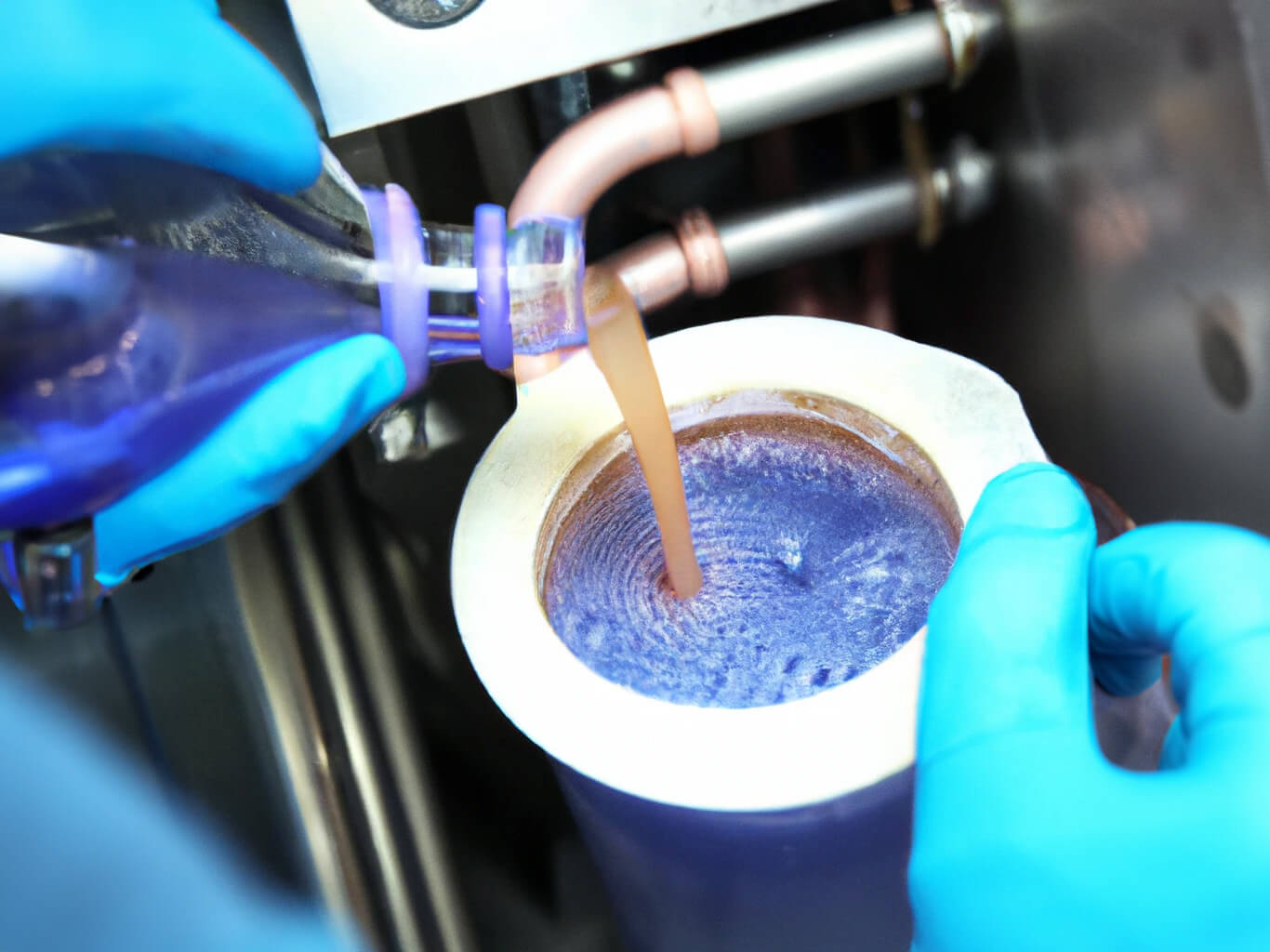

Reduce detergent gel manufacturing costs by increasing efficiency

Detergent gel manufacturing costs can be significant, making it important to find ways to improve efficiency. Arroyo Process Equipment offers a wide range of energy-efficient rotating equipment for detergent gel manufacturing, designed to help you reduce your operating costs.

The Manufacturing Process

Create economies of scale across your system

Detergent gel manufacturers rely on a variety of specialized rotating equipment to optimize their production processes and produce high-quality products. Our team of experts can help you select and maintain the right equipment for your specific needs, so you can focus on your core competencies.

Raw Material Mixing

Our rotating mixers and agitators provide exceptional blending of surfactants, water, and other essential ingredients, setting the foundation for a top-quality product.

Heating and Melting

Ensure a smooth and efficient melting of specific ingredients with our rotating pumps, designed to circulate your mixture through heat exchangers seamlessly.

pH Adjustment

Trust our rotating mixers for perfect dispersion of alkaline or acidic substances, securing the optimum pH level for your detergent gel.

Gelling Agents Addition

Achieve a uniform texture and quality by incorporating gelling agents with our rotating mixers, specifically engineered for even dispersion.

Coloring and Fragrance Addition

Add colorants and fragrances with confidence, as our rotating equipment guarantees an even and thorough mixture.

Homogenization

Utilize our high-speed rotating homogenizers for breaking down particle sizes, delivering a consistently uniform detergent gel.

Cooling

Our rotating pumps ensure that your detergent gel cools down uniformly by circulating it through state-of-the-art cooling systems.

Quality Control

Depend on our rotating viscometers for rigorous testing that confirms your detergent gel meets all industry quality benchmarks.

Packaging

Our rotating pumps and conveyors make the packaging process quick and accurate, minimizing waste and maximizing throughput.

Transfer and Storage

Move your packaged detergent gel effortlessly to your storage or shipping areas with our high-quality rotating conveyors and pumps

Cleaning

End your production cycle with our rotating spray balls and nozzles, designed for efficient and comprehensive equipment cleaning.