Sulzer Equipment We Distribute

Sulzer is a leading manufacturer of a wide range of equipment used in various industries. Their product portfolio includes agitators, mixers, and heat exchangers that are used for mixing and heat transfer applications. Sulzer also produces compressors and aeration equipment that are used for gas compression and air/oxygen transfer applications. In addition, they offer process plants that are designed to handle complex chemical and industrial processes. Sulzer’s pumps are known for their reliability and efficiency, and they offer a range of control and monitoring equipment to optimize the performance of their products. Their lifting stations are used to move fluids and solids in various industrial applications. Sulzer also provides separation technology solutions, including centrifuges and decanters, as well as screening, sedimentation, and filtration solutions that are used in the wastewater treatment and water purification industries.

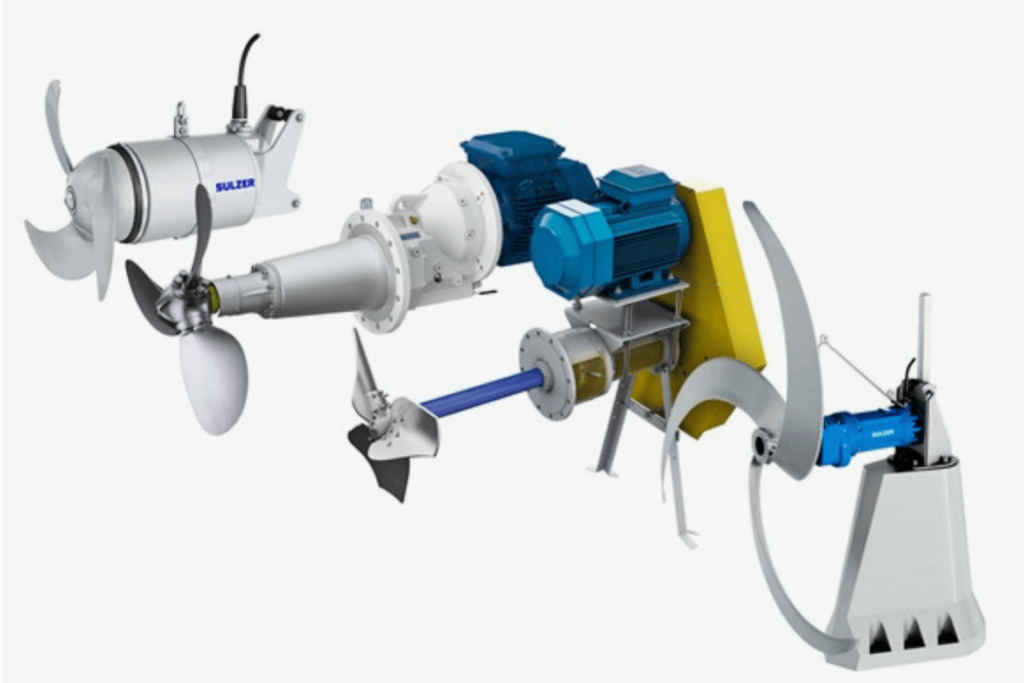

Agitators, mixers and heat exchangers

Sulzer is a leading manufacturer of agitators, mixers, and heat exchangers that are used in various industries such as chemical processing, pharmaceutical, and food and beverage. Sulzer’s agitators are designed to provide efficient mixing of liquids and solids in a variety of applications. They offer agitators for both high-viscosity and low-viscosity fluids, as well as agitators for solid-liquid mixing. Their agitators are highly customizable and can be designed to meet specific customer requirements.

Sulzer’s dynamic mixers are designed to provide efficient mixing of liquids in various applications. They use impellers that rotate in the liquid to provide mixing action. Sulzer offers a range of dynamic mixers including axial flow, radial flow, and mixed flow impellers. Their dynamic mixers can be designed for both low-viscosity and high-viscosity fluids and can be used for blending, solid suspension, and gas-liquid dispersion.

Sulzer’s static mixers are designed to provide mixing of fluids without any moving parts. They are highly efficient and require no external energy source for mixing. Sulzer offers a range of static mixers including helical mixers, Kenics mixers, and SMX mixers. Their static mixers are highly customizable and can be designed to meet specific customer requirements. They can be used for blending, gas-liquid dispersion, and emulsification in a variety of applications.

Compressors and aeration

Sulzer is a leading manufacturer of compressors and aeration equipment that are used in various industries such as wastewater treatment, food and beverage, and pharmaceuticals. Their HST™ turbocompressor is a highly efficient, oil-free compressor that uses magnetic bearings and a permanent magnet motor. It is designed for a wide range of applications, including wastewater treatment, pneumatic conveying, and gas recovery. Sulzer’s HSR turbocompressor is another highly efficient compressor that is designed for low-pressure applications. It uses a radial impeller design and can be used in a range of applications, including wastewater treatment and aeration.

Sulzer’s OKI aerator mixer is a highly efficient, low-speed aerator that is designed for use in wastewater treatment plants. It uses a unique impeller design that provides high oxygen transfer rates and low energy consumption. Sulzer’s submersible aerator type ABS XTA XTAK is another highly efficient aerator that is designed for use in a range of applications, including wastewater treatment and aquaculture. It uses a unique impeller design that provides high oxygen transfer rates and low energy consumption.

Sulzer’s aerator type ABS Venturi jet is a highly efficient aerator that is designed for use in wastewater treatment plants. It uses a Venturi nozzle to entrain air into the liquid, providing high oxygen transfer rates and low energy consumption. Sulzer’s disc diffuser system type ABS is a highly efficient, low-maintenance diffuser system that is designed for use in wastewater treatment plants. It uses a unique disc diffuser design that provides high oxygen transfer rates and low energy consumption.

Process plants

Sulzer is a leading manufacturer of process plants that are used in various industries such as chemical processing, pharmaceutical, and food and beverage. Their complete process plants are designed to handle complex chemical and industrial processes from start to finish. They offer turnkey solutions that include engineering, procurement, construction, and commissioning. Sulzer’s process plants are highly customizable and can be designed to meet specific customer requirements.

Sulzer’s distillation and absorption technology is used to separate and purify chemicals in a variety of applications. They offer a range of distillation and absorption columns, as well as related equipment such as heat exchangers and pumps. Their evaporation technology is used to concentrate and purify liquids in a range of applications, including food and beverage and pharmaceuticals. Sulzer offers a range of evaporation systems, including falling film, rising film, and forced circulation systems.

Sulzer’s hybrid processes combine different technologies to create unique solutions for specific customer requirements. They offer a range of hybrid processes, including distillation-membrane hybrid processes and crystallization-drying hybrid processes. Sulzer’s liquid-liquid extraction technology is used to separate and purify chemicals in a variety of applications. They offer a range of liquid-liquid extraction systems, including mixer-settler and centrifugal extractors. Sulzer’s process and application development services are used to optimize existing processes and develop new processes for specific customer requirements. They offer a range of services, including process simulation and optimization, pilot plant testing, and product development.

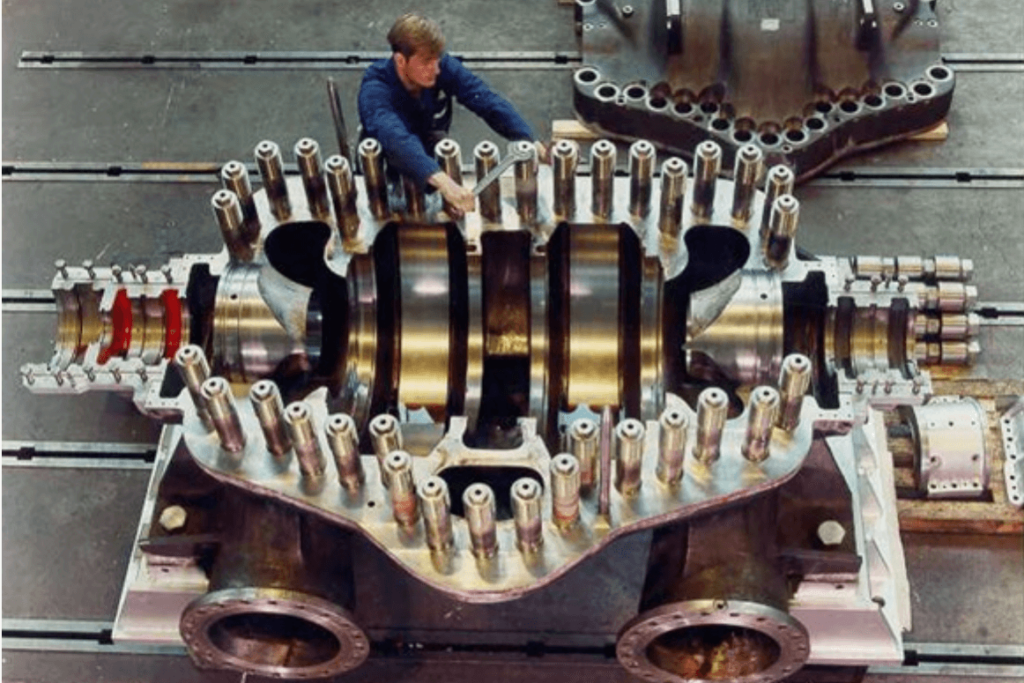

Pumps

Sulzer is a leading manufacturer of pumps that are used in various industries such as water treatment, oil and gas, and power generation. Their product portfolio includes a wide range of pump types to meet different customer requirements. Sulzer’s axial flow pumps are designed for low-head applications and offer high flow rates with low power consumption. They are commonly used in water treatment, irrigation, and flood control applications. Their axially split pumps are designed for high-pressure applications and offer high efficiency and reliability. They are commonly used in oil and gas, chemical processing, and power generation applications.

Sulzer’s dewatering pumps are designed for pumping water from construction sites, mines, and quarries. They offer high flow rates and are designed to handle solids and debris. Their firewater pumps are designed to provide reliable and efficient performance in fire protection systems. Sulzer’s multiphase pumps are designed to pump a mixture of oil, gas, and water in oil and gas production applications. They offer high efficiency and reliability and can handle high gas-to-liquid ratios. Their progressing cavity pumps are designed for pumping viscous and abrasive fluids in a range of applications, including food and beverage and chemical processing.

Sulzer’s radial split pumps are designed for high flow rate and high-pressure applications. They offer high efficiency and reliability and can handle corrosive and abrasive fluids. Their ring section pumps are designed for high-pressure applications and offer high efficiency and reliability. They are commonly used in power generation, water treatment, and oil and gas applications. Sulzer’s single-stage pumps are designed for a wide range of applications, including water supply, irrigation, and industrial processes. Their slurry pumps are designed for pumping abrasive and corrosive fluids in a range of applications, including mining and mineral processing. Sulzer’s submersible pumps are designed for pumping water and other fluids in submerged applications, such as wastewater treatment and oil and gas production. Their vacuum pumps are designed for pumping gases and vapors in a range of applications, including chemical processing and food and beverage. Sulzer’s vertical pumps are designed for pumping liquids from deep wells or sumps, and their lube oil systems are designed to provide lubrication and cooling to rotating equipment such as turbines and compressors.

Control and monitoring equipment

Sulzer offers a range of control and monitoring equipment to optimize the performance of their products. Their control and monitoring software solutions are designed to monitor and control various equipment, including pumps and compressors, and provide data analysis and reporting. Sulzer’s software solutions enable remote monitoring and control, reducing the need for on-site personnel and increasing efficiency.

Sulzer’s measuring devices are used to measure various parameters such as flow rate, pressure, and temperature. They offer a range of measuring devices, including flow meters, pressure gauges, and temperature sensors. Their measuring devices are highly accurate and reliable and can be used in a range of applications.

Sulzer’s pump control panels and pump controllers are designed to provide automatic control and monitoring of pumps. They offer a range of control panels and controllers, including variable frequency drives, soft starters, and pump protection devices. Their pump control panels and controllers are highly customizable and can be designed to meet specific customer requirements. They enable efficient and reliable operation of pumps, reducing downtime and maintenance costs.

Sulzer’s pump monitoring and control accessories are designed to enhance the performance and reliability of their pumps. They offer a range of accessories, including vibration sensors, bearing temperature sensors, and condition monitoring systems. Their accessories enable early detection of potential problems, allowing for timely maintenance and reducing the risk of pump failure. Sulzer’s control and monitoring equipment is designed to optimize the performance and reliability of its products, reducing downtime and maintenance costs, and increasing efficiency.

Lifting stations

Sulzer offers a range of lifting stations that are used to move fluids and solids in various industrial and municipal applications. Their lifting stations are designed to handle different types of wastewater, including toilet wastewater, and are customizable to meet specific customer requirements.

Sulzer’s lifting stations for toilet wastewater are designed to handle the collection and transportation of wastewater from toilets, showers, and sinks in residential and commercial buildings. They are equipped with grinders that can shred solids and prevent the clogging of pipes and pumps. Sulzer’s lifting stations for toilet wastewater are highly efficient and reliable and can be customized to meet specific customer requirements.

Sulzer’s lifting stations without toilet wastewater are designed for the collection and transportation of wastewater from industrial and municipal applications, such as stormwater, surface water, and sewage. They are equipped with pumps that can handle fluids with different viscosities and solid content. Sulzer’s lifting stations without toilet wastewater are highly efficient and reliable and can be customized to meet specific customer requirements.

Sulzer’s lifting stations are designed to meet the highest quality and safety standards. They are equipped with alarms and sensors that can detect malfunctions and prevent overflows. Sulzer’s lifting stations are also designed to be easy to install and maintain, reducing downtime and maintenance costs. Overall, Sulzer’s lifting stations are a reliable and efficient solution for the transportation of fluids and solids in various industrial and municipal applications.

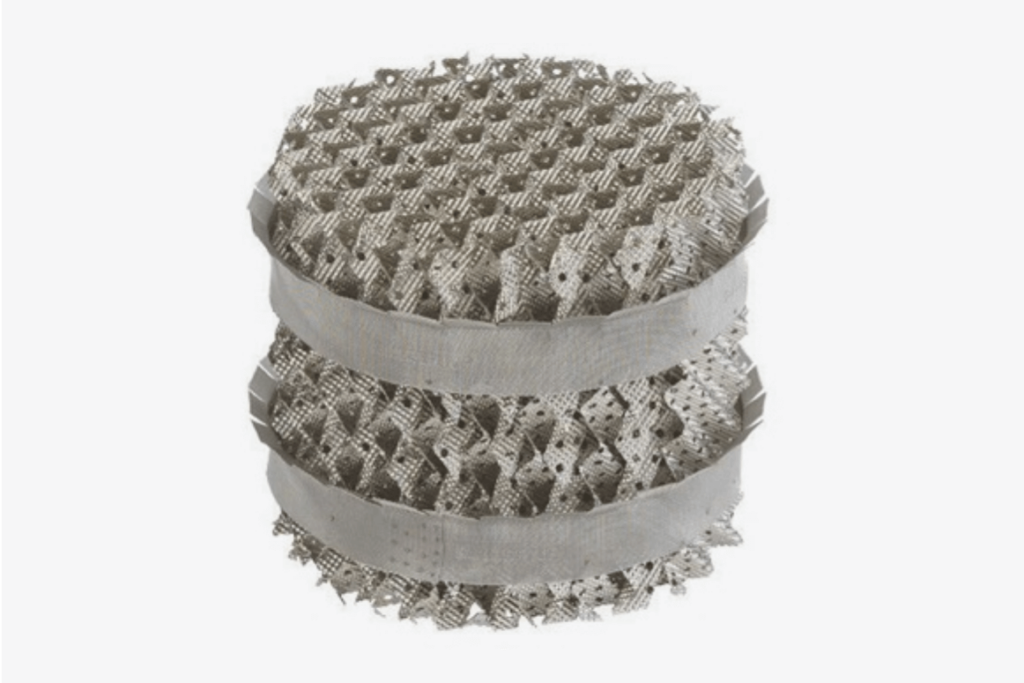

Separation Technology

Sulzer offers a range of separation technology solutions that are used in various industries such as chemical processing, pharmaceuticals, and food and beverage. Their separation technology solutions include structured packings, random packings, column internals, trays, feed inlet devices, separators, coalescers, crystallization, and complete process plants.

Structured packings are used in distillation and absorption columns to provide the efficient mass transfer. Sulzer offers a range of structured packings, including Mellapak, MellaSpiral, and Sulzer BX. Their structured packings are highly efficient and can handle a wide range of liquid and gas flow rates.

Random packings are used in distillation and absorption columns to provide the efficient mass transfer. Sulzer offers a range of random packings, including ceramic, metal, and plastic packing. Their random packings are highly efficient and can handle a wide range of liquid and gas flow rates.

Column internals, such as trays and feed inlet devices, are used in distillation and absorption columns to distribute fluids and provide the efficient mass transfer. Sulzer offers a range of column internals, including bubble cap trays, sieve trays, and tray support systems. Their column internals is highly customizable and can be designed to meet specific customer requirements.

Sulzer’s separation technology solutions also include separators, coalescers, and crystallization systems. Their separators are used to separate liquids and gases in various applications, including oil and gas production and chemical processing. Their coalescers are used to separate liquid-liquid and liquid-solid mixtures in various applications, including wastewater treatment and food and beverage. Sulzer’s crystallization systems are used to separate solids from liquids in various applications, including pharmaceuticals and food and beverage. Sulzer also offers complete process plants that incorporate their separation technology solutions to provide efficient and reliable separation processes.

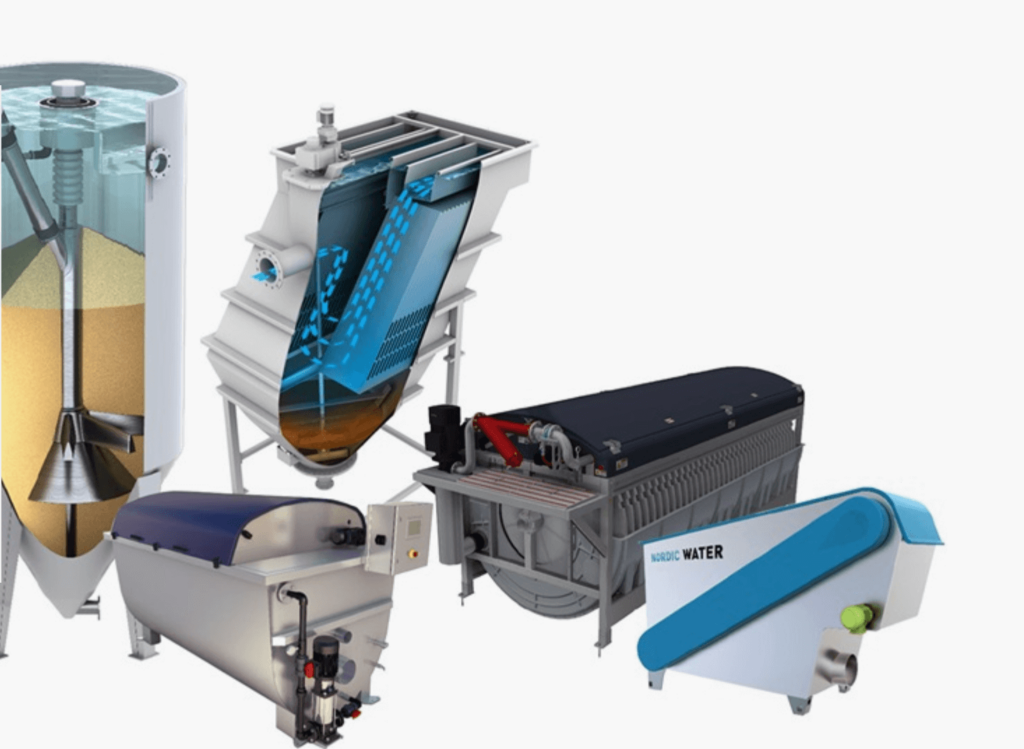

Screening, sedimentation, and filtration solutions

Sulzer offers a range of screening, sedimentation, and filtration solutions that are used in various industries such as wastewater treatment, mining, and food and beverage. Their solutions include screens, sedimentation tanks, and filtration systems.

Sulzer screens are used to remove solids from liquids in various applications, including wastewater treatment and food and beverage. They offer a range of screens, including perforated plate screens, drum screens, and micro screens. Their screens are highly efficient and reliable and can be customized to meet specific customer requirements.

Sulzer’s sedimentation tanks are used to separate solids from liquids in wastewater treatment and mining applications. They offer a range of sedimentation tanks, including lamella settlers and clarifiers. Their sedimentation tanks are highly efficient and can handle a wide range of solid and liquid flow rates.

Sulzer’s filtration systems are used to remove particles from liquids and gases in various applications, including pharmaceuticals, food and beverage, and water treatment. They offer a range of filtration systems, including cartridge filters, bag filters, and membrane filters. Their filtration systems are highly efficient and reliable and can be customized to meet specific customer requirements.

Overall, Sulzer’s screening, sedimentation, and filtration solutions are highly efficient and reliable and can be customized to meet specific customer requirements. They are used in various industries and applications to provide efficient and reliable separation processes. Sulzer’s screening, sedimentation, and filtration solutions are designed to meet the highest quality and safety standards and are backed by Sulzer’s extensive experience and expertise in the field.

Applications of Sulzer Equipment

Sulzer equipment is used across a wide range of industries, including bio-based, recycling, and carbon capture; construction (building and civil engineering); fertilizers; food and beverages; mining and metals; oil, gas, and chemicals; polymer; power generation; pulp, paper, and board; and water and wastewater. In the bio-based industry, Sulzer’s equipment is used for processing biomass and bioproducts. In the recycling and carbon capture industry, their equipment is used for separating and purifying materials. In the construction industry, Sulzer’s equipment is used for pumping and moving fluids and solids on construction sites. In the fertilizers industry, their equipment is used for processing and handling fertilizers.

In the food and beverage industry, Sulzer’s equipment is used for processing and packaging food and beverages. In the mining and metals industry, their equipment is used for pumping and moving fluids and solids in various mining processes. In the oil, gas, and chemicals industry, Sulzer’s equipment is used for processing and transporting oil, gas, and chemicals. In the polymer industry, their equipment is used for processing and handling polymers. In the power generation industry, Sulzer’s equipment is used for generating and transporting power. In the pulp, paper, and board industries, their equipment is used for processing and handling pulp, paper, and board products. In the water and wastewater industry, Sulzer’s equipment is used for treating and transporting water and wastewater. Overall, Sulzer’s equipment is used in a wide range of industries and applications, providing efficient and reliable solutions for handling fluids and solids.

Bio-based, recycling, and carbon capture

Sulzer’s equipment is used in the bio-based, recycling, and carbon capture industry for various applications, including bio-based applications, biopolymers, polymer recycling, carbon capture, utilization, and storage. In bio-based applications, Sulzer’s equipment is used for processing biomass and bioproducts. Their equipment is used for mixing, separation, filtration, and drying processes in the production of biofuels, biochemicals, and other bio-based products.

Sulzer’s equipment is also used in the production of biopolymers, which are biodegradable and renewable alternatives to conventional plastics. Their equipment is used for the polymerization, compounding, and processing of biopolymers. Sulzer’s equipment ensures high efficiency, reliability, and quality in the production of biopolymers, which are increasingly used in various applications, including packaging and textiles.

In recycling, Sulzer’s equipment is used for separating and purifying materials, including polymer recycling. Their equipment is used for sorting, grinding, washing, and drying recycled polymers, increasing their value and reusability. Sulzer’s equipment ensures the high quality and purity of recycled materials, reducing waste and increasing sustainability in the recycling industry.

Sulzer’s equipment is also used in carbon capture, utilization, and storage (CCUS) applications. Their equipment is used for separating and capturing CO2 from industrial processes, converting CO2 into useful products, and storing CO2 safely underground. Sulzer’s equipment ensures high efficiency, reliability, and safety in CCUS applications, contributing to the reduction of greenhouse gas emissions and the mitigation of climate change.

Construction (building and civil engineering)

Sulzer’s equipment is used in construction and civil engineering applications for various purposes, including dewatering in construction and dewatering in tunneling. Dewatering is the process of removing groundwater from construction sites or tunnels to enable construction work and ensure safety.

Sulzer’s dewatering pumps are used for removing groundwater from construction sites. Their pumps are designed to handle solids and debris, ensuring efficient and reliable dewatering. Sulzer pumps are used in various construction projects, including building construction, road construction, and mining.

In tunneling applications, Sulzer’s submersible pumps are used for removing groundwater from tunnels. Their pumps are designed to handle high pressures and can operate in harsh environments. Sulzer pumps are used in various tunneling projects, including metro construction, mining, and infrastructure projects.

Sulzer’s dewatering and submersible pumps are highly efficient and reliable, ensuring efficient and safe construction work. They are designed to meet the specific requirements of construction and civil engineering applications and are backed by Sulzer’s extensive experience and expertise in the field. Sulzer’s pumps are also designed to be easy to install and maintain, reducing downtime and maintenance costs. Overall, Sulzer’s equipment is an essential component in ensuring efficient and safe construction work and civil engineering projects.

Fertilizers

Sulzer’s equipment is used in the fertilizers industry for various applications, including ammonia and urea fertilizers, phosphate fertilizers, and potash fertilizers. In the production of ammonia and urea fertilizers, Sulzer’s pumps are used for handling the various chemicals involved in the process. Their pumps are designed to handle corrosive and abrasive fluids, ensuring high efficiency and reliability.

In the production of phosphate fertilizers, Sulzer’s equipment is used for processing and handling phosphate rock. Their mixers, agitators, and pumps are used for mixing, granulation, and transportation of phosphate rock and other chemicals. Sulzer’s equipment ensures high efficiency and reliability in the production of high-quality phosphate fertilizers.

In the production of potash fertilizers, Sulzer’s equipment is used for processing and handling potassium chloride and other chemicals. Their mixers, agitators, and pumps are used for mixing, granulation, and transportation of potash fertilizers. Sulzer’s equipment ensures high efficiency and reliability in the production of high-quality potash fertilizers.

Overall, Sulzer’s equipment is an essential component in the fertilizers industry, ensuring efficient and reliable production processes for ammonia and urea fertilizers, phosphate fertilizers, and potash fertilizers. Sulzer’s pumps, mixers, and agitators are designed to meet the specific requirements of the fertilizers industry, including the handling of corrosive and abrasive fluids. Sulzer’s equipment is backed by their extensive experience and expertise in the field, ensuring high quality and safety standards in the production of fertilizers.

Food and beverages

Sulzer’s equipment is used in the food and beverage industry for various applications, including sugar, starch, and sweeteners, dairy and chocolate, flavors and fragrances, and freeze concentration. In the production of sugar, starch, and sweeteners, Sulzer’s equipment is used for processing and handling various raw materials, including corn, wheat, and sugar beet. Their pumps, mixers, and agitators are used for mixing, separation, and filtration processes, ensuring high efficiency and reliability in the production of high-quality sugar, starch, and sweeteners.

In the production of dairy and chocolate, Sulzer’s equipment is used for mixing, homogenizing, and processing milk, cream, and chocolate. Their mixers, agitators, and pumps are designed to handle viscous and shear-sensitive fluids, ensuring high-quality and consistent products. Sulzer’s equipment is used in various dairy and chocolate applications, including yogurt, ice cream, and chocolate.

In the production of flavors and fragrances, Sulzer’s equipment is used for extraction, distillation, and filtration processes. Their columns, trays, and packing materials are used for efficient and reliable mass transfer, ensuring high-quality and consistent flavors and fragrances.

Sulzer’s equipment is also used in freeze concentration processes, which are used to remove water from liquids and concentrates. Their heat exchangers and evaporators are used for efficient and reliable freeze concentration processes, ensuring high-quality and consistent products.

Overall, Sulzer’s equipment is an essential component in the food and beverage industry, ensuring efficient and reliable production processes for sugar, starch, and sweeteners, dairy and chocolate, flavors and fragrances, and freeze concentration. Sulzer’s equipment is designed to meet the specific requirements of the food and beverage industry, ensuring high quality and safety standards in the production of food and beverage products.

Mining and metals

Sulzer’s equipment is used in the mining and metals industry for various applications, including metals, mining, and rotating equipment services. In the production of metals, Sulzer’s pumps, mixers, and agitators are used for various processes, including smelting, refining, and casting. Their equipment is designed to handle corrosive and abrasive fluids and slurries, ensuring high efficiency and reliability in the production of high-quality metals.

In the mining industry, Sulzer’s pumps, mixers, and agitators are used for handling various materials, including ores, tailings, and slurries. Their equipment is designed to handle high solids content and ensure efficient and reliable transportation of materials. Sulzer’s equipment is used in various mining applications, including open-pit mining, underground mining, and mineral processing.

Sulzer’s rotating equipment services are used for the maintenance, repair, and upgrade of rotating equipment used in the mining and metals industry. Their services include on-site repair and overhaul of pumps, compressors, and turbines, as well as condition monitoring and predictive maintenance services. Sulzer’s rotating equipment services ensure the high availability, reliability, and safety of equipment used in the mining and metals industry.

Overall, Sulzer’s equipment and services are essential in the mining and metals industry, ensuring efficient and reliable production processes, handling of materials, and maintenance and repair of equipment. Sulzer’s equipment and services are designed to meet the specific requirements of the mining and metals industry, including the handling of corrosive and abrasive fluids and the handling of high solids content. Sulzer’s extensive experience and expertise in the field ensure high quality and safety standards in the mining and metals industry.

Oil, gas, and chemicals

Sulzer’s equipment is used in the oil, gas, and chemicals industry for various applications, including FPSO, oil and gas production, oil sand, shale/coal seam gas, and subsea. In the production of FPSOs, the Sulzer’s equipment is used for handling various fluids, including crude oil and produced water. Their pumps and mixers are designed to handle corrosive and abrasive fluids, ensuring high efficiency and reliability in the production of high-quality fluids.

In oil and gas production, Sulzer’s equipment is used for processing and handling various fluids, including crude oil, natural gas, and produced water. Their pumps, mixers, and agitators are designed to handle corrosive and abrasive fluids and slurries, ensuring high efficiency and reliability in the production of high-quality fluids.

In oil sands, shale/coal seam gas, and subsea applications, Sulzer’s equipment is used for various processes, including separation, filtration, and transportation of fluids and solids. Their pumps, mixers, and agitators are designed to handle high solids content and ensure efficient and reliable transportation of materials. Sulzer’s equipment is used in various oil and gas applications, including oil sand production, hydraulic fracturing, and deep-sea oil production.

Overall, Sulzer’s equipment is essential in the oil, gas, and chemicals industry, ensuring efficient and reliable production processes, handling of materials, and transportation of fluids and solids. Sulzer’s equipment is designed to meet the specific requirements of the oil, gas, and chemicals industry, including the handling of corrosive and abrasive fluids, the handling of high solids content, and the transportation of fluids and solids in various applications. Sulzer’s extensive experience and expertise in the field ensure high quality and safety standards in the oil, gas, and chemicals industry.

Polymer

Sulzer equipment is used in the polymer industry for various applications, including polystyrene (PS), expandable polystyrene (EPS), polylactic acid (PLA), polymer melt cooler, polymer recycling, extrusion-based expanded polypropylene (ePP), and XPET foam extrusion technology.

In the production of PS and EPS, Sulzer’s equipment is used for mixing, extrusion, and injection molding of polystyrene and its derivatives. Their mixers, agitators, and pumps ensure high-quality and consistent products, meeting the strict requirements of the polymer industry.

In the production of PLA, Sulzer’s equipment is used for polymerization, compounding, and processing of polylactic acid, a biodegradable and renewable polymer. Sulzer’s equipment ensures high efficiency and reliability in the production of high-quality PLA, contributing to the sustainability of the polymer industry.

Sulzer’s equipment is also used in polymer recycling, where their pumps, mixers, and agitators are used for sorting, grinding, washing, and drying recycled polymers. Sulzer’s equipment ensures the high quality and purity of recycled materials, reducing waste and increasing sustainability in the polymer industry.

Overall, Sulzer’s equipment is an essential component in the polymer industry, ensuring efficient and reliable production processes for PS, EPS, PLA, polymer melt cooler, polymer recycling, ePP, and XPET foam extrusion technology. Sulzer’s equipment is designed to meet the specific requirements of the polymer industry, including the handling of high-temperature and high-pressure processes, the mixing of various polymers, and the handling of recycled materials. Sulzer’s extensive experience and expertise in the field ensure high quality and safety standards in the polymer industry.

Power generation

Sulzer’s equipment is used in the power generation industry for various applications, including carbon capture, utilization, storage, fossil, nuclear power generation, and renewables. In the production of electricity from fossil fuels, Sulzer’s equipment is used for handling various fluids, including steam, condensate, and cooling water. Their pumps, mixers, and agitators are designed to handle corrosive and abrasive fluids, ensuring high efficiency and reliability in the production of high-quality electricity.

In the production of electricity from nuclear sources, Sulzer’s equipment is used for handling various fluids, including reactor coolant, spent fuel, and waste water. Their pumps, mixers, and agitators are designed to handle radioactive fluids and slurries, ensuring high efficiency and reliability in the production of high-quality electricity.

In the production of electricity from renewables, Sulzer’s equipment is used for various processes, including wind turbine blades and hydroelectric power generation. Their mixers, agitators, and pumps are used for mixing, separation, and transportation of various fluids and solids, ensuring high efficiency and reliability in the production of high-quality electricity.

Overall, Sulzer’s equipment is essential in the power generation industry, ensuring efficient and reliable production processes, handling of materials, and transportation of fluids and solids. Sulzer’s equipment is designed to meet the specific requirements of the power generation industry, including the handling of corrosive and abrasive fluids, the handling of radioactive fluids, and the transportation of fluids and solids in various applications. Sulzer’s extensive experience and expertise in the field ensure high quality and safety standards in the power generation industry.

Pulp, paper, and board

Sulzer’s equipment is used in the pulp, paper, and board industry for various applications, including wood yards, chemical pulp fiber lines, chemical recovery, pulp drying machines, mechanical pulp lines, recycled fiber lines, paper and board machine systems, coating, and finishing, chemicals for pulp, paper, and board, water supply, industrial water and effluent treatment, and power plant.

In the wood yard, Sulzer’s equipment is used for debarking, chipping, and screening of wood chips. Their pumps, mixers, and agitators are designed to handle wood chips and various chemicals used in the wood yard, ensuring high efficiency and reliability in the production of high-quality wood chips.

In the pulp fiber line, Sulzer’s equipment is used for various processes, including cooking, washing, and bleaching of pulp fibers. Their mixers, agitators, and pumps ensure high-quality and consistent pulp fibers, meeting the strict requirements of the pulp, paper, and board industry.

In the paper and board machine systems, Sulzer’s equipment is used for various processes, including forming, pressing, and drying of paper and board. Their pumps, mixers, and agitators ensure high efficiency and reliability in the production of high-quality paper and board.

Overall, Sulzer’s equipment is an essential component in the pulp, paper, and board industry, ensuring efficient and reliable production processes for the wood yard, chemical pulp fiber line, chemical recovery, pulp drying machines, mechanical pulp line, recycled fiber line, paper, and board machine systems, coating and finishing, chemicals for pulp, paper, and board, water supply, industrial water and effluent treatment, and power plant. Sulzer’s equipment is designed to meet the specific requirements of the pulp, paper, and board industry, including the handling of wood chips and various chemicals, the handling of pulp fibers, and the production of high-quality paper and board. Sulzer’s extensive experience and expertise in the field ensure high quality and safety standards in the pulp, paper, and board industries.

Water and wastewater

Sulzer’s equipment is used in the water and wastewater industry for various applications, including desalination, water intake, transportation, and irrigation, municipal clean water, flood control, industrial water treatment, domestic and commercial wastewater, municipal wastewater, and dewatering.

In the desalination process, Sulzer’s equipment is used for handling various fluids, including seawater and brine. Their pumps, mixers, and agitators are designed to handle corrosive and abrasive fluids, ensuring high efficiency and reliability in the production of high-quality desalinated water.

In municipal clean water and flood control applications, Sulzer’s equipment is used for handling and transportation of clean water and wastewater, ensuring efficient and reliable water supply and drainage systems. Their pumps and mixers are designed to handle various fluids and solids, ensuring high efficiency and reliability in the management of water and wastewater.

In industrial water treatment, domestic and commercial wastewater, and municipal wastewater applications, Sulzer’s equipment is used for various processes, including filtration, separation, and treatment of water and wastewater. Their mixers, agitators, and pumps ensure high efficiency and reliability in the production of high-quality water and wastewater.

Overall, Sulzer’s equipment is essential in the water and wastewater industry, ensuring efficient and reliable production processes, handling of materials, and transportation of fluids and solids. Sulzer’s equipment is designed to meet the specific requirements of the water and wastewater industry, including the handling of corrosive and abrasive fluids, the handling of various fluids and solids, and the management of water and wastewater in various applications. Sulzer’s extensive experience and expertise in the field ensure high quality and safety standards in the water and wastewater industry.

About Sulzer

Sulzer is a global industrial manufacturing company with a long and rich history of innovation and engineering excellence. Sulzer is a leading supplier of high-quality products and services for the energy, water, and chemical industries.

Sulzer’s broad range of products and services includes pumps, mixers, agitators, compressors, process plants, lifting stations, and various other industrial equipment. The company’s equipment is used in a variety of applications, including oil and gas production, water treatment, power generation, and pulp and paper production. Sulzer’s commitment to quality, safety, and sustainability is reflected in its extensive research and development efforts, which have resulted in numerous patented technologies and innovative solutions.

Sulzer is a customer-focused company, that works closely with clients to understand their needs and develop custom solutions that meet their specific requirements. The company’s dedicated sales and service teams provide support to customers throughout the entire product lifecycle, ensuring optimal performance and efficiency of their equipment. Sulzer’s strong reputation for quality, reliability, and innovation has made it a trusted partner for many of the world’s leading companies in the energy, water, and chemical industries.