Industries / General Industry / Composite

Revolutionize material science with quality equipment & services

Optimize manufacturing processes with rotating equipment ensures precise mixing of composite ingredients, controlled material placement, efficient molding, and effective curing, resulting in consistent material quality, optimized fiber distribution, reduced waste, and improved overall efficiency. By achieving optimal processing conditions, composite manufacturers can create high-performance materials that meet the demanding requirements of industries such as aerospace, automotive, and construction.

The Manufacturing Process

Create economies of scale across your system

Each of these stages requires specific types of industrial rotating equipment, and proper operation and maintenance of this equipment are crucial for the efficiency and productivity of the composite industry.

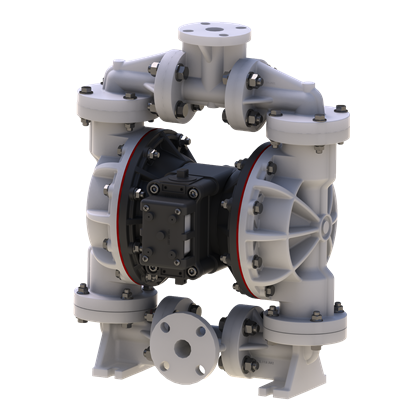

Mixing & Blending

The production of composite materials often begins with the mixing of resin and a hardener, along with fillers, reinforcements, and additives. This process typically involves industrial mixers and blenders.

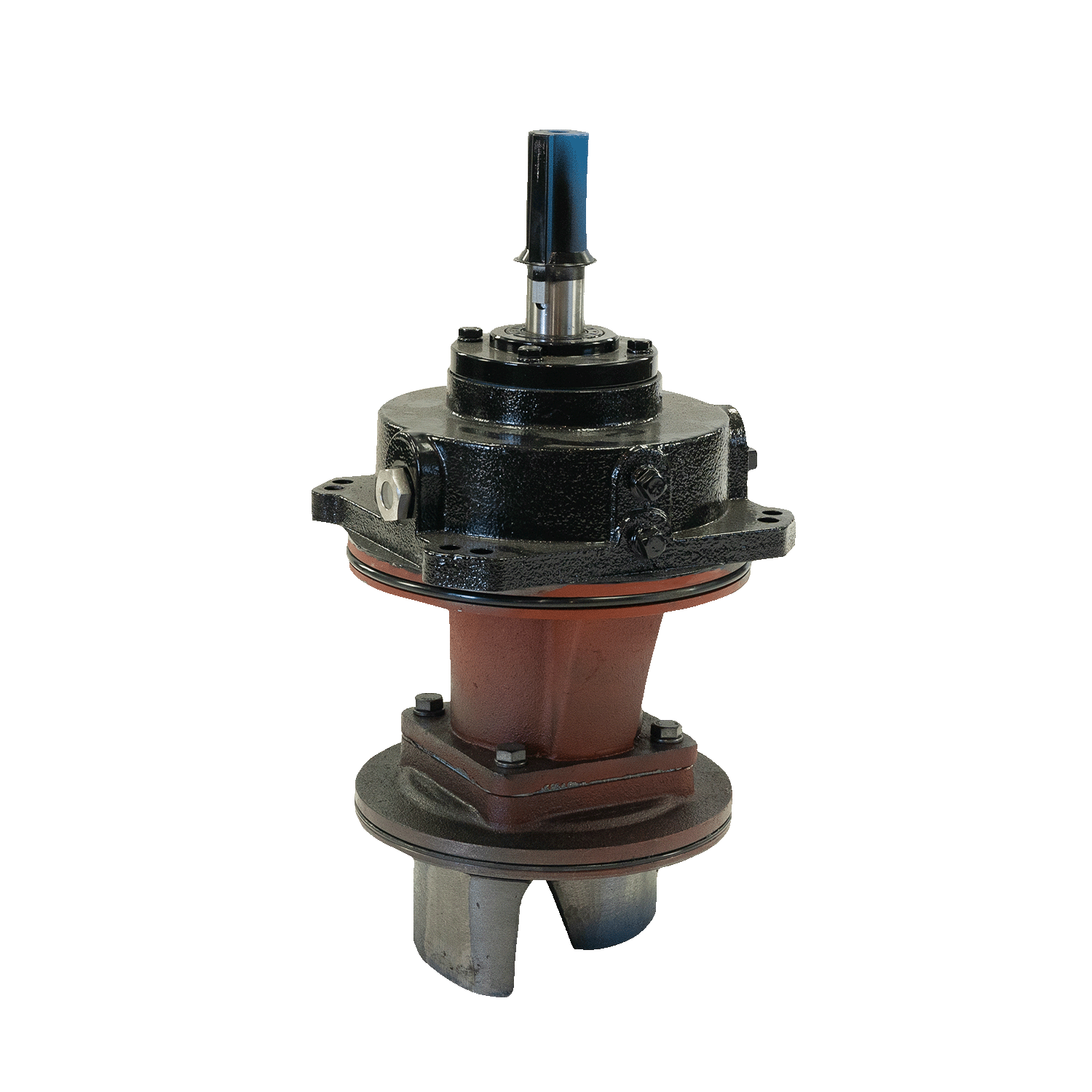

Impregnation

In the manufacture of reinforced composites, fibers (like glass or carbon) are impregnated with the resin mixture. This process may involve rotating machinery to ensure even and thorough coating of the fibers.

Extrusion & Pultrusion

These are methods used to form continuous profiles with composite materials. They involve the use of rotating machinery to pull or push the composite material through a dye.

Filament Winding

In this process, fiber reinforcements are wound around a rotating mandrel in a specified pattern and then impregnated with resin. This is commonly used to produce cylindrical parts like pipes or tanks.

Milling & Grinding

Composite materials often need to be milled or ground into specific shapes or sizes, which involves the use of rotating mills or grinders.

Curing

While not always involving rotating equipment, curing processes can sometimes involve rotating ovens or autoclaves for the even application of heat and pressure.

Trimming & Cutting

After the composite parts have been formed and cured, they often need to be trimmed or cut to the desired size or shape. This typically involves the use of rotating cutting tools or saws.

Finishing

The finishing process, which may involve sanding, buffing, or polishing the composite part to achieve the desired surface finish, often requires rotating tools.

Inspection & Testing

Rotating mechanisms can be found in some inspection and testing equipment used to ensure the quality and consistency of composite materials and parts.

Recycling

Composite recycling processes often involve the use of rotating machinery to shred, grind, or otherwise process waste composite materials for reuse.