High-Quality Gearboxes for Industrial Use

Hansen Industrial Gearboxes are made to handle tough jobs. They are part of Sumitomo Drive Technologies, a leader in gear manufacturing and drive technology. Hansen products are strong, reliable, and efficient. They work well in many industries, including mining, energy, and food processing.

We offer Hansen gear products and services, such as Hansen gearbox parts, Hansen gearbox repair, and rebuilds. Our team also handles emergency Hansen gearbox repair and solutions for Hansen gearbox wind turbines. If you need support for Hansen gearboxes Florida exporter needs, we are here to help.

Types of Hansen Industrial Gearboxes

From Hansen gearbox rebuilds to emergency repair services, Hansen gear systems provide cutting-edge solutions for industrial operations. Explore our range of products designed for single-stage and multi-stage operations, all built to deliver exceptional performance and longevity.

Hansen M4 Air Cooled Condenser Drive

The Hansen M4 Air Cooled Condenser Drive is specially designed for air-cooled condenser applications. It offers efficient heat transfer, high torque capacity, and a compact design, making it ideal for demanding industrial cooling systems.

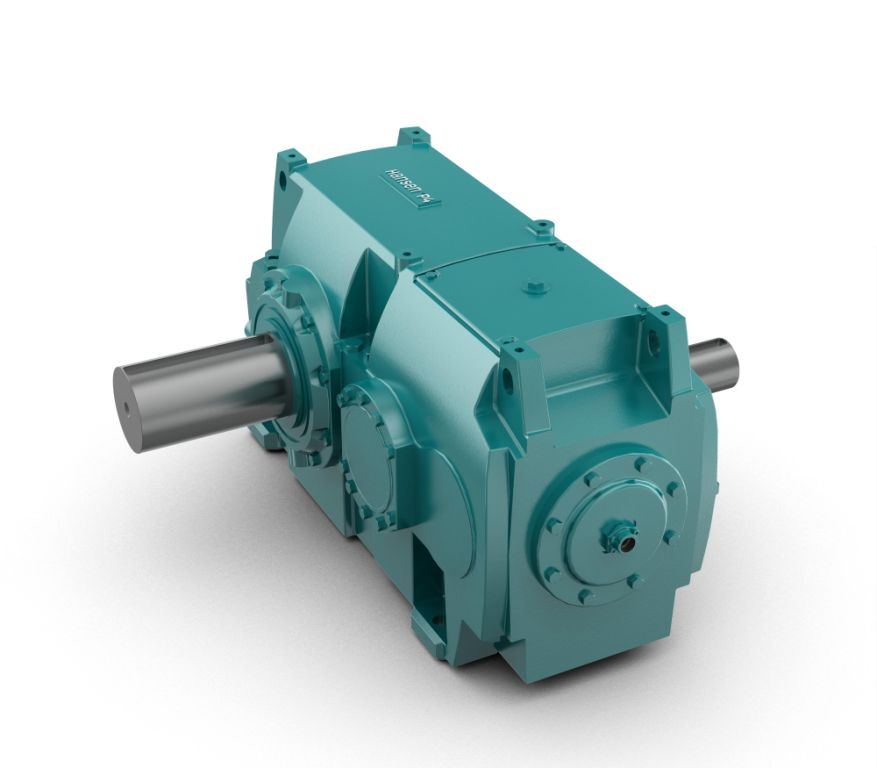

Hansen P4 Multistage – Horizontal

The Hansen P4 Multistage – Horizontal gearbox delivers superior performance in horizontal applications. Its robust construction and advanced design provide high efficiency and reliability, even under heavy loads.

Hansen P4 Multistage – Vertical

The Hansen P4 Multistage – Vertical gearbox is built for vertical applications requiring high torque and precision. Its modular design ensures easy installation and maintenance, making it a trusted solution in industries like energy and material handling.

Hansen P4 Single Stage

The Hansen P4 Single Stage gearbox offers high efficiency and smooth performance for single-stage operations. Its simple yet durable design is perfect for applications needing consistent, low-maintenance power transmission.

Hansen P4 UniMiner

The Hansen P4 UniMiner is designed for mining applications. With its rugged build and high torque capacity, it ensures reliable operation in harsh environments, making it a preferred choice for material handling and processing.

Application Overview

Mining and Material Handling

Hansen gearboxes are perfect for mining and material handling. They work well in conveyor systems, crushers, and hoists. These gearboxes are strong and efficient, even in tough conditions.

Power Generation

In power generation, Hansen gearboxes help run turbines and generators. They provide high torque and smooth performance, even under heavy loads.

Food and Beverage Processing

Hansen gearboxes are used in food and beverage processing. They are great for bottling, mixing, and canning. Their reliable performance helps keep operations running smoothly.

Industrial Wastewater

Hansen gearboxes provide reliable power for pumps, mixers, and aerators in industrial wastewater treatment facilities. They handle harsh fluids and heavy-duty operations, ensuring efficient treatment and disposal processes.

Municipal Wastewater

Hansen gear systems support municipal wastewater treatment, powering essential equipment like aerators and agitators. These gearboxes are designed for durability, ensuring effective water treatment in public facilities.

Wind Turbines

Hansen gearboxes are a top choice for wind turbines. They are designed for high-speed, high-torque operations. These gearboxes help produce clean energy efficiently.

About Hansen Industrial Gearboxes

Hansen Industrial Gearboxes, part of Sumitomo Heavy Industries, is a pioneer in drive technology and gear manufacturing. As one of the world leading manufacturers of industrial gear systems, Hansen provides innovative solutions tailored to meet the needs of industries worldwide. From Hansen transmissions international to specialized gear systems for electric motor applications, their products combine advanced engineering with reliability, ensuring maximum performance in any setting.

About Arroyo Process Equipment

At Arroyo Process Equipment, we are dedicated to providing exceptional service and solutions for your industrial needs. Whether you require a Hansen gearbox Florida exporter, expert Hansen gearbox repair specialists, or support for a Hansen gearbox rebuild, we deliver high-quality products and reliable service. Contact us today to learn how our Hansen Industrial Gearboxes offerings can enhance your operations and drive success.