Pulsafeeder Equipment

Pulsafeeder is a leading manufacturer of fluid handling equipment, offering a comprehensive range of high-performance products for various industrial applications. The company offers a wide range of pumps, controllers, and systems designed to handle fluids of all types, including corrosive, viscous, and abrasive liquids.

Diaphragm Pumps

Pulsafeeder Diaphragm Pumps are known for their reliability and flexibility, making them suitable for various applications. These pumps come in a variety of materials, including polypropylene, PVDF, TFE, and stainless steel, making them compatible with different chemicals and substances. Additionally, the pumps come in different sizes and are capable of pumping different flow rates, making them versatile for different applications.

The diaphragm pumps have a seal-less design, meaning they do not require a mechanical seal, which reduces the chance of leaks and other issues caused by seal failure. They are also self-priming and can handle solids, making them ideal for transferring liquids containing suspended solids, such as slurry and slurries. Some of the common applications of Pulsafeeder Diaphragm Pumps include chemical dosing, water treatment, food and beverage processing, and wastewater treatment.

Pulsafeeder Diaphragm Pumps are designed to be energy-efficient and low-maintenance, which reduces the operating costs associated with them. The pumps are easy to install and operate, and the company provides excellent after-sales support to ensure that customers get the most out of their equipment. Furthermore, Pulsafeeder offers a variety of options for customizing pumps to meet specific requirements, making them a great choice for clients looking for tailored solutions for their pumping needs.

Pulsafeeder Diaphragm Pumps are used in various industries for different applications such as chemical processing, water treatment, agriculture, and manufacturing. These pumps are capable of handling highly corrosive, abrasive, and viscous fluids, making them ideal for various challenging applications. The use of Pulsafeeder Diaphragm Pumps can ensure accurate and consistent flow rates, resulting in efficient and cost-effective operations.

In the chemical processing industry, Pulsafeeder Diaphragm Pumps are widely used for the transfer and dosing of various chemicals, including acids, solvents, and corrosive materials. In the water treatment industry, these pumps are used for metering chemicals such as chlorine, acids, and alkalis for various applications such as pH adjustment, disinfection, and coagulation. In the agriculture industry, Pulsafeeder Diaphragm Pumps are used for the dosing of fertilizers, herbicides, and pesticides in irrigation systems.

In the manufacturing industry, Pulsafeeder Diaphragm Pumps are used for various applications such as chemical transfer, mixing, and dosing of various fluids, including solvents, acids, and alkalis. These pumps can be used for precise and accurate dosing of fluids in batch or continuous processes, ensuring consistent quality of the final product. Overall, Pulsafeeder Diaphragm Pumps offer reliable, efficient, and accurate fluid handling solutions for various industries and applications.

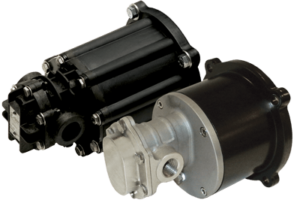

Rotary Gear Pumps

Pulsafeeder Rotary Gear Pumps are used in various industrial applications for transferring fluids from one place to another. These pumps are a popular choice for low-pressure and low-viscosity fluid applications. They are capable of handling fluids with viscosities up to 500 cSt and are suitable for a range of fluids, including chemicals, oils, fuels, and solvents.

The Rotary Gear Pumps by Pulsafeeder are designed with precision to ensure accurate and consistent fluid transfer. They have a compact and modular design that makes them easy to install and maintain. The pumps come with a variety of materials for the construction of the gears and housing, including cast iron, stainless steel, and bronze.

These pumps are often used in the oil and gas industry, as well as in the chemical and food processing industries. Their precise and accurate transfer capabilities make them an ideal choice for applications that require the exact measurement of fluids. They can also be used in high-temperature applications, up to 650°F, and have a maximum flow rate of up to 300 GPM.

They are known for their high accuracy and consistency, making them ideal for applications where precise flow control is essential. These pumps are typically used in the chemical processing, oil and gas, and food and beverage industries.

In the chemical processing industry, Pulsafeeder’s rotary gear pumps are used to transfer corrosive and abrasive fluids such as acids, solvents, and slurries. They are also used to meter chemicals for water treatment applications. Their precise flow control and ability to handle high solids content make them ideal for applications such as transferring resins, polymers, and adhesives.

In the oil and gas industry, Pulsafeeder’s rotary gear pumps are used for a variety of applications, including transferring crude oil, lubricants, and other fluids. Their ability to handle high viscosity fluids and maintain accurate flow control makes them an ideal choice for these types of applications. Additionally, they are used to meter and inject chemicals for oil and gas production and processing, including chemical injection for well stimulation and acidizing.

Peristaltic Pumps

Pulsafeeder offers a wide range of peristaltic pumps that are known for their accuracy and reliability. Peristaltic pumps are positive displacement pumps that use a flexible tube and rollers to move fluids. The pumps are designed to handle a wide range of liquids, including abrasive and viscous fluids. Pulsafeeder’s peristaltic pumps are known for their self-priming capabilities and are ideal for transferring chemicals, acids, and alkalis.

Pulsafeeder’s peristaltic pumps are widely used in the water treatment, chemical processing, and pharmaceutical industries. In the water treatment industry, the pumps are used for dosing chemicals such as chlorine, fluoride, and alum. They are also used for pH control, disinfection, and coagulation. In the chemical processing industry, the pumps are used for transferring corrosive and abrasive fluids, while in the pharmaceutical industry, they are used for filling, bottling, and transfer applications.

Pulsafeeder’s peristaltic pumps offer several benefits over other types of pumps. They have no seals, which means that there is no risk of leakage. The pumps are also self-priming, which makes them easy to install and operate. In addition, the peristaltic design means that there is no contact between the fluid and the moving parts of the pump, which reduces the risk of contamination. Overall, Pulsafeeder’s peristaltic pumps are an excellent choice for applications that require accurate dosing, easy operation, and minimal maintenance.

Pulsafeeder peristaltic pumps are commonly used in a variety of industrial applications due to their accuracy and reliability. These pumps are ideal for applications requiring precise dosing of liquids or for pumping abrasive, shear-sensitive, or viscous fluids. The unique design of the peristaltic pump allows it to pump a wide range of fluids without damaging the fluid or the pump itself.

One of the main applications of Pulsafeeder peristaltic pumps is in the chemical processing industry. These pumps are commonly used to pump acids, alkalis, and other chemicals, due to their ability to handle corrosive fluids. They are also used in the food and beverage industry for pumping ingredients such as flavorings, colors, and preservatives.

Another application of Pulsafeeder peristaltic pumps is in the pharmaceutical industry. These pumps are used to pump precise doses of pharmaceuticals and chemicals during the manufacturing process. Peristaltic pumps are also commonly used in the water treatment industry for pumping chemicals such as chlorine and fluoride. They are able to accurately dose these chemicals into the water supply, ensuring safe drinking water for the public.

Controllers

Pulsafeeder controllers are designed to offer precise control and monitoring capabilities to ensure reliable and accurate operation of pumps and other process equipment. The controllers are available in a variety of models to meet different needs, and they can be used with Pulsafeeder pumps as well as pumps from other manufacturers. Some of the features that are common to many Pulsafeeder controllers include user-friendly interfaces, digital displays, and intuitive programming capabilities.

One of the most popular types of Pulsafeeder controllers is the EZ series, which is designed for use with a range of metering pumps. These controllers offer a range of features, including proportional control, batch control, and timer modes, which allow operators to precisely control pump operation for a variety of applications. The EZ series also includes models with enhanced features such as pH/ORP control, programmable inputs and outputs, and remote control capabilities.

Another popular series of Pulsafeeder controllers is the Eclipse series, which is designed for use with diaphragm and peristaltic pumps. These controllers offer a range of features, including batch control, feed forward control, and multiple alarm settings, which allow operators to closely monitor and control pump operation. The Eclipse series also includes models with enhanced features such as multi-language displays, multiple inputs and outputs, and remote monitoring and control capabilities.

Pulsafeeder offers a wide range of controllers that are designed to provide reliable and accurate control of chemical feed systems. The company’s controllers are used in a variety of industries including water treatment, chemical processing, food and beverage, and pharmaceuticals.

One of the main applications of Pulsafeeder controllers is in water treatment. The controllers are used to regulate the amount of chemicals that are added to the water to ensure that it meets regulatory standards and is safe for consumption. They can be used to control the dosage of chlorine, sodium hypochlorite, hydrogen peroxide, and other chemicals.

Pulsafeeder controllers are also commonly used in chemical processing applications. They are used to accurately measure and control the flow of chemicals into the process to ensure that the desired results are achieved. This is critical in industries such as petrochemicals, where precise control of the chemical feed is essential to maintaining process efficiency and product quality.

In the food and beverage industry, Pulsafeeder controllers are used to ensure the proper dosage of ingredients is added to the product during the production process. This is important for maintaining consistency and quality of the finished product. Pulsafeeder’s controllers are designed to handle a variety of food-grade chemicals and meet FDA requirements.

Metering Pumps

Metering pumps are designed to accurately dispense small volumes of fluids and chemicals, making them ideal for industries where precision is essential. Pulsafeeder’s metering pumps are built to withstand harsh conditions, including high pressures, corrosive materials, and extreme temperatures.

One of the key features of Pulsafeeder’s metering pumps is their accuracy. These pumps use advanced technology to ensure that the amount of fluid being dispensed is precise and consistent, which is essential in applications where even a small deviation can have significant consequences. Pulsafeeder’s metering pumps are also highly reliable, with minimal maintenance required, making them an ideal choice for industries where downtime can be costly.

Pulsafeeder’s metering pumps are used in a wide range of industries, including chemical processing, water treatment, food and beverage, and pharmaceuticals. In the chemical processing industry, metering pumps are used to dispense precise amounts of chemicals for a variety of applications, such as cleaning, processing, and disinfection. In the water treatment industry, metering pumps are used to add chemicals to water systems to ensure that they remain clean and safe to use. In the food and beverage industry, metering pumps are used to dispense precise amounts of ingredients in the production of food and beverages. In the pharmaceutical industry, metering pumps are used to dispense precise amounts of drugs and other chemicals during the production process.

Systems

The company offers a wide range of pumping systems, including chemical feed systems, boiler feed systems, cooling tower and condensate return systems, and many others. Pulsafeeder’s systems are designed to be easy to install and maintain, while providing reliable performance and efficient operation.

One of Pulsafeeder’s most popular systems is its chemical feed system, which is used to automatically inject chemicals into water or other fluids. This system is widely used in a variety of industries, including water treatment, chemical processing, and food and beverage production. Pulsafeeder’s chemical feed systems are available in a range of sizes and configurations to meet the needs of different applications.

Pulsafeeder also offers a range of boiler feed systems, which are designed to supply high-pressure water to boilers for heating and other purposes. These systems are typically used in industrial and commercial settings where large amounts of hot water are required. Pulsafeeder’s boiler feed systems are designed to be efficient and reliable, while also being easy to install and maintain. They are available in a variety of sizes and configurations to meet the needs of different applications.

Overall, Pulsafeeder offers a comprehensive range of equipment designed to handle fluids of all types and provide precise and reliable fluid handling solutions. Whether you are looking for metering pumps, controllers and systems, chemical feed systems, or mixers and agitators, Pulsafeeder has a range of products that can meet your needs. With its commitment to quality and customer service, Pulsafeeder is a trusted and reliable provider of fluid handling equipment for various industries.

Pulsafeeder Applications

Pulsafeeder pumps are used in a wide range of industries and applications, where precise and reliable fluid handling solutions are required. The following are some of the common applications of Pulsafeeder pumps:

Chemical Processing

Pulsafeeder’s products are designed to deliver precise and accurate metering of chemicals, including acids, caustics, and other hazardous materials, in a variety of chemical processing applications. Pulsafeeder’s chemical metering pumps and systems are built to withstand harsh chemical environments and are highly reliable, making them ideal for use in demanding chemical processing applications.

One of the key applications of Pulsafeeder’s chemical metering pumps and systems in the chemical processing industry is the accurate and precise dosing of chemicals. Chemical dosing is an essential part of many chemical processing operations, and Pulsafeeder’s products are designed to ensure that the correct amount of chemicals is added to the process at the right time. This is crucial for maintaining consistent product quality and ensuring that the process operates efficiently and safely.

Another important application of Pulsafeeder’s products in the chemical processing industry is the treatment of wastewater. Many chemical processing operations generate wastewater that contains high concentrations of pollutants and other hazardous substances. Pulsafeeder’s chemical metering pumps and systems are designed to accurately and reliably deliver chemicals for the treatment of wastewater, helping to ensure compliance with environmental regulations and protecting the environment.

Pulsafeeder’s chemical metering pumps and systems are also used in the production of a wide range of chemical products, including fertilizers, polymers, and specialty chemicals. These products require precise metering of chemicals to ensure that the desired chemical reactions occur, and Pulsafeeder’s products are designed to deliver the required level of accuracy and reliability. Overall, Pulsafeeder’s chemical metering pumps and systems are a critical component of many chemical processing operations, delivering precise and reliable chemical dosing, wastewater treatment, and chemical production.

Water Treatment

Pulsafeeder is a leading manufacturer of fluid handling equipment, including metering pumps, controllers, and systems. Their equipment has a wide range of applications, including the water treatment industry.

In the water treatment industry, Pulsafeeder’s equipment is used for chemical dosing and disinfection. For example, in wastewater treatment plants, Pulsafeeder metering pumps are used to inject chemicals such as chlorine or sodium hypochlorite to disinfect the water. Additionally, Pulsafeeder controllers are used to monitor and control pH levels, ensuring that the water is at the correct acidity level for effective treatment.

Pulsafeeder’s peristaltic pumps are also used in the water treatment industry for dosing coagulants and flocculants. These pumps are ideal for handling abrasive and viscous fluids, making them well-suited for the demands of water treatment applications.

Another application of Pulsafeeder equipment in the water treatment industry is in the dosing of chemicals for boiler and cooling tower treatment. Pulsafeeder’s metering pumps are used to accurately inject chemicals such as antiscalants and corrosion inhibitors into the water, ensuring that the systems run efficiently and with minimal downtime.

Overall, Pulsafeeder’s equipment plays a critical role in the water treatment industry, helping to ensure that water is treated effectively and efficiently, and meets the necessary regulatory requirements for safe consumption and discharge.

Oil and Gas

Pulsafeeder’s products are designed to meet the specific needs of each industry, ensuring reliable and efficient performance in even the most challenging environments.

In the oil and gas industry, Pulsafeeder’s metering pumps, diaphragm pumps, and rotary gear pumps are commonly used for chemical injection applications. These pumps are designed to handle a variety of chemicals, such as corrosion inhibitors, demulsifiers, and biocides, which are used to maintain the integrity and productivity of oil and gas wells.

Pulsafeeder’s controllers and tank systems are also critical components in oil and gas operations. These products are used to monitor and maintain chemical levels in tanks and pipelines, ensuring that the right amount of chemicals are injected at the right time. This is essential for preventing corrosion, controlling scale formation, and optimizing well productivity.

In addition to chemical injection applications, Pulsafeeder’s pumps and equipment can be used for other critical processes in the oil and gas industry, such as water treatment, refinery processing, and petrochemical production. With a wide range of products and solutions, Pulsafeeder is committed to providing reliable and efficient equipment that meets the unique needs of the oil and gas industry.

Food and Beverage

Pulsafeeder has a wide range of products that cater to the food and beverage industry. From precise dosing to handling aggressive fluids, Pulsafeeder equipment is designed to deliver efficient and reliable performance.

One of the most common applications of Pulsafeeder equipment in the food and beverage industry is for flavor injection. Flavor injection is a process that injects flavoring directly into the food product, creating a consistent and precise flavor profile. Pulsafeeder diaphragm pumps are often used for this process due to their accuracy and reliability.

Pulsafeeder peristaltic pumps are also commonly used in the food and beverage industry for metering and transferring fluids. These pumps are ideal for handling viscous liquids like sauces and syrups, which can be difficult to pump with traditional pumping systems. The peristaltic design also makes them easy to clean and maintain, reducing the risk of contamination.

In addition, Pulsafeeder pH and conductivity controllers are used for monitoring and controlling pH levels and conductivity in food and beverage processing. This is critical for maintaining product quality and safety. With Pulsafeeder controllers, manufacturers can ensure precise control over their processing conditions and achieve consistent product quality.

Overall, Pulsafeeder equipment is an important part of the food and beverage industry, helping manufacturers to ensure the safety and quality of their products while also increasing efficiency and productivity.

Pharmaceuticals

Pulsafeeder’s equipment is used for the production of pharmaceuticals, including active pharmaceutical ingredients (APIs), excipients, and final drug formulations.

One common application of Pulsafeeder’s equipment in the pharmaceutical industry is for the precise dosing of chemicals during the manufacturing process. Pulsafeeder’s metering pumps and controllers can deliver accurate and consistent flow rates of chemicals such as acids, bases, and solvents, which are critical to the formulation of pharmaceutical products.

In addition to dosing chemicals, Pulsafeeder’s equipment is used for pH and conductivity control in pharmaceutical manufacturing. Pulsafeeder’s pH and conductivity controllers can be used to monitor and maintain the pH and conductivity of process solutions, ensuring consistency and quality throughout the manufacturing process.

Another application of Pulsafeeder’s equipment in the pharmaceutical industry is for the production of high-purity water. Pulsafeeder’s pumps and controllers can be used in the reverse osmosis (RO) and ultrafiltration (UF) systems used to purify water for use in pharmaceutical manufacturing.

Overall, Pulsafeeder’s equipment is an essential component in the pharmaceutical industry, providing precise dosing and control of critical process parameters for the production of high-quality pharmaceutical products.

Overall, Pulsafeeder pumps are used in a wide range of industries and applications, where precise and reliable fluid handling solutions are required. With their accurate dosing capabilities, robust construction, and range of customizable options, Pulsafeeder pumps are an ideal choice for any industry that requires precise fluid handling solutions.

Factors to Consider When Buying Pulsafeeeder

When considering purchasing equipment from Pulsafeeder, there are several factors that professionals should take into consideration. These include:

Application Requirements

Professionals should evaluate their specific application requirements before selecting a Pulsafeeder pump. The type of fluid, flow rate, pressure, and temperature requirements should be taken into account to ensure that the selected pump is capable of meeting the specific application needs.

Compatibility

Professionals should ensure that the selected Pulsafeeder pump is compatible with the specific fluid being handled. This is particularly important when handling corrosive or abrasive fluids, which can cause damage to pumps that are not designed to handle them. Pulsafeeder offers a range of pump materials and configurations to ensure compatibility with a wide range of fluids.

Installation Requirements

Professionals should consider the installation requirements of the selected Pulsafeeder pump. This includes factors such as space requirements, electrical and plumbing connections, and mounting options. Pulsafeeder offers a range of pump sizes and configurations to accommodate various installation requirements.

Maintenance Requirements

Professionals should consider the maintenance requirements of the selected Pulsafeeder pump. This includes factors such as frequency of maintenance, availability of replacement parts, and the level of technical expertise required for maintenance. Pulsafeeder offers a range of pumps with varying maintenance requirements, and also provides support services such as technical assistance, training, and replacement parts.

Cost

Professionals should consider the total cost of ownership when selecting a Pulsafeeder pump. This includes not only the upfront purchase price, but also the cost of maintenance, replacement parts, and downtime. Pulsafeeder offers a range of pumps with varying costs, and also provides support services to minimize the total cost of ownership.

Overall, when considering purchasing equipment from Pulsafeeder, professionals should evaluate their specific application requirements, ensure compatibility with the specific fluid being handled, consider installation and maintenance requirements, and evaluate the total cost of ownership. By taking these factors into account, professionals can select the most appropriate Pulsafeeder pump for their specific needs.

About Pulsafeeder

Pulsafeeder is a leading manufacturer of fluid handling equipment, providing a comprehensive range of high-performance products for various industrial applications. The company has been in the business for over 75 years and is renowned for its innovative and reliable solutions.

Pulsafeeder offers a wide range of products, including metering pumps, controllers, and systems, which are designed to handle fluids of all types, including corrosive, viscous, and abrasive liquids. These products are used in various industries, such as chemical processing, oil and gas, water treatment, and food and beverage.

The metering pumps offered by Pulsafeeder are known for their accurate and consistent dosing capabilities, which are essential for many industrial applications. These pumps can handle a wide range of fluids and offer precise flow control, making them ideal for applications where accuracy is critical. Pulsafeeder also offers a range of controllers and systems that work in tandem with their metering pumps to provide advanced control and monitoring capabilities.

In addition to metering pumps, Pulsafeeder also offers a range of chemical feed systems, mixers, and agitators, which are designed to improve fluid handling and mixing capabilities. These products are ideal for applications where a high level of precision and control is required to achieve optimal results.

Pulsafeeder is known for its commitment to quality and customer service. The company’s products are manufactured to the highest standards, ensuring that they are reliable and long-lasting. Pulsafeeder also offers a comprehensive range of technical support services, including training, installation, and maintenance services, to ensure that its customers get the most out of their products.

Affiliation with Idex Corporation

Pulsafeeder is a leading manufacturer of metering pumps, gear pumps, and chemical feed systems, serving customers across a range of industries including water treatment, agriculture, chemical processing, and more. The company was founded in 1942 and has since been recognized for its high-quality products and commitment to customer service.

In 1986, Pulsafeeder was acquired by IDEX Corporation, a diversified manufacturing company with a global presence in a variety of industries. This partnership has allowed Pulsafeeder to expand its offerings and capabilities, while still maintaining its dedication to innovation and customer satisfaction.

Overall, Pulsafeeder’s affiliation with IDEX Corporation has strengthened its position as a leading manufacturer of pumps and chemical feed systems. By leveraging the resources and expertise of its parent company, Pulsafeeder is well-positioned to continue driving innovation and growth in its industry, while maintaining its commitment to delivering high-quality products and exceptional customer service.