Industries / Asphalt / Roofing & Shingles

Get cutting-edge asphalt pumps and engineered solutions that drive results

The Manufacturing Process

Create economies of scale across roofing and shingles production

We enable you to get access to manufacturers and meet large-scale production demands while ensuring consistent and high-quality results. The equipment we source is widely used in refineries, terminals, hot mix plants, roofing plants, distributor trucks, and tar kettles/tack tanks.

-

Transfer and Handling of Raw Materials

-

Processing and Transformation

-

Waste Management

-

Application and Distribution

-

Production and Blending

-

Coating and Finishing

Unload Flux from Railcars

The asphalt pumps we distribute, including dredge pumps, facilitate the efficient transfer of flux from railcars to tank farms, ensuring a seamless and reliable process. This is particularly crucial in terminals and refineries where large volumes of materials are handled. We source dredge pumps designed to handle various types of materials, including thick and viscous substances, ensuring that the transfer process is both efficient and reliable.

Move Flux from Tank Farm to Preheater

The asphalt pumps we source enable the efficient transfer of flux from the tank farm to the preheater, ensuring a consistent and controlled supply. This step is vital in hot mix plants and roofing plants to maintain production efficiency. By utilizing advanced pump technology, we ensure that the flux is moved at the correct temperature and pressure, minimizing the risk of blockages and ensuring smooth operation.

Move from Preheater to Blowing Stills

Our asphalt pumps, including the Viking 1224A-ASP, 1324-A-ASP Series, Viking 34 Series internal gear pumps, and Viking 124E & 324E Series electrically heated pumps, safely and seamlessly transfer the flux from the preheater to the blowing stills, ensuring precise and efficient control over the production process. This application is essential in refineries and roofing plants. The electrically heated options are particularly beneficial in maintaining the ideal viscosity of the flux, preventing any cooling and solidification during the transfer.

Move Blown Asphalt to Storage

Once the flux is blown (oxidized) asphalt, our equipment, including slurry pumps and submersible pumps, facilitates the transfer from the production process to storage. This ensures proper handling and preservation of the valuable material, especially in terminals and roofing plants. Our pumps are designed to handle the abrasive nature of asphalt, ensuring longevity and reliability in demanding environments.

Move Knockdown Liquids to Disposal

We distribute equipment that facilitates the effective transfer of knockdown tank liquids to disposal, ensuring safe and efficient management of waste materials. This process is crucial in refineries and hot mix plants. Our pumps ensure that even the most challenging waste materials are handled efficiently, minimizing environmental impact and ensuring compliance with regulatory standards.

Unload PMA, Seal-Down, and Laminate

Quality asphalt pumps, such as the Viking 1224A-ASP, 1324-A-ASP, Viking 34 Series internal gear pumps, and Viking 124E & 324E Series electrically heated pumps, can effectively unload PMA, seal-down, and laminate (adhesive) asphalt from trucks, ensuring seamless transfer to storage for further processing and manufacturing. This is particularly important in distributor trucks and roofing plants. The reliability and precision of our pumps ensure that these materials are handled with care, maintaining their integrity and performance.

Move Product to Plant Day Tank

Our asphalt pumps ensure the smooth transfer of blown asphalt or PMA (Polymer Modified Asphalt) to the plant day tank to ensure a consistent supply for the production process and precise control over the mixture composition. This step is critical in hot mix plants and roofing plants. By maintaining consistent flow rates and pressures, our pumps help optimize the mixing process, ensuring high-quality end products.

Transfer from Day Tank to Mix Tank

Our equipment improves the transfer from the day tank to the mix tank, allowing for seamless blending of asphalt with fillers to achieve the desired composition for optimal roofing and shingle production. This application is vital in hot mix plants. Our pumps are designed to handle a variety of filler materials, ensuring that the mixture is homogeneous and of the highest quality.

Transfer Coating Asphalt to Coater

With quality asphalt pumps, including the Viking 1224A-ASP, 1324-A-ASP, Viking 34 Series, and Viking 124E & 324E Series, precisely transfer the coating asphalt from storage to the coater to ensure uniform application and impeccable coating quality. This process is essential in roofing plants. The precision of our pumps ensures that the coating is applied evenly, improving the durability and performance of the shingles.

Return Coating Asphalt to Mix Tank

Efficiently return the coating asphalt from the coater to the mix tank with reliable equipment, allowing for proper recycling and utilization of materials in the production process. This step is important in hot mix plants and roofing plants. Our pumps ensure that valuable materials are not wasted and are reused efficiently, contributing to cost savings and environmental sustainability.

Meter Seal-Down onto Shingles

Accurately meter and apply seal-down onto shingles using heavy-duty rotating equipment, ensuring precise and uniform coverage for enhanced durability and weather resistance. This process is crucial in roofing plants and distributor trucks. The accuracy of our pumps ensures that the seal-down is applied correctly, improving the longevity and performance of the shingles.

Meter Laminate onto Shingles

Improve the metering and application of laminate onto shingles with high-quality equipment that ensures consistent and even distribution for enhanced strength and protection against external elements. This step is vital in roofing plants. The even distribution of laminate provided by our pumps enhances the structural integrity and weather resistance of the shingles.

Tar Kettles / Tack Tanks

Our SG-05 Series pumps are specifically designed for Tar Kettles and Tack Tank applications, ensuring efficient handling and processing of materials in these critical components of the asphalt industry. These pumps are built to handle high temperatures and the abrasive nature of tar, ensuring reliable performance and durability.

Featured Equipment

Our range of top-performing asphalt pumps and rotating equipment

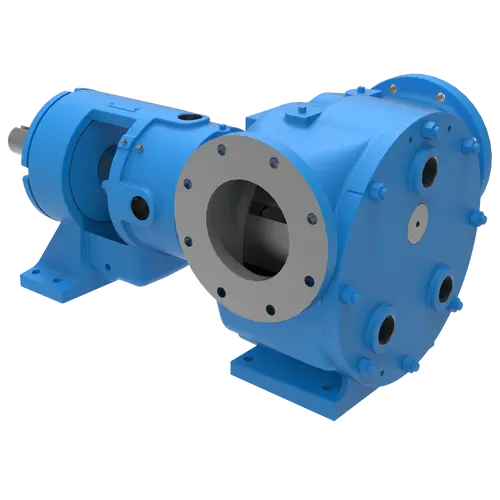

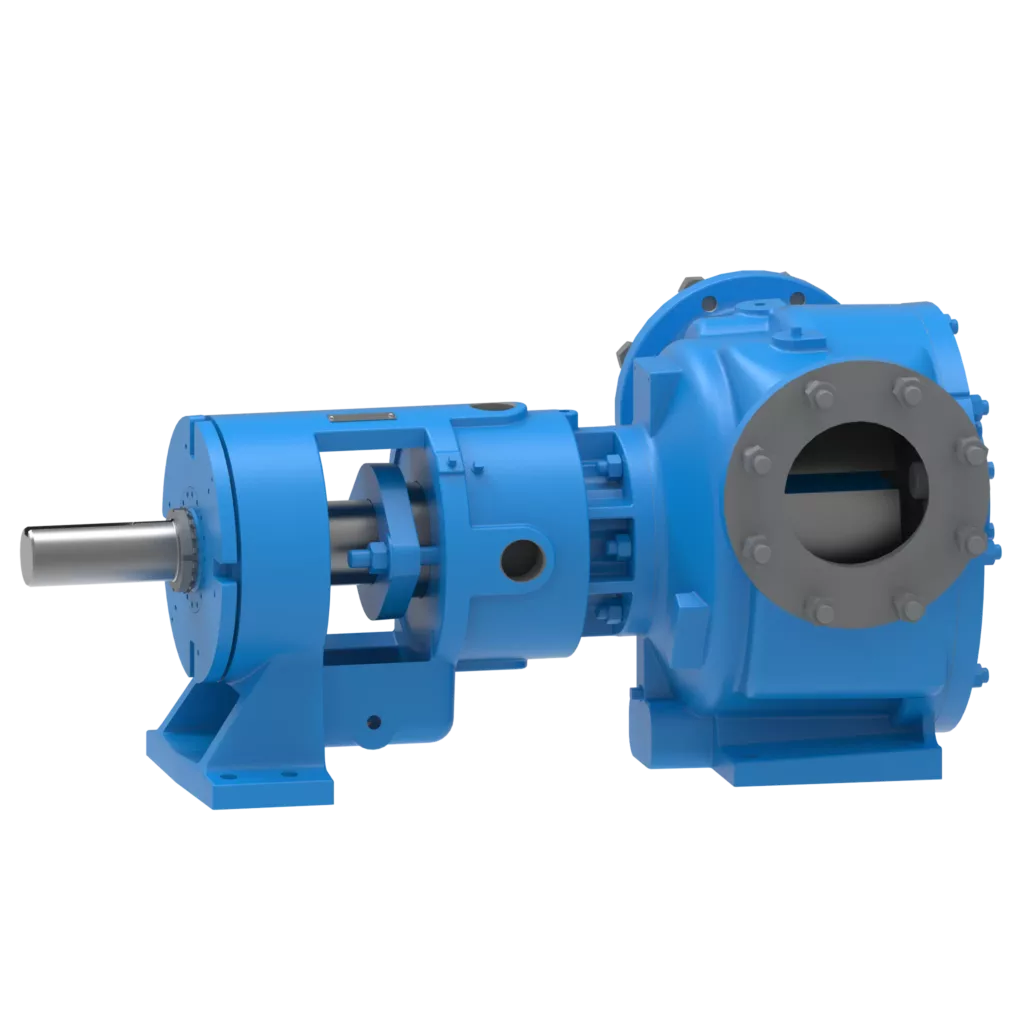

Viking Pumps 1324A-ASP Series™

High-performance internal gear pump for efficient asphalt handling.

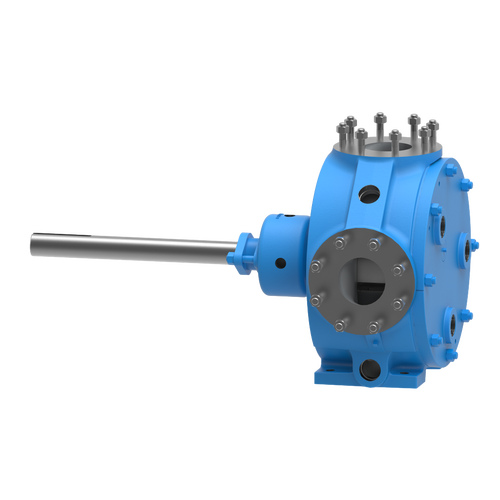

Viking Pumps 34 Series™

Ideal for low-pressure applications throughout the manufacturing life cycle.

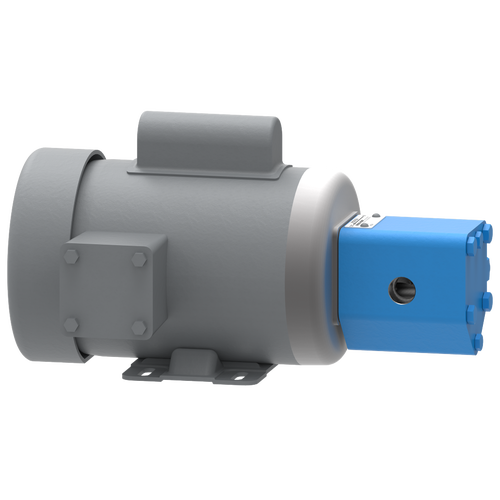

Viking Pumps SG-05 Series™

Specifically designed for Tar Kettles and Tack Tank applications.

Applications Across the Industry

Asphalt pumps and equipment applications

Refineries

Ensuring efficient handling and processing of asphalt materials. Our pumps are designed to withstand high temperatures and abrasive materials, ensuring continuous and reliable performance.

Terminals

Facilitating the transfer and storage of large volumes of asphalt. Our dredge pumps ensure efficient transfer from railcars to storage tanks and maintain the quality of materials during storage.

Hot Mix Plants

Optimizing the blending and mixing of asphalt with fillers for high-quality production. Our pumps ensure seamless blending, resulting in a uniform mixture for durable asphalt products.

Roofing Plants

Enhancing the application of coatings and laminates for durable shingles. Our pumps, including electrically heated pumps, ensure even application of asphalt coatings, resulting in high-quality shingles.

Distributor Trucks

Ensuring precise unloading of PMA, seal-down, and laminate asphalt. Our pumps enable accurate unloading and application of these materials, enhancing on-site efficiency.

Tar Kettles / Tack Tanks

Providing pumps for the high-temperature and abrasive conditions of tar handling. This ensures effective heating and circulation of tar, preventing solidification and blockages.

Looking for asphalt pumps fast?

Shop our quick ship equipment catalog

MPN: S1FB1ABWANS000

Lead Time: Ready to Ship

MPN: NDP-25BST

Lead Time: Ready to Ship