Griswold Equipment We Distribute

Griswold is a leading manufacturer of high-quality pumps for various industrial applications. The company offers a broad range of pumps designed to meet the specific needs of each application, including the 811 ANSI Series Pumps, 811SP Series Pumps, Griswold® 811CC Series Pumps, 850 Series Pumps, E, F&G Series Pumps, and H Series Pumps.

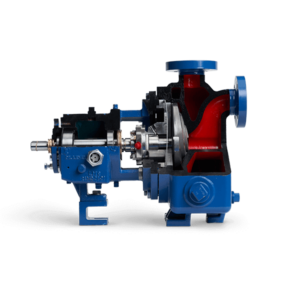

The 811 ANSI Series Pumps are ideal for a variety of applications, including chemical processing, refineries, and general industrial use. They are designed to meet ANSI/ASME B73.1 standards and are available in various sizes and materials, including ductile iron, carbon steel, and stainless steel.

The 811SP Series Pumps are self-priming and feature a unique design that allows them to handle solids and slurries with ease. They are ideal for applications such as waste handling, food processing, and mining.

The Griswold® 811CC Series Pumps are specifically designed for chemical processing applications and feature a close-coupled design that reduces the overall footprint of the pump. They are available in various materials, including ductile iron, 316 stainless steel, and Alloy 20.

811 ANSI Series Pumps

Griswold’s 811 ANSI Series Pumps are designed to meet ANSI/ASME B73.1 standards and are suitable for various industrial applications, including chemical processing, refineries, and general industrial use. These pumps are available in different sizes, from 1×1.5-6 to 10×12-17, and materials, such as ductile iron, carbon steel, and stainless steel. They have a maximum flow rate of 5000 GPM and a maximum head of 730 feet, making them ideal for high-flow and high-head applications.

One of the key features of the 811 ANSI Series Pumps is their back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. This design feature also reduces downtime and increases the lifespan of the pump, ultimately saving time and money for the user.

Another important feature of the 811 ANSI Series Pumps is their open impeller design, which makes them ideal for handling fluids with high solids content. The open impeller design reduces clogging and damage to the pump, resulting in increased efficiency and lower maintenance costs. Additionally, the pumps are available with a range of sealing options, including mechanical seals, packing, and lip seals, to provide optimal sealing for each application.

Overall, Griswold’s 811 ANSI Series Pumps offer reliable and efficient solutions for a variety of industrial applications. Their back pull-out design, open impeller design, and range of sealing options make them easy to maintain, durable, and versatile. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for companies around the world.

811SP Series Pumps

Griswold’s 811SP Series Pumps are a self-priming option that is ideal for various applications, including waste handling, food processing, and mining. These pumps feature a unique design that allows them to handle solids and slurries with ease. They are available in sizes from 2×2-10 to 6×6-13 and are constructed of ductile iron, carbon steel, or stainless steel materials.

One of the key features of the 811SP Series Pumps is their ability to prime without the need for an external vacuum or priming equipment. This self-priming feature makes these pumps easy to install and operate, ultimately saving time and money for the user. Additionally, the pumps are available with a range of impeller designs, including closed, semi-open, and open impellers, to suit each application’s specific needs.

The 811SP Series Pumps also feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. This design feature reduces downtime and increases the pump’s lifespan, ultimately saving time and money for the user. The pumps are also available with a range of sealing options, including mechanical seals, packing, and lip seals, to provide optimal sealing for each application.

Overall, Griswold’s 811SP Series Pumps offer reliable and efficient solutions for various applications that require self-priming capabilities and the ability to handle solids and slurries. Their self-priming feature, range of impeller designs, back pull-out design, and range of sealing options make them easy to maintain, durable, and versatile. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for companies around the world.

Griswold® 811CC Series Pumps

Griswold’s Griswold® 811CC Series Pumps are specifically designed for chemical processing applications. These pumps feature a close-coupled design, which reduces the overall footprint of the pump and eliminates the need for a separate coupling. They are available in various materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs.

The Griswold® 811CC Series Pumps are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17. They have a maximum flow rate of 2500 GPM and a maximum head of 425 feet, making them ideal for chemical processing applications that require high flow rates and moderate head pressures.

The pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. This design feature reduces downtime and increases the pump’s lifespan, ultimately saving time and money for the user. The pumps are also available with a range of sealing options, including mechanical seals, packing, and lip seals, to provide optimal sealing for each application.

Overall, Griswold’s Griswold® 811CC Series Pumps offer reliable and efficient solutions for chemical processing applications. Their close-coupled design, range of materials, back pull-out design, and range of sealing options make them easy to maintain, durable, and versatile. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for companies around the world in various industries.

850 Series Pumps

Griswold’s 850 Series Pumps are designed for various industrial applications, including chemical processing, refineries, and general industrial use. These pumps are constructed with durable materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs. They are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17.

The Griswold® 850 Series Pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. This design feature reduces downtime and increases the pump’s lifespan, ultimately saving time and money for the user. Additionally, the pumps are available with a range of sealing options, including mechanical seals, packing, and lip seals, to provide optimal sealing for each application.

The pumps are available with various impeller designs, including closed, semi-open, and open impellers, to suit each application’s specific needs. The closed impeller design is ideal for handling fluids with low solids content, while the semi-open and open impeller designs are suitable for fluids with higher solids content. Overall, Griswold’s 850 Series Pumps offer reliable and efficient solutions for various industrial applications. Their back pull-out design, range of materials, and impeller designs make them easy to maintain, durable, and versatile.

E,F&G Series Pumps

Griswold’s E, F & G Series Pumps are designed for various industrial applications, including water and wastewater, general industry, and power generation. These pumps are constructed with durable materials, including cast iron and ductile iron, to suit each application’s specific needs. They are available in sizes from 1×1.5-6 to 8×10-17.

The E, F & G Series Pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. This design feature reduces downtime and increases the pump’s lifespan, ultimately saving time and money for the user. Additionally, the pumps are available with a range of sealing options, including mechanical seals, packing, and lip seals, to provide optimal sealing for each application.

The pumps are available with various impeller designs, including closed, semi-open, and open impellers, to suit each application’s specific needs. The closed impeller design is ideal for handling fluids with low solids content, while the semi-open and open impeller designs are suitable for fluids with higher solids content. Overall, Griswold’s E, F & G Series Pumps offer reliable and efficient solutions for various industrial applications. Their back pull-out design, range of materials, and impeller designs make them easy to maintain, durable, and versatile.

H Series Pumps

Griswold’s H Series Pumps are designed for high-pressure applications, including boiler feed, water injection, and high-pressure washdown. These pumps are constructed with durable materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs. They are designed to meet API 610 specifications and are available in sizes from 1×1.5-6 to 8×10-17.

The H Series Pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. This design feature reduces downtime and increases the pump’s lifespan, ultimately saving time and money for the user. Additionally, the pumps are available with a range of sealing options, including mechanical seals, packing, and lip seals, to provide optimal sealing for each application.

The pumps are available with various impeller designs, including closed, semi-open, and open impellers, to suit each application’s specific needs. The closed impeller design is ideal for handling fluids with low solids content, while the semi-open and open impeller designs are suitable for fluids with higher solids content. The H Series Pumps also feature a range of options, including a variety of material and bearing options, to provide the user with a customizable and versatile solution for their high-pressure application needs. Overall, Griswold’s H Series Pumps offer reliable and efficient solutions for high-pressure applications in various industries. Their back pull-out design, range of materials, and impeller designs make them easy to maintain, durable, and versatile.

Applications of Griswold Equipment

Griswold equipment is designed to provide reliable and efficient solutions for various industrial applications. The company’s products are used in industries such as chemical processing, oil and gas, energy, general industrial, mining, and water. In chemical processing, Griswold pumps are used for handling corrosive and abrasive liquids, while in the oil and gas industry, their pumps are used for offshore drilling and crude oil transport.

In the energy industry, Griswold pumps are used in power generation and heating, ventilation, and air conditioning (HVAC) systems. In general industrial applications, Griswold pumps are used in manufacturing processes such as food processing, plastics production, and wastewater treatment. The company’s pumps are also used in the mining industry for mineral extraction and processing.

In the water industry, Griswold pumps are used for a range of applications, including water treatment, wastewater treatment, and desalination. Their pumps are designed to handle a range of fluids, from clean water to abrasive slurry. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for companies around the world in various industries.

Chemical Process

Griswold equipment plays a vital role in the chemical processing industry, where pumps are required to handle corrosive and abrasive liquids. Griswold pumps are designed to handle a wide range of chemicals, from acids and solvents to polymers and slurries. The pumps are available in various materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs.

Griswold’s 811 ANSI Series Pumps and 811SP Series Pumps are specifically designed for chemical processing applications. These pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. They are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 2500 GPM and a maximum head of 425 feet.

The Griswold® 811CC Series Pumps are also designed for chemical processing applications. These pumps feature a close-coupled design, which reduces the overall footprint of the pump and eliminates the need for a separate coupling. They are designed to meet ANSI/ASME B73.1 standards and are available in various materials, including ductile iron, 316 stainless steel, and Alloy 20. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for the chemical processing industry, providing reliable and efficient solutions to companies around the world.

Oil & Gas

Griswold equipment is used in the oil and gas industry for various applications, including offshore drilling and crude oil transport. The industry demands reliable equipment that can withstand the harsh conditions of the oil and gas field. Griswold’s 811 ANSI Series Pumps and 811SP Series Pumps are ideal for oil and gas applications. These pumps are constructed with durable materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs.

Griswold’s H Series Pumps are designed for high-pressure applications, making them ideal for use in the oil and gas industry. These pumps are designed to meet API 610 specifications and are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 6000 GPM and a maximum head of 3000 feet. They feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly.

In addition to pumps, Griswold also offers rotating equipment services for the oil and gas industry. These services include repairs, upgrades, and maintenance for pumps, motors, and other rotating equipment. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of equipment and services for the oil and gas industry, providing reliable and efficient solutions to companies around the world.

Energy

Griswold equipment is used in the energy industry for various applications, including power generation and HVAC systems. Griswold’s 850 Series Pumps are ideal for power generation applications, including condensate extraction, boiler feed, and high-pressure washdown. These pumps are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 5000 GPM and a maximum head of 720 feet.

Griswold’s E, F & G Series Pumps are ideal for HVAC systems, including heating and cooling systems. These pumps are constructed with durable materials, including cast iron and ductile iron, to suit each application’s specific needs. They are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 5000 GPM and a maximum head of 720 feet.

In addition to pumps, Griswold also offers rotating equipment services for the energy industry. These services include repairs, upgrades, and maintenance for pumps, motors, and other rotating equipment. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of equipment and services for the energy industry, providing reliable and efficient solutions to companies around the world.

General Industrial

Griswold equipment is used in various general industrial applications, including food processing, plastics production, and wastewater treatment. Griswold’s pumps are designed to handle a wide range of fluids, from clean water to abrasive slurries, making them ideal for use in the general industrial industry. The pumps are available in various materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs.

Griswold’s 811 ANSI Series Pumps and 811SP Series Pumps are ideal for general industrial applications. These pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. They are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 2500 GPM and a maximum head of 425 feet.

Griswold’s H Series Pumps are also suitable for general industrial applications. These pumps are designed for high-pressure applications, including boiler feed, water injection, and high-pressure washdown. They are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 6000 GPM and a maximum head of 3000 feet. The pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for the general industrial industry, providing reliable and efficient solutions to companies around the world.

Mining

Griswold equipment is used in the mining industry for various applications, including mineral extraction and processing. The mining industry requires reliable equipment that can withstand the harsh conditions of mining operations. Griswold’s pumps are constructed with durable materials, including ductile iron, 316 stainless steel, and Alloy 20, to suit each application’s specific needs.

Griswold’s 811 ANSI Series Pumps and 811SP Series Pumps are ideal for mining applications. These pumps are designed to handle abrasive slurries, making them suitable for mineral extraction and processing. They feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. They are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 2500 GPM and a maximum head of 425 feet.

Griswold’s H Series Pumps are also suitable for mining applications. These pumps are designed for high-pressure applications, including water injection and high-pressure washdown. They are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 6000 GPM and a maximum head of 3000 feet. The pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for the mining industry, providing reliable and efficient solutions to companies around the world.

Water

Griswold equipment is used in the water industry for various applications, including water treatment, desalination, and wastewater treatment. The water industry requires reliable equipment that can handle the high flow rates and pressures associated with water treatment processes. Griswold’s pumps are designed to handle clean water, wastewater, and abrasive slurries, making them suitable for use in the water industry.

Griswold’s 811 ANSI Series Pumps and 811SP Series Pumps are ideal for water industry applications. These pumps are designed to meet ANSI/ASME B73.1 standards and are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 2500 GPM and a maximum head of 425 feet. They feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly.

Griswold’s H Series Pumps are also suitable for water industry applications. These pumps are designed for high-pressure applications, including water injection and high-pressure washdown. They are available in sizes from 1×1.5-6 to 8×10-17, with a maximum flow rate of 6000 GPM and a maximum head of 3000 feet. The pumps feature a back pull-out design, which allows for easy maintenance and repair without the need for complete disassembly. Griswold’s commitment to innovation and engineering excellence has made them a trusted supplier of pumps for the water industry, providing reliable and efficient solutions to companies around the world.

About Griswold

Griswold is a leading industrial manufacturing company that has been providing innovative pumping solutions for over 100 years. The company offers a wide range of pumps and related products that are used in various industries, including chemical processing, oil and gas, mining, water treatment, and general industrial. Griswold is committed to providing reliable and efficient equipment that meets the needs of its customers and exceeds their expectations.

Founded in 1893, Griswold has a long history of innovation and engineering excellence. The company has been at the forefront of developing new pumping technologies, including the self-priming pump and the ANSI pump, which have become industry standards. Griswold’s commitment to innovation is reflected in its state-of-the-art research and development facility, which is equipped with the latest technology and staffed by a team of experienced engineers and technicians.

Griswold is known for its high-quality products and exceptional customer service. The company has a global network of distributors and service centers, which allows them to provide support to its customers wherever they are located. Griswold is committed to building long-term relationships with their customers by providing them with the best possible solutions and supporting them throughout the life of their equipment. With a reputation for quality, reliability, and innovation, Griswold is a trusted supplier of pumping solutions to companies around the world.

Affiliation with Dover Company

Griswold is a subsidiary of the Dover Corporation, a global industrial products company that operates in several markets, including fluid management, engineered systems, refrigeration, and food equipment. Dover acquired Griswold in 1998, and since then, the company has continued to grow and expand its product offerings. The affiliation with Dover has provided Griswold with access to additional resources and expertise, enabling the company to develop new technologies and expand into new markets.

As part of Dover’s fluid management division, Griswold works alongside other industry-leading brands, including Wilden, Maag, and PSG. Dover’s fluid management division offers a comprehensive range of fluid handling solutions, including pumps, mixers, valves, and filters, for a wide range of applications. The division’s expertise and resources allow Griswold to provide its customers with integrated solutions that meet their specific needs.

The affiliation with Dover has also enabled Griswold to expand its global reach. With operations and customers around the world, Dover’s global presence has allowed Griswold to provide its pumping solutions to customers in new markets and regions. The affiliation with Dover has been a key factor in Griswold’s success, enabling the company to grow and continue to provide innovative pumping solutions to its customers.