Introduction, Types of Equipment, Industries, and Applications

Sandpiper pumps are known for their reliability, versatility, and efficiency in various industrial applications. The company is a part of Warren Rupp, a global manufacturer of pumping solutions. In this article, we will introduce Sandpiper pumps and explore the types of equipment they make, the industries they are used in, and their applications.

Affliation with Warren Rupp, Inc.

Warren Rupp, a global manufacturer of pumping solutions, is the parent company of Sandpiper pumps. Warren Rupp was founded in 1965 and is headquartered in Mansfield, Ohio, USA. Sandpiper pumps were acquired by Warren Rupp in 2001 and have since become one of their most successful product lines.

The affiliation between Warren Rupp and Sandpiper pumps has resulted in a significant expansion of Sandpiper’s product offerings, as well as increased global reach and distribution capabilities. Sandpiper pumps benefit from Warren Rupp’s expertise in the pump industry, including engineering, manufacturing, and customer support.

Warren Rupp’s parent company, IDEX Corporation, is a diversified global manufacturing company that specializes in fluid handling, health and science technologies, and fire and safety products. IDEX’s expertise and resources have also contributed to the growth and success of Sandpiper pumps.

As a part of Warren Rupp, Sandpiper pumps benefit from a strong focus on innovation, reliability, and customer service. Warren Rupp’s engineering team has worked to improve the design of Sandpiper pumps, resulting in enhanced performance and efficiency. The company also offers exceptional customer support, including technical assistance, training, and spare parts availability.

Types of Equipment

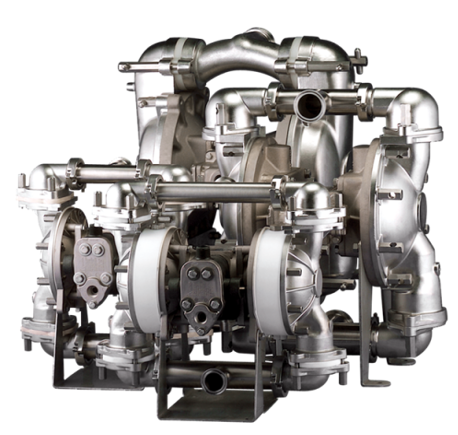

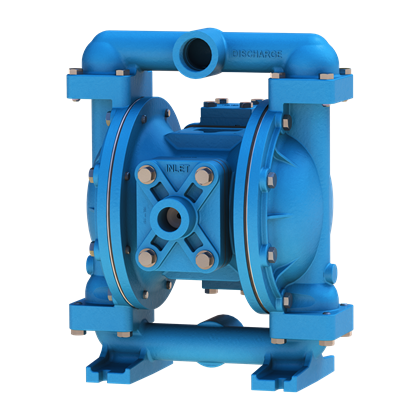

Sandpiper pumps offer a wide range of equipment, including air-operated diaphragm pumps (AODD), specialty pumps, and accessories. AODD pumps are their most popular product and come in a variety of sizes and materials to suit different applications. Specialty pumps include double diaphragm pumps, high-pressure pumps, and centrifugal pumps. Accessories include pump controllers, hoses, and fittings.

Air-Operated Diaphragm Pumps (AODD)

Air-operated diaphragm pumps (AODD) are Sandpiper’s most popular product line. These pumps are driven by compressed air and use a reciprocating motion to move fluid through the pump. AODD pumps are available in different sizes and materials to suit various applications. They are versatile and can handle a wide range of fluids, from water to highly viscous liquids.

Specialty Pumps

Sandpiper pumps also offer specialty pumps for more specific applications. These pumps include:

Double Diaphragm Pumps: These pumps have two diaphragms and can handle highly viscous fluids and abrasive materials.

High-Pressure Pumps: These pumps are designed for applications that require high pressure, such as in the oil and gas industry.

Centrifugal Pumps: These pumps use centrifugal force to move fluids and are suitable for high flow rate applications.

Accessories

Sandpiper pumps also offer a range of accessories that complement their pumping solutions. These accessories include:

Pump Controllers: These devices help to control the pump’s operation, including starting and stopping the pump, monitoring the pump’s performance, and adjusting the pump’s speed.

Hoses: Sandpiper pumps offer a wide range of hoses to suit different applications. These hoses are made from various materials, including rubber and PVC.

Fittings: These components connect the pump to the piping system and ensure a secure and leak-proof connection.

Applications

Sandpiper pumps’ equipment is used in a variety of industries, including chemicals, oil and gas, water and wastewater, and food and beverage. Their products are designed to handle a wide range of fluids and meet the specific needs of various applications.

Chemical Processing

Sandpiper pumps are used for transferring chemicals, acids, and alkalis in the chemical processing industry. AODD pumps are commonly used in this industry due to their ability to handle corrosive and abrasive fluids.

Water and Wastewater

Sandpiper pumps are used for transferring and treating water and wastewater in the water and wastewater industry. AODD pumps are ideal for this industry due to their ability to handle solids and slurries.

Oil and Gas

Sandpiper pumps are used for oil and gas production, refining, and processing. They are used for transferring fluids, handling abrasive slurries, and metering chemicals. The oil and gas industry requires pumps that can handle harsh and corrosive environments, and Sandpiper pumps are designed to meet these needs.

Mining

Sandpiper pumps are used for handling abrasive slurries, transferring fluids, and dewatering in the mining industry. The mining industry requires pumps that can handle high solids and abrasive materials, and Sandpiper pumps are known for their ability to perform in these conditions.

Food and Beverage

Sandpiper pumps are used for transferring fluids, mixing and blending liquids, and processing food and beverage products in the food and beverage industry. Sandpiper pumps offer sanitary pump solutions for food and beverage applications, ensuring safe and hygienic processes.

Other Applications

Sandpiper pumps are used in many other industries and applications, including agriculture, pharmaceuticals, construction, and general industrial processes. Sandpiper pumps are versatile and can handle various fluids, making them suitable for a wide range of applications.

Factors to Consider When Buying Sandpiper Equipment

When considering purchasing equipment from Sandpiper pumps, there are several factors that professionals should consider. These factors will help ensure that the equipment they choose meets their needs and will provide reliable and efficient performance for their application. Here are some key factors to consider:

Application Requirements

The first consideration is the application requirements. The type of fluid being pumped, the flow rate, and the pressure needed are all factors that should be considered. Sandpiper pumps offer a wide range of pumping solutions that cater to various applications, so it is important to choose the right pump for the specific application.

Material Compatibility

The next consideration is material compatibility. The pump’s materials must be compatible with the fluid being pumped to ensure proper performance and longevity. Sandpiper pumps offer a variety of materials, including metals, plastics, and elastomers, to suit different applications and fluids.

Environmental Conditions

The environmental conditions in which the pump will operate is another consideration. Factors such as temperature, humidity, and the presence of corrosive or abrasive materials can affect the performance and lifespan of the pump. Sandpiper pumps are designed to handle harsh environments, but it is still important to consider the specific conditions and choose a pump that is suitable.

Maintenance and Service

Maintenance and service requirements are also important considerations. Sandpiper pumps are known for their reliability, but regular maintenance is still necessary to ensure optimal performance and longevity. It is important to consider the ease of maintenance and the availability of spare parts when choosing a pump.

Cost and Return on Investment

Finally, the cost of the equipment and the return on investment (ROI) should be considered. Sandpiper pumps offer a range of pumping solutions at different price points, so it is important to choose a pump that fits within the budget. Additionally, the ROI of the pump should be considered, taking into account factors such as energy efficiency and maintenance costs.

In conclusion, when considering purchasing equipment from Sandpiper pumps, it is important to consider the application requirements, material compatibility, environmental conditions, maintenance and service requirements, and cost and ROI. By taking these factors into account, professionals can choose a pump that meets their needs and provides reliable and efficient performance for their application.