Busch Vacuum Solutions Equipment We Distribute

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment, providing a wide range of products for various applications. Their equipment includes vacuum pumps, blowers, compressors, and complete vacuum systems. The vacuum pumps are available in a variety of technologies, such as rotary vane, dry screw, and liquid ring, and can handle both low and high vacuum levels. The blowers are designed for applications that require high volume flow rates and low pressure differentials. The compressors are used for the compression of gases and can operate at high pressures. Additionally, Busch Vacuum Solutions offers complete vacuum systems that include vacuum pumps, control systems, and accessories. All their equipment is designed to be reliable, efficient, and environmentally friendly, meeting the highest standards of quality and performance.

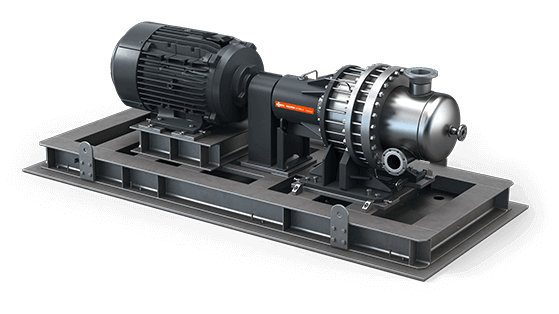

Vacuum Pumps

Busch Vacuum Solutions offers a range of vacuum pumps, each designed to meet the specific needs of different applications. The rotary vane pump is one of the most popular types, known for its simple design and reliable performance. It is ideal for low and medium vacuum applications and is often used in industries such as packaging, woodworking, and plastics processing. The claw pump is another type of vacuum pump, which is oil-free and operates at a higher vacuum level. This makes it suitable for applications that require clean, dry vacuum, such as in the food and beverage industry.

Screw pumps are another type of vacuum pump offered by Busch Vacuum Solutions. They are known for their high efficiency and can handle both wet and dry applications. They are often used in the chemical and pharmaceutical industries, where corrosive or hazardous gases need to be removed from the process. Liquid ring pumps are another popular type of vacuum pump, which use water or another liquid as a sealing medium. They are used in applications that require high vacuum levels, such as in the power generation and paper industries.

In addition to these types, Busch Vacuum Solutions also offers a range of other vacuum pumps, such as rotary lobe, scroll, booster, diffusion, and intelligent vacuum pumps. The rotary lobe pump is ideal for pumping gas with a high solids content, such as in the wastewater treatment industry. The scroll pump is oil-free and ideal for laboratory applications that require clean vacuum. The booster pump is used to increase the pumping speed of other vacuum pumps, while the diffusion pump is used in high vacuum applications, such as in the semiconductor industry. Finally, the intelligent vacuum pump uses advanced technology to monitor and optimize performance, making it ideal for applications that require precise control over the vacuum level.

Compressors

Busch Vacuum Solutions is a leading manufacturer of compressors that are designed to meet the demands of various industrial applications. Their range of compressors includes rotary vane, claw, and liquid ring compressors, each with its unique characteristics and capabilities.

The rotary vane compressor is a popular type of compressor that is known for its reliability and low maintenance requirements. It operates by compressing gas between rotating vanes and a stationary housing, making it suitable for applications that require high volumes of gas at low pressure. Rotary vane compressors are commonly used in industries such as printing, packaging, and plastics processing.

The claw compressor is another type of compressor offered by Busch Vacuum Solutions. It is a dry, oil-free compressor that operates at a high vacuum level, making it ideal for applications that require clean, dry gas, such as in the food and beverage industry. The claw compressor operates by trapping gas between two claw-shaped rotors and a housing, compressing it as the rotors rotate.

Finally, Busch Vacuum Solutions also offers liquid ring compressors, which are used in applications that require high vacuum levels. These compressors use a liquid ring as the sealing medium, compressing gas by squeezing it between the rotating impeller and the liquid ring. Liquid ring compressors are commonly used in industries such as chemical processing, oil and gas, and power generation.

Overall, Busch Vacuum Solutions’s range of compressors offers a reliable, efficient, and versatile solution for a wide range of industrial applications. Their compressors are designed to meet the highest standards of quality and performance, making them a trusted choice for many businesses.

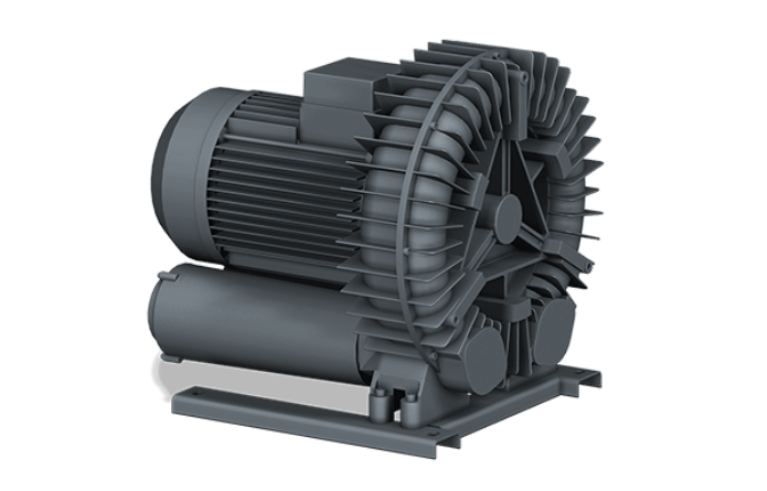

Blowers

Busch Vacuum Solutions offers a range of blowers that are designed to meet the specific needs of different industrial applications. Their range of blowers includes rotary lobe and side channel blowers, each with its unique characteristics and capabilities.

The rotary lobe blower is a popular type of blower that is known for its reliable performance and low maintenance requirements. It operates by trapping gas between two rotating lobes and a housing, compressing it as the lobes rotate. Rotary lobe blowers are commonly used in industries such as wastewater treatment, pneumatic conveying, and food processing.

The side channel blower is another type of blower offered by Busch Vacuum Solutions. It is a compact and lightweight blower that operates by compressing gas using a series of impellers rotating within a casing. Side channel blowers are commonly used in applications that require low-pressure air, such as in the medical industry for breathing assistance.

Overall, Busch Vacuum Solutions’s range of blowers offers a reliable, efficient, and versatile solution for a wide range of industrial applications. Their blowers are designed to meet the highest standards of quality and performance, making them a trusted choice for many businesses.

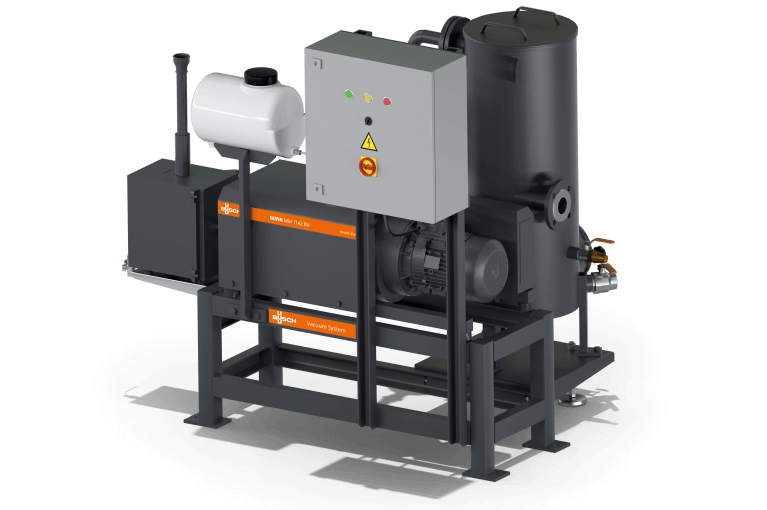

Vacuum Systems

Busch Vacuum Solutions offers a range of vacuum systems that are designed to meet the specific needs of different industrial applications. Their range of vacuum systems includes standard vacuum systems, customized vacuum systems, and central vacuum systems, each with its unique characteristics and capabilities.

The standard vacuum system is a pre-engineered system that is designed to provide a complete vacuum solution for a variety of applications. It includes a vacuum pump, control system, and accessories such as filters, valves, and gauges. These systems are ideal for applications that require a reliable and cost-effective vacuum solution.

The customized vacuum system is a bespoke system that is designed to meet the specific needs of a particular application. It is designed in collaboration with the customer to ensure that all requirements are met, and it includes a vacuum pump, control system, and accessories tailored to the application. These systems are ideal for applications that require a unique vacuum solution.

Finally, Busch Vacuum Solutions offers central vacuum systems, which are designed to provide a centralized vacuum solution for multiple applications. These systems can include multiple vacuum pumps, control systems, and accessories, all connected to a central pipeline network. Central vacuum systems are commonly used in large facilities, such as hospitals, universities, and manufacturing plants.

Overall, Busch Vacuum Solutions’s range of vacuum systems offers a reliable, efficient, and versatile solution for a wide range of industrial applications. Their systems are designed to meet the highest standards of quality and performance, making them a trusted choice for many businesses.

Applications of Busch Vacuum Solutions Equipment

Busch Vacuum Solutions provides vacuum solutions for a wide range of industrial applications, including packaging, pneumatic conveying, degassing, drying, freeze-drying, distillation, evacuation, forming, pressing, and laminating, as well as handling and lifting, and lithium battery manufacturing. In the packaging industry, vacuum pumps are used for airtight packaging of food and other perishable products. Pneumatic conveying involves the transfer of materials using a vacuum, and Busch’s vacuum solutions are used in this process to transport various powders and bulk materials. Degassing and drying processes require efficient vacuum technology, and Busch’s products are ideal for these applications. Freeze-drying is a process that preserves food and pharmaceuticals, and Busch’s vacuum solutions are used for the sublimation process. In distillation, vacuum pumps are used to create a low-pressure environment, while evacuation is the process of removing air from a space or container, and Busch’s vacuum pumps are essential for this task. In forming, pressing, and laminating processes, vacuum pumps are used to hold and shape materials, while handling and lifting equipment uses vacuum technology for efficient and safe material handling. Finally, in lithium battery manufacturing, vacuum pumps are used to create a controlled environment for the production process.

Packaging

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the packaging industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including vacuum packaging of foodstuff, vacuum packaging in other industries, and centralization in vacuum packaging.

One of the most important applications of Busch Vacuum Solutions’ equipment in the packaging industry is in the vacuum packaging of foodstuff. Vacuum packaging is a process of removing air from the package before sealing it, which helps to preserve the freshness and quality of the food for longer periods of time. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including rotary vane, claw, and liquid ring pumps. These pumps are reliable, efficient, and able to handle the high vacuum levels required for vacuum packaging.

In addition to food packaging, Busch Vacuum Solutions’ equipment is also used in vacuum packaging in other industries, such as pharmaceuticals, electronics, and automotive. In the pharmaceutical industry, vacuum packaging is used to protect sensitive drugs from moisture and oxygen, while in the electronics industry, it is used to protect components from dust and moisture. In the automotive industry, vacuum packaging is used to protect parts during shipping and storage. Busch Vacuum Solutions’ range of vacuum pumps, compressors, and blowers are designed to meet the specific needs of each of these industries, ensuring that their products are protected and preserved during packaging and transport.

Finally, Busch Vacuum Solutions’ equipment is also used in the centralization of vacuum packaging. Centralization is a process of consolidating vacuum packaging equipment into a central location, which can help to improve efficiency and reduce costs. Busch Vacuum Solutions offers a range of vacuum systems that are designed for centralization, including custom-built systems that are tailored to the specific needs of each customer. These systems can include multiple vacuum pumps, control systems, and accessories, all connected to a central pipeline network, providing a centralized solution for multiple applications.

Pneumatic Conveying

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the pneumatic conveying industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including pneumatic conveying in the plastics industry, pneumatic conveying in other industries, and pneumatic conveying in practice.

One of the most important applications of Busch Vacuum Solutions’ equipment in the pneumatic conveying industry is in the plastics industry. Pneumatic conveying is a process of moving bulk materials, such as plastic pellets, through a pipeline using air pressure. Busch Vacuum Solutions offers a range of blowers that are suitable for this application, including rotary lobe and side channel blowers. These blowers are reliable, efficient, and able to handle the high volumes of air required for pneumatic conveying.

In addition to the plastics industry, Busch Vacuum Solutions’ equipment is also used in pneumatic conveying in other industries, such as pharmaceuticals, chemicals, and food processing. In the pharmaceutical industry, pneumatic conveying is used to move powders and granules between processing stages, while in the chemical industry, it is used to transfer materials between storage and production areas. In the food processing industry, pneumatic conveying is used to move ingredients, such as flour and sugar, between storage and processing areas. Busch Vacuum Solutions’ range of vacuum pumps, compressors, and blowers are designed to meet the specific needs of each of these industries, ensuring that materials are moved efficiently and safely.

Busch Vacuum Solutions’ equipment is also used in pneumatic conveying in practice. Pneumatic conveying is a complex process that requires careful planning, design, and implementation. Busch Vacuum Solutions offers a range of vacuum systems that are designed for pneumatic conveying, including custom-built systems that are tailored to the specific needs of each customer. These systems can include multiple vacuum pumps, control systems, and accessories, all connected to a central pipeline network, providing a reliable and efficient solution for pneumatic conveying.

Busch Vacuum Solutions’ equipment is widely used in the pneumatic conveying industry for a variety of applications, including pneumatic conveying in the plastics industry, pneumatic conveying in other industries, and pneumatic conveying in practice. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the pneumatic conveying industry.

Degassing

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the degassing industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including melt degassing, vacuum degassing in the beverage industry, vacuum degassing in other industries, and vacuum degassing in practice.

One of the most important applications of Busch Vacuum Solutions’ equipment in the degassing industry is in melt degassing. Melt degassing is a process of removing dissolved gases from molten metals and alloys to improve their quality and performance. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including rotary vane, claw, and liquid ring pumps. These pumps are reliable, efficient, and able to handle the high vacuum levels required for melt degassing.

In addition to melt degassing, Busch Vacuum Solutions’ equipment is also used in vacuum degassing in the beverage industry. Vacuum degassing is a process of removing air from liquids, such as wine and beer, to improve their taste and quality. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including liquid ring pumps that are ideal for wet applications. These pumps are designed to meet the specific needs of the beverage industry, ensuring that liquids are degassed efficiently and safely.

Busch Vacuum Solutions’ equipment is also used in vacuum degassing in other industries, such as pharmaceuticals, chemicals, and food processing. In the pharmaceutical industry, vacuum degassing is used to remove air from liquid formulations to improve their stability and shelf life, while in the chemical industry, it is used to remove impurities from chemicals. In the food processing industry, vacuum degassing is used to remove air from liquids, such as syrups and sauces, to improve their quality and shelf life. Busch Vacuum Solutions’ range of vacuum pumps, compressors, and blowers are designed to meet the specific needs of each of these industries, ensuring that liquids are degassed efficiently and safely.

Finally, Busch Vacuum Solutions’ equipment is also used in vacuum degassing in practice. Vacuum degassing is a complex process that requires careful planning, design, and implementation. Busch Vacuum Solutions offers a range of vacuum systems that are designed for vacuum degassing, including custom-built systems that are tailored to the specific needs of each customer. These systems can include multiple vacuum pumps, control systems, and accessories, all connected to a central pipeline network, providing a reliable and efficient solution for vacuum degassing.

In conclusion, Busch Vacuum Solutions’ equipment is widely used in the degassing industry for a variety of applications, including melt degassing, vacuum degassing in the beverage industry, vacuum degassing in other industries, and vacuum degassing in practice. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the degassing industry.

Drying

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the drying industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including vacuum drying in the food industry, vacuum drying in other industries, and vacuum drying in practice.

One of the most important applications of Busch Vacuum Solutions’ equipment in the drying industry is in vacuum drying in the food industry. Vacuum drying is a process of removing moisture from food products while preserving their quality and flavor. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including liquid ring and dry screw pumps. These pumps are reliable, efficient, and able to handle the high vacuum levels required for vacuum drying.

In addition to the food industry, Busch Vacuum Solutions’ equipment is also used in vacuum drying in other industries, such as pharmaceuticals, chemicals, and electronics. In the pharmaceutical industry, vacuum drying is used to remove moisture from drugs and other products, while in the chemical industry, it is used to dry chemical products, such as powders and granules. In the electronics industry, vacuum drying is used to remove moisture from sensitive components, such as semiconductors. Busch Vacuum Solutions’ range of vacuum pumps, compressors, and blowers are designed to meet the specific needs of each of these industries, ensuring that products are dried efficiently and safely.

Finally, Busch Vacuum Solutions’ equipment is also used in vacuum drying in practice. Vacuum drying is a complex process that requires careful planning, design, and implementation. Busch Vacuum Solutions offers a range of vacuum systems that are designed for vacuum drying, including custom-built systems that are tailored to the specific needs of each customer. These systems can include multiple vacuum pumps, control systems, and accessories, all connected to a central pipeline network, providing a reliable and efficient solution for vacuum drying.

In conclusion, Busch Vacuum Solutions’ equipment is widely used in the drying industry for a variety of applications, including vacuum drying in the food industry, vacuum drying in other industries, and vacuum drying in practice. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the drying industry.

Freeze Drying

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the freeze drying industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including sublimation in freeze drying.

Freeze drying, also known as lyophilization, is a process of removing water from a product by sublimation, which is the conversion of a solid directly into a gas without passing through a liquid phase. This process is commonly used in the pharmaceutical, food, and biotechnology industries to preserve and extend the shelf life of products.

Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for freeze drying applications, including dry screw pumps, liquid ring pumps, and scroll pumps. These pumps are designed to handle the high vacuum levels required for sublimation and provide a reliable, efficient, and consistent vacuum for the freeze drying process.

In addition to vacuum pumps, Busch Vacuum Solutions also offers a range of vacuum systems that are specifically designed for freeze drying. These systems can include multiple vacuum pumps, control systems, and accessories, all connected to a central pipeline network. The vacuum systems are custom-built to meet the specific needs of each customer and ensure the highest level of performance and quality.

Busch Vacuum Solutions’ equipment is used in a wide range of freeze drying applications, including pharmaceuticals, biotechnology, and food processing. In the pharmaceutical industry, freeze drying is used to preserve drugs and vaccines, while in the biotechnology industry, it is used to preserve enzymes, antibodies, and other biological materials. In the food processing industry, freeze drying is used to preserve foods, such as fruits, vegetables, and meats, while maintaining their nutritional value and flavor.

In conclusion, Busch Vacuum Solutions’ equipment is widely used in the freeze drying industry for sublimation and other applications. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the freeze drying industry. With their expertise in vacuum technology, Busch Vacuum Solutions is a trusted partner for businesses in the freeze drying industry seeking to optimize their processes and maximize their product quality.

Distillation

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the distillation industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including vacuum distillation in chemical and pharmaceuticals, crude oil distillation, and vacuum distillation of essential oils.

One of the most important applications of Busch Vacuum Solutions’ equipment in the distillation industry is in vacuum distillation in chemical and pharmaceuticals. Vacuum distillation is a process of separating and purifying chemical compounds by heating them in a vacuum. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including liquid ring, dry screw, and claw pumps. These pumps are reliable, efficient, and able to handle the high vacuum levels required for vacuum distillation.

In addition to chemical and pharmaceuticals, Busch Vacuum Solutions’ equipment is also used in crude oil distillation. Crude oil distillation is a process of separating crude oil into different fractions based on their boiling points. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed to handle the harsh conditions of crude oil distillation, including high temperatures and corrosive environments.

Busch Vacuum Solutions’ equipment is also used in vacuum distillation of essential oils. Vacuum distillation is a process of extracting essential oils from plants by heating them in a vacuum. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including liquid ring and dry screw pumps. These pumps are designed to handle the delicate nature of essential oils and provide a reliable, efficient, and consistent vacuum for the vacuum distillation process.

In conclusion, Busch Vacuum Solutions’ equipment is widely used in the distillation industry for a variety of applications, including vacuum distillation in chemical and pharmaceuticals, crude oil distillation, and vacuum distillation of essential oils. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the distillation industry. With their expertise in vacuum technology, Busch Vacuum Solutions is a trusted partner for businesses in the distillation industry seeking to optimize their processes and maximize their product quality.

Evacuation

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the evacuation industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including evacuation of semiconductor process chambers, space simulation chambers, and vacuum furnaces or coating chambers.

One of the most important applications of Busch Vacuum Solutions’ equipment in the evacuation industry is in semiconductor process chambers. Semiconductor manufacturing is a complex process that requires the use of high vacuum levels to prevent contamination and ensure product quality. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including dry screw pumps and claw pumps. These pumps are designed to handle the high vacuum levels required for semiconductor processing and provide a reliable and efficient vacuum for the process chambers.

In addition to semiconductor manufacturing, Busch Vacuum Solutions’ equipment is also used in space simulation chambers. Space simulation chambers are used to simulate the extreme conditions of space, including high vacuum levels and extreme temperatures. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed to handle these extreme conditions, including cryogenic pumps and turbo pumps. These pumps and systems are designed to provide a reliable and efficient vacuum for space simulation chambers.

Busch Vacuum Solutions’ equipment is also used in vacuum furnaces or coating chambers evacuation. These processes require high vacuum levels to ensure a clean and controlled environment for the materials being processed. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including liquid ring and dry screw pumps. These pumps are designed to handle the high vacuum levels required for vacuum furnaces and coating chambers, ensuring a reliable and efficient vacuum for these applications.

In conclusion, Busch Vacuum Solutions’ equipment is widely used in the evacuation industry for a variety of applications, including semiconductor process chambers, space simulation chambers, and vacuum furnaces or coating chambers evacuation. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the evacuation industry. With their expertise in vacuum technology, Busch Vacuum Solutions is a trusted partner for businesses in the evacuation industry seeking to optimize their processes and maximize their product quality.

Forming, Pressing, and Laminating

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the forming, pressing, and laminating industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including packaging, plastics, wood, and solar panel manufacturing.

One of the most important applications of Busch Vacuum Solutions’ equipment in the forming, pressing, and laminating industry is in packaging. Vacuum packaging is a popular method of packaging that involves removing air from the packaging to create a tight seal and preserve the quality of the product. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, including rotary vane and claw pumps. These pumps are designed to handle the high vacuum levels required for vacuum packaging and provide a reliable and efficient vacuum for the process.

In addition to packaging, Busch Vacuum Solutions’ equipment is also used in plastics manufacturing. Plastics are commonly formed and pressed using vacuum technology, and Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application, including liquid ring pumps and dry screw pumps. These pumps are designed to handle the high vacuum levels required for plastics forming and pressing, ensuring a reliable and efficient vacuum for these applications.

Busch Vacuum Solutions’ equipment is also used in wood processing, particularly in laminating. Wood laminating is a process of joining layers of wood together to create a strong and durable composite material. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application, including dry screw pumps and liquid ring pumps. These pumps are designed to handle the high vacuum levels required for wood laminating, ensuring a reliable and efficient vacuum for this application.

Finally, Busch Vacuum Solutions’ equipment is also used in the manufacturing of solar panels. Vacuum technology is used in the process of laminating the layers of the solar panel together, and Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application, including dry screw pumps and liquid ring pumps. These pumps are designed to handle the high vacuum levels required for solar panel manufacturing, ensuring a reliable and efficient vacuum for this application.

Busch Vacuum Solutions’ equipment is widely used in the forming, pressing, and laminating industry for a variety of applications, including packaging, plastics, wood, and solar panel manufacturing. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the forming, pressing, and laminating industry. With their expertise in vacuum technology, Busch Vacuum Solutions is a trusted partner for businesses in this industry seeking to optimize their processes and maximize their product quality.

Handling and Lifting

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the handling and lifting industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications, including packaging and woodworking.

One of the most important applications of Busch Vacuum Solutions’ equipment in the handling and lifting industry is in packaging. Vacuum technology is commonly used in the packaging industry to handle and lift products, particularly in situations where manual handling is not possible or practical. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application, including vacuum lifters and vacuum grippers. These systems are designed to provide a reliable and efficient way to handle and lift products of different shapes and sizes.

In addition to packaging, Busch Vacuum Solutions’ equipment is also used in woodworking. Woodworking often involves handling and lifting large and heavy pieces of wood, and vacuum technology is a popular way to do this. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application, including vacuum lifters and clamping systems. These systems are designed to provide a reliable and efficient way to handle and lift wood pieces of different sizes and shapes.

Busch Vacuum Solutions’ equipment is also used in other applications in the handling and lifting industry, such as in the transportation and logistics industry. Vacuum technology is commonly used in the loading and unloading of trucks and containers, as well as in the movement of products within warehouses and distribution centers. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for these applications, including vacuum tube lifters and conveyor systems. These systems are designed to provide a reliable and efficient way to handle and transport products in different situations.

In conclusion, Busch Vacuum Solutions’ equipment is widely used in the handling and lifting industry for a variety of applications, including packaging and woodworking. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the handling and lifting industry. With their expertise in vacuum technology, Busch Vacuum Solutions is a trusted partner for businesses in this industry seeking to optimize their processes and maximize their productivity.

Lithium Battery Manufacturing

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that is widely used in the lithium battery manufacturing industry. The company’s vacuum pumps, compressors, blowers, and vacuum systems are used in a variety of applications throughout the battery manufacturing process.

The lithium battery manufacturing process involves a number of steps that require vacuum technology, including the production of anodes and cathodes, electrode coating, and assembly of the battery cells. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for these applications, including dry screw pumps, liquid ring pumps, and claw pumps.

One of the most important applications of Busch Vacuum Solutions’ equipment in the lithium battery manufacturing industry is in the production of anodes and cathodes. Anodes and cathodes are critical components of the battery, and they require a high vacuum level to ensure their quality and consistency. Busch Vacuum Solutions offers a range of vacuum pumps that are suitable for this application, providing a reliable and efficient vacuum for the production process.

In addition to anode and cathode production, Busch Vacuum Solutions’ equipment is also used in the electrode coating process. Electrode coating involves applying a thin layer of active material to the surface of the anode and cathode to increase the battery’s capacity and performance. This process requires a high vacuum level to ensure the quality of the coating, and Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application.

Busch Vacuum Solutions’ equipment is also used in the final assembly of the battery cells. The assembly process requires a high vacuum level to ensure the battery cells are free from impurities and contaminants. Busch Vacuum Solutions offers a range of vacuum pumps and systems that are designed for this application, ensuring a reliable and efficient vacuum for the assembly process.

Their equipment is widely used in the lithium battery manufacturing industry for a variety of applications, including anode and cathode production, electrode coating, and battery cell assembly. Their range of vacuum pumps, compressors, blowers, and vacuum systems is designed to meet the specific needs of each application, providing a reliable, efficient, and cost-effective solution for the lithium battery manufacturing industry. With their expertise in vacuum technology, Busch Vacuum Solutions is a trusted partner for businesses in this industry seeking to optimize their processes and maximize their product quality.

About Busch Vacuum Solutions

Busch Vacuum Solutions is a leading manufacturer of vacuum technology equipment that serves industrial manufacturing companies across a variety of industries.

Busch Vacuum Solutions’ equipment is used in a variety of industrial manufacturing applications, including vacuum distillation, evacuation, forming, pressing, and laminating, among others. The company’s range of vacuum pumps, compressors, blowers, and vacuum systems are designed to meet the specific needs of each application, providing a reliable and efficient solution for businesses seeking to optimize their processes and maximize their product quality.

In addition to its range of products and services, Busch Vacuum Solutions also offers expert consulting and support to its customers. The company’s team of engineers and technicians work closely with customers to design and implement vacuum solutions that meet their specific needs, providing a comprehensive approach to vacuum technology that goes beyond just selling equipment. With its focus on innovation, reliability, and customer satisfaction, Busch Vacuum Solutions is a trusted partner for businesses seeking to optimize their manufacturing processes and stay competitive in their respective industries.