An Authorized Hevvy | Toyo Pumps Distributor

Industrial & Sanitary Pump Solutions

Arroyo Process Equipment is proud to represent Hevvy | Toyo Pumps, a global leader in slurry and solids-handling pump technology. Built for aggressive applications where other pumps fail, Hevvy | Toyo delivers innovative, high-efficiency solutions for the most demanding environments—from mining and power plants to wastewater and chemical processing.

Durability Meets Design

Explore the Full Line of Hevvy Pumps at Arroyo

As an official distributor, we give you direct access to Hevvy | Toyo’s full portfolio, including pumps designed for some of the harshest operating conditions in industry. These pumps move high-solids slurries, abrasive mixtures, and corrosive fluids—without sacrificing uptime or performance. Our engineering team will help you size and select the right pump for your duty point, with support every step of the way.

Submersible Slurry Pumps

Built to operate fully submerged, Hevvy’s submersible slurry pumps are designed to thrive in abrasive, high-solid environments where downtime isn’t an option. With rugged wet-end materials and integrated agitators, these pumps keep solids suspended and perform reliably in deep or confined spaces.

Ideal for:

- Sumps and process pits

- Tailings ponds and containment basins

- Settling tanks and clarifiers

- Dredging operations and barge unloading

- Washdown and slurry reclamation zones

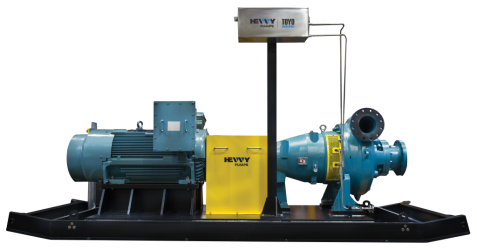

Horizontal Slurry Pumps

These above-ground workhorses are engineered for continuous-duty operation in tough environments. Easy access to wear components and a range of material options make them a go-to for plants that need high-performance and low-maintenance pumping.

Great for:

- Mining and mineral slurries

- Ball or SAG mill discharge

- Sand, gravel, and aggregate transfer

- Thickened chemical slurries

- Cement and lime plant process flows

Sanitary Gear Pumps

Hevvy’s cantilever-style vertical pumps feature no submerged bearings, making them ideal for corrosive or abrasive fluids with entrained solids. These pumps simplify maintenance while offering long life in sumps, pits, and tanks—especially where reliability is critical.

Common in:

- Acidic or caustic waste sumps

- Floor drain systems with grit and solids

- Refinery waste streams and loading areas

- Pickling, plating, or electrochemical tanks

- Bio-chemical and pH-adjustment pits

Agitator Pumps

A hallmark of the Hevvy line, these pumps feature an integrated agitator that actively stirs solids at the suction inlet—eliminating dead zones and reducing clogging. They are the ideal solution for thick, heavy media where standard pumps would stall or cavitate.

Designed for:

- Sludge ponds and lagoons

- Lime slurry handling

- Fly ash and coal ash transport

- Tank cleanouts and recirculation

- Thickener underflow or overflow systems

Custom Configurations

We offer complete custom Hevvy pump + motor packages, built around your application’s exact requirements. From metallurgy to mounting style, Arroyo helps you design a unit that works with your site conditions, preferred maintenance practices, and operational targets.

Custom options for:

- Skid-mounted, vertical, or horizontal installations

- ATEX-rated or explosion-proof duty environments

- Multiple sealing options: mechanical, packing, or seal-less

- Controls, starters, and variable frequency drives

- Hardened components for abrasive wear or corrosive duty

Engineered for Tough Environments

Hevvy Pumps at Work Across Key Sectors

Hevvy | Toyo Pumps are trusted by industries that face high wear, aggressive media, and critical uptime demands. Arroyo helps operations in these sectors select, install, and maintain the right pump for long-term performance.

Mining & Mineral Processing

Hevvy pumps are a staple in the global mining industry, engineered to perform where solids content is high, wear rates are severe, and access for maintenance is limited. Whether you’re dealing with abrasive tailings or highly viscous ore slurries, Hevvy’s rugged construction and powerful agitator technology help maintain consistent throughput and reduce costly shutdowns.

Common uses:

- Tailings and mine waste handling

- Cyclone and hydrocyclone feed

- Primary and secondary slurry transport

- Roofing material production

- Thickener underflow

- Concentrate and reagent transfer

Power Generation

Power plants—especially those using fossil fuel combustion—rely on slurry pumps for a range of fluid handling needs, from ash removal to environmental treatment systems. Hevvy pumps are built to withstand thermal shock, chemical exposure, and highly abrasive byproducts common in utility and cogeneration facilities.

Applications include:

- Fly ash and bottom ash slurry removal

- Flue gas desulfurization (FGD) scrubber feed

- Cooling pond or tower recirculation

- Limestone slurry and chemical handling

- Emergency and backup sump dewatering

Pulp & Paper

In pulp and paper mills, uptime is non-negotiable and fluids are anything but clean. Hevvy pumps are used to manage thick stock, fibrous waste, and abrasive slurries that can destroy conventional pumps. Their cantilever and submersible designs are especially well-suited to tight mechanical spaces and highly variable loads.

Perfect for:

- Recycled pulp and thick stock transfer

- Wastewater lagoon pumping

- Coating waste recirculation

- Screen rejects and solids transport

- Sludge removal in primary clarifiers

Wastewater Treatment

Municipal and industrial treatment plants depend on pumps that can manage fibrous, sandy, and biologically active sludges without clogging or wearing out prematurely. Hevvy’s slurry-ready submersible and vertical pumps are up to the task—offering exceptional uptime in even the grittiest environments.

Best for:

- Influent channel and grit chamber transfer

- Clarifier underflow and sludge thickening

- Return activated sludge (RAS) and waste activated sludge (WAS)

- Bio-solid digestion and dewatering

- Septage receiving station pumping

Chemical & Industrial Processing

For operations that involve aggressive chemicals or abrasive slurry flows, Hevvy’s corrosion-resistant materials, sealing technologies, and modular pump configurations offer peace of mind and system longevity. From neutralization pits to high-pH waste, we’ll help you specify the right solution.

Used in:

- Caustic or acidic slurry circulation

- Reactor and scrubber discharge

- Effluent treatment in plating or metal finishing

- Slurry transport in bulk chemical plants

- Corrosive drainage and spill containment systems

Start Your Next Order

Ready to Get Started?

As your dedicated Hevvy | Toyo Pumps distributor, we provide more than just products—we offer hands-on support, expert sizing, and fast lead times.

Explore Hevvy Pump Series

Browse our blog-style series pages to learn more about individual pump models, applications, and how Arroyo supports their long-term performance in the field.

Hevvy Pumps | Toyo Pumps: A Manufacturer Overview

Hevvy Pumps | Toyo Pumps are industry leaders in industrial slurry pump technology ranging in submersible, horizontal, custom, and cantilever pumps fo