Abel Pumps Equipment We Distribute

Abel Pumps is a leading manufacturer of high-quality pumps that are used in a variety of industries worldwide. They offer a wide range of pumps including diaphragm pumps and piston pumps that are known for their durability, reliability, and efficiency. Abel’s diaphragm pumps are designed for handling abrasive, aggressive, and viscous fluids, making them ideal for applications in the chemical, mining, and food processing industries. These pumps are available in various sizes and materials, making them suitable for different fluids and operating conditions. Abel’s piston pumps, on the other hand, are designed for applications where high-pressure and high flow rates are required. They are commonly used in oil and gas, water treatment, and chemical industries. Abel’s piston pumps are also available in different sizes and materials to suit different applications. Whether you need a pump for your industrial process, waste management, or any other application, Abel Pumps has a solution that can meet your needs.

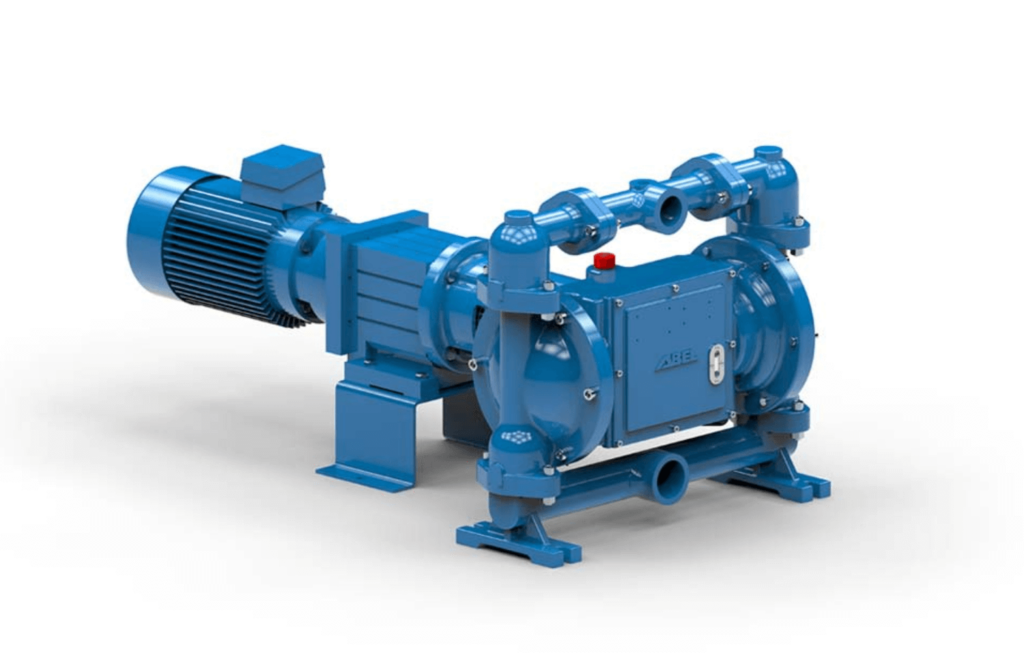

Diaphragm Pumps

Abel Pumps’ Diaphragm Pumps are highly efficient, durable, and reliable, making them a popular choice for various industrial applications. The EM Electric Diaphragm Pumps series is designed for handling abrasive, aggressive, and viscous fluids, such as slurries, sludge, and acids. They are powered by an electric motor, making them more efficient and reliable than traditional air-operated diaphragm pumps. These pumps are also designed for easy maintenance, with fewer components and a modular design that simplifies the replacement of parts.

The CM Compact Diaphragm Pumps series is designed for applications where space is limited, but high performance is still required. They are designed with a compact size and low weight, making them easy to install and transport. These pumps are also highly versatile, with a modular design that allows for easy customization to suit different applications. They are commonly used in the chemical, pharmaceutical, and food processing industries.

The HM Piston Diaphragm Pump Series is designed for applications that require high flow rates and high pressure. These pumps are designed with a piston instead of a diaphragm, making them capable of handling high-pressure applications. They are commonly used in the oil and gas industry, water treatment, and chemical processing. The HM series is highly reliable, with a simple design that minimizes the risk of breakdowns and downtime. Overall, Abel Pumps’ Diaphragm Pump series provides a versatile, efficient, and reliable solution for a wide range of industrial applications.

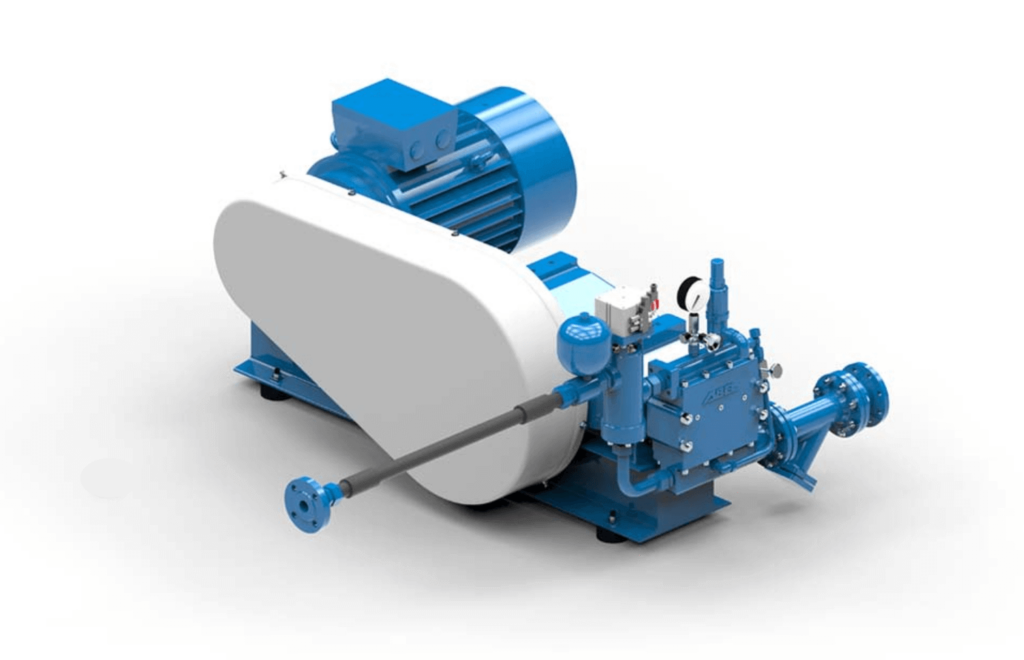

Piston Pumps

Abel Pumps’ Piston Pumps are designed to handle high-pressure applications and deliver reliable performance in tough conditions. The HP / HPT High-Pressure Pumps series is designed for high-pressure applications in the oil and gas industry, water treatment, and chemical processing. These pumps are capable of delivering pressures of up to 700 bar and flow rates of up to 1,500 liters per minute. They are also highly efficient, with a compact design that minimizes energy consumption and reduces maintenance requirements.

The SH Solids Handling Pump Series is designed for applications where solid particles are present in the fluid being pumped. These pumps are capable of handling solids of up to 100mm in diameter, making them ideal for use in mining, dredging, and waste management applications. The SH series is highly versatile, with a modular design that allows for easy customization to suit different applications. They are also highly reliable, with a robust design that can withstand the toughest conditions.

Abel Pumps’ Piston Pumps are also designed for easy maintenance, with fewer components and a modular design that simplifies the replacement of parts. They are also designed to be energy-efficient, with a compact size that minimizes energy consumption. Overall, Abel Pumps’ Piston Pumps series provides a versatile, efficient, and reliable solution for high-pressure and solids handling applications in a variety of industries.

Applications of Abel Pumps Equipment

Abel Pumps offers a wide range of pumps that are used across industries for various applications. In the mining and minerals industry, Abel’s diaphragm and piston pumps are commonly used for handling abrasive slurry, tailings, and wastewater. In industrial wastewater treatment, Abel’s pumps are used for the transfer of various types of wastewater, including those containing solid particles and chemicals.

Abel’s pumps are also widely used in the water and wastewater treatment industry, where they are used for water transfer, filtration, and disinfection. In the power industry, Abel’s pumps are used for boiler feedwater and condensate transfer. For the oil and gas industry, Abel’s piston pumps are used for oil transfer and injection, as well as other high-pressure applications.

In the food industry, Abel’s pumps are used for the transfer of viscous and abrasive fluids, such as fruit pulp, syrup, and chocolate. In the chemical industry, Abel’s diaphragm and piston pumps are used for transferring chemicals and other aggressive liquids. For the corrugated media and cement industry, Abel’s pumps are used for the transfer of abrasive media, including slurry and cement. Finally, in the marine industry, Abel’s pumps are used for ballast water treatment and other applications. Overall, Abel Pumps offers a range of pumps that can meet the needs of various industries and applications.

Mining and Minerals

Abel Pumps are widely used in the mining and mineral industry for various applications. One of the most common applications is mine dewatering, where Abel’s diaphragm pumps are used for the removal of water from underground mines. Abel’s pumps are also used for thickener underflow transfer, backfilling, and tailings transfer. In backfilling, the pumps are used to transfer tailings and other waste material back into the mine, while in tailings transfer, they are used to transport tailings from the processing plant to the tailings storage facility.

Another important application of Abel’s pumps in the mining and mineral industry is the transfer of ore sludge and paste. Abel’s piston pumps are designed to handle high-pressure applications and are commonly used for paste transfer. They are also used for the transfer of ore sludge, which is a byproduct of the ore preparation process. Abel’s diaphragm and piston pumps are also used for ore preparation and leaching, where they are used to transfer chemicals and other liquids to the processing plant.

Abel’s pumps are also used for autoclave feed, filter press feed, filter cloth washing, and gland seal water applications in the mining and mineral industry. Autoclave feed pumps are used to transfer slurry to autoclaves for the extraction of metals, while filter press feed pumps are used to transfer slurry to filter presses for solid-liquid separation. Abel’s pumps are also used for filter cloth washing, which is an important step in the filtration process. Finally, gland-seal water pumps are used to provide a continuous flow of clean water to the gland seal of slurry pumps, ensuring that they operate efficiently and last longer.

Industrial Wastewater

Abel Pumps are widely used in the industrial wastewater industry for various applications, including filter press feed, filter cloth cleaning, and primary and secondary sludge transfer. In filter press feed applications, Abel’s diaphragm and piston pumps are used to transfer slurry to the filter press for solid-liquid separation. The pumps are capable of handling high-pressure and abrasive slurries, making them ideal for this application. Abel’s pumps are also used for filter cloth cleaning, which is a critical step in the filtration process. The pumps are used to provide a continuous flow of clean water to the filter cloth, ensuring that it stays clean and efficient.

Abel’s pumps are also used for primary and secondary sludge transfer in industrial wastewater treatment plants. Primary sludge is the sludge that settles at the bottom of the primary clarifier, while secondary sludge is the sludge that is produced during the biological treatment process. Abel’s diaphragm and piston pumps are used to transfer the sludge from the treatment process to the sludge treatment facility. The pumps are designed to handle the high solids content of the sludge and are also suitable for handling corrosive and abrasive liquids.

Overall, Abel Pumps provides reliable and efficient solutions for the industrial wastewater industry. Their pumps are designed to handle a wide range of applications, including those that involve abrasive and corrosive liquids, high-pressure transfer, and solid-liquid separation. Abel’s pumps are also designed for easy maintenance, with fewer components and a modular design that simplifies the replacement of parts, minimizing downtime and maintenance costs.

Water and Wastewater

Abel Pumps are widely used in the water and wastewater industry for various applications, including sewage transfer, filter press feed, filter cloth cleaning, filter cake transfer, sludge transfer, lime milk dosing, ferric chloride dosing, polymer dosing, and autoclave feed. In sewage transfer applications, Abel’s diaphragm and piston pumps are used to transfer raw sewage from the collection tank to the treatment facility. The pumps are designed to handle the high solids content of the sewage, making them ideal for this application.

Abel’s pumps are also used for filter press feed and filter cake transfer in the water and wastewater industry. The pumps are used to transfer slurry to the filter press for solid-liquid separation and to transfer the resulting filter cake to the sludge treatment facility. Abel’s pumps are also used for filter cloth cleaning, which is a critical step in the filtration process. The pumps are used to provide a continuous flow of clean water to the filter cloth, ensuring that it stays clean and efficient.

Abel’s pumps are also used for dosing lime milk, ferric chloride, and polymer in the water and wastewater treatment process. Lime milk is used to adjust the pH level of the water, while ferric chloride and polymer are used for coagulation and flocculation. Abel’s diaphragm and piston pumps are designed to handle the high viscosity and abrasive nature of these chemicals, making them ideal for dosing applications. Finally, Abel’s pumps are also used for autoclave feed in the water and wastewater industry, where they are used to transfer slurry to autoclaves for disinfection and sterilization.

Power

Abel Pumps are used in the power industry for various applications, including filter press feed, filter cloth cleaning, FGD-sludge transfer, acids/leach-dosing, fly-/bottom-ash transfer, and naphta-/diesel transfer. In filter press feed applications, Abel’s diaphragm and piston pumps are used to transfer slurry to the filter press for solid-liquid separation. The pumps are capable of handling high-pressure and abrasive slurries, making them ideal for this application. Abel’s pumps are also used for filter cloth cleaning, which is a critical step in the filtration process. The pumps are used to provide a continuous flow of clean water to the filter cloth, ensuring that it stays clean and efficient.

Abel’s pumps are also used for FGD-sludge transfer in the power industry. Flue gas desulfurization (FGD) is a process used to remove sulfur dioxide from flue gas emissions. Abel’s diaphragm and piston pumps are used to transfer the resulting sludge to the sludge treatment facility. The pumps are designed to handle the high solids content of the sludge and are also suitable for handling corrosive and abrasive liquids.

Abel’s pumps are also used for acids/leach-dosing, fly-/bottom-ash transfer, and naphta-/diesel transfer in the power industry. Acids and leach are used for cleaning and maintaining equipment, while fly and bottom ash are byproducts of the combustion process. Abel’s pumps are designed to handle the high viscosity and abrasive nature of these liquids. They are also used for the transfer of naphta and diesel, which are commonly used as fuels for power generation. Overall, Abel Pumps provides reliable and efficient solutions for the power industry, helping to ensure the safe and efficient operation of power plants.

Oil and Gas

Abel Pumps are used in the oil and gas industry for various applications, including filter cloth washing, slops tank dewatering, oil and waste oil transfer, flare knockout tank service, tank bottoms service, well injection, washing and drying of gas, oil rig, and oil field. In filter cloth washing applications, Abel’s pumps are used to provide a continuous flow of clean water to the filter cloth, ensuring that it stays clean and efficient. Abel’s pumps are also used for slops tank dewatering, where they are used to remove water from the tank, leaving behind a concentrated mixture of oil and solids.

Abel’s pumps are also used for oil and waste oil transfer in the oil and gas industry. Abel’s diaphragm and piston pumps are designed to handle high-viscosity liquids, making them ideal for transferring oil and waste oil. They are also used for flare knockout tank service and tank bottoms service, where they are used to transfer sludge and other materials from the bottom of tanks. Abel’s pumps are designed to handle abrasive and corrosive materials, making them ideal for this application.

Abel’s pumps are also used for well injection, washing, and drying of gas, oil rig, and oil field applications in the oil and gas industry. Well injection pumps are used to inject chemicals into the well for enhanced oil recovery while washing and drying of gas pumps are used to remove moisture from the gas stream. Abel’s pumps are also used for oil rig and oil field applications, such as the transfer of drilling mud and the handling of wastewater. Overall, Abel Pumps provides reliable and efficient solutions for the oil and gas industry, helping to ensure the safe and efficient operation of oil and gas facilities.

Food

Abel Pumps are used in the food industry for various applications, including margarine process, fruit pulp transfer, slaughterhouse waste transfer, molasses transfer, and spray dryer feed. In the margarine process, Abel’s pumps are used to transfer oils and fats between various stages of the process. Abel’s pumps are also used for fruit pulp transfer, where they are used to transfer viscous fruit pulp from the processing plant to the packaging facility.

Abel’s pumps are also used for the transfer of slaughterhouse waste in the food industry. The pumps are designed to handle solids and fluids of various densities, making them ideal for this application. Abel’s pumps are also used for the transfer of molasses, which is commonly used as a sweetener in the food industry. The pumps are designed to handle the high viscosity of molasses, ensuring a smooth and efficient transfer process.

Abel’s pumps are also used for spray dryer feed in the food industry. Spray dryers are used to produce powders and granules from liquid materials. Abel’s pumps are used to transfer the liquid material to the spray dryer for atomization. Abel’s pumps are designed to handle high-viscosity liquids, ensuring a consistent and efficient feed to the spray dryer. Overall, Abel Pumps provides reliable and efficient solutions for the food industry, helping to ensure the safe and efficient processing of food products.

Chemical Industry

Abel Pumps are used in the chemical industry for various applications, including filter press feed, transfer of chemicals, dyes, dispersion paints, spray dryer feed, powder transfer, and bottling. In filter press feed applications, Abel’s diaphragm and piston pumps are used to transfer slurry to the filter press for solid-liquid separation. The pumps are capable of handling high-pressure and abrasive slurries, making them ideal for this application.

Abel’s pumps are also used for the transfer of chemicals, dyes, and dispersion paints in the chemical industry. Abel’s diaphragm and piston pumps are designed to handle aggressive and corrosive chemicals, making them suitable for this application. Abel’s pumps are also used for spray dryer feed, where they are used to transfer liquid material to the spray dryer for atomization. Abel’s pumps are designed to handle high-viscosity liquids, ensuring a consistent and efficient feed to the spray dryer.

Abel’s pumps are also used for powder transfer and bottling in the chemical industry. Abel’s diaphragm and piston pumps are used to transfer powders from one location to another, ensuring a smooth and efficient transfer process. Abel’s pumps are also used for bottling, where they are used to transfer liquid products to the bottling line. Abel’s pumps are designed for easy maintenance and are highly reliable, ensuring a consistent and efficient bottling process. Overall, Abel Pumps provides reliable and efficient solutions for the chemical industry, helping to ensure the safe and efficient processing of chemical products.

Corrugated Media

Abel Pumps are used in the corrugated media industry for various applications, including starch and glue transfer. In the production of corrugated media, starch, and glue are applied to the paper to create a rigid and durable structure. Abel’s diaphragm and piston pumps are used to transfer the starch and glue from the mixing tank to the application point, ensuring a smooth and consistent application process.

Abel’s pumps are designed to handle the high viscosity and abrasive nature of starch and glue, making them ideal for this application. The pumps are highly reliable and are designed for easy maintenance, ensuring minimal downtime and maximum efficiency in the production process.

Overall, Abel Pumps provides reliable and efficient solutions for the corrugated media industry, helping to ensure the safe and efficient production of high-quality corrugated media products.

Ceramics

Abel Pumps are used in the ceramics industry for various applications, including filter press feed, ceramic slip transfer, glaze transfer, and spray dryer feed. In filter press feed applications, Abel’s diaphragm and piston pumps are used to transfer slurry to the filter press for solid-liquid separation. The pumps are capable of handling high-pressure and abrasive slurries, making them ideal for this application.

Abel’s pumps are also used for the transfer of ceramic slip and glaze in the ceramics industry. Abel’s diaphragm and piston pumps are designed to handle the high viscosity and abrasive nature of these materials, ensuring a smooth and efficient transfer process. Abel’s pumps are also used for spray dryer feed, where they are used to transfer liquid material to the spray dryer for atomization. Abel’s pumps are designed to handle high-viscosity liquids, ensuring a consistent and efficient feed to the spray dryer.

Overall, Abel Pumps provides reliable and efficient solutions for the ceramics industry, helping to ensure the safe and efficient production of high-quality ceramic products. Abel’s pumps are designed for easy maintenance and are highly reliable, ensuring minimal downtime and maximum efficiency in the production process.

Cement

Abel Pumps are used in the cement industry for various applications, including filter press feed, filter cloth cleaning, and rotary kiln feed. In filter press feed applications, Abel’s diaphragm and piston pumps are used to transfer slurry to the filter press for solid-liquid separation. The pumps are capable of handling high-pressure and abrasive slurries, making them ideal for this application.

Abel’s pumps are also used for filter cloth cleaning, which is a critical step in the filtration process. The pumps are used to provide a continuous flow of clean water to the filter cloth, ensuring that it stays clean and efficient. Abel’s pumps are also used for rotary kiln feed, where they are used to transfer raw materials to the kiln for processing. Abel’s pumps are designed to handle the high viscosity and abrasive nature of these materials, ensuring a smooth and efficient transfer process.

Overall, Abel Pumps provides reliable and efficient solutions for the cement industry, helping to ensure the safe and efficient production of high-quality cement products. Abel’s pumps are designed for easy maintenance and are highly reliable, ensuring minimal downtime and maximum efficiency in the production process.

Marine

Abel Pumps are used in the marine industry for various applications, including bilge water transfer and dock-spill-removal. In bilge water transfer applications, Abel’s diaphragm and piston pumps are used to transfer water from the bilge to the holding tank. The pumps are designed to handle the high viscosity and abrasive nature of the water, ensuring a smooth and efficient transfer process.

Abel’s pumps are also used for dock-spill-removal, where they are used to remove oil spills from the dock. The pumps are designed to handle a variety of liquids, including oil, water, and sludge. Abel’s pumps are highly reliable and are designed for easy maintenance, ensuring minimal downtime and maximum efficiency in the spill cleanup process.

Overall, Abel Pumps provides reliable and efficient solutions for the marine industry, helping to ensure the safe and efficient operation of ships and docks. Abel’s pumps are designed to handle a variety of liquids and are highly reliable, ensuring minimal downtime and maximum efficiency in the transfer and cleanup processes.

About Abel Pumps

Abel Pumps is an industrial manufacturing company that specializes in designing and producing high-quality diaphragm and piston pumps for various industries. The company has a rich history of providing innovative and reliable pumping solutions to its customers. Abel Pumps’ dedication to quality and customer satisfaction has earned them a reputation as one of the leading pump manufacturers in the world.

Abel Pumps’ product line includes a range of diaphragm and piston pumps that are designed to handle a wide variety of liquids, including abrasive and corrosive materials. The company’s pumps are used in industries such as mining and minerals, industrial wastewater, water and wastewater, power, oil and gas, food, chemical industry, corrugated media, cement, and marine. Abel Pumps’ pumps are known for their reliability, efficiency, and easy maintenance.

Abel Pumps’ commitment to quality extends beyond their products to their customer service and support. The company has a team of experienced engineers and technicians who work closely with customers to design and implement customized pumping solutions to meet their specific needs. Abel Pumps’ dedication to providing exceptional customer service has earned them a loyal customer base that spans the globe. With a focus on innovation, reliability, and customer satisfaction, Abel Pumps continues to be a leader in the pump manufacturing industry.