Mechanical Seals, Gland Packing, Seal Support Systems, Accessories, & Lubrication

We proudly distribute Flexaseal Engineered Seals and Systems, designed for superior sealing solutions across industries. Flexaseal products are recognized for their quality, durability, and innovative design, serving as essential components in various applications. From mechanical seals to seal support systems, Flexaseal products enhance equipment reliability and minimize downtime.

Boiler Feed / Condensate

Flexaseal provides robust sealing solutions for boiler feed and condensate systems, where durability and heat resistance are critical. These seals withstand high temperatures and pressures, effectively containing condensate and preventing leakage, thus maintaining system integrity and efficiency in demanding boiler operations.

Cryogenics

For cryogenic applications, Flexaseal offers specialized seals designed to perform in ultra-low temperatures. These seals maintain flexibility and integrity even in extreme cold, ensuring a secure seal in applications involving liquefied gases and other cryogenic processes where precision is crucial.

Emissions Control

Flexaseal’s emissions control seals are engineered to prevent fugitive emissions, helping industries comply with environmental regulations. These seals are ideal for applications where containment of volatile organic compounds (VOCs) and other emissions is essential, offering reliable sealing to support sustainable and compliant operations.

High Pressure, Temperature, and Heat Transfer Fluids

In applications involving high pressure, temperature, and heat transfer fluids, Flexaseal’s engineered seals provide superior resilience and safety. These seals are built to handle the stress of extreme conditions, ensuring consistent performance and reliability in industries such as power generation and chemical processing.

Mechanical Seals: Sealing Solutions That Get The Job Done Right

Flexaseal’s range of mechanical seals is tailored to meet diverse industrial needs, providing sealing solutions that optimize equipment efficiency and longevity. From industry-standard ANSI and API seals to specialized slurry and gas barrier seals, Flexaseal mechanical seals are designed to reduce leakage, minimize downtime, and improve operational stability in challenging environments.

ANSI Seals

Flexaseal ANSI seals meet American National Standards Institute (ANSI) specifications, offering a reliable and robust sealing solution for general-purpose pumps. They are ideal for standard industrial applications, delivering dependable performance across a variety of sectors.

API Seals

Flexaseal API seals are crafted to adhere to the American Petroleum Institute’s standards, making them a reliable choice for high-pressure applications in oil, gas, and petrochemical industries, where regulatory compliance is paramount.

Slurry Pump Seals

Designed for abrasive environments, Flexaseal’s slurry pump seals are engineered to resist wear from solid particles. These seals excel in mining, wastewater, and pulp processing applications, extending operational uptime in harsh conditions.

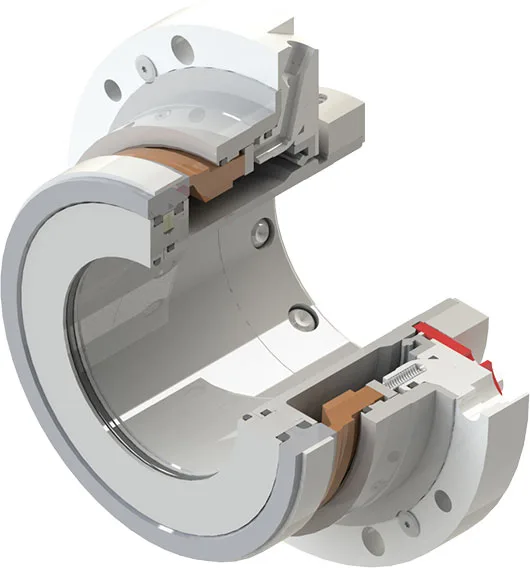

Mixer Seals

Mixer seals from Flexaseal are specially designed to prevent contamination and ensure robust sealing in equipment with rotating or oscillating shafts. These seals are ideal for industries such as food processing, chemicals, and pharmaceuticals, where hygiene and seal reliability are crucial.

Compressor Seals

Flexaseal compressor seals provide secure containment and leak prevention for high-pressure compressor applications, offering superior performance in demanding environments such as refrigeration, gas processing, and petrochemical facilities.

Gas Barrier Seals

For applications requiring containment of gases, Flexaseal’s gas barrier seals provide a high level of integrity and protection. They are an ideal choice for compressors and other equipment operating under high pressure, where maintaining system integrity is essential.

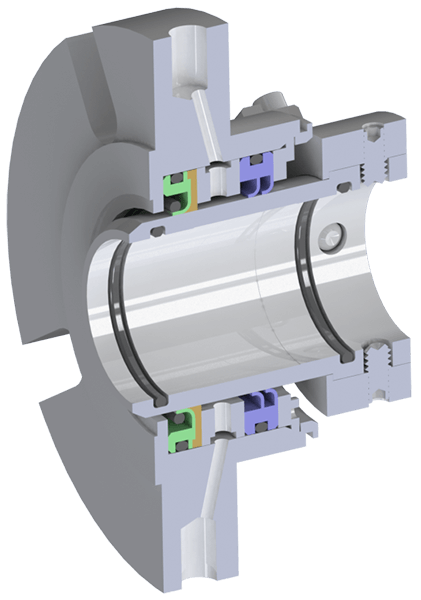

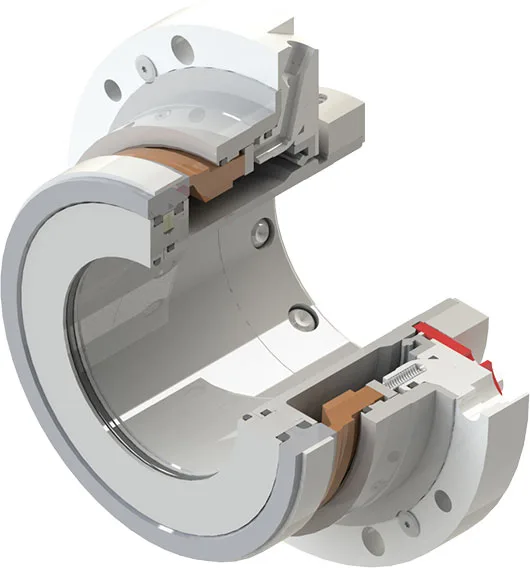

Split Cartridge Seals

Flexaseal’s split cartridge seals simplify installation and maintenance, as they can be replaced without dismantling equipment. These seals are a time-saving solution for operations needing quick and efficient maintenance procedures.

Single Cartridge Seals

Flexaseal single cartridge seals provide an efficient sealing option for various applications. These seals are easy to install and maintain, offering an effective solution for general-purpose sealing needs.

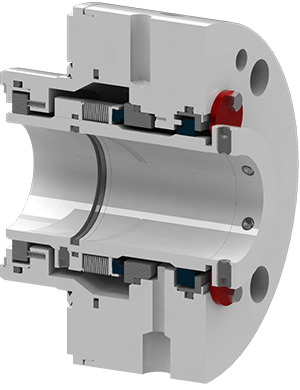

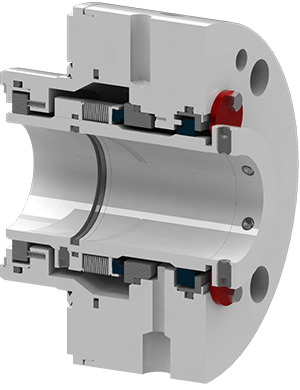

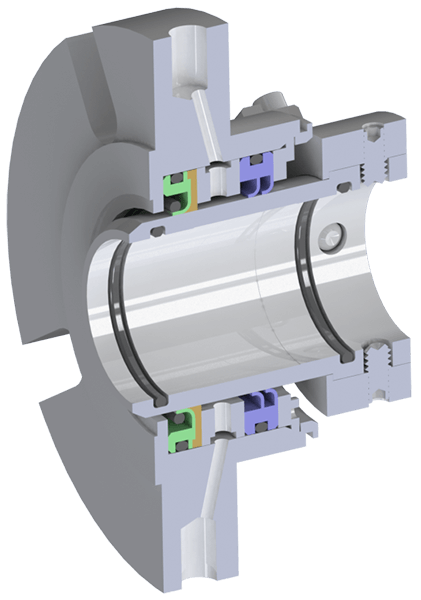

Dual Cartridge Seals

Dual cartridge seals from Flexaseal offer double-seal protection, enhancing performance and reliability in critical applications. These seals are particularly suitable for industries where leakage prevention is a top priority.

Multi-Lip Cartridge Seal

The multi-lip cartridge seal from Flexaseal provides added protection in applications prone to contamination. Its multiple lip design prevents ingress of contaminants, making it ideal for demanding environments.

Edge Welded Metal Bellows

Flexaseal’s edge-welded metal bellows seals are engineered for high-temperature and high-pressure applications. These durable seals are highly flexible, resistant to corrosion, and suited for challenging environments such as chemical and power generation industries.

Component Seals

Flexaseal component seals are adaptable sealing solutions that cater to various rotating equipment. They are ideal for applications with specific requirements, offering flexible, reliable performance across industries.

About Flexaseal

Flexaseal is a leader in the design and manufacturing of engineered seals and systems, serving industries worldwide with reliable, high-quality products. From mechanical seals and support systems to OEM replacements, Flexaseal Engineered Seals and Systems provide innovative solutions that withstand demanding applications. Flexaseal’s commitment to quality ensures that its products perform well, even in harsh conditions, making them a trusted choice across multiple industries.

About Arroyo Process Equipment

At Arroyo Process Equipment, we are here to help you find the right Flender product for your business. Contact us today to learn more about our Flender offerings and how they can improve your operations.