Jacketed pumps are essential for handling temperature-sensitive and viscous fluids across various industries, including food processing, chemical production, and asphalt handling. Engineers design these pumps to maintain optimal temperature control, ensuring smooth operation and preventing fluid solidification during transfer.

What Is a Jacketed Pump?

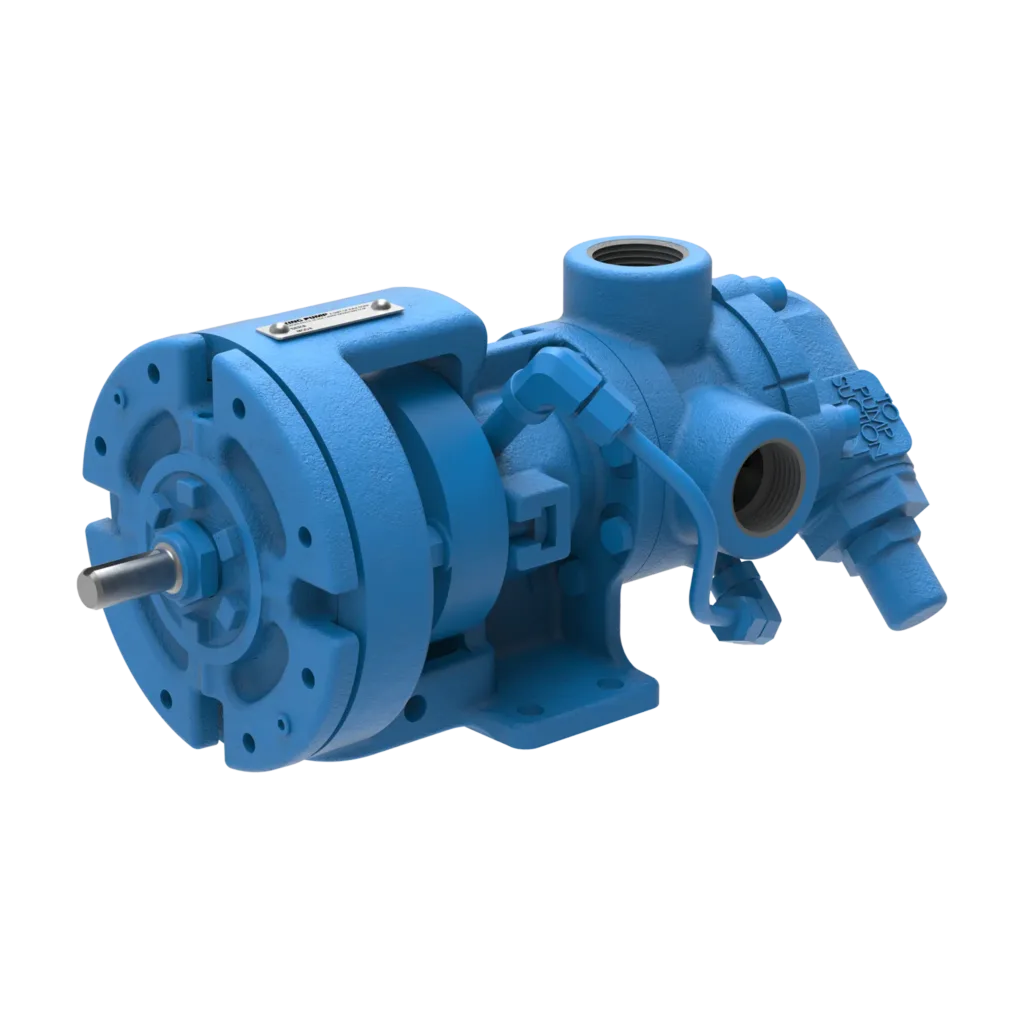

A jacketed pump has a jacket around its body. This jacket lets heated or cooled fluids flow around the pump. This design maintains the temperature of the pumped fluid, preventing issues such as freezing or thickening.

Jacketed gear pumps are often used in places that need careful temperature control. This includes asphalt plants, food processing facilities, and chemical manufacturing.

Internal Gear Pump Design for Temperature Control

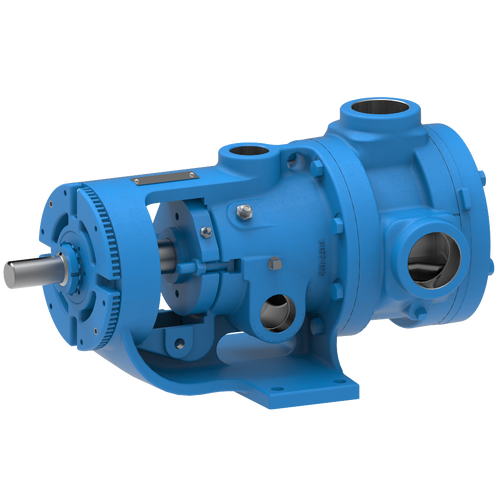

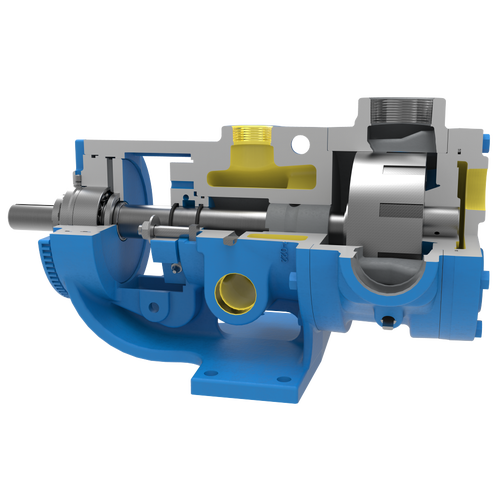

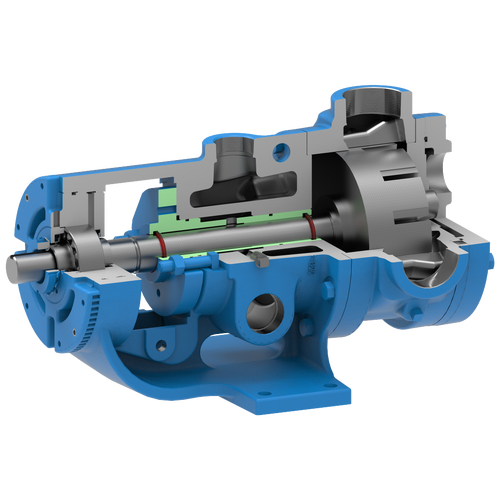

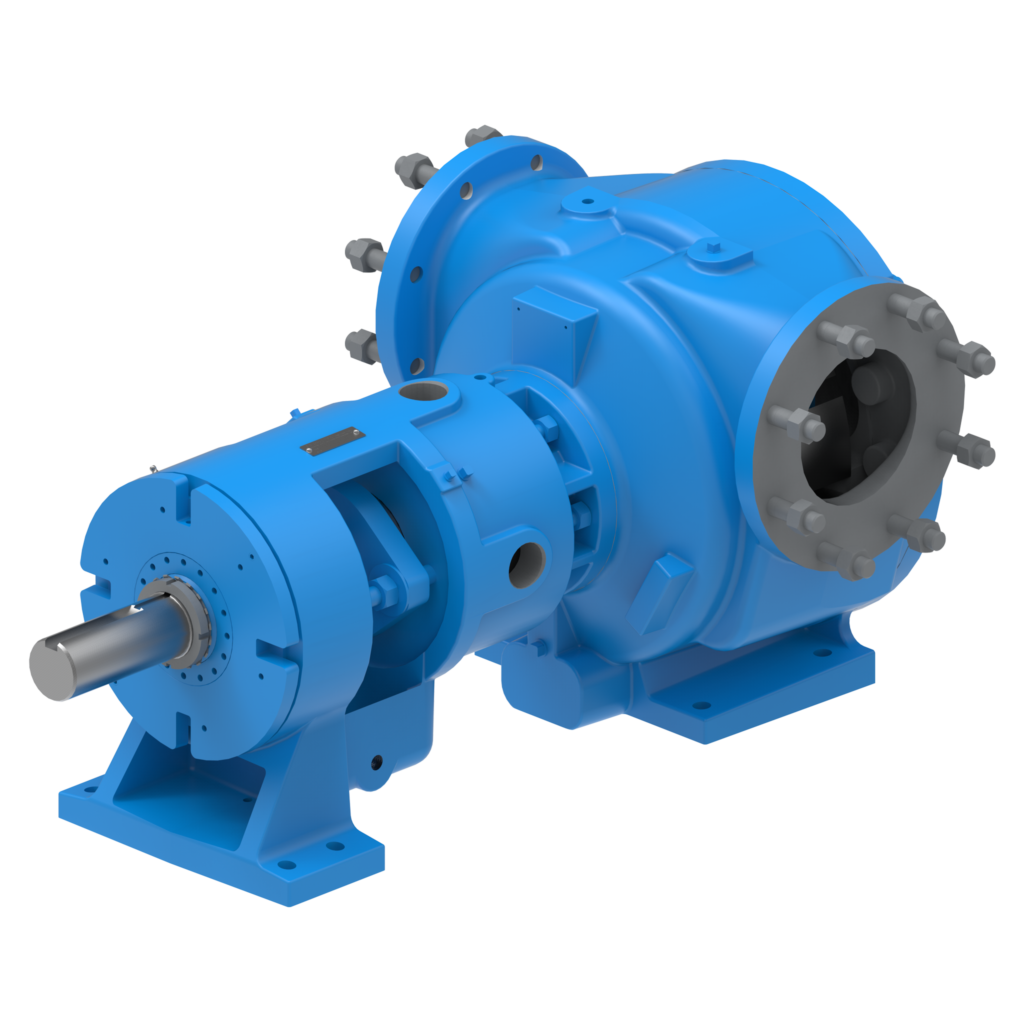

Industries commonly use internal gear pumps, especially jacketed models. They help transfer thick or temperature-sensitive fluids. These pumps operate by using a rotor gear and an idler gear to move fluid through the pump. The jacketed design enhances the pump’s ability to handle fluids with varying viscosities by maintaining a consistent temperature within the pump chamber.

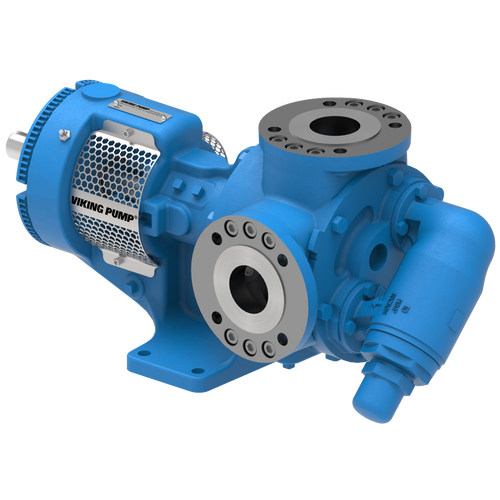

The Viking Pump brand is known for its creative pump designs. They offer jacketed internal gear pumps for industries that handle asphalt, oils, resins, and other thick substances. Viking pumps are known for their strong design. They have cast iron or stainless steel housings. This makes them great for tough jobs.

Key Applications for Jacketed Pumps

Jacketed pumps are used across a range of industries for various critical processes, including:

- Asphalt Handling: Viking asphalt gear pumps are designed to maintain high temperatures, ensuring the asphalt remains fluid during transfer. Steam jacketed pumps are particularly useful in this application to prevent solidification.

- Food Processing: In the food industry, jacketed pumps are essential for handling chocolate, syrups, and oils that require temperature control to remain in a liquid state.

- Chemical Manufacturing: Jacketed gear pumps help maintain precise temperature ranges for chemicals, preventing crystallization or degradation.

- Cannabis Processing: Cannabis processing gear pumps are increasingly popular for maintaining the quality of oils and extracts, requiring precise temperature regulation.

How Does a Gear Pump Work?

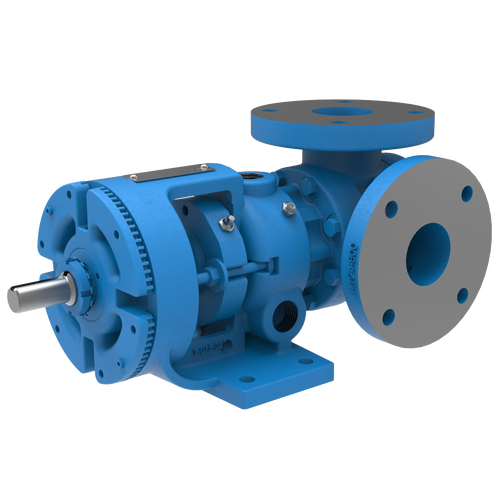

A gear pump operates using two rotating gears to create a vacuum that draws fluid into the pump chamber. The fluid is trapped between the gear teeth and the pump casing, then pushed toward the discharge side of the pump. This positive displacement mechanism ensures consistent flow rates, even for highly viscous fluids.

Internal Gear Pumps vs. Centrifugal Pumps

Centrifugal pumps use fast rotation to move fluids. In contrast, internal gear pumps offer a steady and controlled flow. This makes them great for handling thick fluids and temperature-sensitive tasks.

Internal gear pumps work better at low flow rates and thick fluids. Centrifugal pumps are best for high-volume, thin fluids.

Benefits of Jacketed Gear Pumps

Jacketed gear pumps offer several key advantages for industries handling viscous fluids:

- Temperature Control: Maintaining the fluid’s temperature prevents solidification and ensures smooth transfer.

- Versatility: Suitable for a wide range of applications, including asphalt, food products, and chemicals.

- Durability: Heavy-duty construction with materials such as cast iron or stainless steel ensures long-lasting performance.

- Positive Displacement: Provides consistent flow rates, even for thick or viscous fluids.

- Customizable Designs: Viking pumps and other manufacturers offer various pump models tailored to specific industrial needs.

Choosing the Right Jacketed Pump for Your Application

When selecting a jacketed pump, it is essential to consider the following factors:

- Fluid Viscosity: The pump must be capable of handling the viscosity of the fluid being transferred.

- Temperature Range: Ensure the pump can maintain the required temperature range for your application.

- Material Construction: Choose between cast iron, stainless steel, or other materials based on the application’s requirements.

- Flow Rates and Pressure Requirements: Determine the necessary flow rates and pressure to select the appropriate pump model.

Viking Pumps has been a trusted name for many years. They offer high-quality jacketed pumps for tough jobs. Their product line includes:

- Asphalt Gear Pumps: Designed to handle high-temperature asphalt with ease.

- Steam Jacketed Pumps: Ideal for applications requiring constant heating to maintain fluid flow.

- Refrigeration Plant Inner Gear Oil Pumps: Specialized pumps for maintaining precise oil flow rates in refrigeration systems.

Common Jacketed Pump Configurations

By understanding the function, benefits, and applications of jacketed pumps, businesses can make informed decisions to optimize their operations and improve overall efficiency. Jacketed pumps can be customized to meet specific industrial requirements. Common configurations include:

- Gear Pump Packages: Complete systems with integrated gear pumps, jackets, and heating elements for seamless operation.

- Steam Jacketed Pumps: Ideal for high-temperature applications, using steam to maintain fluid temperature.

- Rotary Gear Pumps: Suitable for a variety of fluids, offering precise flow control.

- Inspect Gear Teeth: Check for wear or damage to the gear teeth, as these are critical moving parts.

- Monitor Temperature Control Systems: Ensure the jacket heating or cooling system is functioning correctly.

- Lubricate Bearings and Seals: Proper lubrication reduces friction and prevents premature wear.

- Check for Leaks: Regularly inspect the pump for leaks to prevent downtime and ensure safety.

Jacketed pumps, particularly jacketed gear pumps, are essential components in industries requiring temperature control for viscous fluids. From asphalt plants to cannabis processing facilities, these pumps provide reliable, efficient fluid transfer solutions. Viking Pumps remains a trusted brand for heavy-duty jacketed pumps, offering models designed to meet various industrial needs.