Industries / Asphalt / Asphalt Emulsions

Reduce asphalt emulsions manufacturing downtime with top-notch equipment

We understand that production downtime is a major concern. That’s why we offer a wide range of high-quality rotating equipment that is designed to withstand the rigors of continuous operation. Our equipment is also backed by a team of experienced engineers and technicians who can provide expert advice and support to help you keep your equipment running smoothly.

The Manufacturing Process

Create economies of scale across your system

Preparation of Base Asphalt

Our rotating heat exchangers deliver uniform heating of your base asphalt, setting the stage for a high-quality emulsion.

Emulsification

Achieve a perfect blend of asphalt, water, and emulsifying agents with our high-shear rotating mills and colloid mills, engineered for unparalleled emulsion quality.

Additive Mixing

Utilize our top-grade rotating mixers to flawlessly incorporate stabilizers and additives, enhancing the performance and durability of your emulsion.

Homogenization

Trust our high-speed rotating homogenizers for a consistently smooth and stable emulsion, even when complex additive combinations are involved.

Quality Control

Count on our rotating viscometers and other test equipment for reliable, precise measurements of your emulsion's properties, ensuring they meet all industry standards.

Filtration

Eliminate any undesired solids or impurities from your emulsion with our efficient rotating filters, guaranteeing a pure end product.

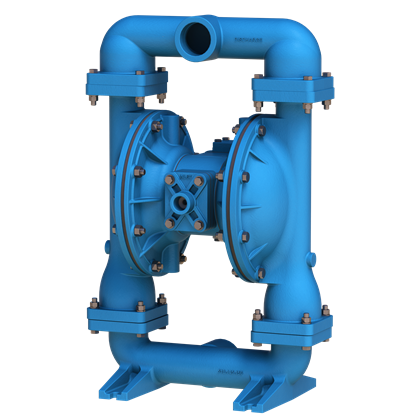

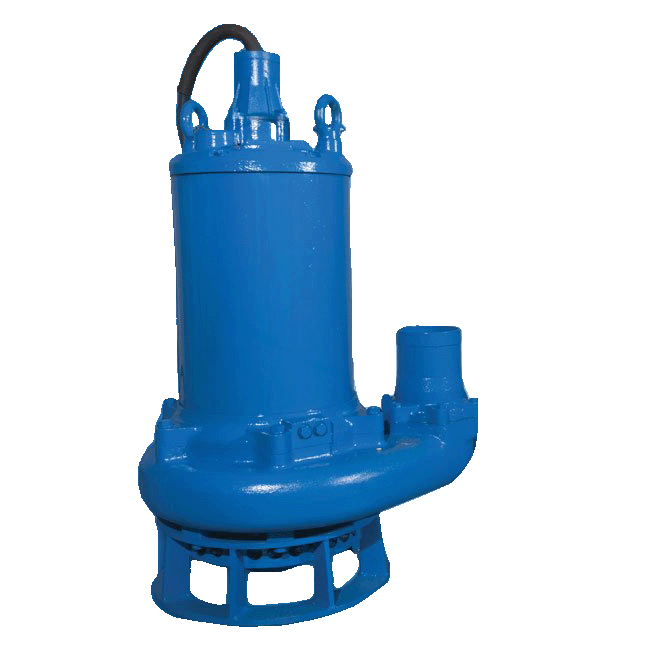

Storage

Our robust rotating pumps make transferring your approved emulsion into storage tanks a hassle-free experience.

Distribution

Equip your distribution phase with our rotating pumps, designed to efficiently pump your finished emulsion into trucks or other transport containers.

Cleaning

Round off your manufacturing cycle with our rotating spray heads and nozzles, making your equipment ready for the next batch in no time.