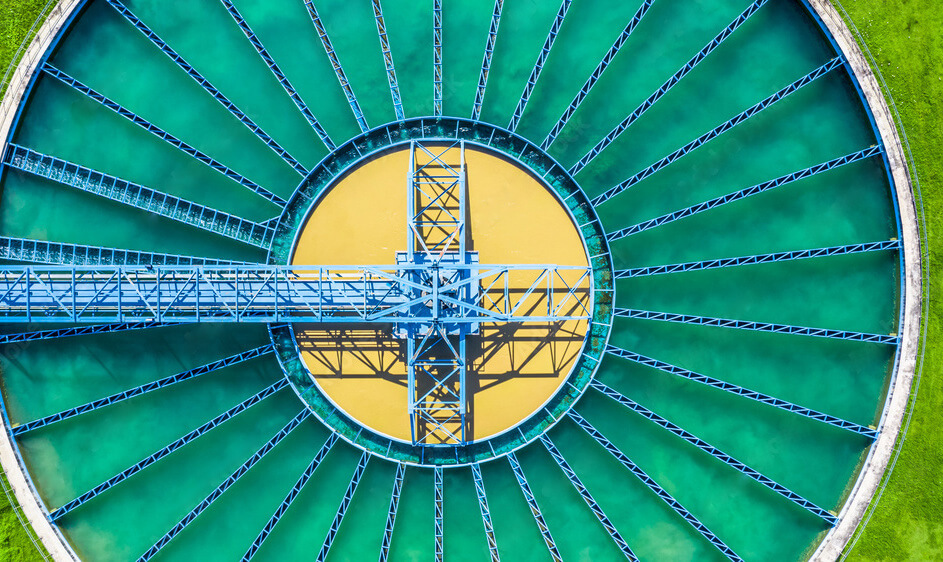

Industries / Water & Wastewater / Water Treatment Plants

Maximizing water quality with rotating equipment for WTPs

Optimize treatment processes with high-quality rotating equipment and services that ensure efficient pumping, thorough mixing, effective filtration, and reliable aeration, resulting in improved water quality, reduced contaminants, and enhanced overall treatment efficiency. By achieving optimal treatment conditions, WTPs can deliver clean and safe water that meets stringent regulatory standards and fulfills the needs of communities.

The Manufacturing Process

Create economies of scale across your system

Each of these stages requires specific types of industrial rotating equipment. Proper operation and maintenance of this equipment are crucial for the efficiency, safety, and reliability of water treatment plants.

Intake Pumps

At the intake, large pumps are used to draw water from the source (like a river, lake, or groundwater well) into the treatment plant.

Coagulation & Flocculation

These processes often use mixers or agitators to mix the water with coagulants and flocculants, which help particles in the water to cluster together into larger, more easily removable, particles.

Sedimentation

In sedimentation tanks, particles settle to the bottom under gravity. Some designs of these tanks involve rotating equipment to collect the settled solids.

Filtration

After sedimentation, the water flows through filters to remove any remaining particles. Some types of filters, like rotating drum filters, use rotating equipment.

Disinfection

Pumps, which are a type of rotating equipment, are used to dose disinfectants like chlorine or UV light to kill bacteria and other microorganisms.

Pumps for Water Distribution

After treatment, the clean water is pumped into the distribution system to reach homes and businesses. Pumps are also used to pressurize the water so it can reach all parts of the distribution network.

Blowers

These are used in aeration tanks where water may be treated biologically. The blowers provide the necessary oxygen for microorganisms that break down any remaining organic matter.

Sludge Treatment

Any sludge generated during the treatment process (for example, from sedimentation tanks) needs to be treated and disposed of safely. This can involve rotating equipment like mixers, thickeners, centrifuges, or screw presses.

Maintenance & Cleaning

Equipment like pressure washers and rotary brushes, which include rotating parts, can be used for cleaning and maintaining other water treatment equipment.