump model meets the necessary industry standards and guidelines, such as FDA, 3A, or EHEDG certification.

Integration with Existing Infrastructure

Before purchasing Bredel equipment, it is crucial to consider how the pump will integrate with the existing process infrastructure. Professionals should evaluate the compatibility of the pump’s connections, control systems, and other accessories with the current setup to ensure seamless integration and smooth operation. It may also be necessary to make adjustments or modifications to the existing infrastructure to accommodate the new equipment.

Maintenance and Support

The ease of maintenance and availability of support services are essential factors to consider before investing in Bredel equipment. Bredel pumps are designed with low maintenance requirements, but it is still crucial to ensure that spare parts, such as hoses and accessories, are readily available when needed. Professionals should also assess the availability of local support services, such as technical assistance and training, to ensure that they can adequately maintain and troubleshoot their equipment.

About Bredel

Bredel is a global leader in the manufacture of peristaltic hose pumps and associated accessories for fluid handling applications. The company’s equipment is designed to provide robust and reliable solutions that cater to the specific needs of a diverse range of industries, from mining and chemical processing to food and beverage and wastewater treatment. With a commitment to engineering excellence, innovation, and customer satisfaction, Bredel continues to set the standard for fluid handling solutions across various sectors.

Bredel’s success is based on its unique approach to fluid handling, which utilizes the peristaltic pumping principle. Unlike traditional pumping systems that rely on the impeller or diaphragm technology, peristaltic pumps use a rotating roller or shoe to compress a flexible hose, creating a positive displacement action that moves the fluid through the hose. This design offers several advantages, including the ability to handle abrasive, corrosive, and high-viscosity fluids with ease, low maintenance requirements, and gentle pumping action that avoids damage to the product.

Founded in 1959, Bredel has established a reputation as a reliable and innovative provider of fluid handling solutions. Today, the company operates in more than 50 countries, with a global network of sales and service partners that ensure customers have access to the highest level of technical support and after-sales service. With a comprehensive range of pumps, hoses, and accessories, Bredel continues to meet the evolving needs and challenges of various industries, providing efficient, reliable, and cost-effective solutions for fluid handling applications.

Affiliation with Watson Marlow Pumps

Bredel is a brand of the Watson-Marlow Fluid Technology Group, a global leader in the manufacture of positive displacement pumps and associated technologies for fluid handling applications. The acquisition of Bredel by Watson-Marlow has strengthened the Group’s position in the peristaltic pump market, providing customers with an even wider range of solutions for their fluid handling needs. Under the Watson-Marlow umbrella, Bredel continues to offer its customers innovative and reliable fluid-handling solutions, backed by the Group’s global network of sales and support services.

The affiliation between Bredel and Watson-Marlow has enabled both companies to leverage their respective strengths, expertise, and resources, delivering enhanced value to their customers across various industries. With a shared commitment to engineering excellence, innovation, and customer satisfaction, the partnership between Bredel and Watson-Marlow has led to the development of new technologies and solutions that meet the evolving needs and challenges of various sectors. As part of the Watson-Marlow Fluid Technology Group, Bredel continues to build on its legacy of providing high-quality peristaltic hose pumps and accessories, ensuring that customers receive the most reliable, efficient, and cost-effective fluid handling solutions available.