Understanding Ammonia Pumps

Ammonia pumps are crucial in various industrial applications, from refrigeration to chemical processing. These pumps are designed to handle the specific properties of ammonia, a common refrigerant and chemical feedstock, ensuring safe and efficient transfer and handling. In this comprehensive guide, we will delve into the types of ammonia pumps, their applications, and the leading manufacturers in the industry.

Leading Manufacturers and Their Products

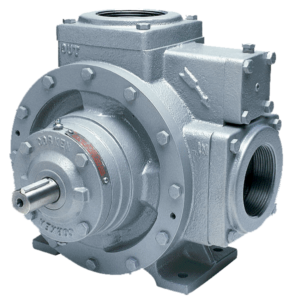

Viking Pump 4924A Series (Internal Gear Pumps with Double Mechanical Seals)

- Enhanced Sealing: Viking Pump’s internal gear pumps feature double mechanical seals, providing superior sealing capabilities. This design prevents leaks and ensures safe handling of ammonia and other hazardous liquids.

- Robust Construction: These pumps are built with durability in mind, using materials that resist corrosion and wear. This robust construction ensures long-lasting performance even in harsh environments.

- Versatile Applications: Viking internal gear pumps are suitable for a wide range of applications, from chemical processing to refrigeration. Their versatility and reliability make them a popular choice for ammonia transfer.

- Learn More →

Corken Standard Model Sliding Vane Pumps for High Pressure Applications

- High Pressure Capabilities: Corken’s standard model sliding vane pumps are designed to handle high-pressure applications, making them ideal for transferring ammonia in industrial settings. These pumps can operate efficiently under demanding conditions, ensuring reliability and longevity.

- Durable Construction: The robust construction of these pumps includes high-quality materials that can withstand the corrosive nature of ammonia. This durability reduces maintenance needs and extends the service life of the pumps.

- Efficiency: These pumps are known for their high efficiency, providing consistent flow rates and minimizing energy consumption. This makes them a cost-effective solution for ammonia transfer.

- Learn More →

Corken Z-Model Sliding Vane Pumps Available in 5 Sizes

- Versatility: The Z-Model series comes in five different sizes, offering versatility for various ammonia transfer applications. This allows users to select the appropriate pump size for their specific needs.

- Advanced Design: These pumps feature an advanced sliding vane design that ensures smooth operation and minimizes wear and tear. This design also helps maintain high efficiency and reduces operational costs.

- Application Flexibility: Whether for small-scale operations or large industrial processes, the Z-Model pumps provide reliable performance across different applications, including chemical processing and refrigeration.

- Learn More →

Corken Regenerative Turbine Pump Series

- Long-lasting Performance: The regenerative turbine pumps from Corken are designed for longevity, featuring free-floating impellers that reduce mechanical wear. This design enhances the pump’s durability and reduces the frequency of maintenance.

- High Efficiency: These pumps are known for their high efficiency in handling ammonia and other volatile liquids. They provide a consistent flow rate and are suitable for high-precision applications.

- Low Maintenance: The free-floating impellers in these pumps reduce the need for frequent maintenance, making them a cost-effective solution for continuous operation in demanding environments.

- Learn More →

Corken SC-Model Side Channel Pumps

- Continuous Duty Operation: The SC-Model side channel pumps are designed for continuous duty, ensuring reliable performance in industrial applications. They can handle varying flow rates and pressures, making them versatile for different processes.

- Long Service Life: These pumps are built to last, with high-quality materials and construction that withstands the rigors of ammonia transfer. Their long service life reduces downtime and maintenance costs.

- High Efficiency: The side channel design enhances the pump’s efficiency, providing smooth and consistent flow rates for various ammonia applications, including refrigeration and chemical processing.

- Learn More →

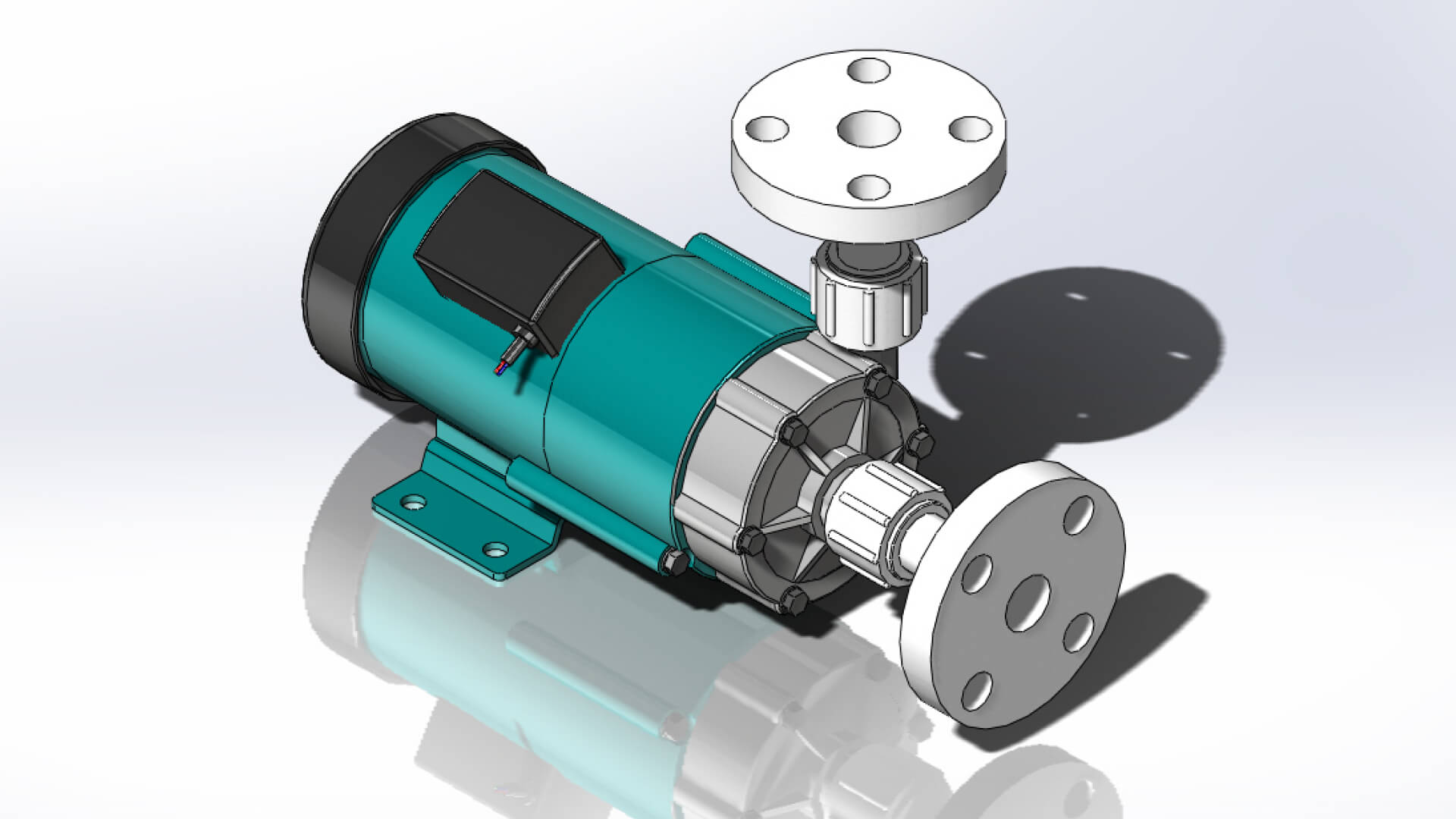

Phantom Pumps Self-Priming Centrifugal Pumps

- Drop-In Compatibility: Phantom Pumps offers self-priming centrifugal pumps that are drop-in compatible with Goulds and Gorman Rupp models. This compatibility makes it easy to replace existing pumps without extensive modifications.

- High Efficiency: These pumps are designed for high efficiency, providing reliable performance while minimizing energy consumption. They are ideal for various industrial applications, including ammonia transfer.

- Cost-Effective Solution: Phantom Pumps’ self-priming centrifugal pumps offer a cost-effective solution for ammonia transfer, providing high performance at a competitive price. Their durability and efficiency make them a valuable addition to any processing system.

- Learn More →

Types of Ammonia Pumps

Vacuum Pump Yellow Jacket

Used primarily in HVAC and refrigeration applications, these vacuum pumps are essential for evacuating air and moisture from systems before charging them with ammonia. The Yellow Jacket series is known for its durability and efficiency, making it a top choice for technicians.

Refrigeration Pump

These pumps are specifically designed for use in ammonia-based refrigeration systems. They ensure the smooth circulation of ammonia, maintaining optimal temperatures in industrial and commercial settings. Their robust design allows them to withstand the harsh conditions often found in refrigeration environments.

Ammonia Heat Pump

Ammonia heat pumps are used in industrial heating applications, leveraging the thermodynamic properties of ammonia to transfer heat efficiently. These pumps are particularly effective in processes requiring heat recovery and redistribution, contributing to energy savings and reduced operational costs.

Ammonia Dosing Pump

These precision pumps are used to add exact amounts of ammonia into a process stream. They are essential in industries such as water treatment and chemical manufacturing, where accurate dosing of ammonia is crucial for maintaining process integrity and product quality.

Ammonia Liquid Pump Recirculation System

This system involves pumps that recirculate ammonia within a closed-loop system, ensuring continuous flow and consistent temperature control. It is widely used in refrigeration and process cooling applications, providing reliable performance and efficiency.

Applications of Ammonia Pumps

Ammonia pumps play a crucial role in several industrial applications, including:

Refrigeration

Ammonia is widely used as a refrigerant due to its excellent thermodynamic properties. Ammonia pumps ensure the efficient circulation of ammonia in refrigeration systems, maintaining optimal temperatures and performance.

Chemical Processing

In chemical manufacturing, ammonia pumps are used to transfer ammonia for various processes, including synthesis and neutralization. Their precise flow control and durability are essential for maintaining process integrity.

Heat Transfer

Ammonia heat pumps are employed in industrial heating applications, utilizing the heat transfer properties of ammonia to recover and redistribute heat. This application helps reduce energy consumption and operational costs.

Water Treatment

Ammonia dosing pumps are used in water treatment plants to add ammonia for processes like chloramination. Accurate dosing is crucial for ensuring the effectiveness of the treatment process and maintaining water quality.

Conclusion

Ammonia pumps are indispensable in various industries, providing reliable and efficient handling of ammonia for different applications. Understanding the different types of ammonia pumps and their features can help you select the right pump for your specific needs. Leading manufacturers like Corken, Viking Pump, and Phantom Pumps offer high-quality solutions designed to meet the demands of industrial applications. Whether you need a pump for refrigeration, chemical processing, or heat transfer, choosing the right ammonia pump ensures optimal performance and safety.

If you need assistance selecting, repairing, replacing, or maintaining an ammonia pump, contact Arroyo Process Equipment today. Our team of experts is ready to help you find the perfect solution for your specific needs.