Industries / Oil & Gas / Oil

Drive efficiency in oil operations with equipment

Optimize oil handling processes and equipment that ensures efficient pumping, precise compression, reliable energy conversion, and effective separation, resulting in enhanced oil production rates, reduced emissions, and improved overall efficiency. By achieving optimal processing conditions, oil operators can extract, transport, and refine crude oil more efficiently, meeting the global energy demand with minimal environmental impact.

The Manufacturing Process

Create economies of scale across your system

Each of these stages requires specific types of industrial rotating equipment. Proper operation and maintenance of this equipment are essential for the efficiency, safety, and profitability of the oil industry.

Exploration & Drilling

Rotary drills are used to bore holes into the earth to reach oil reservoirs. The drill uses a rotating drill bit to penetrate rock formations.

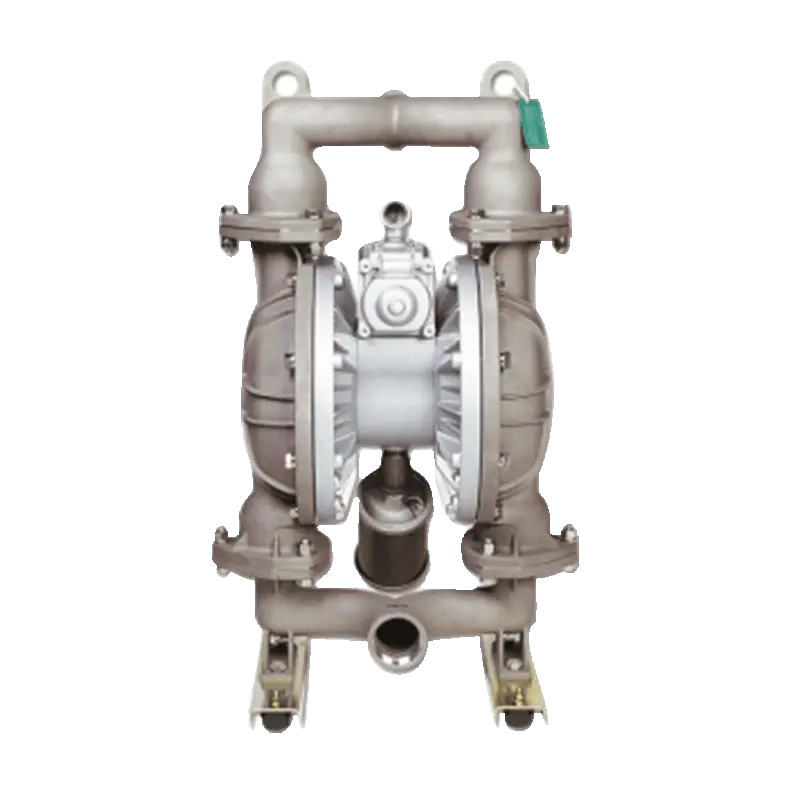

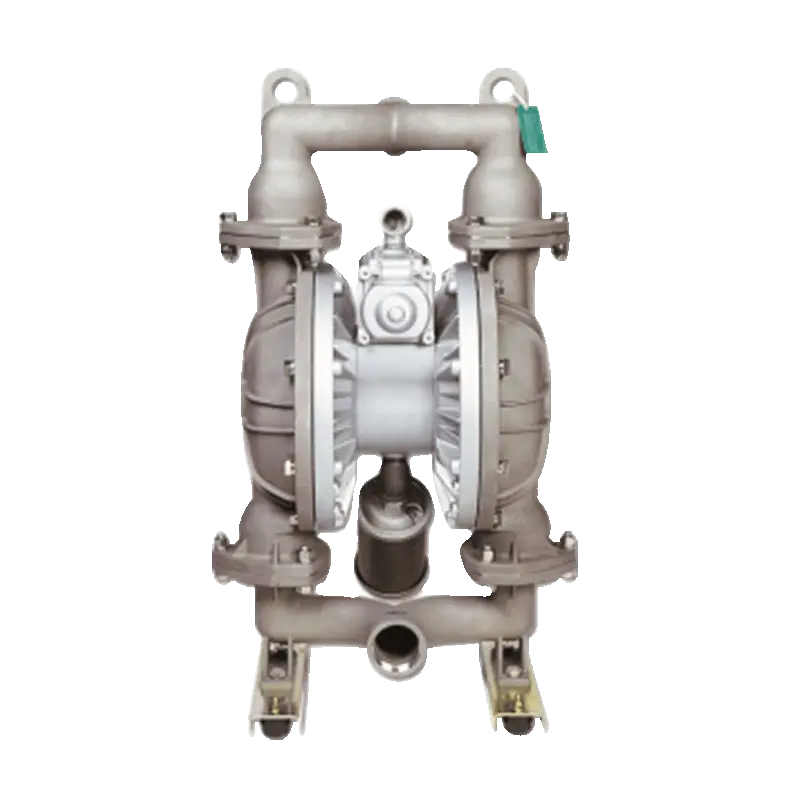

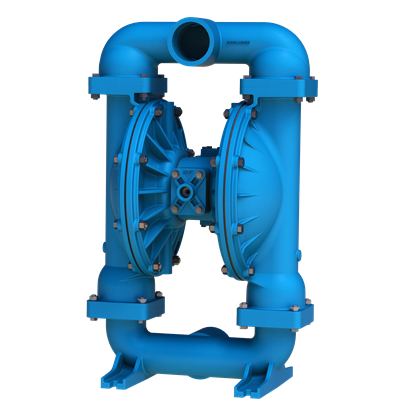

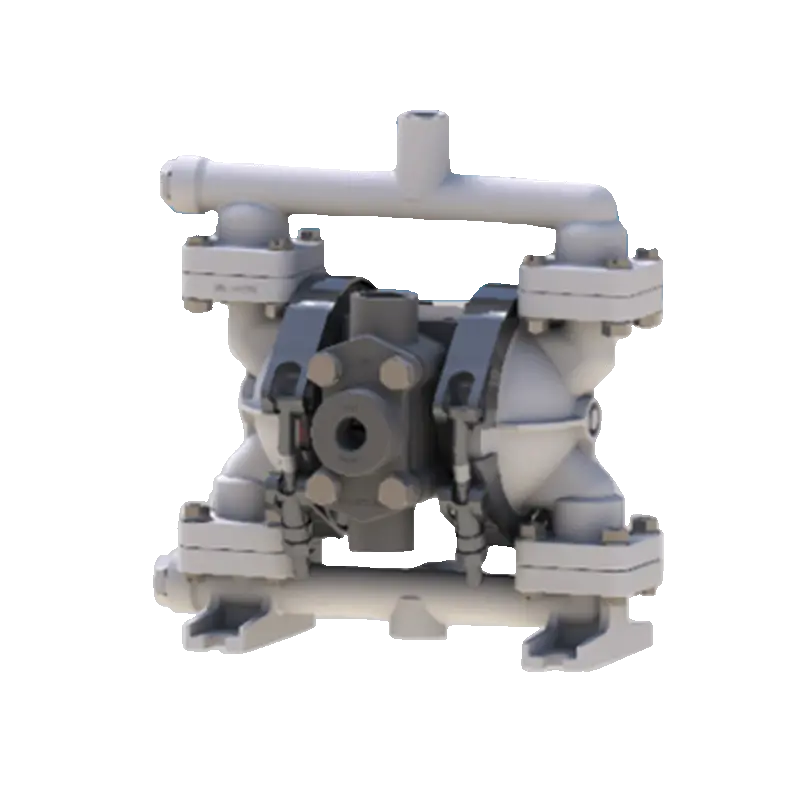

Oumping

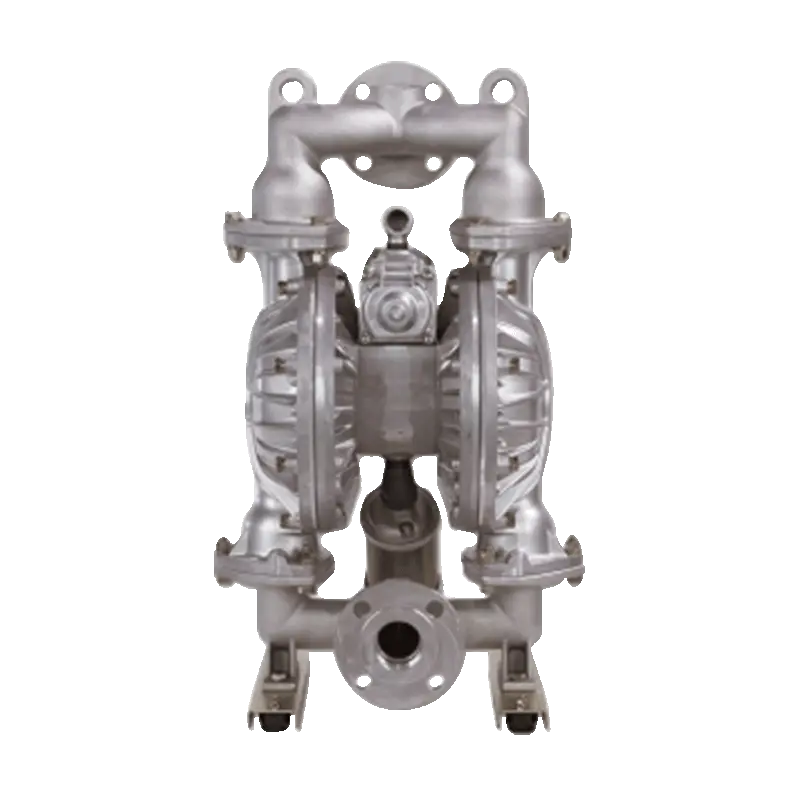

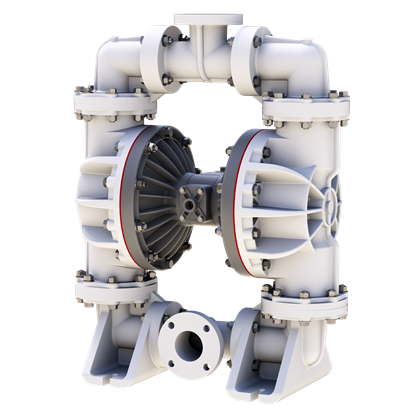

Various types of pumps, such as centrifugal pumps, positive displacement pumps, and specialized pumps like Electrical Submersible Pumps (ESPs) are used in the extraction of oil from the ground (oil lifting), for transporting fluids around the site, and in refining processes.

Oil Separation

Rotating equipment, such as centrifuges, are used to separate oil, water, and gas that come from the wellhead.

Gas Compression

Gas compressors, which use rotating parts, are used to increase the pressure of associated gas extracted during oil production. This allows the gas to be transported through pipelines for further processing or reinjected into wells to maintain reservoir pressure.

Power Generation

Gas turbines and diesel generators, which are types of rotating machinery, are often used to generate electricity for the operation of oil extraction and processing facilities.

Refining

A variety of rotating equipment is used in oil refining, such as pumps for moving fluids between units, compressors for increasing the pressure of gases, and various types of agitators for mixing in reactors.

Heat Exchanges

While not always involving rotation, heat exchangers often include rotating parts to enhance heat transfer efficiency in various processes within the oil sector.

Maintenance & Cleaning

Equipment like pressure washers and rotary brushes, which include rotating parts, can be used for cleaning and maintaining other oil industry equipment.

Artificial Lift Systems

Systems like Progressive Cavity Pumps (PCP), ESPs and Rod Lifts (also known as pump jacks) employ rotating equipment to lift oil from wells that do not have enough pressure for the oil to flow naturally.

Pipelines & Storage

Pumps and compressors play an essential role in transporting oil through pipelines to storage facilities and refineries, and then to end-users.