CECO Environmental Equipment We Distribute

CECO Environmental is a leading manufacturer of advanced environmental solutions that play a crucial role in optimizing industrial processes and promoting cleaner, more sustainable operations. The company’s comprehensive product lineup includes cutting-edge biofiltration systems that harness the power of natural microbes to remove contaminants from air and water, as well as carbon filtration technology that employs activated carbon to capture impurities from various streams. CECO’s state-of-the-art controls ensure precise regulation and monitoring of critical environmental parameters, while their robust dampers facilitate airflow management. The desalter/dehydrator equipment is designed to efficiently remove salts and water from crude oil, ensuring smooth refinery operations. CECO’s high-performance dust collectors efficiently capture and remove particulate matter from air streams, while their versatile filtration solutions cater to a wide range of applications. The company’s industrial ventilation systems are engineered to maintain optimal indoor air quality, while the mist control systems adeptly capture and eliminate mist and vapor contaminants. CECO’s advanced oxidizers leverage innovative thermal and catalytic technologies to mitigate harmful emissions, and their diverse pump offerings cater to various industrial fluid-handling needs. The company’s scrubbers are expertly designed to neutralize and eliminate gaseous pollutants, and their silencers attenuate noise in various industrial settings, ensuring compliance with stringent noise regulations.

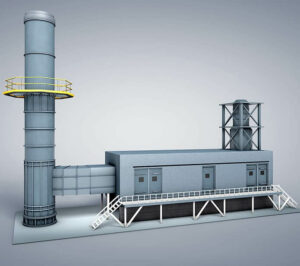

Biofiltration

CECO Environmental’s biofiltration equipment represents a cutting-edge and eco-friendly approach to treating air and water emissions from various industrial processes. This innovative technology harnesses the power of naturally occurring microorganisms to remove contaminants such as volatile organic compounds (VOCs), hydrogen sulfide, and other odorous compounds. As a result, the biofiltration systems not only contribute to improved air and water quality but also support the goals of sustainability and environmental stewardship.

The core of CECO Environmental’s biofiltration equipment lies in the biofilter media, which serves as a habitat for the microorganisms responsible for breaking down pollutants. These microorganisms, typically bacteria, and fungi, are immobilized on the surface of the media, where they form biofilms. The contaminated air or water is then passed through the biofilter, where the microorganisms metabolize the pollutants into harmless byproducts such as carbon dioxide, water, and inorganic salts. By selecting the appropriate media and microorganisms, CECO’s biofiltration equipment can be customized to target specific contaminants and tailored to suit various industrial requirements.

In addition to its environmental benefits, CECO Environmental’s biofiltration technology offers several advantages over conventional air and water treatment methods. Biofiltration systems have a relatively small footprint, making them suitable for space-constrained facilities. Furthermore, they have low energy requirements, translating into reduced operational costs for businesses. The low waste generation from the biofiltration process also minimizes waste disposal costs and the associated environmental impact. Overall, CECO Environmental’s biofiltration equipment provides a sustainable and cost-effective solution for industries seeking to improve their environmental performance and adhere to stringent emissions regulations.

Carbon Filtration

CECO Environmental’s carbon filtration equipment offers a highly effective solution for purifying air and water streams in various industrial applications. Utilizing the adsorptive properties of activated carbon, this advanced technology efficiently captures and removes a wide range of contaminants, including volatile organic compounds (VOCs), odorous gases, and hazardous chemicals. The versatility of carbon filtration makes it a valuable tool for industries looking to meet rigorous environmental standards while ensuring the safety and well-being of their workforce.

The heart of CECO Environmental’s carbon filtration equipment lies in activated carbon, a porous material derived from organic sources such as coal, wood, or coconut shells. The activation process, which typically involves high-temperature steam or chemical treatment, significantly increases the surface area of the carbon, enabling it to adsorb a greater amount of contaminants per unit mass. As contaminated air or water passes through the carbon filter, the pollutants adhere to the carbon’s surface, effectively removing them from the stream. CECO offers a variety of activated carbon types and configurations, allowing for the customization of filtration systems to target specific contaminants and meet unique industry needs.

One of the key advantages of CECO Environmental’s carbon filtration equipment is its adaptability to a wide array of applications, ranging from air and water treatment in manufacturing plants to odor control in wastewater treatment facilities. The low operating costs and ease of maintenance further contribute to the appeal of carbon filtration systems for businesses seeking an economical and reliable method for managing emissions. Additionally, the spent activated carbon can often be reactivated through thermal or chemical processes, reducing waste generation and promoting sustainability. Overall, CECO Environmental’s carbon filtration equipment offers a flexible and environmentally responsible solution for industries aiming to maintain compliance with stringent air and water quality regulations.

Controls

CECO Environmental’s control equipment is designed to offer precision management and monitoring of various environmental parameters in industrial processes. These state-of-the-art control systems ensure that equipment operates efficiently, optimally, and in compliance with environmental regulations. By providing real-time data and accurate control over process variables, CECO’s control systems not only contribute to improved productivity but also help safeguard the environment and protect the health and safety of workers.

At the core of CECO Environmental’s control equipment is the integration of advanced hardware and software components. The hardware includes sensors, actuators, and control modules that work together to collect and process data from various points in the industrial process. The software, on the other hand, enables the analysis of this data, providing valuable insights into process performance and facilitating informed decision-making. By combining these elements, CECO’s control systems are able to seamlessly manage air and water treatment, pollutant abatement, energy conservation, and other critical environmental aspects in a wide range of industries.

One of the significant advantages of CECO Environmental’s control equipment is its adaptability, allowing for integration with existing infrastructure and compatibility with various types of environmental equipment. The control systems can be customized to meet the unique requirements of each industry, ensuring optimal performance and regulatory compliance. Furthermore, CECO’s control systems offer remote monitoring and control capabilities, enabling operators to access real-time data and make adjustments from anywhere, increasing efficiency and reducing downtime. By providing comprehensive management and monitoring solutions, CECO Environmental’s control equipment empowers industries to maintain a cleaner, safer and more sustainable operation.

Dampers

CECO Environmental’s dampers equipment plays a critical role in managing airflow within industrial facilities and ensuring efficient operation of various process systems. Designed for diverse applications, these robust dampers are utilized in air pollution control systems, HVAC systems, and exhaust ductwork to regulate and isolate airflows, thereby maintaining optimal indoor air quality, temperature, and humidity levels. With their precision engineering and high-quality materials, CECO’s dampers ensure reliable and long-lasting performance in a wide range of environments.

CECO Environmental offers a comprehensive range of dampers, including butterfly dampers, louver dampers, guillotine dampers, and diverter dampers, to cater to the specific needs of different industries. Butterfly dampers are well-suited for modulating and isolating airflows, while louver dampers offer precise flow control and low leakage rates. Guillotine dampers, with their ability to provide a full, unobstructed opening, are ideal for applications requiring complete isolation of airflows. Diverter dampers, on the other hand, are employed to direct airflow between multiple outlets, often used in heat recovery and pollution control systems. Each damper type is available in various sizes, materials, and actuation options to accommodate the unique requirements of each application.

One of the key benefits of CECO Environmental’s dampers equipment is its adaptability and customizability. With a variety of sizes, materials, and control options available, these dampers can be tailored to meet the specifications of any industrial process, ensuring optimal performance and compliance with industry standards. In addition, CECO’s dampers are designed to withstand harsh operating conditions, including high temperatures, corrosive environments, and heavy-duty cycles, ensuring durability and long service life. By providing precise control and reliable operation, CECO Environmental’s dampers equipment helps industries maintain a safe, efficient, and environmentally responsible operation.

Desalter/Dehydrator

CECO Environmental’s desalter/dehydrator equipment is specifically designed to improve the quality of crude oil in refinery operations by effectively removing salts, water, and other impurities. The presence of these contaminants can lead to corrosion, fouling, and other operational issues, negatively impacting the efficiency and longevity of refinery equipment. By implementing CECO’s desalter/dehydrator systems, refineries can optimize their processes, reduce maintenance costs, and enhance the overall safety and environmental performance of their operations.

The core principle behind CECO Environmental’s desalter/dehydrator equipment is the use of electrostatic technology to separate the water and salt content from the crude oil. In a typical desalting/dehydration process, the crude oil is mixed with a dilution water stream, forming an emulsion. The mixture then enters the desalter/dehydrator unit, where an electric field is applied, causing the water droplets to coalesce and separate from the oil. The contaminants, being water-soluble, are removed along with the separated water phase. The treated crude oil, now free from salts and water, exits the unit and proceeds to downstream refinery processes.

One of the key advantages of CECO Environmental’s desalter/dehydrator equipment is its ability to adapt to a wide range of crude oil types and processing conditions. By offering customizable designs and control systems, CECO’s desalter/dehydrator systems can be tailored to meet specific refinery requirements, ensuring optimal performance and regulatory compliance. Moreover, the use of high-quality materials and innovative designs ensures durability and low maintenance costs. By providing an effective solution for crude oil desalting and dehydration, CECO Environmental’s desalter/dehydrator equipment supports the goals of increased efficiency, reduced environmental impact, and enhanced safety in the oil and gas industry.

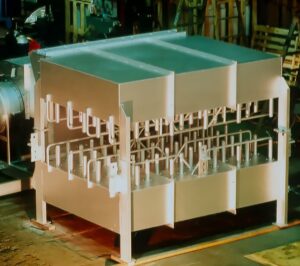

Filtration

CECO Environmental’s filtration equipment provides versatile and efficient solutions for separating solids, liquids, and gases in a wide range of industrial applications. With a commitment to innovation and quality, CECO’s filtration systems are designed to improve process efficiency, protect downstream equipment, and ensure compliance with environmental regulations. By offering a diverse portfolio of filtration technologies, CECO enables industries to address their unique filtration needs while promoting a cleaner and more sustainable operation.

CECO Environmental offers a comprehensive range of filtration equipment, including liquid filtration, gas filtration, and air filtration systems. Liquid filtration systems are designed to remove solids and contaminants from various process liquids, ensuring the quality and purity of the final product. These systems can be customized with various filter media, such as cartridges, bags, or membranes, to target specific contaminants and meet the desired filtration efficiency. Gas filtration systems, on the other hand, are engineered to separate particulates and impurities from process gases, protecting downstream equipment and maintaining environmental compliance. Air filtration systems, including dust collectors and air purifiers, are aimed at maintaining optimal indoor air quality by capturing airborne particles, allergens, and pollutants in industrial and commercial settings.

One of the key advantages of CECO Environmental’s filtration equipment is its flexibility and customizability, which allows for seamless integration into existing processes and infrastructure. By offering a variety of filter media, sizes, and configurations, CECO’s filtration systems can be tailored to meet the specific requirements of each industry and application, ensuring optimal performance and regulatory compliance. Moreover, the use of high-quality materials and innovative designs ensures durability, low maintenance costs, and long service life. By providing efficient and reliable filtration solutions, CECO Environmental’s filtration equipment supports industries in their pursuit of enhanced productivity, reduced environmental impact, and improved safety.

Industrial Ventilation

CECO Environmental’s industrial ventilation equipment plays a vital role in maintaining a healthy and safe working environment in a wide range of industries. These advanced systems are designed to control air quality, temperature, and humidity levels by effectively managing the flow of air within industrial facilities. By providing efficient air exchange and removing airborne pollutants, CECO’s industrial ventilation equipment helps companies adhere to occupational health and safety standards while also ensuring compliance with environmental regulations.

CECO Environmental offers a comprehensive range of industrial ventilation solutions, including make-up air units, exhaust fans, and air handling units, to meet the specific needs of various applications. Make-up air units are designed to introduce fresh, conditioned air into the facility, helping to maintain a balanced indoor environment and prevent the buildup of contaminants. Exhaust fans play a crucial role in removing stale or contaminated air from the premises, ensuring that hazardous fumes, dust, and other pollutants are effectively vented out. Air handling units are responsible for conditioning and circulating the air within the facility, providing optimal temperature and humidity control for worker comfort and process efficiency.

One of the key advantages of CECO Environmental’s industrial ventilation equipment is its adaptability and customizability, which allows for seamless integration with existing infrastructure and processes. By offering a variety of sizes, capacities, and configurations, CECO’s ventilation systems can be tailored to meet the unique requirements of each industry and application, ensuring optimal performance and regulatory compliance. Furthermore, the use of high-quality materials and innovative designs ensures durability, low maintenance costs, and long service life. By providing efficient and reliable industrial ventilation solutions, CECO Environmental supports industries in their pursuit of a safe, healthy, and environmentally responsible work environment.

Mist Control

CECO Environmental’s mist control equipment is designed to efficiently capture and remove liquid droplets, or mist, from air streams in various industrial processes. The presence of mist can lead to operational issues, such as corrosion, equipment fouling, and reduced efficiency, as well as pose health and safety risks to employees. By employing advanced mist elimination technologies, CECO’s mist control equipment helps industries maintain compliance with air quality regulations while promoting a cleaner, safer work environment.

CECO Environmental offers a diverse range of mist control solutions, including mesh pad mist eliminators, vane mist eliminators, and fiber bed filters, to cater to the specific needs of different industries and applications. Mesh pad mist eliminators utilize a mesh pad made of fine fibers or wire to capture and coalesce mist droplets, allowing them to be drained away. Vane mist eliminators use a series of curved vanes to separate mist droplets from the air stream by impingement and centrifugal action. Fiber bed filters, on the other hand, are designed to capture submicron-sized droplets by employing layers of fibrous materials that offer high filtration efficiency. Each mist control technology is available in various sizes, materials, and configurations to accommodate the unique requirements of each application.

One of the key benefits of CECO Environmental’s mist control equipment is its adaptability and customizability. With a variety of sizes, materials, and mist elimination technologies available, these systems can be tailored to meet the specifications of any industrial process, ensuring optimal performance and compliance with industry standards. Additionally, CECO’s mist control equipment is designed to withstand harsh operating conditions, including high temperatures, corrosive environments, and heavy-duty cycles, ensuring durability and long service life. By providing efficient mist elimination and reliable operation, CECO Environmental’s mist control equipment helps industries maintain a safe, efficient, and environmentally responsible operation.

Oxidizers

CECO Environmental’s oxidizers equipment offers an advanced solution for the effective treatment and reduction of volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and other harmful emissions in various industrial processes. By utilizing thermal, catalytic, or regenerative oxidation technologies, these systems efficiently convert pollutants into less harmful byproducts, such as carbon dioxide and water vapor. CECO’s oxidizers help industries maintain compliance with stringent air quality regulations while promoting a cleaner and more sustainable operation.

CECO Environmental offers a comprehensive range of oxidizers, including thermal oxidizers, catalytic oxidizers, and regenerative thermal oxidizers (RTOs), to cater to the specific needs of different industries and applications. Thermal oxidizers use high-temperature combustion to break down harmful pollutants in the process exhaust stream. Catalytic oxidizers, on the other hand, employ a catalyst to promote oxidation reactions at lower temperatures, resulting in reduced energy consumption and operating costs. Regenerative thermal oxidizers (RTOs) utilize a unique heat recovery system that captures and reuses thermal energy from the oxidation process, significantly improving energy efficiency and reducing operational expenses.

One of the key advantages of CECO Environmental’s oxidizers equipment is its adaptability and customizability. With a variety of sizes, capacities, and oxidation technologies available, these systems can be tailored to meet the unique requirements of each industry and application, ensuring optimal performance and regulatory compliance. Furthermore, the use of high-quality materials and innovative designs ensures durability, low maintenance costs, and long service life. By providing efficient and reliable emission control solutions, CECO Environmental’s oxidizers equipment supports industries in their pursuit of a cleaner, safer, and more environmentally responsible operation.

Pumps

CECO Environmental’s pump equipment provides reliable and efficient fluid handling solutions for a wide range of industries and applications. Designed to meet the specific requirements of various process fluids, CECO’s pumps are engineered to optimize performance, minimize downtime, and ensure compliance with industry standards. By offering a diverse portfolio of pumping technologies, CECO enables industries to address their unique fluid handling needs while promoting a more sustainable and efficient operation.

CECO Environmental offers a comprehensive range of pumps, including centrifugal pumps, diaphragm pumps, and gear pumps, to cater to the specific needs of different industries and applications. Centrifugal pumps are versatile and commonly used for transferring liquids in various process industries, offering a simple design and low maintenance requirements. Diaphragm pumps, also known as air-operated double diaphragm (AODD) pumps, use reciprocating diaphragms to move fluids and are particularly suitable for handling abrasive, corrosive, or viscous materials. Gear pumps employ meshing gears to displace fluids and are ideal for applications requiring precise flow control and high-pressure capabilities. Each pump type is available in various sizes, materials, and configurations to accommodate the unique requirements of each application.

One of the key benefits of CECO Environmental’s pump equipment is its adaptability and customizability. With a variety of sizes, materials, and pumping technologies available, these systems can be tailored to meet the specifications of any industrial process, ensuring optimal performance and compliance with industry standards. Additionally, CECO’s pumps are designed to withstand harsh operating conditions, including high temperatures, corrosive environments, and heavy-duty cycles, ensuring durability and long service life. By providing efficient fluid handling and reliable operation, CECO Environmental’s pump equipment helps industries maintain a safe, efficient, and environmentally responsible operation.

Applications of CECO Environmental Equipment

CECO Environmental is a leading provider of innovative air pollution control, industrial ventilation, and fluid handling solutions across a wide range of industries. Their equipment is used in commercial facilities to improve air quality and safety, in hygienic settings to prevent the spread of contaminants, and in chemical and mineral processing plants to reduce emissions and increase efficiency. CECO equipment is also utilized in marine applications to manage exhaust and waste streams, in pulp and paper manufacturing to control dust and improve air quality, and in water treatment to ensure compliance with environmental regulations. Additionally, CECO equipment is used in power generation to reduce emissions and improve energy efficiency, making it a versatile solution for a variety of industrial applications.

Commercial

In the commercial sector, CECO Environmental equipment is utilized across a range of industries to improve air quality, enhance safety, and increase efficiency. For example, in the cement industry, CECO equipment such as baghouses, cyclones, and electrostatic precipitators are used to capture particulate matter and reduce emissions. This not only improves air quality but also helps cement manufacturers meet environmental regulations and avoid fines. CECO equipment is also used in the wood and textile industry to control dust and prevent the spread of potentially hazardous fibers. In wood products manufacturing, for example, dust collection systems are used to reduce the risk of fire and explosions, while in textile manufacturing, air pollution control systems are used to manage waste streams and prevent contamination.

CECO Environmental equipment is also commonly used in the glass industry, where air pollution control systems are used to reduce emissions and improve safety. In glass manufacturing, various pollutants such as particulate matter, sulfur dioxide, and nitrogen oxides are generated during the melting and refining process. CECO equipment such as scrubbers, baghouses, and wet electrostatic precipitators are used to capture these pollutants and prevent them from being released into the environment. Additionally, CECO equipment is utilized in the powder coating industry to capture overspray and prevent it from contaminating the surrounding environment. This helps powder coating manufacturers meet environmental regulations and avoid fines.

Overall, CECO Environmental equipment is a critical component of many commercial operations, helping companies to improve their environmental performance, protect their workers, and comply with regulatory requirements. By providing innovative air pollution control, industrial ventilation, and fluid handling solutions, CECO helps companies in a range of industries to operate more efficiently and sustainably.

Hygienic

In the hygienic sector, CECO Environmental equipment is utilized to prevent the spread of contaminants and maintain a clean, safe environment. In the bottling and beverage can industry, CECO equipment such as air pollution control systems and ductwork is used to manage emissions and prevent the release of harmful pollutants. Additionally, CECO equipment is used to manage waste streams and prevent contamination during the bottling and canning process. By preventing contamination, CECO equipment helps ensure the safety and quality of bottled and canned beverages.

CECO Environmental equipment is also utilized in the food processing industry to prevent the spread of harmful bacteria and other pathogens. In meat processing plants, for example, CECO equipment such as ventilation systems and air filtration systems are used to control the spread of airborne contaminants and prevent the growth of harmful bacteria. Additionally, CECO equipment is used in food processing facilities to manage waste streams and prevent contamination of nearby water sources.

Overall, CECO Environmental equipment plays a critical role in maintaining hygienic conditions in a variety of industries. By providing innovative solutions for air pollution control, industrial ventilation, and fluid handling, CECO helps companies maintain a clean and safe environment, protect their workers, and ensure the safety and quality of their products.

Chemical Processing

In the chemical processing industry, CECO Environmental equipment is utilized to reduce emissions and increase efficiency. In ammonia and urea plants, for example, CECO equipment such as scrubbers and mist eliminators is used to capture pollutants such as ammonia, nitrogen oxides, and carbon dioxide. Additionally, CECO equipment is used to recover and reuse chemicals, reducing waste and increasing efficiency. This helps chemical processing plants operate more sustainably and in compliance with environmental regulations.

CECO Environmental equipment is also utilized in chemical recovery applications, where it is used to recover and reuse chemicals that would otherwise be lost during the manufacturing process. In the pulp and paper industry, for example, CECO equipment such as evaporators and recovery boilers is used to recover and reuse chemicals such as black liquor, which is a byproduct of the pulping process. This helps pulp and paper manufacturers reduce waste and increase efficiency while also reducing emissions.

Overall, CECO Environmental equipment plays a critical role in the chemical processing industry, helping companies to reduce emissions, increase efficiency, and operate more sustainably. By providing innovative solutions for air pollution control, industrial ventilation, and fluid handling, CECO helps chemical processing plants meet regulatory requirements, reduce costs, and enhance their environmental performance.

Mineral Processing

In mineral processing, CECO Environmental equipment is used to control emissions, improve efficiency, and reduce waste. In the iron and steel industry, for example, CECO equipment such as scrubbers and baghouses is used to capture particulate matter and control emissions of pollutants such as sulfur dioxide and nitrogen oxides. Additionally, CECO equipment is used in steelmaking to recover waste gases and heat, reducing energy consumption and improving efficiency.

CECO Environmental equipment is also utilized in the gypsum industry to control emissions and prevent the spread of dust. In gypsum manufacturing, CECO equipment such as scrubbers, baghouses, and electrostatic precipitators is used to capture dust and prevent it from being released into the environment. Additionally, CECO equipment is used in aluminum anodizing and hot dip galvanizing to manage emissions of pollutants and improve the quality of the final product.

Overall, CECO Environmental equipment plays a critical role in the mineral processing industry, helping companies to improve their environmental performance, reduce costs, and comply with regulatory requirements. By providing innovative solutions for air pollution control, industrial ventilation, and fluid handling, CECO helps mineral processing plants operate more efficiently and sustainably.

Marine

In the marine industry, CECO Environmental equipment is used to manage exhaust and waste streams and prevent pollution of the ocean and other waterways. CECO equipment such as scrubbers and catalytic converters is used to reduce emissions from ship engines, helping to comply with environmental regulations and reduce the environmental impact of marine transportation. Additionally, CECO equipment is used in ballast water treatment systems to prevent the spread of invasive species, which can have devastating ecological and economic impacts.

CECO Environmental equipment is also utilized in the offshore oil and gas industry to manage waste streams and prevent pollution of the ocean. In offshore drilling operations, CECO equipment such as centrifuges and filtration systems is used to separate oil and other contaminants from wastewater, allowing it to be safely discharged into the ocean or recycled. Additionally, CECO equipment is used in oil spill response efforts to help contain and clean up oil spills, mitigating the environmental impact of such incidents.

Overall, CECO Environmental equipment plays a critical role in the marine industry, helping to protect the health of the ocean and other waterways and mitigate the environmental impact of marine transportation and offshore drilling. By providing innovative solutions for air pollution control, industrial ventilation, and fluid handling, CECO helps marine operations comply with environmental regulations, reduce costs, and enhance their environmental performance.

Pulp & Paper

In the pulp and paper industry, CECO Environmental equipment is used to manage waste streams and prevent pollution of the environment. CECO equipment such as scrubbers, electrostatic precipitators, and baghouses is used to capture particulate matter and reduce emissions of pollutants such as sulfur dioxide and nitrogen oxides. Additionally, CECO equipment is used in the pulp and paper manufacturing process to control dust and improve air quality, and recover and reuse chemicals, reducing waste and increasing efficiency.

CECO Environmental equipment is also utilized in the packaging industry to reduce waste and increase efficiency. In paperboard manufacturing, for example, CECO equipment such as air pollution control systems and fluid handling systems is used to manage waste streams and prevent contamination of nearby water sources. Additionally, CECO equipment is used in paper packaging manufacturing to control emissions and prevent the release of harmful pollutants into the environment.

Overall, CECO Environmental equipment plays a critical role in the pulp and paper industry, helping companies to reduce their environmental footprint, increase efficiency, and comply with regulatory requirements. By providing innovative solutions for air pollution control, industrial ventilation, and fluid handling, CECO helps pulp and paper manufacturers operate more sustainably and with less impact on the environment.

Water Treatment

In the water treatment industry, CECO Environmental equipment is used to treat wastewater and manage water resources, reducing pollution and increasing efficiency. CECO equipment such as sedimentation tanks, flocculation systems, and filtration systems is used to remove solids, chemicals, and other contaminants from wastewater, making it safe to discharge into the environment or reuse in other applications. Additionally, CECO equipment is used in water treatment plants to manage water resources, such as in hydroelectric power generation, where it is used to control water flow and protect the environment.

CECO Environmental equipment is also utilized in desalination, where it is used to remove salt and other contaminants from seawater, making it safe to drink or use in other applications. In desalination plants, CECO equipment such as reverse osmosis systems and electrodialysis systems is used to separate salt and other contaminants from seawater, making it potable and safe for consumption.

Overall, CECO Environmental equipment plays a critical role in the water treatment industry, helping to reduce pollution and manage water resources. By providing innovative solutions for water treatment, CECO helps water treatment plants operate more efficiently and sustainably, protecting the environment and providing safe, clean water for communities around the world.

Power Generation

In the power generation industry, CECO Environmental equipment is used to reduce emissions, increase efficiency, and improve safety. In the renewable energy sector, such as in solar and wind power generation, CECO equipment such as air pollution control systems and scrubbers is used to reduce emissions of pollutants such as nitrogen oxides and sulfur dioxide. Additionally, CECO equipment is used in biomass power generation to control emissions and improve the efficiency of the combustion process.

CECO Environmental equipment is also utilized in the oil and gas industry to manage emissions and prevent pollution. In refineries and petrochemical plants, CECO equipment such as catalytic converters and flue gas desulfurization systems is used to reduce emissions of pollutants such as carbon monoxide and sulfur dioxide. Additionally, CECO equipment is used in natural gas processing and transmission to control emissions and prevent leaks, ensuring the safety of workers and nearby communities.

Overall, CECO Environmental equipment plays a critical role in the power generation industry, helping to reduce emissions, increase efficiency, and improve safety. By providing innovative solutions for air pollution control, industrial ventilation, and fluid handling, CECO helps power generation companies operate more sustainably and with less impact on the environment.

About CECO Environmental

CECO Environmental is a leading industrial manufacturer company that provides innovative air pollution control, industrial ventilation, and fluid handling solutions for a variety of industries. With over a century of experience, CECO has developed a reputation for delivering high-quality products and exceptional customer service. They offer a wide range of equipment, including scrubbers, cyclones, electrostatic precipitators, and baghouses, as well as a range of services, such as maintenance, repair, and training.

CECO Environmental serves a diverse range of industries, including commercial, hygienic, chemical processing, mineral processing, marine, pulp and paper, water treatment, and power generation. Their equipment is utilized to improve air quality, enhance safety, and increase efficiency, helping companies to comply with regulatory requirements, reduce costs, and enhance their environmental performance. CECO is committed to sustainability and operates with a focus on reducing its own environmental impact as well as helping its customers do the same.

With a global presence and a team of experienced engineers and technicians, CECO Environmental is a trusted partner for companies around the world. They are dedicated to providing customized solutions that meet the specific needs of each customer, ensuring that their equipment is optimized for maximum efficiency and performance. Whether it is reducing emissions, managing waste streams, or improving safety, CECO Environmental is committed to helping companies achieve their goals and operate more sustainably.