Hayward Gordon Equipment We Distribute

Hayward Gordon, a renowned manufacturer in the world of industrial pumps, offers a diverse range of high-quality pumping solutions designed to meet the unique needs of various industries. Their cutting-edge product line encompasses Process Pumping Solutions, Solids Handling Pumps, Vertical Pumps, ANSIMax Pumps, SmartFlex Peristaltic Pumps, Sulfur Pumps, Gear Pumps, and Waukesha Sanitary Pumps. Each category boasts innovative engineering, exceptional durability, and unparalleled efficiency, guaranteeing seamless operation and optimal performance across various applications.

Our experts delve into the intricacies of these specialized pumps, examining their distinct features and capabilities when selecting equipment for our customers.

Solids Handling Pumps

Hayward Gordon’s Solids Handling Pumps are designed to manage the complexities and challenges of pumping solid-laden fluids, slurries, and sludges. These pumps are built to handle high concentrations of solids and abrasive materials, making them ideal for mining, wastewater treatment, pulp and paper, and oil and gas. These pumps’ robust construction and innovative engineering ensure minimal downtime, reduced maintenance costs, and optimal performance even under the most demanding conditions. Hayward Gordon’s Solids Handling Pumps offer exceptional wear resistance and longevity by incorporating heavy-duty bearings, rigid metal or elastomeric liners, and cutting-edge impeller designs.

One of the critical aspects of Hayward Gordon’s Solids Handling Pumps is their versatility. These pumps are available in various horizontal, vertical, and submersible configurations to suit different applications and installation requirements. To accommodate the specific needs of each industry, Hayward Gordon offers custom-engineered solutions that can be tailored to handle various types and concentrations of solids, fluid viscosities, and flow rates. The company’s dedication to providing tailored solutions ensures that their Solids Handling Pumps deliver consistent and reliable performance, even when confronted with the most challenging pumping scenarios.

Besides their impressive performance and versatility, Hayward Gordon’s Solids Handling Pumps are also designed with environmental and operational safety in mind. By minimizing the risk of leaks and spills, these pumps help maintain the integrity of the environment and protect the health and safety of workers. Furthermore, their advanced sealing technology and monitoring systems provided early detection of potential issues, allowing for proactive maintenance and reduced downtime. With a commitment to quality, innovation, and customer satisfaction, Hayward Gordon’s Solids Handling Pumps continue to set the industry standard for handling abrasive and solid-laden fluids.

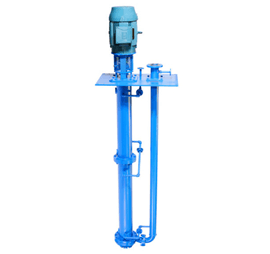

Vertical Pumps

Hayward Gordon’s Vertical Pumps are expertly engineered to provide efficient and reliable fluid handling solutions, particularly in applications where space constraints or the need to minimize footprints are crucial. These pumps are ideal for industries such as chemical processing, water treatment, mining, and power generation, where the vertical configuration offers advantages over traditional horizontal pumps. By utilizing a compact design, Hayward Gordon’s Vertical Pumps save valuable floor space and reduce installation complexity and maintenance costs, making them an attractive option for various industrial applications.

One of the standout features of Hayward Gordon’s Vertical Pumps is their ability to manage various fluid types, including corrosive and abrasive liquids, high-temperature fluids, and volatile substances. Their extensive line of vertical pumps includes options such as cantilevered, submerged, and double-suction designs, each tailored to address specific pumping requirements. By offering an assortment of materials for construction, including corrosion-resistant alloys and specialized elastomers, Hayward Gordon ensures the durability and longevity of their vertical pumps under the most challenging conditions. This adaptability allows customers to select the ideal pump solution for their unique application needs.

Besides their versatile design and construction, Hayward Gordon’s Vertical Pumps are also built with energy efficiency and environmental sustainability in mind. These pumps achieve optimized performance with minimal energy consumption by leveraging advanced hydraulic designs and precision engineering. Furthermore, the company’s commitment to innovative sealing technology helps prevent leaks and spills, ensuring the safety of the environment and personnel. Combining compact design, versatility, and eco-friendly features, Hayward Gordon’s Vertical Pumps remain an industry-leading choice for fluid handling in various demanding applications.

ANSIMax Pumps

Hayward Gordon’s ANSIMax Pumps are a line of centrifugal pumps designed and built to exceed the rigorous standards set by the American National Standards Institute (ANSI) for chemical process pumps. These state-of-the-art pumps are ideal for industries such as chemical processing, petrochemical, pharmaceutical, and food and beverage, where reliable, high-performance pumping solutions are essential. By adhering to and surpassing the ANSI standards, Hayward Gordon’s ANSIMax Pumps deliver exceptional durability, corrosion resistance, and operational reliability in demanding environments, ensuring maximum efficiency and minimal downtime.

One key feature that sets Hayward Gordon’s ANSIMax Pumps apart from their competitors is their innovative design, which prioritizes both performance and ease of maintenance. These pumps incorporate a back pull-out design, allowing easy access to the pump’s internals without disassembling the entire unit or disturbing the piping. This design significantly reduces the time and effort required for maintenance tasks, minimizing downtime and operational costs. Moreover, the ANSIMax Pumps have robust power frames, optimized impellers, and heavy-duty shafts, resulting in unparalleled mechanical reliability, extended service life, and improved energy efficiency.

Besides their superior design and performance, Hayward Gordon’s ANSIMax Pumps are highly customizable, enabling them to cater to various applications and customer requirements. The company offers a range of materials for construction, including corrosion-resistant alloys and specialized elastomers, which can be tailored to handle specific types of aggressive and corrosive fluids. Moreover, their sealing technology options, such as single, double, or cartridge seals, provide the flexibility to choose the most suitable sealing solution for the intended application. By combining cutting-edge design, outstanding performance, and customizable features, Hayward Gordon’s ANSIMax Pumps continue to set the benchmark for excellence in the chemical process pumping industry.

SmartFlex Peristaltic Pumps

Hayward Gordon’s SmartFlex Peristaltic Pumps are a versatile and innovative range of positive displacement pumps designed to handle a wide variety of fluids, including viscous, abrasive, and shear-sensitive substances. With applications across numerous industries, such as wastewater treatment, pharmaceuticals, food and beverage, and chemical processing, these pumps provide efficient and accurate fluid transfer while ensuring minimal wear and tear on components. The SmartFlex Peristaltic Pumps are renowned for their gentle pumping action, which makes them ideal for handling delicate and sensitive materials without causing damage or altering their properties.

A key advantage of Hayward Gordon’s SmartFlex Peristaltic Pumps is their unique operating principle, which relies on the compression and relaxation of a flexible hose or tube to create a peristaltic motion, effectively moving the fluid through the pump. This design eliminates the need for valves, impellers, or seals, significantly reducing maintenance requirements and the risk of leaks or contamination. Additionally, the SmartFlex pumps offer exceptional metering capabilities, ensuring precise and consistent flow rates that can be easily adjusted to accommodate various application requirements. Combining a low-maintenance design with accurate fluid handling, the SmartFlex Peristaltic Pumps provide a cost-effective and reliable solution for many pumping needs.

Hayward Gordon’s commitment to innovation and customer satisfaction is evident in the SmartFlex Peristaltic Pumps’ advanced features and customizable options. The pumps are available in various sizes and configurations, catering to different flow rates, pressures, and installation requirements. Furthermore, Hayward Gordon offers a selection of specialized hoses and tubes constructed from natural rubber, nitrile, and silicone, to suit the specific needs of each application. The SmartFlex pumps can also be integrated with advanced control systems for remote monitoring and automation, ensuring seamless operation and optimal performance. Through their innovative design, unparalleled versatility, and customizable features, Hayward Gordon’s SmartFlex Peristaltic Pumps are a top choice for efficient and reliable fluid handling across numerous industries.

Sulfur Pumps

Hayward Gordon’s Sulfur Pumps are a specialized range of pumping solutions designed to address the unique challenges of handling molten sulfur and sulfuric compounds. Utilized in petrochemical, mining, and power generation industries, these pumps are engineered to provide reliable and efficient performance under the demanding conditions of high temperatures and corrosive environments. By incorporating cutting-edge materials and advanced design principles, Hayward Gordon’s Sulfur Pumps ensure the safe, effective, and continuous transfer of molten sulfur while minimizing operational downtime and maintenance costs.

One of the critical features of Hayward Gordon’s Sulfur Pumps is their ability to maintain consistent temperature control throughout the pumping process. The precise handling of temperature is crucial in preventing sulfur solidification or degradation, which can lead to blockages and equipment damage. To achieve optimal temperature management, these pumps have advanced heating systems and insulation materials that ensure uniform heat distribution and minimal heat loss. Additionally, the pumps are constructed from corrosion-resistant alloys and specialized elastomers that can withstand the harsh conditions associated with molten sulfur, offering enhanced durability and longevity.

Besides their exceptional performance and temperature management capabilities, Hayward Gordon’s Sulfur Pumps are also designed to focus on safety and environmental responsibility. The pumps incorporate advanced sealing technology and monitoring systems that help minimize the risk of leaks and spills, protecting the environment and ensuring worker safety. Furthermore, the Sulfur Pumps are built to comply with strict industry standards and regulations, demonstrating Hayward Gordon’s commitment to delivering reliable and responsible pumping solutions. By combining robust design, precise temperature control, and a dedication to safety, Hayward Gordon’s Sulfur Pumps remain the go-to choice for handling molten sulfur and sulfuric compounds in various industrial applications.

Gear Pumps

Hayward Gordon’s Gear Pumps are a range of high-quality, positive displacement pumps designed for reliable and efficient fluid handling in various industries, including chemical processing, petrochemical, food, beverage, and pharmaceuticals. These pumps are engineered to deliver consistent and precise flow rates, making them ideal for applications that require accurate metering, dosing, and fluid transfer. With their robust construction and innovative design, Hayward Gordon’s Gear Pumps provide exceptional durability and performance, even in demanding conditions and when handling challenging fluids such as high-viscosity liquids or those with high solid content.

A distinguishing feature of Hayward Gordon’s Gear Pumps is their operating principle, which relies on the meshing of two interlocking gears to create a pumping action. As the gears rotate, they expand and contract cavities that move the fluid through the pump. This design ensures a smooth, pulse-free flow, enabling the efficient and accurate handling of various fluids, including shear-sensitive and abrasive substances. Furthermore, the Gear Pumps’ compact design and low noise levels make them an attractive option for installations where space constraints and noise reduction are important considerations.

Besides their superior performance and compact design, Hayward Gordon’s Gear Pumps are also highly customizable to cater to the specific needs of each application. The pumps are available in various materials, including corrosion-resistant alloys and specialized elastomers, ensuring compatibility with various fluids and chemicals. Moreover, the company offers multiple sealing options, such as mechanical seals, magnetic couplings, or packing, to provide the most suitable sealing solution for each application. Combining efficient operation, customizable features, and a commitment to quality and innovation, Hayward Gordon’s Gear Pumps remain a top choice for reliable and precise fluid handling across numerous industries.

Waukesha Sanitary Pumps

Hayward Gordon’s Waukesha Sanitary Pumps are a premium line of hygienic pumping solutions designed to meet the stringent requirements of industries where sanitation and product integrity are of paramount importance. These pumps are widely used in the food and beverage, pharmaceutical, cosmetic, and biotechnology sectors, where maintaining cleanliness, preventing contamination, and ensuring product quality are essential. Built to comply with strict sanitary standards, such as 3-A, EHEDG, and FDA, Hayward Gordon’s Waukesha Sanitary Pumps offer exceptional performance, reliability, and ease of cleaning, making them the ideal choice for critical applications in hygiene-sensitive environments.

One of the standout features of Hayward Gordon’s Waukesha Sanitary Pumps is their advanced design, which prioritizes hygienic operation and efficient fluid handling. These pumps incorporate crevice-free construction, electropolished surfaces, and easy-to-clean seal configurations, which minimize the risk of product contamination and facilitate efficient cleaning-in-place (CIP) processes. In addition to their sanitary design, Waukesha Sanitary Pumps also provide gentle and precise fluid handling, ensuring that delicate or shear-sensitive products are not damaged or altered during the pumping process.

Besides their hygienic operation and exceptional performance, Hayward Gordon’s Waukesha Sanitary Pumps are designed with versatility and customization. The pumps are available in various configurations, including rotary lobe, centrifugal, and diaphragm designs, to cater to the specific requirements of different applications and industries. Furthermore, the company offers a range of construction materials and surface finishes, ensuring compatibility with various products and cleaning solutions. By combining cutting-edge sanitary design, superior performance, and customizable features, Hayward Gordon’s Waukesha Sanitary Pumps continue to set the industry standard for hygienic fluid handling solutions.

Applications of Hayward Gordon Equipment

Hayward Gordon serves diverse industries by addressing their unique fluid handling challenges with precision and reliability. The company’s wide range of pumps and equipment cater to various applications in sectors such as Water and Wastewater, Mining and Mineral Processing, Oil and Gas, Food and Beverage, Cosmetic and Personal Care, Pharmaceutical, Agriculture, Chemical, General Industry, and Pulp and Paper. By leveraging advanced engineering, innovative designs, and adaptable features, Hayward Gordon consistently provides tailor-made solutions that enhance efficiency, ensure product integrity, and promote environmental sustainability across multiple industries, solidifying its reputation as a trusted partner for fluid handling solutions worldwide.

Water and Wastewater

Hayward Gordon plays a crucial role in the water and wastewater industry by providing advanced and reliable pumping solutions that cater to this sector’s specific needs and challenges. With a focus on efficiency, durability, and environmental sustainability, the company’s diverse range of pumps, such as Solids Handling Pumps, Vertical Pumps, and SmartFlex Peristaltic Pumps, are designed to handle a wide variety of water and wastewater applications, including water supply, treatment, distribution, and disposal. These pumps are engineered to withstand harsh conditions and demanding industry requirements, such as high solid content, corrosive chemicals, and fluctuating flow rates, ensuring optimal performance and minimizing downtime.

One of the critical applications of Hayward Gordon’s pumps in the water and wastewater industry is the efficient handling and treatment of sewage and sludge. For instance, the company’s Solids Handling Pumps are specifically designed to manage the complexities associated with pumping solid-laden fluids and slurries, making them ideal for wastewater treatment processes such as primary and secondary clarifiers and grit removal, and sludge dewatering. Similarly, the SmartFlex Peristaltic Pumps provide gentle and precise fluid handling, enabling the accurate dosing of chemicals for disinfection, pH control, and coagulation, ensuring the proper water and wastewater treatment.

Another significant application of Hayward Gordon’s pumps in the water and wastewater industry is managing stormwater and flood control. The company’s Vertical Pumps, with their compact design and powerful performance, are well-suited for stormwater pumping stations and flood mitigation projects, ensuring efficient water removal and distribution while minimizing the risk of property damage and environmental hazards. By offering a comprehensive range of pumping solutions specifically tailored to the water and wastewater industry’s needs, Hayward Gordon plays a pivotal role in safeguarding public health, protecting the environment, and ensuring the efficient use of our planet’s most precious resource – water.

Mining and Mineral Processing

Hayward Gordon plays a vital role in the mining and mineral processing industry by providing robust and efficient pumping solutions designed to handle the rigorous demands and harsh conditions often encountered in this sector. The company’s extensive range of pumps, including Solids Handling Pumps, Vertical Pumps, and SmartFlex Peristaltic Pumps, are engineered to manage abrasive and corrosive fluids, high solid content, and fluctuating flow rates, ensuring optimal performance, reduced downtime, and minimal maintenance costs. These pumps are widely used in various mining and mineral processing applications, such as dewatering, tailings management, slurry transfer, and chemical dosing, contributing to the overall efficiency and productivity of mining operations.

One of the critical applications of Hayward Gordon’s pumps in the mining and mineral processing industry is handling and transporting abrasive slurries. For instance, the company’s Solids Handling Pumps are specifically designed to manage the challenges associated with pumping solid-laden fluids, making them ideal for mill discharge, froth flotation, and tailings transfer processes. Their robust construction, combined with specialized materials and wear-resistant components, ensures these pumps deliver long-lasting performance and reliability, even under the most demanding conditions.

Another vital application of Hayward Gordon’s pumps in the mining and mineral processing industry is in mine dewatering and flood control. The company’s Vertical Pumps, with their compact design and powerful performance, are well-suited for dewatering applications in underground and open-pit mines, ensuring efficient water removal and maintaining a safe working environment. Moreover, the SmartFlex Peristaltic Pumps provide precise and gentle fluid handling, enabling the accurate dosing of chemicals for process control, water treatment, and reagent addition. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the mining and mineral processing industry, Hayward Gordon continues to play a crucial role in enhancing operational efficiency, worker safety, and environmental protection.

Oil and Gas

Hayward Gordon is a prominent player in the oil and gas industry, providing reliable and high-performance pumping solutions tailored to this sector’s unique challenges and requirements. The company’s extensive range of pumps, including ANSIMax Pumps, SmartFlex Peristaltic Pumps, and Gear Pumps, are designed to handle various fluids and operating conditions, such as high pressures, extreme temperatures, and corrosive environments. These pumps are utilized in multiple oil and gas applications, including crude oil transfer, refining processes, chemical injection, and produced water management, ensuring efficient, safe, and environmentally responsible operations throughout the industry.

One of the critical applications of Hayward Gordon’s pumps in the oil and gas industry is the accurate and efficient handling of crude oil and its derivatives. The company’s ANSIMax Pumps, for example, are built to exceed the rigorous standards set by the American National Standards Institute (ANSI) for chemical process pumps, making them ideal for the transfer and processing of crude oil and refined products in petrochemical plants, refineries, and pipeline systems. These pumps deliver exceptional durability, corrosion resistance, and operational reliability, ensuring maximum efficiency and minimal downtime in demanding oil and gas environments.

Another critical application of Hayward Gordon’s pumps in the oil and gas industry is in chemical injection and dosing processes. The SmartFlex Peristaltic Pumps, with their gentle pumping action and precise metering capabilities, are well-suited for injecting chemicals such as corrosion inhibitors, biocides, and demulsifiers into oil and gas production systems. These pumps ensure consistent and accurate dosing, optimizing the effectiveness of chemical treatments and minimizing operational costs. Furthermore, the company’s Gear Pumps are commonly used to efficiently transfer viscous fluids, such as lubricants and heavy oils, in various oil and gas applications. Hayward Gordon continues to play a significant role in enhancing operational efficiency, safety, and environmental stewardship by offering a comprehensive range of pumping solutions specifically designed for the oil and gas industry.

Food and Beverage

Hayward Gordon plays a significant role in the food and beverage industry by providing specialized pumping solutions that cater to the unique requirements of this sector, including strict hygiene standards, product integrity, and gentle fluid handling. The company’s range of pumps, such as Waukesha Sanitary Pumps and SmartFlex Peristaltic Pumps, are designed to comply with stringent sanitary regulations, such as 3-A, EHEDG, and FDA, ensuring that food and beverage products are processed and transferred safely and efficiently. These pumps are widely used in various food and beverage applications, including ingredient transfer, product mixing, filling and bottling, and cleaning-in-place (CIP) processes.

One of the key applications of Hayward Gordon’s pumps in the food and beverage industry is the gentle and precise handling of delicate or shear-sensitive products, such as dairy, fruit purees, and sauces. For instance, the company’s Waukesha Sanitary Pumps are designed with crevice-free construction, electropolished surfaces, and easy-to-clean seal configurations, which minimize the risk of product contamination and facilitate efficient CIP processes. In addition, these pumps provide gentle fluid handling, ensuring that product quality and consistency are maintained throughout the production process.

Another essential application of Hayward Gordon’s pumps in the food and beverage industry is the accurate dosing and metering of ingredients and additives. The SmartFlex Peristaltic Pumps, with their exceptional metering capabilities and gentle pumping action, is well-suited for injecting flavors, colors, preservatives, and other ingredients into food and beverage products. These pumps ensure precise and consistent dosing, optimizing product quality and minimizing waste. Furthermore, the SmartFlex pumps’ easy-to-clean design and compatibility with a wide range of tubing materials make them ideal for hygienic food and beverage processing environments. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the food and beverage industry, Hayward Gordon continues to play a pivotal role in ensuring product safety, quality, and efficiency.

Cosmetic and Personal Care

Hayward Gordon has established itself as a reliable partner in the cosmetic and personal care industry by providing innovative pumping solutions designed to meet the unique requirements of this sector. The company’s range of pumps, such as Waukesha Sanitary Pumps and SmartFlex Peristaltic Pumps, are specifically engineered to comply with strict hygiene standards and to handle a wide variety of fluids, including viscous creams, gels, lotions, and emulsions. These pumps are widely used in cosmetic and personal care applications, such as ingredient transfer, product mixing, filling and packaging, and cleaning-in-place (CIP) processes, ensuring efficient and hygienic production while maintaining product quality and integrity.

One of the key applications of Hayward Gordon’s pumps in the cosmetic and personal care industry is the gentle and precise handling of delicate and shear-sensitive formulations. For instance, the company’s Waukesha Sanitary Pumps are designed with crevice-free construction, electropolished surfaces, and easy-to-clean seal configurations, which minimize the risk of product contamination and facilitate efficient CIP processes. Additionally, these pumps provide gentle fluid handling, ensuring that product quality, texture, and consistency are maintained throughout the production process without causing damage to sensitive ingredients or compromising product stability.

Another crucial application of Hayward Gordon’s pumps in the cosmetic and personal care industry is the accurate dosing and metering of ingredients, such as fragrances, preservatives, and active compounds. The SmartFlex Peristaltic Pumps, with their exceptional metering capabilities and gentle pumping action, is well-suited for injecting these ingredients into cosmetic and personal care products. These pumps ensure precise and consistent dosing, optimizing product quality and minimizing waste. Furthermore, the SmartFlex pumps’ easy-to-clean design and compatibility with a wide range of tubing materials make them ideal for use in hygienic cosmetic and personal care processing environments. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the cosmetic and personal care industry, Hayward Gordon continues to play a pivotal role in ensuring product safety, quality, and efficiency.

Pharmaceutical

Hayward Gordon is a trusted partner in the pharmaceutical industry, providing cutting-edge pumping solutions designed to meet the stringent requirements and challenges of this highly regulated sector. The company’s range of pumps, such as Waukesha Sanitary Pumps and SmartFlex Peristaltic Pumps, are specifically engineered to comply with rigorous hygiene standards, ensuring the safe and efficient processing and transfer of pharmaceutical products. These pumps are widely used in various pharmaceutical applications, including ingredient transfer, product mixing, sterile filling and packaging, and cleaning-in-place (CIP) processes, ensuring the highest levels of product safety, quality, and efficacy while maintaining compliance with regulatory standards.

One of the critical applications of Hayward Gordon’s pumps in the pharmaceutical industry is the gentle and precise handling of delicate and shear-sensitive formulations, such as vaccines, biopharmaceuticals, and cell cultures. For instance, the company’s Waukesha Sanitary Pumps are designed with crevice-free construction, electropolished surfaces, and easy-to-clean seal configurations, which minimize the risk of product contamination and facilitate efficient CIP and sterilization-in-place (SIP) processes. Additionally, these pumps provide gentle fluid handling, ensuring that product quality, potency, and consistency are maintained throughout the production process without causing damage to sensitive ingredients or compromising product stability.

Another essential application of Hayward Gordon’s pumps in the pharmaceutical industry is the accurate dosing and metering of ingredients, such as active pharmaceutical ingredients (APIs), excipients, and buffer solutions. The SmartFlex Peristaltic Pumps, with their exceptional metering capabilities and gentle pumping action, is well-suited for injecting these ingredients into pharmaceutical products. These pumps ensure precise and consistent dosing, optimizing product quality and minimizing waste while reducing the risk of cross-contamination between batches. Furthermore, the SmartFlex pumps’ easy-to-clean design and compatibility with a wide range of tubing materials make them ideal for use in sterile pharmaceutical processing environments. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the pharmaceutical industry, Hayward Gordon continues to play a pivotal role in ensuring product safety, quality, and compliance with regulatory requirements.

Agriculture

Hayward Gordon has been making a significant impact on the agriculture industry by providing efficient and reliable pumping solutions tailored to the specific needs of this sector. The company’s diverse range of pumps, including SmartFlex Peristaltic Pumps, Solids Handling Pumps, and Gear Pumps, are designed to handle various fluids and operating conditions, such as viscous slurries, corrosive chemicals, and fluctuating flow rates. These pumps are widely used in various agricultural applications, including irrigation, fertigation, manure management, and crop protection, ensuring increased productivity, reduced waste, and environmentally responsible farming practices.

One of the critical applications of Hayward Gordon’s pumps in the agriculture industry is the efficient and accurate delivery of water and nutrients to crops. For instance, the company’s SmartFlex Peristaltic Pumps are well-suited for precision fertigation, enabling the accurate dosing of fertilizers, nutrients, and other additives into irrigation systems. These pumps ensure consistent and precise dosing, optimizing crop yield and minimizing the environmental impact of nutrient runoff. Additionally, the gentle pumping action of SmartFlex Peristaltic Pumps preserves the integrity of sensitive components, such as biological and organic fertilizers, ensuring their effectiveness in promoting plant growth.

Another essential application of Hayward Gordon’s pumps in agriculture is managing manure and other waste byproducts. The company’s Solids Handling Pumps and Gear Pumps are designed to handle the challenges associated with pumping solid-laden fluids and viscous materials, making them ideal for manure transfer, storage, and land application processes. These pumps deliver robust performance, reduced maintenance costs, and enhanced durability, even under the most demanding conditions, contributing to farm waste’s efficient and sustainable management. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the agriculture industry, Hayward Gordon continues to play a vital role in promoting sustainable farming practices and enhancing overall agricultural productivity.

Chemical

Hayward Gordon has established itself as a reliable partner in the chemical industry by providing innovative and robust pumping solutions designed to meet this sector’s unique requirements and challenges. The company’s range of pumps, including ANSIMax Pumps, SmartFlex Peristaltic Pumps, and Gear Pumps, are specifically engineered to handle various fluids, including corrosive and abrasive chemicals, high-viscosity liquids, and volatile substances. These pumps are widely used in various chemical processing applications, such as chemical transfer, mixing and blending, chemical dosing, and solvent recovery, ensuring safe and efficient operations while maintaining product quality and environmental compliance.

One of the critical applications of Hayward Gordon’s pumps in the chemical industry is the efficient and accurate handling of corrosive and abrasive fluids. For example, the company’s ANSIMax Pumps are built to exceed the rigorous standards set by the American National Standards Institute (ANSI) for chemical process pumps. These pumps are designed with specialized materials and wear-resistant components, ensuring exceptional durability, corrosion resistance, and operational reliability even when handling aggressive chemicals. The ANSIMax Pumps are ideal for various chemical processing applications, including transferring and circulating acids, caustics, and other hazardous substances.

Another vital application of Hayward Gordon’s pumps in the chemical industry is the precise dosing and metering of chemicals and reagents. The SmartFlex Peristaltic Pumps, with their excellent metering capabilities and gentle pumping action, is well-suited for injecting additives, catalysts, and other ingredients into chemical processing systems. These pumps ensure accurate and consistent dosing, optimizing the effectiveness of chemical reactions and minimizing waste. Furthermore, the company’s Gear Pumps are commonly used to efficiently transfer viscous fluids, such as resins, polymers, and adhesives, in various chemical processing applications. Hayward Gordon continues to play a significant role in enhancing operational efficiency, safety, and environmental stewardship by offering a comprehensive range of pumping solutions specifically designed for the chemical industry.

General Industry

Hayward Gordon has been a trusted partner in the general industry by providing versatile and reliable pumping solutions catering to various applications and operational requirements. The company’s diverse range of pumps, including Process Pumping Solutions, Solids Handling Pumps, Vertical Pumps, and Gear Pumps, are designed to handle various fluids and operating conditions, such as high pressures, extreme temperatures, and abrasive or corrosive environments. These pumps are widely used in numerous general industry applications, including fluid transfer, mixing and blending cooling and heating, and wastewater management, ensuring efficient and cost-effective operations across different sectors.

One of the critical applications of Hayward Gordon’s pumps in the general industry is the efficient and accurate handling of various fluids across diverse processes. The company’s Process Pumping Solutions, for instance, are designed to meet the specific needs of different industries, ensuring optimal performance, durability, and ease of maintenance. These pumps are ideal for fluid transfer applications, such as the circulation of cooling and heating fluids, transfer of raw materials, and handling process liquids. With their robust design and versatile capabilities, Hayward Gordon’s process pumps help optimize productivity and reduce downtime in various industrial settings.

Another vital application of Hayward Gordon’s pumps in the general industry is the management of solid-laden fluids and slurries. The company’s Solids Handling Pumps and Vertical Pumps are specifically engineered to handle the challenges associated with pumping abrasive and viscous materials, making them ideal for slurry transfer, sump drainage, and wastewater management. These pumps deliver robust performance, reduced maintenance costs, and enhanced durability, even under the most demanding conditions, contributing to the efficient handling of challenging fluids in various industrial processes. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the general industry, Hayward Gordon continues to play a vital role in enhancing overall operational efficiency and productivity across various sectors.

Pulp and Paper

Hayward Gordon has established itself as a reliable partner in the pulp and paper industry by providing innovative and robust pumping solutions designed to meet this sector’s unique requirements and challenges. The company’s range of pumps, including Solids Handling Pumps, Vertical Pumps, and Gear Pumps, are specifically engineered to handle various fluids and operating conditions, such as high-consistency pulp, abrasive slurries, and corrosive chemicals. These pumps are widely used in various pulp and paper applications, including stock preparation, chemical recovery, pulp transfer, and wastewater management, ensuring efficient and cost-effective operations while maintaining product quality and environmental compliance.

One of the key applications of Hayward Gordon’s pumps in the pulp and paper industry is the efficient handling of high-consistency pulp and abrasive slurries. The company’s Solids Handling Pumps and Vertical Pumps are designed to manage the challenges associated with pumping these demanding fluids, making them ideal for pulp transfer, stock preparation, and sludge removal. These pumps deliver robust performance, reduced maintenance costs, and enhanced durability, even under the most demanding conditions. With their ability to handle high solids concentrations and abrasive materials, Hayward Gordon’s pumps contribute to the efficient and reliable operation of various pulp and paper processes.

Another important application of Hayward Gordon’s pumps in the pulp and paper industry is the management of chemical recovery and wastewater treatment processes. The company’s Gear Pumps, for example, are commonly used to efficiently transfer viscous fluids, such as black liquor and other chemical byproducts, in various chemical recovery applications. In addition, Hayward Gordon’s pumping solutions play a vital role in the treatment and disposal of wastewater generated during pulp and paper production, helping to minimize the industry’s environmental impact. By offering a comprehensive range of pumping solutions specifically tailored to the needs of the pulp and paper industry, Hayward Gordon continues to play a significant role in enhancing operational efficiency, product quality, and environmental stewardship.

About Hayward Gordon

Hayward Gordon is a leading global manufacturer of high-quality pumps, mixers, and engineered systems, firmly committed to delivering innovative and reliable solutions to a diverse range of industries. It built a solid reputation for engineering excellence, operational reliability, and outstanding customer service. With a vast portfolio of products, including Process Pumping Solutions, Solids Handling Pumps, Vertical Pumps, ANSIMax Pumps, SmartFlex Peristaltic Pumps, Sulfur Pumps, Gear Pumps, and Waukesha Sanitary Pumps, Hayward Gordon caters to various industrial sectors, such as water and wastewater, mining and mineral processing, oil and gas, food and beverage, cosmetic and personal care, pharmaceutical, agriculture, chemical, general industry, and pulp and paper.

At the core of Hayward Gordon’s success is its dedication to designing and manufacturing high-performance pumping and mixing solutions that meet and exceed the unique demands of its customers. The company invests heavily in research and development, leveraging cutting-edge technology and engineering expertise to create products that deliver optimal performance, efficiency, and durability. Through a collaborative approach with its clients, Hayward Gordon ensures that its solutions are tailored to meet the specific requirements of each application, resulting in increased productivity, reduced operational costs, and improved environmental stewardship.

Besides its extensive product offering, Hayward Gordon prides itself on providing exceptional customer support and aftermarket services. With a global network of sales representatives, service centers, and technical support teams, the company is well-equipped to offer comprehensive assistance, from project consultation and product selection to installation, commissioning, and maintenance. Hayward Gordon’s dedication to quality, innovation, and customer satisfaction has cemented its position as a trusted partner in the world of pumping and mixing solutions, continuously contributing to the success and growth of businesses across various industries.