Viking Pumps Equipment We Distribute

Viking Pump is a leading manufacturer that produces a wide range of pump types designed to handle various liquids, including viscous and abrasive fluids, as well as gases. Here are some of the types of Viking Pumps equipment that we distribute:

Internal Gear Pumps

Viking Pumps, a leading manufacturer of pumping solutions, is well-known for its high-quality internal gear pumps, which are widely used across a range of industries, such as chemical, petrochemical, food and beverage, and pharmaceutical. Internal gear pumps are valued for their ability to handle a diverse range of fluids, including those with high viscosity and varying levels of lubricity. These pumps have a compact design, ensuring a small footprint, and are recognized for their robustness, durability, and efficiency. Viking Pumps’ internal gear pumps are designed to provide reliable, long-lasting performance in a variety of demanding applications, making them an excellent choice for many different pumping needs.

Among the wide array of internal gear pumps offered by Viking Pumps, several popular series stand out for their exceptional performance and unique features. These include the 1124A SERIES™, 1224A-ASP SERIES™, 124A SERIES™, 1327A SERIES™, and the 34 SERIES. Each series is tailored to meet specific application requirements and customer needs, ensuring optimized performance and functionality. For example, the 1124A and 124A SERIES™ are designed for medium to heavy-duty applications, featuring advanced sealing options and materials, which enable them to handle a wide range of fluids, including corrosive and abrasive materials. The 1224A-ASP SERIES™, on the other hand, is specifically designed to address the challenges of pumping asphalt and other high-viscosity fluids, providing exceptional temperature control and efficient pumping capabilities.

The 1327A SERIES™ is another highly versatile internal gear pump designed for handling fluids with low to high viscosity, as well as those with poor lubricity. This series is engineered to provide reliable performance in both high and low-pressure applications, feature

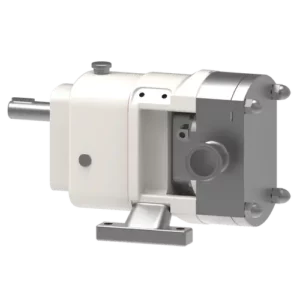

External Gear Pumps

Viking Pumps, a leader in the manufacturing of high-quality pumping solutions, also offers a diverse range of external gear pumps designed for various applications and industries, such as chemical processing, fuel transfer, and hydraulic systems. External gear pumps are recognized for their compact design, high-pressure capabilities, and ability to handle a wide range of fluids, including those with high viscosity and varying lubricity. Viking Pumps’ external gear pumps are designed with precision engineering and robust materials to ensure reliable, efficient, and long-lasting performance, making them an ideal choice for many pumping requirements.

Among Viking Pumps’ external gear pump offerings, several series stand out for their exceptional performance and unique features. These include the GB-410 SERIES™, CMD SERIES™, SG SERIES™, SG-X Series™, and GB-414 SERIES™. The GB-410 SERIES™ is designed for high-pressure applications, providing smooth, pulsation-free flow and exceptional performance across a wide range of operating conditions. The CMD SERIES™, on the other hand, is a versatile, low-flow external gear pump designed for precise metering and fluid transfer applications, offering a combination of high efficiency and excellent reliability. The SG SERIES™ and SG-X Series™ are designed for general-purpose applications, featuring robust construction and a range of sealing options to accommodate various fluid types and system pressures.

The GB-414 SERIES™ is another noteworthy external gear pump designed for handling a wide range of fluids, including corrosive and abrasive materials, as well as those with high viscosity. This series features advanced sealing options and materials to ensure reliable performance in even the most challenging applications. The GB-414 SERIES™ is also known for its high-pressure capabilities and compact design, making it a suitable choice for applications with limited space and demanding performance requirements.

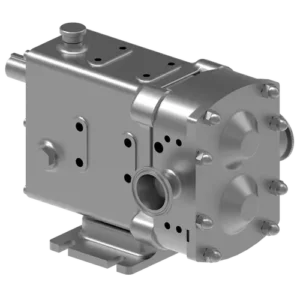

Rotary Lobe Pumps

Viking Pumps, a reputable manufacturer of high-quality pumping solutions, is also recognized for its range of rotary lobe pumps designed to meet the demands of various industries and applications, such as food and beverage, pharmaceutical, chemical, and cosmetics. Rotary lobe pumps are valued for their ability to handle a wide range of fluids, including those with high viscosity and shear-sensitive properties, while providing consistent flow rates and minimal pulsation. Viking Pumps’ rotary lobe pumps are constructed with robust materials and precision engineering to ensure reliable, efficient, and long-lasting performance, making them a preferred choice for numerous pumping needs.

Among the comprehensive range of rotary lobe pumps offered by Viking Pumps, several series stand out for their exceptional performance and unique features, including the CLASSIC+ SERIES™/MULTIPUMP® SERIES, REVOLUTION® SERIES, RTP® SERIES, RTPe SERIES™, and STERILOBE® SERIES. The CLASSIC+ SERIES™/MULTIPUMP® SERIES is designed for handling fluids with a broad range of viscosity and is well-suited for applications requiring both high and low shear capabilities. These pumps are versatile and can accommodate various fluid types and system pressures, making them ideal for multipurpose applications. The REVOLUTION® SERIES is engineered for superior performance and features a unique design that enables efficient pumping of even the most challenging fluids, including those with high solids content or shear-sensitive properties.

The RTP® SERIES and RTPe SERIES™ are high-performance rotary lobe pumps specifically designed for handling fluids with poor lubricity and high viscosity, offering reliability and efficiency across a wide range of operating conditions. These series are particularly well-suited for applications in the chemical and petrochemical industries. Lastly, the STERILOBE® SERIES is designed for sanitary applications in industries with strict hygiene requirements, such as food and beverage, pharmaceutical, and cosmetics. This series complies with stringent sanitary standards and features stainless steel construction, a crevice-free design, and polished surfaces to ensure easy cleaning and minimize the risk of contamination. Overall, Viking Pumps’ rotary lobe pump offerings, including the CLASSIC+ SERIES™/MULTIPUMP® SERIES, REVOLUTION® SERIES, RTP® SERIES, RTPe SERIES™, and STERILOBE® SERIES, demonstrate the company’s dedication to providing reliable, efficient, and high-quality pumping solutions for a diverse range of industries and applications.

Vane Pumps

Viking Pumps, a prominent manufacturer of high-quality pumping solutions, also offers an exceptional range of vane pumps designed to address the needs of various industries and applications. Vane pumps are known for their versatility, ability to handle a wide range of fluid types, and their capacity to operate at high pressures. Additionally, vane pumps are valued for their consistent flow rates, low noise levels, and minimal pulsation, making them an ideal choice for many pumping requirements. Viking Pumps’ vane pumps are designed with a combination of robust materials and precision engineering to ensure reliable, efficient, and long-lasting performance.

Among Viking Pumps’ vane pump offerings, the LVP SERIES™ stands out for its remarkable performance and unique features. The LVP SERIES™ is a high-performance, low-viscosity vane pump specifically designed to handle fluids with low lubricities, such as solvents, additives, and light oils. This series is engineered to provide smooth, pulsation-free flow across a wide range of operating conditions, ensuring reliable performance and extended service life. The LVP SERIES™ vane pumps feature a compact design, making them suitable for applications with limited space, and their advanced sealing options accommodate various fluid types and system pressures.

Viking Pumps’ LVP SERIES™ vane pumps also offer numerous benefits to their users, such as reduced maintenance costs, improved efficiency, and enhanced product quality. The innovative design of these pumps enables quick and easy disassembly, facilitating fast and thorough cleaning during scheduled maintenance or product changeovers. The LVP SERIES™ vane pumps are also engineered to deliver consistent flow rates with minimal pulsation, ensuring accurate and uniform fluid handling. Furthermore, the use of high-quality materials and precision engineering ensures that the LVP SERIES™ vane pumps provide excellent wear resistance and durability, even in demanding applications. In summary, Viking Pumps’ vane pump offerings, including the LVP SERIES™, showcase the company’s commitment to delivering reliable, efficient, and high-quality pumping solutions for a diverse range of industries and applications.

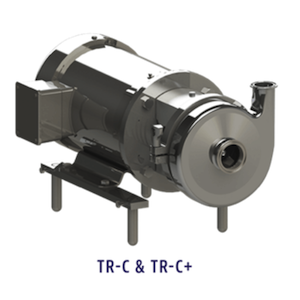

Centrifugal Pumps

Viking Pumps, a world-renowned manufacturer of pumping solutions, offers a comprehensive range of centrifugal pumps designed to cater to various industries and applications. Their centrifugal pumps are known for their high-quality construction, efficiency, and reliability, which has made them the preferred choice for numerous industries, such as food processing, pharmaceutical, chemical, and beverage, among others. One of the primary advantages of Viking’s centrifugal pumps is their ability to handle a wide range of fluids with varying viscosity, temperature, and chemical compatibility, making them an ideal solution for many different pumping needs.

In particular, Viking Pumps’ Hygienic Series of centrifugal pumps showcases their commitment to producing high-quality and sanitary pumping solutions for industries with stringent hygiene requirements. The Hygienic Series centrifugal pumps are designed in compliance with the stringent standards of 3-A Sanitary Standards, Inc., ensuring their suitability for sensitive applications. These pumps feature stainless steel construction, crevice-free design, and polished surfaces, which minimizes the risk of contamination and makes them easy to clean. Furthermore, their seal-less and self-draining design ensures that no product is trapped within the pump, reducing the chances of bacterial growth and cross-contamination.

Viking Pumps’ Hygienic Series centrifugal pumps also offer numerous benefits to their users, such as improved efficiency, reduced maintenance costs, and enhanced product quality. Their innovative design allows for quick and easy disassembly, enabling fast and thorough cleaning during scheduled maintenance or product changeovers. The pumps are also engineered to deliver consistent flow rates and minimal pulsation, ensuring a gentle and uniform product handling process, which is crucial in preserving product integrity in sensitive applications. Overall, Viking Pumps’ centrifugal pumps, including their Hygienic Series, demonstrate the company’s dedication to providing reliable, efficient, and high-quality pumping solutions for a diverse range of industries and applications.

Circumferential Piston Pump

Viking Pumps, a leading manufacturer of high-quality pumping solutions, offers an exceptional range of circumferential piston pumps designed to cater to various industries and applications. Circumferential piston pumps are known for their ability to handle a wide range of fluids, including those with high viscosity, shear sensitivity, and varying levels of solids content. These pumps are valued for their consistent flow rates, low pulsation, and gentle product handling capabilities, making them an ideal choice for many pumping requirements. Viking Pumps’ circumferential piston pumps are constructed with robust materials and precision engineering to ensure reliable, efficient, and long-lasting performance.

Among Viking Pumps’ circumferential piston pump offerings, several series stand out for their exceptional performance and unique features, including the REVOLUTION® SERIES, TRA®10 SERIES, and TRA®20 SERIES. The REVOLUTION® SERIES is designed for high-performance and is particularly well-suited for applications in the food, beverage, and pharmaceutical industries. These pumps are engineered to provide smooth, consistent flow across a wide range of operating conditions, ensuring gentle handling of sensitive products. The TRA®10 SERIES, on the other hand, is specifically designed for sanitary applications, featuring stainless steel construction, a crevice-free design, and polished surfaces that ensure easy cleaning and minimize the risk of contamination.

The TRA®20 SERIES is another high-performance circumferential piston pump designed for handling fluids with a broad range of viscosity, making it suitable for a wide variety of applications, including those in the chemical, food, and pharmaceutical industries. This series is engineered to provide reliable performance and extended service life, even in demanding operating conditions. The TRA®20 SERIES pumps also feature advanced sealing options to accommodate various fluid types and system pressures. Overall, Viking Pumps’ circumferential piston pump offerings, including the REVOLUTION® SERIES, TRA®10 SERIES, and TRA®20 SERIES, demonstrate the company’s commitment to providing reliable, efficient, and high-quality pumping solutions for a diverse range of industries and applications.

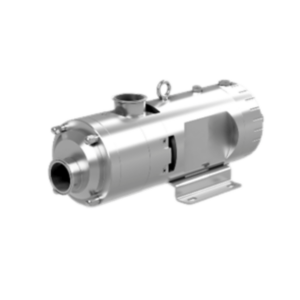

Twin Screw Pumps

Viking Pumps, a renowned manufacturer of high-quality pumping solutions, offers a comprehensive range of twin screw pumps designed to cater to various industries and applications, including dairy product processing, food and beverage, pharmaceutical, personal care, and more. Twin screw pumps are known for their ability to handle a wide range of fluids with varying viscosity, shear sensitivity, and solids content. These pumps are particularly valued for their gentle product handling, consistent flow rates, and low pulsation, making them an ideal choice for numerous pumping requirements in sensitive applications. Viking Pumps’ twin screw pumps are constructed with robust materials and precision engineering to ensure reliable, efficient, and long-lasting performance.

Twin screw pumps from Viking Pumps are well-suited for a variety of applications, such as processing dough, sauces, confectionery, meat, pharmaceuticals, oil, honey, purees, personal care products, pulps, and syrups. These pumps are designed to accommodate the diverse requirements of these applications, ensuring that product quality is maintained while delivering optimal performance. Their gentle handling capabilities are particularly advantageous in preserving the integrity of delicate products, such as emulsions, foams, and other shear-sensitive fluids. Furthermore, the twin screw pumps’ consistent flow rates and low pulsation contribute to maintaining the uniformity of the processed products.

Viking Pumps’ twin screw pumps are also designed to comply with relevant certifications and standards, such as 3-A, FDA, and EHEDG, which are crucial for ensuring sanitary and hygienic operation in industries with stringent hygiene requirements, such as food and beverage, dairy, and pharmaceuticals. These certifications attest to the pumps’ suitability for sensitive applications, as they adhere to strict guidelines for material selection, surface finish, and design principles, ensuring that contamination risks are minimized. Overall, Viking Pumps’ twin screw pumps showcase the company’s dedication to providing reliable, efficient, and high-quality pumping solutions for a diverse range of industries and applications, while meeting the most demanding certification standards.

Strainers

Viking Pumps strainers are a top choice for professionals seeking superior filtration solutions. Renowned for their exceptional quality and reliability, these strainers are designed to effectively remove debris, contaminants, and unwanted particles from fluids, ensuring optimal performance and extended equipment life. Built with precision engineering and utilizing advanced filtration technologies, Viking Pumps strainers offer exceptional efficiency and durability. Professionals across industries such as manufacturing, chemical processing, oil and gas, and water treatment find great value in these strainers as they enhance operational efficiency, protect valuable equipment, and minimize downtime. With Viking Pumps strainers, professionals can trust in a dependable filtration solution that meets their high standards and delivers consistent, high-quality results.

Viking Pumps Applications

Viking Pump is a manufacturer of positive displacement pumps for various industries, with a focus on reliability, efficiency, and performance. Viking Pumps are used in a wide range of applications across multiple industries.

Industrial Segment

Viking Pumps, a leading manufacturer of high-quality pumping solutions, offers an extensive range of equipment specifically designed to cater to various industrial applications. The company’s pumps are engineered with robust materials, precision engineering, and innovative designs to ensure reliable, efficient, and long-lasting performance across a diverse range of industries. Viking Pumps’ equipment is well-suited for handling various fluid types, including those with high viscosity, shear sensitivity, and solids content, making them an ideal choice for numerous industrial pumping requirements.

Among Viking Pumps’ industrial segment offerings, several series stand out for their exceptional performance and unique features, including Universal, Motor Speed, and Liquid Specific series. The Universal series of pumps are designed for versatility, catering to a wide range of applications and fluid types. These pumps are highly adaptable and can be customized with various sealing options, materials of construction, and accessory options to suit specific requirements. The Motor Speed series, on the other hand, is engineered for applications that require direct motor coupling and a compact footprint. These pumps offer high efficiency and are designed to operate at motor speeds, eliminating the need for additional gear reducers, which in turn reduces maintenance costs and simplifies installation.

The Liquid Specific series from Viking Pumps is designed to address the unique challenges associated with handling specific fluids, such as asphalt, molten sulfur, and chocolate, among others. These pumps feature specialized materials, innovative designs, and advanced sealing options to ensure optimal performance in handling fluids with unique properties or specific temperature requirements. The Liquid Specific series demonstrates Viking Pumps’ commitment to providing tailored solutions for various industries, ensuring that customers receive pumps that are optimized for their specific applications.

Energy Segment

Viking Pumps, a renowned manufacturer of high-quality pumping solutions, offers a comprehensive range of equipment specifically designed to cater to the energy segment, including applications in the oil and gas, petrochemical, and power generation industries. The company’s pumps are engineered with robust materials, precision engineering, and innovative designs to ensure reliable, efficient, and long-lasting performance across a diverse range of energy-related applications. Viking Pumps’ equipment is well-suited for handling various fluid types, including crude oil, refined petroleum products, chemicals, and other energy-related fluids, making them an ideal choice for numerous energy segment pumping requirements.

Among Viking Pumps’ energy segment offerings, several series stand out for their exceptional performance and unique features, including LACT, Glycol, API, and Liquid Specific series. The LACT (Lease Automatic Custody Transfer) series is designed for applications involving the transfer and measurement of crude oil and other petroleum products. These pumps offer precise flow control, ensuring accurate and efficient custody transfer operations. The Glycol series, on the other hand, is specifically engineered for applications involving glycol recirculation and dehydration systems in natural gas processing plants. These pumps feature robust construction and advanced sealing options to ensure reliable performance in handling glycol and other chemicals used in the energy industry.

The API (American Petroleum Institute) series of pumps from Viking Pumps are designed to comply with API 676 standards, which are crucial for ensuring reliable and safe operation in the oil and gas and petrochemical industries. These pumps are built with high-quality materials and are engineered to meet stringent design and performance requirements, ensuring that they can handle the demanding conditions often encountered in these industries. The Liquid Specific series is tailored to address the unique challenges associated with handling specific fluids in the energy segment, such as crude oil, asphalt, and other energy-related products. These pumps feature specialized materials, innovative designs, and advanced sealing options to ensure optimal performance in handling fluids with unique properties or specific temperature requirements. In summary, Viking Pumps’ equipment offerings across the energy segment, including the LACT, Glycol, API, and Liquid Specific series, highlight the company’s dedication to delivering reliable, efficient, and high-quality pumping solutions for a diverse range of industries and applications within the energy sector.

Hygienic Segment

Viking Pumps, a leading manufacturer of high-quality pumping solutions, offers an extensive range of equipment specifically designed to cater to the hygienic segment, including applications in the food and beverage, pharmaceutical, personal care, and cosmetic industries. The company’s pumps are engineered with robust materials, precision engineering, and innovative designs to ensure reliable, efficient, and long-lasting performance across a diverse range of hygienic applications. Viking Pumps’ equipment is well-suited for handling various fluid types, including those with high viscosity, shear sensitivity, and varying levels of solids content, making them an ideal choice for numerous hygienic segment pumping requirements.

Among Viking Pumps’ hygienic segment offerings, several series stand out for their exceptional performance and unique features, including Circumferential Piston, Rotary Lobe, and Liquid Specific series. The Circumferential Piston series is designed to provide gentle product handling and consistent flow rates, ensuring that sensitive fluids are processed without damage. These pumps are particularly well-suited for applications in the food, beverage, and pharmaceutical industries, where maintaining product quality and integrity is of utmost importance. The Rotary Lobe series, on the other hand, is engineered to handle a wide range of fluids, including those with high viscosity and shear-sensitive properties, while providing consistent flow rates and minimal pulsation. This series is suitable for a variety of hygienic applications, such as food and beverage processing, personal care product manufacturing, and pharmaceutical production.

The Liquid Specific series from Viking Pumps is tailored to address the unique challenges associated with handling specific fluids in the hygienic segment, such as chocolate, yogurt, and other viscous or shear-sensitive products. These pumps feature specialized materials, innovative designs, and advanced sealing options to ensure optimal performance in handling fluids with unique properties or specific temperature requirements. Viking Pumps’ hygienic segment pumps are also designed to comply with relevant certifications and standards, such as 3-A, FDA, and EHEDG, which are crucial for ensuring sanitary and hygienic operation in industries with stringent hygiene requirements.

Municipalities

Viking Pumps, a prominent manufacturer of high-quality pumping solutions, offers a comprehensive range of equipment specifically designed to cater to the municipal segment, including applications in water treatment, wastewater management, and other public infrastructure projects. The company’s pumps are engineered with robust materials, precision engineering, and innovative designs to ensure reliable, efficient, and long-lasting performance across a diverse range of municipal applications. Viking Pumps’ equipment is well-suited for handling various fluid types, including water, sludge, chemicals, and other materials commonly encountered in municipal settings, making them an ideal choice for numerous municipal segment pumping requirements.

Among Viking Pumps’ municipal segment offerings, several features stand out for their exceptional performance and unique capabilities. These pumps are designed to operate reliably in challenging environments, ensuring that critical infrastructure projects can continue to function effectively and efficiently. Viking Pumps’ equipment is also engineered with a focus on durability, minimizing the need for frequent maintenance and reducing downtime, which is particularly important in the context of municipal applications where uninterrupted service is often essential. Furthermore, Viking Pumps’ pumps offer versatile solutions for various municipal applications, including water and wastewater treatment, chemical dosing, sludge handling, and flood control, among others.

In summary, Viking Pumps are used in a variety of industries, including chemical, oil and gas, food and beverage, power generation, pulp and paper, transportation, and water and wastewater. The applications for Viking Pumps are diverse and varied, ranging from chemical transfer to fuel oil transfer, and from pumping food products to sewage. Regardless of the application, Viking Pumps are known for their reliability and efficiency, making them a top choice for professionals in various industries.

Factors to Consider When Buying Viking Pumps

Viking Pump is a leading manufacturer of positive displacement pumps and fluid handling equipment for a wide range of applications. Before purchasing equipment from Viking Pumps, professionals should consider a few key factors to ensure they choose the right equipment for their specific needs.

Application Requirements

The first and foremost consideration is to determine the application requirements for the equipment. Viking Pump offers a variety of pumps and fluid handling equipment suitable for handling a wide range of fluids, including corrosive and abrasive fluids, high-viscosity liquids, and chemicals. Professionals should carefully evaluate their specific application requirements and choose a pump or equipment that can handle the required flow rate, pressure, and fluid characteristics.

Industry

Viking Pump products are used in a variety of industries such as chemical, industrial, food and beverage, oil and gas, and power generation. Professionals should choose equipment that is specifically designed for their industry and its unique requirements. Viking Pump offers specialized products for each industry, and choosing the right product can ensure optimum performance and longevity.

Materials of Construction

Depending on the fluid being pumped and the application, the material of construction of the equipment may be critical. Viking Pump offers a range of materials, including cast iron, stainless steel, and specialty alloys to ensure compatibility with a wide range of fluids. It’s important to choose a material that can withstand the chemical properties of the fluid being handled and any corrosive or abrasive environments it may be exposed to.

Maintenance

The maintenance requirements of the equipment should be evaluated before purchasing. Viking Pump offers pumps that require minimal maintenance, while others may require more frequent maintenance to ensure maximum efficiency and longevity. Professionals should consider the availability of service and support from Viking Pump or its authorized service providers to ensure the equipment can be properly maintained and serviced.

Cost

Cost is always a consideration when purchasing equipment. While Viking Pump offers a range of products at various price points, professionals should evaluate the total cost of ownership, including maintenance, downtime, and energy consumption, to determine the best value for their investment.

In summary, before buying equipment from Viking Pumps, professionals should carefully evaluate their application requirements, industry, materials of construction, maintenance requirements, and cost to ensure they choose the right product for their specific needs. By considering these factors, they can ensure optimum performance, longevity, and value for their investment.

About Viking Pumps

Viking Pump is a manufacturer of positive displacement pumps, which are used in a wide range of industrial applications. The company was founded in 1911 in Cedar Falls, Iowa, and has since become a leading provider of high-quality pumps that are known for their reliability, durability, and performance.

Viking Pump offers a wide range of pump types, including internal gear pumps, external gear pumps, rotary vane pumps, and more. These pumps are used in a variety of industries, including chemical processing, food and beverage, oil and gas, power generation, and water and wastewater treatment. The company’s pumps are designed to handle a variety of liquids, including chemicals, fuels, oils, and viscous fluids.

One of the key strengths of Viking Pump is its commitment to innovation and engineering excellence. The company has a team of highly skilled engineers and technicians who work closely with customers to develop customized solutions that meet their unique needs. Viking Pump also invests heavily in research and development, using advanced technologies and materials to continually improve the performance and efficiency of its pumps.

In addition to its commitment to innovation, Viking Pump is also known for its exceptional customer service. The company has a global network of service centers and distributors that provide customers with comprehensive support, including installation, maintenance, and repair services. Viking Pump’s customer service team is dedicated to providing prompt and effective solutions to customers’ needs, ensuring that their operations run smoothly and efficiently.

Viking Pump is also committed to sustainability and social responsibility. The company has implemented a number of initiatives to reduce its environmental impact, including the use of energy-efficient manufacturing processes, waste reduction programs, and recycling programs. Viking Pump also supports local communities through charitable donations and volunteer programs.

Overall, Viking Pump is a leading provider of high-quality pumps for industrial applications. The company’s commitment to innovation, engineering excellence, customer service, and sustainability has helped it to establish a strong reputation in the industry and position itself for continued growth and success.

Affiliation Between Viking Pumps and IDEX Corporation

Viking Pump is a manufacturer of positive displacement pumps for various industrial applications. The company was founded in 1911 and is headquartered in Cedar Falls, Iowa. Since its founding, Viking Pump has become a leader in the pump industry, providing high-quality pumps that are known for their durability and reliability.

The affiliation between Viking Pump and IDEX Corporation has enabled Viking Pump to expand its product offerings and capabilities, while maintaining its commitment to high-quality products and excellent customer service. As part of IDEX Corporation, Viking Pump has access to a wide range of resources, including advanced manufacturing technologies, engineering expertise, and global distribution channels. This has allowed Viking Pump to further enhance its product offerings and capabilities, while continuing to provide its customers with reliable, high-quality products and exceptional service.

In addition, IDEX Corporation has a strong commitment to sustainability and social responsibility, and this is reflected in Viking Pump’s operations and practices. The company is dedicated to reducing its environmental impact and promoting sustainable practices throughout its operations. Viking Pump also supports local communities through various charitable initiatives and volunteer programs.

Overall, the affiliation between Viking Pump and IDEX Corporation has been a beneficial partnership that has enabled Viking Pump to expand its capabilities and continue to provide its customers with high-quality pumps and exceptional service. The company’s commitment to sustainability and social responsibility has also helped to position it as a leader in the industry and a responsible corporate citizen.