Crane Pumps & Systems is a leading manufacturer of industrial equipment, producing a broad range of pumps and related products for various industries. One of the most popular product lines is the Burks line of industrial equipment, which offers a versatile and reliable pumping solution for a wide range of applications. In this article, we will explore what the Burks line of industrial equipment is, how it works, and what its applications are.

What is the Burks Line of Industrial Equipment?

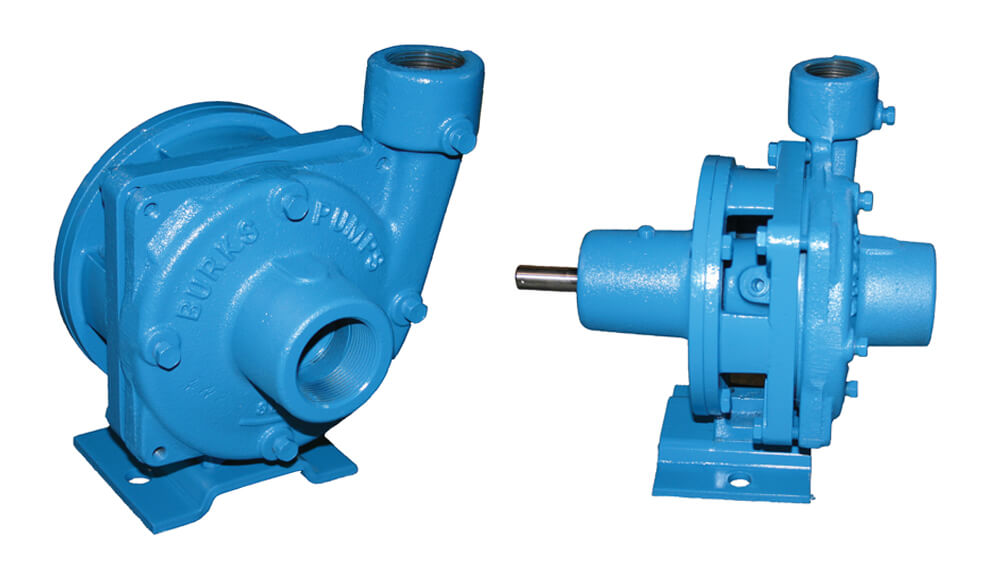

The Burks line of industrial equipment is a range of centrifugal pumps and related products manufactured by Crane Pumps & Systems. The product line includes close-coupled, end-suction, and self-priming centrifugal pumps, as well as vertical turbine pumps, submersible pumps, and accessories such as suction diffusers and check valves. The pumps are designed for various applications, including water supply, wastewater treatment, HVAC, industrial processes, and many others.

How Does the Burks Line of Industrial Equipment Work?

The Burks line of industrial equipment consists of centrifugal pumps that work by using a rotating impeller to move fluid through the pump. As the impeller rotates, it creates a centrifugal force that pushes the fluid towards the pump’s discharge port. The pump’s housing and impeller are designed to create a specific flow rate and pressure, depending on the application’s requirements. The Burks line of industrial equipment includes pumps with various impeller designs and materials of construction to handle different fluids, temperatures, and pressures.

What are the Applications of the Burks Line of Industrial Equipment?

The Burks line of industrial equipment is designed for various applications, including:

Water Supply: Burks pumps are ideal for water supply applications, such as municipal water distribution, irrigation, and fire protection systems. The pumps can handle clean water, as well as water with low levels of solids and chemicals.

Wastewater Treatment: Burks pumps are commonly used in wastewater treatment applications, such as lift stations, sewage treatment plants, and industrial wastewater treatment. The pumps can handle wastewater with high solids content and abrasive materials.

HVAC: Burks pumps are used in HVAC systems to circulate water for heating and cooling applications. The pumps can handle high temperatures and pressures and are available in various sizes and configurations to meet specific HVAC system requirements.

Industrial Processes: Burks pumps are used in various industrial processes, such as chemical processing, food and beverage production, and manufacturing. The pumps can handle corrosive and abrasive fluids, as well as fluids with high temperatures and pressures.

What to Consider When Buying a Burks Pump?

When looking to buy a Burks pump, there are several factors to consider to ensure that you select the right pump for your application. Here are some essential factors to keep in mind:

- Application Requirements: The first factor to consider before buying equipment from the Burks line of industrial equipment is the application requirements. Different types of pumps and related products are designed for specific applications, such as water supply, wastewater treatment, HVAC, and industrial processes. It is essential to select equipment that is specifically designed to meet the application requirements to ensure reliable performance and long service life.

- Flow Rate and Pressure Requirements: Another critical factor to consider is the flow rate and pressure requirements of the application. The Burks line of industrial equipment includes pumps with various flow rates and pressure ratings. It is crucial to select equipment that can handle the desired flow rate and pressure requirements while considering factors such as pipeline length, elevation changes, and fluid viscosity.

- Material of Construction: The material of construction is another important consideration when selecting equipment from the Burks line of industrial equipment. The equipment’s housing and internal components must be made from materials that are compatible with the fluid being handled. For example, if the fluid is highly corrosive, the equipment’s housing and internal components must be made from materials such as stainless steel or Hastelloy. Similarly, if the fluid is abrasive, the equipment’s internal components must be made from materials such as ceramic or tungsten carbide.

- Maintenance and Repair: Maintenance and repair requirements are another crucial factor to consider when selecting equipment from the Burks line of industrial equipment. Some models may require specialized tools and expertise to perform maintenance and repairs, while others may have readily available spare parts and require minimal maintenance. It is essential to select equipment that is easy to maintain and repair to minimize downtime and reduce maintenance costs.

- Operating Conditions: Finally, it is essential to consider the operating conditions when selecting equipment from the Burks line of industrial equipment. The equipment’s performance can be affected by factors such as temperature, humidity, and ambient conditions. It is crucial to select equipment that can operate effectively under the expected operating conditions to ensure reliable performance and long service life.

In conclusion, selecting the right equipment from the Burks line of industrial equipment requires careful consideration of several factors, including application requirements, flow rate and pressure requirements, material of construction, maintenance and repair requirements, and operating conditions. Working with an experienced equipment supplier can help ensure that the equipment selected meets the application’s requirements and delivers reliable performance and long service life.