Boerger Equipment We Distribute

Boerger is a leading manufacturer of industrial pumps, macerating units, solid/liquid separation equipment, and liquid manure technology. Boerger’s product line includes rotary lobe pumps, mobile pumps, and macerating units, designed for use in a wide range of applications, such as industrial waste processing, biogas production, and agriculture. Additionally, Boerger offers a range of solid/liquid separation equipment, including the Bioselect system, which separates organic solids from wastewater, and the Biogas/Powerfeed Entry Technology, which separates coarse particles from biogas substrates. Boerger’s liquid manure technology includes pumps and separation systems designed for use in the agriculture industry.

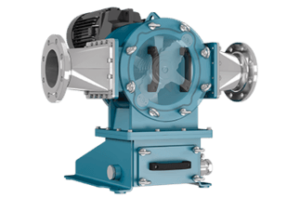

Rotary Lobe Pumps

Boerger’s rotary lobe pumps are designed for use in a wide range of applications, such as chemical processing, food and beverage production, and wastewater treatment. Rotary lobe pumps are positive displacement pumps that are ideal for handling viscous, abrasive or shear-sensitive materials. Boerger’s rotary lobe pumps are highly efficient, with low energy consumption and minimal pulsation, making them a reliable and cost-effective solution for a variety of industries.

One of the key benefits of Boerger’s rotary lobe pumps is their versatility. The pumps are highly customizable, allowing them to be tailored to the specific needs of each application. Boerger’s rotary lobe pumps are available in a variety of materials, such as stainless steel, cast iron, and plastic, and can be equipped with a range of seal and rotor options. Additionally, Boerger’s rotary lobe pumps can be configured with variable speed drives, allowing for precise control over flow rates and pressures.

Boerger’s rotary lobe pumps are designed to be highly durable and require minimal maintenance. The pumps feature a simple design with few moving parts, minimizing the risk of breakdowns and reducing the need for frequent maintenance. Additionally, Boerger’s rotary lobe pumps are easy to clean, with a design that eliminates dead spots and allows for thorough cleaning in place. Overall, Boerger’s rotary lobe pumps are a reliable and efficient solution for a wide range of industrial applications.

Mobile Pumps

Boerger’s mobile pumps are designed for use in applications where a fixed pumping solution is not feasible or convenient. Boerger’s mobile pumps are mounted on skids or trailers, allowing them to be easily transported to different locations as needed. Boerger’s mobile pumps are highly versatile and can be used for a range of applications, such as emergency pumping, temporary bypass pumping, or on-site dewatering.

One of the key benefits of Boerger’s mobile pumps is their flexibility. Boerger’s mobile pumps are available in a variety of sizes and configurations, allowing them to be customized to meet the specific needs of each application. Additionally, Boerger’s mobile pumps can be equipped with a range of accessories, such as hoses, valves, and control panels, making them a complete pumping solution for a wide range of applications.

Boerger’s mobile pumps are designed to be highly durable and reliable, with a focus on ease of use and maintenance. The pumps feature a simple design with few moving parts, minimizing the risk of breakdowns and reducing the need for frequent maintenance. Additionally, Boerger’s mobile pumps are easy to operate, with intuitive controls and a user-friendly interface. Overall, Boerger’s mobile pumps are a reliable and convenient solution for a range of pumping applications, providing flexibility, versatility, and ease of use in a mobile package.

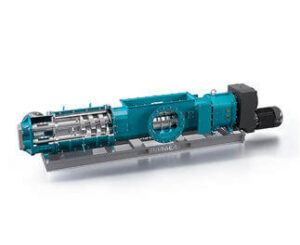

Macerating Units

Boerger’s macerating units are designed to macerate solid materials, such as organic waste, sludge, or animal byproducts, into smaller particles that can be more easily processed or transported. Boerger’s macerating units are ideal for use in applications such as biogas production, food processing, and wastewater treatment. Boerger’s macerating units are highly efficient, with low energy consumption and minimal wear and tear on equipment, making them a reliable and cost-effective solution for a variety of industries.

One of the key benefits of Boerger’s macerating units is their versatility. The units are highly customizable, allowing them to be tailored to the specific needs of each application. Boerger’s macerating units are available in a variety of materials, such as stainless steel, cast iron, and plastic, and can be equipped with a range of screens, cutters, and rotors. Additionally, Boerger’s macerating units can be configured with variable speed drives, allowing for precise control over particle size and output rates.

Boerger’s macerating units are designed to be highly durable and require minimal maintenance. The units feature a simple design with few moving parts, minimizing the risk of breakdowns and reducing the need for frequent maintenance. Additionally, Boerger’s macerating units are easy to clean, with a design that eliminates dead spots and allows for thorough cleaning in place. Overall, Boerger’s macerating units are a reliable and efficient solution for a wide range of industrial applications, providing versatility, durability, and ease of use in a compact package.

Solid/Liquid Separation – Bioselect

Boerger’s Bioselect system is a solid/liquid separation solution designed for use in a range of applications, such as agricultural and municipal wastewater treatment, and biogas production. The Bioselect system uses a combination of mechanical separation and biological treatment to remove organic solids from wastewater streams. The system is highly efficient, with a compact design and low energy consumption, making it a reliable and cost-effective solution for a variety of industries.

One of the key benefits of Boerger’s Bioselect system is its flexibility. The system is highly customizable, allowing it to be tailored to the specific needs of each application. The Bioselect system is available in a range of sizes and configurations and can be designed to handle various wastewater streams, such as animal manure, municipal sewage, or industrial wastewater. Additionally, the Bioselect system can be integrated with other Boerger equipment, such as macerating units or rotary lobe pumps, to provide a complete solid/liquid separation solution.

Boerger’s Bioselect system is designed to be highly durable and requires minimal maintenance. The system features a simple design with few moving parts, minimizing the risk of breakdowns and reducing the need for frequent maintenance. Additionally, the Bioselect system is easy to clean, with a design that allows for thorough cleaning in place. Overall, Boerger’s Bioselect system is a reliable and efficient solution for solid/liquid separation, providing flexibility, durability, and ease of use in a compact package.

Biogas / Powerfeed Entry Technology

Boerger’s Biogas/Powerfeed Entry Technology is a solid/liquid separation solution designed specifically for biogas production. The system uses a combination of mechanical separation and biological treatment to separate coarse particles from biogas substrates. The separated particles can be used as a nutrient-rich fertilizer, while the biogas substrate can be used to produce biogas. Boerger’s Biogas/Powerfeed Entry Technology is highly efficient, with a compact design and low energy consumption, making it a reliable and cost-effective solution for biogas producers.

One of the key benefits of Boerger’s Biogas/Powerfeed Entry Technology is its versatility. The system is highly customizable, allowing it to be tailored to the specific needs of each biogas production application. The Biogas/Powerfeed Entry Technology is available in a range of sizes and configurations and can be designed to handle various biogas substrates, such as organic waste, animal manure, or agricultural byproducts. Additionally, the Biogas/Powerfeed Entry Technology can be integrated with other Boerger equipment, such as macerating units or rotary lobe pumps, to provide a complete biogas production solution.

Boerger’s Biogas/Powerfeed Entry Technology is designed to be highly durable and requires minimal maintenance. The system features a simple design with few moving parts, minimizing the risk of breakdowns and reducing the need for frequent maintenance. Additionally, the Biogas/Powerfeed Entry Technology is easy to clean, with a design that allows for thorough cleaning in place. Overall, Boerger’s Biogas/Powerfeed Entry Technology is a reliable and efficient solution for biogas production, providing flexibility, durability, and ease of use in a compact package.

Liquid Manure Technology

Boerger’s liquid manure technology is a comprehensive solution designed for use in the agriculture industry. The system includes pumps, macerating units, and solid/liquid separation equipment, designed to handle the transportation and processing of liquid manure. Boerger’s liquid manure technology is highly efficient, with a compact design and low energy consumption, making it a reliable and cost-effective solution for farmers.

One of the key benefits of Boerger’s liquid manure technology is its versatility. The system is highly customizable, allowing it to be tailored to the specific needs of each farm. Boerger’s liquid manure technology is available in a range of sizes and configurations and can be designed to handle various types of liquid manure, such as dairy manure, swine manure, or poultry manure. Additionally, the liquid manure technology can be integrated with other Boerger equipment, such as pumps or macerating units, to provide a complete solution for liquid manure management.

Boerger’s liquid manure technology is designed to be highly durable and requires minimal maintenance. The system features a simple design with few moving parts, minimizing the risk of breakdowns and reducing the need for frequent maintenance. Additionally, the liquid manure technology is easy to clean, with a design that allows for thorough cleaning in place. Overall, Boerger’s liquid manure technology is a reliable and efficient solution for liquid manure management, providing flexibility, durability, and ease of use in a compact package.

Applications of Boerger Equipment

Boerger equipment is used across a variety of industries and applications, including general industrial, environmental and municipal technology, food industry, marine and offshore, agriculture and biogas, and disaster relief. In the general industrial sector, Boerger equipment is used in chemical processing, construction chemistry, paints, lacquers & adhesives, oil and gas, and paper, cardboard & tissue production. In environmental and municipal technology, Boerger equipment is used in municipal wastewater treatment, industrial wastewater treatment, and disposal and recycling. Boerger equipment is also used in the food industry, particularly in the sugar and starch industry. In the marine and offshore sector, Boerger equipment is used for a variety of applications, such as shipbuilding and offshore oil and gas production. Boerger equipment is also used in agriculture and biogas production, with solutions for liquid manure management, biogas production, and nutrient recovery. Finally, Boerger equipment is used by disaster relief organizations such as THW and the fire department, providing reliable and efficient pumping solutions in emergency situations. Boerger equipment is versatile and customizable, making it a trusted solution for a wide range of industries and applications.

General Industrial

Boerger equipment is used in a variety of applications within the general industrial sector. In the chemical industry, Boerger equipment is used for the safe and efficient transfer of chemicals and other hazardous materials. Boerger’s rotary lobe pumps, macerating units, and solid/liquid separation equipment are highly customizable, making them a reliable solution for a range of chemical processing applications.

In the construction chemistry, paints, lacquers, and adhesives industries, Boerger equipment is used for the transfer and processing of raw materials, such as resins, solvents, and pigments. Boerger’s mobile pumps and macerating units are highly versatile, allowing them to be used for emergency pumping or temporary bypass pumping in a range of construction sites.

In the oil and gas industry, Boerger equipment is used for the transfer and processing of crude oil, refined products, and drilling muds. Boerger’s rotary lobe pumps are highly efficient, with a low pulsation flow that is ideal for transferring high-viscosity fluids. Additionally, Boerger’s macerating units and solid/liquid separation equipment are used for the efficient processing of drilling muds and other oil and gas waste streams. Overall, Boerger equipment is a reliable and efficient solution for a wide range of general industrial applications, providing versatility, durability, and ease of use in a compact package.

Environmental and Municipal Technology

Boerger equipment is used extensively in the environmental and municipal technology industry. In municipal wastewater treatment, Boerger equipment is used for the efficient and effective treatment of wastewater. Boerger’s solid/liquid separation equipment, such as the Bioselect system, is highly efficient at removing organic solids from wastewater streams. Additionally, Boerger’s rotary lobe pumps and macerating units are used for the safe and efficient transfer and processing of wastewater at treatment facilities.

In industrial wastewater treatment, Boerger equipment is used for the treatment of a variety of industrial waste streams. Boerger’s solid/liquid separation equipment is highly customizable, allowing it to be tailored to the specific needs of each application. Additionally, Boerger’s rotary lobe pumps and macerating units are used for the transfer and processing of industrial waste streams, such as sludges and effluent.

In disposal and recycling, Boerger equipment is used for the processing and transportation of waste materials. Boerger’s rotary lobe pumps and macerating units are highly efficient, making them a reliable solution for the transfer and processing of waste materials such as municipal solid waste and organic waste. Additionally, Boerger’s solid/liquid separation equipment is used for the efficient separation and processing of wastewater and waste streams. Overall, Boerger equipment is a reliable and efficient solution for a wide range of environmental and municipal technology applications, providing versatility, durability, and ease of use in a compact package.

Food Industry

Boerger equipment is used extensively in the food industry, particularly in the sugar and starch industry. In the sugar and starch industry, Boerger’s rotary lobe pumps and macerating units are used for the transfer and processing of raw materials, such as sugar beets and corn. Additionally, Boerger’s solid/liquid separation equipment is used for the efficient separation and processing of wastewater and byproducts generated during the production process.

Boerger’s rotary lobe pumps are highly efficient and reliable, making them a trusted solution for the transfer of high-viscosity materials such as molasses and syrup. Boerger’s macerating units are also highly efficient, allowing them to process a range of materials, from whole corn kernels to sugar beets. Additionally, Boerger’s solid/liquid separation equipment is highly customizable, allowing it to be tailored to the specific needs of each application.

Overall, Boerger equipment is a reliable and efficient solution for a wide range of food industry applications. Boerger’s equipment is highly versatile, making it a trusted solution for the transfer and processing of raw materials, byproducts, and wastewater generated during the production process. Boerger’s equipment is also highly customizable, allowing it to be tailored to the specific needs of each application, making it a reliable and cost-effective solution for food industry producers.

Marine & Offshore

Boerger equipment is used extensively in the marine and offshore industry. Boerger’s rotary lobe pumps and macerating units are highly efficient, making them a trusted solution for the transfer and processing of fluids and solids in marine and offshore applications. Boerger’s equipment is highly durable and reliable, making it a trusted solution for use in harsh marine environments.

Boerger’s rotary lobe pumps are used for a range of marine applications, including shipbuilding and offshore oil and gas production. Boerger’s pumps are highly efficient and reliable, providing a low pulsation flow that is ideal for the transfer of high-viscosity fluids such as crude oil and drilling mud. Additionally, Boerger’s macerating units are used for the processing of waste materials generated during offshore oil and gas production, such as drilling cuttings and slop oil.

Boerger’s equipment is also highly customizable, allowing it to be tailored to the specific needs of each marine application. Boerger’s equipment can be designed to handle a range of fluids and solids, from seawater and bilge water to drilling muds and waste materials. Additionally, Boerger’s equipment is easy to install and maintain, making it a reliable and cost-effective solution for marine and offshore applications. Overall, Boerger equipment is a trusted solution for marine and offshore applications, providing versatility, durability, and ease of use in a compact package.

Agriculture and Biogas

Boerger equipment is extensively used in the agriculture and biogas industry. Boerger’s equipment is highly efficient and reliable, making it a trusted solution for the transportation and processing of manure, slurry, and other waste materials generated in agriculture and biogas production. Boerger’s equipment is highly customizable, allowing it to be tailored to the specific needs of each application, making it a reliable and cost-effective solution for agricultural and biogas producers.

In the agriculture industry, Boerger’s liquid manure technology is used for the efficient management of liquid manure generated on farms. Boerger’s pumps, macerating units, and solid/liquid separation equipment are highly efficient and reliable, making them a trusted solution for the transportation and processing of liquid manure. Additionally, Boerger’s nutrient recovery solutions are used to recover valuable nutrients such as phosphorus and nitrogen from liquid manure, making them a cost-effective solution for farmers.

In the biogas industry, Boerger’s equipment is used for the efficient production of biogas. Boerger’s equipment, such as its biogas/power feed entry technology, is used for the safe and efficient transportation and processing of feedstock materials, such as agricultural waste, food waste, and manure. Additionally, Boerger’s equipment is highly efficient, providing a reliable and cost-effective solution for the production of biogas. Overall, Boerger equipment is a trusted solution for agricultural and biogas producers, providing versatility, durability, and ease of use in a compact package.

Disaster Relief

Boerger equipment is used in the disaster relief industry to provide reliable pumping solutions in emergency situations. Boerger’s equipment is highly efficient and reliable, making it a trusted solution for the transportation and processing of fluids and solids in disaster relief applications. Boerger’s equipment is also highly portable and easy to use, making it a reliable solution for use in emergency situations.

In the THW (Technisches Hilfswerk), Boerger’s equipment is used for a variety of disaster relief applications, such as flood control and firefighting. Boerger’s mobile pumps and macerating units are highly versatile, allowing them to be used for emergency pumping or temporary bypass pumping in a range of disaster relief situations. Additionally, Boerger’s solid/liquid separation equipment is used for the efficient separation and processing of waste materials generated during disaster relief operations.

In the fire department, Boerger’s equipment is used for the efficient and safe transfer of water and other fluids during firefighting operations. Boerger’s rotary lobe pumps are highly efficient and reliable, providing a low pulsation flow that is ideal for the transfer of high-viscosity fluids such as firefighting foam. Boerger’s pumps are also highly portable, allowing them to be used in remote locations or in situations where access to water is limited.

Overall, Boerger equipment is a trusted solution for disaster relief applications, providing versatility, durability, and ease of use in a compact package. Boerger’s equipment is highly customizable, allowing it to be tailored to the specific needs of each disaster relief application, making it a reliable and cost-effective solution for disaster relief organizations.

About Boerger

Boerger is an industrial manufacturing company that specializes in the production of reliable and efficient pumping solutions for a wide range of industries. Boerger has expanded its operations to become a global leader in the design and manufacture of rotary lobe pumps, macerating units, and solid/liquid separation equipment. Boerger’s equipment is used in a variety of industries, including agriculture, biogas, marine and offshore, food and beverage, and disaster relief.

Boerger’s equipment is highly customizable, allowing it to be tailored to the specific needs of each application. Boerger’s rotary lobe pumps, for example, are available in a range of materials and configurations, allowing them to handle a wide range of fluids and solids. Boerger’s macerating units are also highly customizable, allowing them to be used for the processing of a variety of materials, from agricultural waste to food waste and municipal solid waste.

Boerger is committed to providing its customers with the highest level of service and support. Boerger’s equipment is designed to be easy to install, use, and maintain, providing customers with a reliable and cost-effective solution for their pumping needs. Additionally, Boerger’s experienced team of engineers and technicians is available to provide support and assistance throughout the entire equipment lifecycle, from design and installation to maintenance and repair. Overall, Boerger is a trusted and reliable solution for pumping needs across a wide range of industries.