PumpWorks Equipment We Distribute

PumpWorks is a leading manufacturer and provider of various types of pumps and equipment, catering to a range of industries. Among its products, PumpWorks specializes in API 610 pumps, which are ideal for handling high-pressure and high-temperature fluids in demanding applications such as oil and gas refineries, petrochemical plants, and chemical processing facilities. Additionally, PumpWorks offers ANSI process/industrial pumps, which are highly reliable and efficient for various industrial applications. The HP Plus Centrifugal Pump is another popular product known for its energy efficiency and ease of maintenance. PumpWorks also provides remanufactured pumps restored to like-new condition, helping customers save money while ensuring optimal performance. PumpWorks’ pump packages are custom-designed for specific applications and are pre-assembled, reducing installation time and costs. Finally, the Predict-Plus small pump monitoring system helps customers track their pumps’ performance in real-time, enabling proactive maintenance and minimizing downtime.

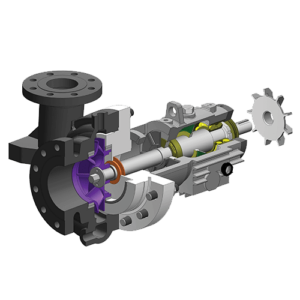

API 610 Pumps

PumpWorks’ API 610 pumps are some of the most reliable and robust pumps on the market, specifically designed to meet the demanding needs of the oil and gas industry. These pumps are designed and manufactured to API 610 standards, ensuring they meet the highest quality and performance requirements. PumpWorks offers a range of API 610 pumps, including OH2, OH3, BB1, BB2, BB3, and BB5 pumps, designed for various applications such as crude oil, refined products, and petrochemicals. These pumps suit many fluids, including high-temperature and high-pressure liquids.

One of the key features of PumpWorks’ API 610 pumps is their superior reliability. These pumps are engineered with advanced design features, such as heavy-duty casing and impeller construction, which enhance their resistance to wear and tear, ensuring long service life. These modular pumps allow easy maintenance and repair, minimize downtime, and reduce operating costs.

PumpWorks’ API 610 pumps are also highly efficient, offering superior energy performance, which helps reduce operational costs. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption. They are also designed to reduce vibration and noise, providing a more comfortable working environment. Overall, PumpWorks’ API 610 pumps offer exceptional reliability, performance, and energy efficiency, making them an ideal choice for oil and gas industry applications.

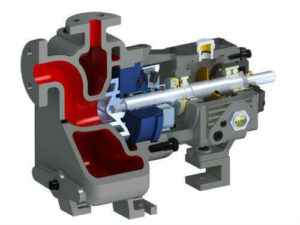

ANSI Process / Industrial Pumps

PumpWorks’ ANSI process/industrial pumps are highly reliable and efficient pumps that can handle various industrial applications. These pumps are designed and manufactured to meet ANSI B73.1 standards, ensuring they meet the highest quality and performance requirements. PumpWorks offers a range of ANSI process/industrial pumps, including horizontal, vertical, and self-priming pumps, designed for various applications such as chemical processing, wastewater treatment, and power generation.

One of the critical features of PumpWorks’ ANSI process/industrial pumps is their durability. These pumps are engineered with robust materials such as ductile iron, stainless steel, and high-nickel alloys, making them highly resistant to corrosion, erosion, and abrasion. Additionally, these pumps are designed with heavy-duty bearings, seals, and gaskets, which enhance their durability and reduce the risk of leaks or failures.

PumpWorks’ ANSI process/industrial pumps are also highly efficient, offering superior energy performance, which helps reduce operational costs. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption. They are also designed with easy-to-replace components, which helps reduce maintenance time and costs. Overall, PumpWorks’ ANSI process/industrial pumps offer exceptional durability, performance, and energy efficiency, making them an ideal choice for various industrial applications.

HP Plus Centrifugal Pump

PumpWorks’ HP Plus Centrifugal Pump is a highly efficient and reliable pump offering superior performance for various industrial applications. This pump is designed with advanced hydraulic technology, including an impeller with a unique suction booster, which increases suction pressure and reduces the risk of cavitation. Additionally, the HP Plus Centrifugal Pump is designed with a low NPSH requirement, allowing it to handle low-pressure and low-flow rate applications easily.

One of the key features of the HP Plus Centrifugal Pump is its energy efficiency. This pump’s advanced hydraulic design optimizes performance and minimizes energy consumption. Additionally, the HP Plus Centrifugal Pump has a back pull-out design, making it easy to access the impeller and other internal components for maintenance, reducing downtime and operating costs.

PumpWorks’ HP Plus Centrifugal Pump is also highly versatile. It offers a wide range of flow and head capabilities, making it suitable for various industrial applications such as chemical processing, water treatment, and HVAC systems. The pump is designed with various materials, including cast iron, ductile iron, and stainless steel, making it highly resistant to corrosion and wear. Overall, PumpWorks’ HP Plus Centrifugal Pump is a reliable, efficient, and versatile pump that offers exceptional performance and value for industrial applications.

Remanufactured Pumps

PumpWorks’ Remanufactured Pumps are restored to like-new condition, providing customers with an affordable and reliable alternative to purchasing new pumps. PumpWorks’ remanufacturing process includes thoroughly inspecting the pump and its components, followed by replacing worn or damaged parts. The pump is reassembled, tested, and painted to meet OEM specifications. PumpWorks’ remanufactured pumps are designed to deliver the same performance and reliability as new pumps at a fraction of the cost.

One of the critical benefits of PumpWorks’ Remanufactured Pumps is their reduced environmental impact. By restoring pumps to like-new condition, PumpWorks helps minimize the amount of waste generated by the pump industry. Additionally, remanufacturing pumps consume fewer resources than new pumps, making them a more sustainable option for customers.

PumpWorks’ Remanufactured Pumps are highly versatile and can be used in various industrial applications, including oil and gas, chemical processing, and water treatment. The remanufacturing process also provides an opportunity to upgrade the pump with the latest technology, enhancing its performance and efficiency. Overall, PumpWorks’ Remanufactured Pumps provide customers with a cost-effective and sustainable solution for their pump needs while delivering the same performance and reliability as new pumps.

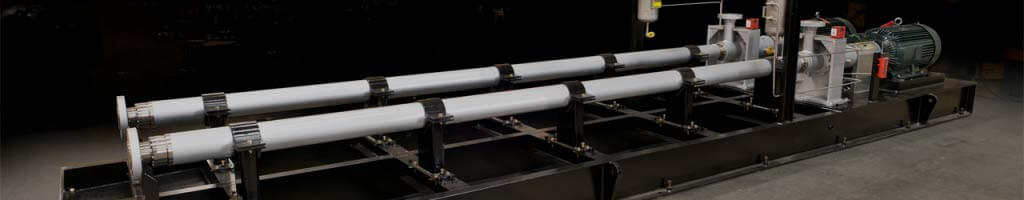

Pump Packages

PumpWorks’ Pump Packages are custom-designed pump systems pre-assembled and tested before shipment, reducing installation time and customer costs. These pump packages are designed to meet customers’ specific needs, incorporating a range of pumps, valves, motors, and controls. PumpWorks’ pump packages can be designed for various applications, including chemical processing, water treatment, and power generation.

One of the critical benefits of PumpWorks’ Pump Packages is their ease of installation. The pre-assembled pump package eliminates the need for on-site assembly, reducing installation time and costs. The pump package is also designed with all necessary components, including piping, electrical wiring, and controls, simplifying installation and commissioning.

PumpWorks’ Pump Packages are highly reliable and efficient, incorporating advanced hydraulic designs and energy-efficient components. These pump packages are designed to optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ pump packages are designed with advanced monitoring and control systems, allowing for remote monitoring and control of the pump system, ensuring optimal performance and reducing downtime.

Overall, PumpWorks’ Pump Packages provide customers with a turnkey solution for their pump needs, delivering reliable and efficient pump systems that are easy to install and maintain. These pump packages are designed to meet customers’ specific needs, incorporating the latest technology and components, ensuring optimal performance and efficiency.

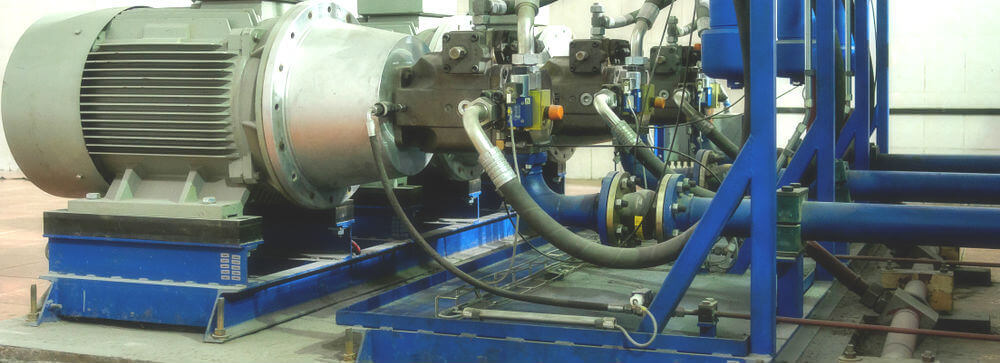

Predict-Plus – Remote Pump Monitoring System

PumpWorks’ Predict-Plus – Remote Pump Monitoring System is an advanced remote monitoring and predictive maintenance system that helps customers track their pumps’ real-time performance. This system includes advanced sensors and analytics that collect data on the pump’s performance, such as flow rate, pressure, and temperature. This data is then analyzed using advanced algorithms that give customers insights into their pumps’ performance and potential issues before they become critical.

One of the significant benefits of PumpWorks’ Predict-Plus system is its ability to reduce downtime and maintenance costs. Predict-Plus helps customers identify potential issues before they escalate by monitoring the pump’s performance in real time, allowing for proactive maintenance and repair. Moreover, Predict-Plus provides customers with detailed reports and analytics on their pumps’ performance, allowing them to optimize their system’s efficiency and reduce energy consumption.

PumpWorks’ Predict-Plus system is highly customizable, allowing customers to monitor multiple pumps and systems simultaneously from a single dashboard. The system can integrate with existing control systems and software, providing seamless integration and control. Moreover, Predict-Plus is user-friendly, with an intuitive interface and easy-to-understand reports, making it accessible to customers with varying technical expertise.

In conclusion, PumpWorks’ Predict-Plus – Remote Pump Monitoring System is an exceptional tool for optimizing the performance and efficiency of pump systems. This system provides real-time monitoring and predictive maintenance, reduces downtime and maintenance costs, and provides valuable insights into the pumps’ performance. With its customizable features and user-friendly interface, Predict-Plus is a powerful solution for customers looking to optimize their pump systems’ performance and efficiency.

Applications of Pump Works Equipment

PumpWorks equipment has wide-ranging applications across multiple industries, including oil and gas, power generation, chemical processing, and general industrial industries. Their pumps and equipment are renowned for their durability, reliability, and efficiency, making them ideal for handling demanding applications in these industries. PumpWorks’ API 610 pumps are designed specifically for the oil and gas industry, where they are used for high-pressure and high-temperature fluid handling. PumpWorks’ pumps are used for cooling, fuel oil, and condensate handling applications in the power generation industry. Additionally, PumpWorks’ pumps and equipment are used in chemical processing, where they are ideal for handling corrosive and hazardous fluids. The company’s ANSI process/industrial pumps and HP Plus Centrifugal Pumps are also used in various general industrial applications, delivering exceptional performance and efficiency. Overall, PumpWorks equipment offers reliable and efficient solutions that meet customers’ specific needs in various industries.

Oil and Gas

PumpWorks equipment plays a vital role in the oil and gas industry, providing reliable and efficient solutions for a range of applications. Upstream oil and gas pumps are used in drilling and extraction operations, where they handle various fluids such as crude oil, natural gas, and drilling mud. PumpWorks’ API 610 pumps are ideal for these applications, providing high-pressure and high-temperature fluid handling capabilities. Additionally, PumpWorks’ pumps are designed to withstand the harsh conditions in these operations, including extreme temperatures, high pressures, and corrosive fluids.

Midstream oil and gas pumps transport fluids such as crude oil, refined products, and natural gas. PumpWorks’ pumps and equipment are designed for these applications, providing reliable and efficient fluid transportation capabilities. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ pumps are designed to handle varying fluid viscosities, allowing them to handle a wide range of fluids.

Downstream oil and gas pumps are used in refineries and chemical processing plants, which handle various fluids such as fuels, lubricants, and petrochemicals. PumpWorks’ pumps and equipment are ideal for these applications, providing reliable and efficient fluid handling capabilities. These pumps are designed to handle corrosive and hazardous fluids, ensuring optimal performance and durability. Additionally, PumpWorks’ ANSI process/industrial pumps are highly reliable and efficient, making them an ideal choice for downstream oil and gas applications. Overall, PumpWorks equipment is crucial in the oil and gas industry, providing reliable and efficient solutions for upstream, midstream, and downstream operations.

Power Generation

PumpWorks equipment is also used in the power generation industry, providing reliable and efficient solutions for a range of applications. API pumps are commonly used in power generation for cooling, fuel oil, and condensate handling applications. PumpWorks’ API pumps are designed to meet the specific needs of power generation applications, delivering exceptional performance and efficiency. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ API pumps are engineered to handle high temperatures and pressures, making them ideal for power generation applications.

In power generation, cooling water pumps are critical components for maintaining the temperature of the power generation equipment. PumpWorks’ cooling water pumps are designed to handle high flow rates and temperatures, providing reliable and efficient cooling capabilities for power generation equipment. Additionally, PumpWorks’ cooling water pumps are designed with corrosion-resistant materials, ensuring optimal performance and durability.

Fuel oil pumps are also critical components in power generation, providing the necessary fuel for power generation equipment. PumpWorks’ fuel oil pumps are designed to handle various fuel types, including heavy fuel oil, diesel, and gas. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ fuel oil pumps are engineered to handle high pressures and temperatures, ensuring optimal performance and reliability. Overall, PumpWorks equipment provides reliable and efficient solutions for the power generation industry, ensuring optimal performance and efficiency for critical power generation equipment.

Chemical Processing

PumpWorks equipment plays a crucial role in the chemical processing industry, providing reliable and efficient solutions for a range of applications. Basic chemicals such as acids, alkalis, and solvents are commonly used in chemical processing, and PumpWorks’ ANSI process/industrial pumps are ideal for handling these chemicals. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ ANSI pumps are engineered to handle corrosive fluids, ensuring optimal performance and durability.

Specialty chemicals, such as high-performance materials and coatings, are also used in chemical processing. PumpWorks’ pumps and equipment are designed to handle specialty chemicals, providing reliable and efficient fluid handling capabilities. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. PumpWorks’ pumps are also engineered to handle high pressures and temperatures, making them ideal for specialty chemical applications.

Pharmaceuticals and biofuels are other applications in the chemical processing industry where PumpWorks’ equipment is used. PumpWorks’ pumps and equipment in pharmaceuticals are designed to handle various chemicals and solvents, ensuring optimal performance and reliability. Additionally, PumpWorks’ equipment is designed to meet the specific needs of biofuel production, providing reliable and efficient solutions for handling various feedstocks and fuels. Overall, PumpWorks equipment provides reliable and efficient solutions for chemical processing applications, ensuring optimal performance and efficiency for critical chemical processing equipment.

General Industry

PumpWorks equipment has a wide range of applications in the general industry, providing reliable and efficient solutions for various applications. The ANSI process/industrial pumps are ideal for general industrial applications, including water treatment, HVAC, and manufacturing processes. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ pumps are engineered to handle varying fluid viscosities, making them suitable for handling a wide range of fluids in general industrial applications.

PumpWorks’ HP Plus Centrifugal Pumps are also used in general industrial applications, providing reliable and efficient solutions for fluid handling. These pumps have advanced hydraulic designs that optimize performance and minimize energy consumption, reducing customer operational costs. Additionally, PumpWorks’ HP Plus Centrifugal Pumps are engineered to handle high pressures and temperatures, making them ideal for general industrial applications requiring high-performance pumps.

PumpWorks’ remote monitoring system, Predict-Plus, is another ideal solution for the general industry. This system provides real-time monitoring and predictive maintenance, helping customers reduce downtime and maintenance costs. Additionally, Predict-Plus provides detailed analytics and reports on the pump’s performance, allowing customers to optimize their pump system’s efficiency and reduce energy consumption. Overall, PumpWorks equipment provides reliable and efficient solutions for the general industry, ensuring optimal performance and efficiency for various industrial applications.

Factors to Consider When Buying PumpWorks

Choosing the right pump and related equipment is crucial for many professionals, such as engineers, facility managers, and maintenance supervisors. Our expert team generally considers these items before recommending PumpWorks equipment:

Application and Industry

Each industry has unique needs and requirements, and choosing a pump suitable for the specific application is essential. For example, a chemical or slurry pump will be required if the pump is needed for transferring corrosive or abrasive fluids. Similarly, a submersible pump may be the best choice if the pump is to be used for wastewater treatment.

Pump Type

PumpWorks offers a variety of pumps, including centrifugal pumps, ANSI pumps, and API pumps, each with unique features and benefits. Centrifugal pumps are ideal for low-viscosity fluids, ANSI pumps are suitable for moderate-viscosity fluids, and API pumps are best for high-pressure applications. It is vital to select the correct type of pump that will deliver the required flow rate and pressure for the application.

Pump Material

Another key consideration is the pump material. The pump material is critical because it determines its ability to withstand the corrosive and abrasive nature of the pumped fluid. PumpWorks offers pumps made from various materials, such as stainless steel, cast iron, and high-strength alloys. The material chosen should be compatible with the fluid being pumped and the application’s operating conditions.

Pump Size and Capacity

The pump size and capacity are also essential considerations. The pump’s size should be chosen based on the amount of fluid that needs to be pumped and the head pressure required. The pump capacity and the amount of fluid the pump can handle should also be considered. PumpWorks offers pumps with various capacities and sizes, so it is essential to select the right size and capacity for the specific application.

Operating Conditions

The application’s operating conditions are also a critical factor to consider when choosing a pump. These conditions can include the temperature, pressure, viscosity of the fluid being pumped, as well as the environmental conditions of the application, such as humidity, dust, and vibration. The pump selected should be able to operate safely and efficiently under specific operating conditions.

Pump Features

PumpWorks pumps have various features, such as self-priming capabilities, variable speed drives, and corrosion-resistant coatings. These features can enhance the pump’s performance and extend its lifespan, so choosing a pump with features that meet the application requirements is essential.

About PumpWorks

PumpWorks is a leading manufacturer and provider of pumps and equipment for various industries. It established a reputation for delivering high-quality, reliable, and efficient pump solutions that meet customers’ needs.

PumpWorks offers a wide range of pump products, including API 610 pumps, ANSI process/industrial pumps, HP Plus Centrifugal Pumps, and remanufactured pumps. These pumps are designed and manufactured to the highest standards, ensuring optimal performance and durability. Moreover, PumpWorks’ pump packages and remote monitoring systems, such as Predict-Plus, provide customers with turnkey solutions that help optimize the performance and efficiency of their pump systems.

PumpWorks has an experienced team of engineers and technicians who work closely with customers to understand their needs and develop custom solutions that meet their requirements. The company’s state-of-the-art manufacturing facility in Houston, Texas, uses advanced technology and equipment to produce high-quality pump products and equipment.

PumpWorks’ commitment to quality, reliability, and customer satisfaction has earned it a loyal customer base across various industries, including oil and gas, chemical processing, water treatment, and power generation. The company’s pumps and equipment are renowned for their durability, performance, and efficiency, helping customers reduce downtime, maintenance costs, and energy consumption.

In conclusion, PumpWorks is a leading provider of pumps and equipment, offering a wide range of pump products and solutions for various industries. With its commitment to quality, reliability, and customer satisfaction, PumpWorks has established a reputation for delivering exceptional pump solutions that meet most needs.