Industries / Chemical / Paint & Pigments

Unleash vibrant possibilities with innovative solutions

Streamline the production process with high-quality, reliable equipment. These machines ensure precise mixing, controlled dispersion, efficient grinding, and accurate classification, resulting in consistent color quality, optimal particle size, and homogeneity. By achieving optimal processing conditions, paints and pigment manufacturers can create vibrant and durable products that meet the highest industry standards and inspire creativity.

The Manufacturing Process

Create economies of scale across your system

Each stage of the paint and pigment manufacturing requires specific types of industrial rotating equipment, and the proper operation and maintenance of this equipment is crucial for the efficiency and productivity of the paint and pigments industry.

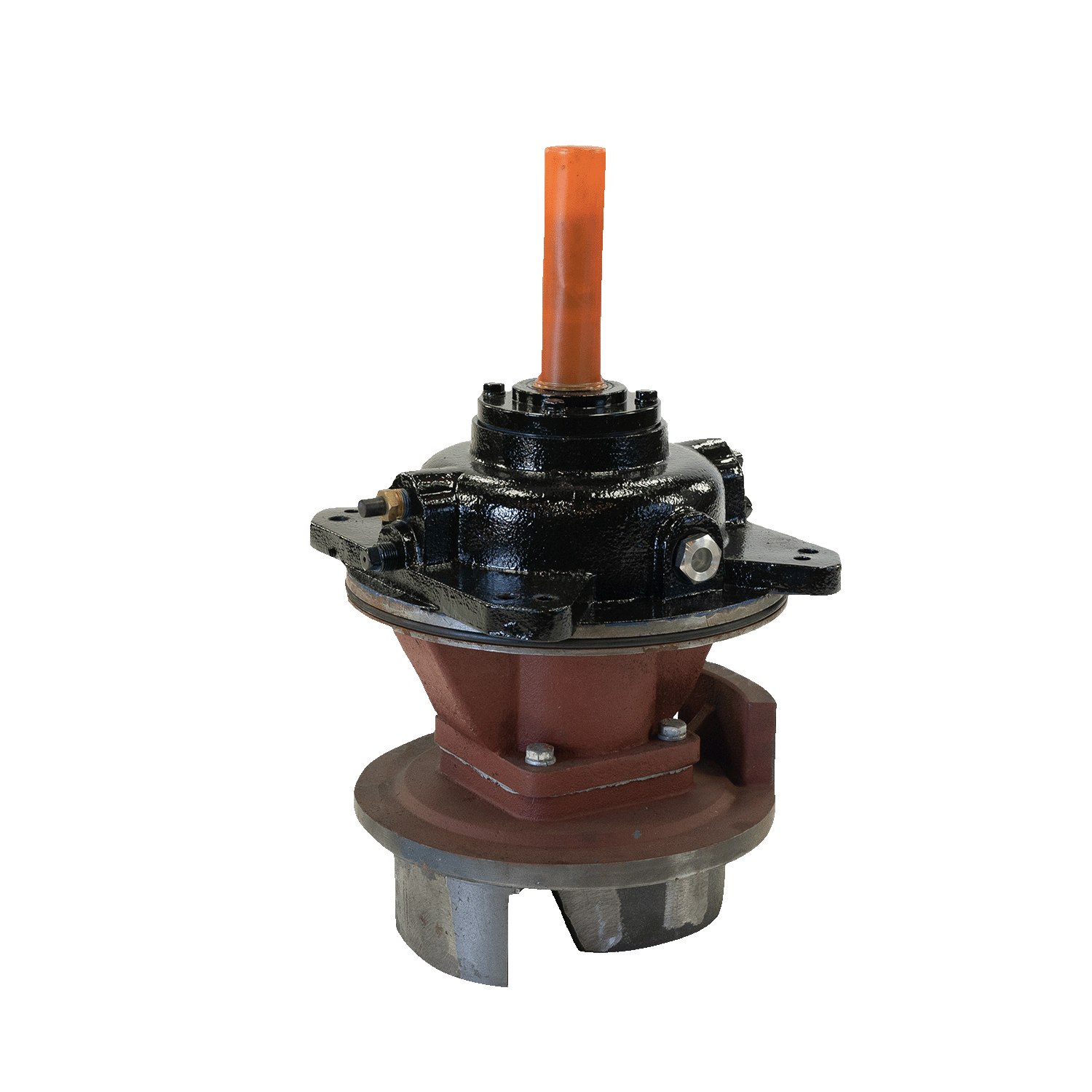

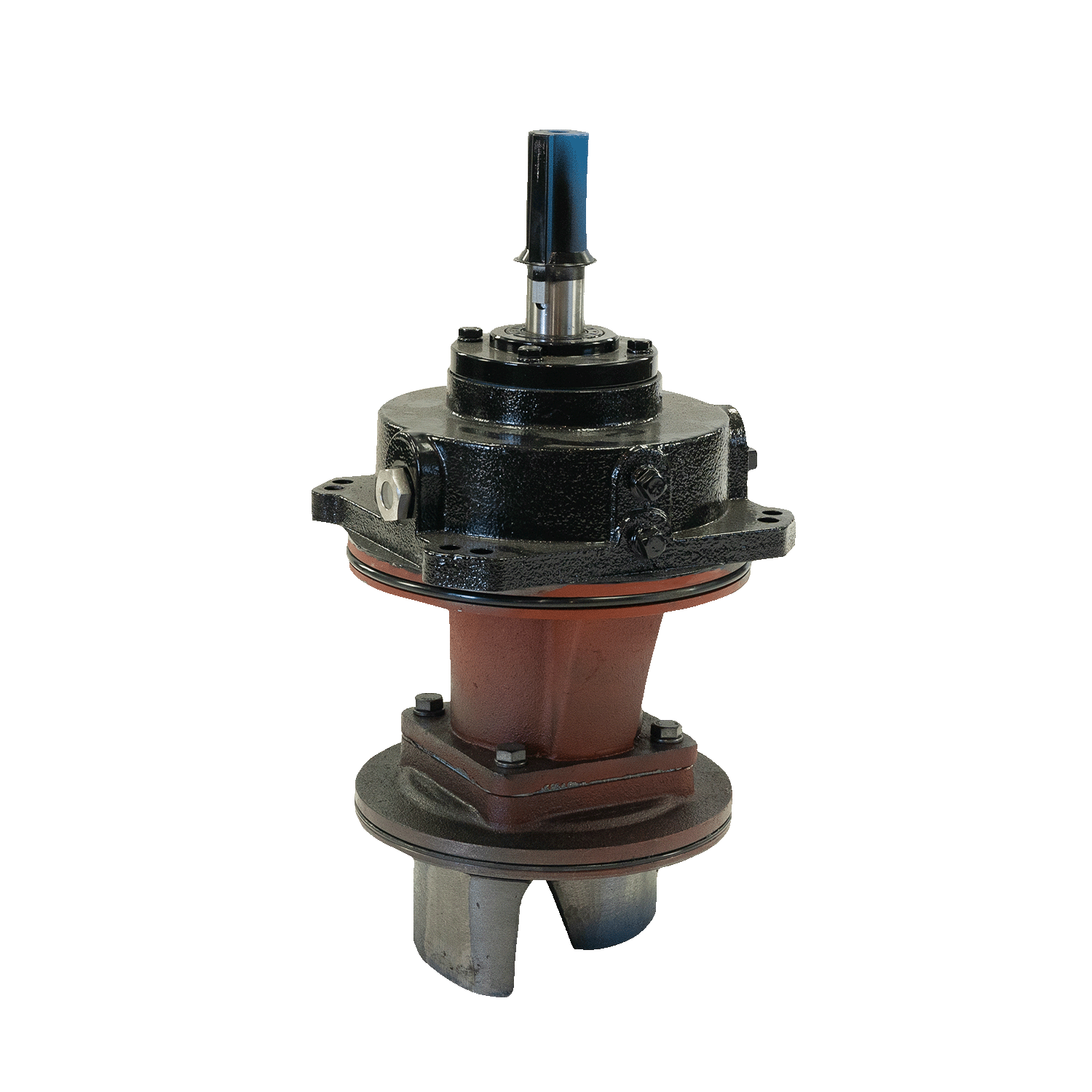

Mixing & Blending

The creation of paint involves mixing various components, including pigments, binders, and solvents. Industrial mixers, which use rotating blades or impellers, are often used to ensure a uniform blend.

Milling & Grinding

Pigments for paints need to be milled or ground to a very fine consistency to ensure a smooth finish when applied. This process often involves rotating mills, which grind the pigment particles to the required size.

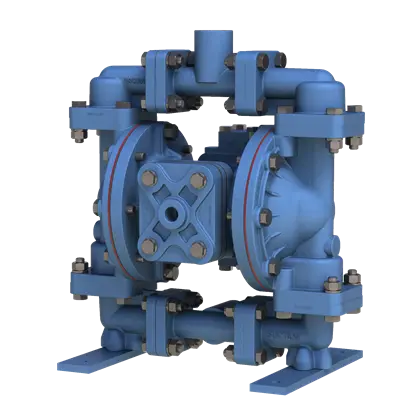

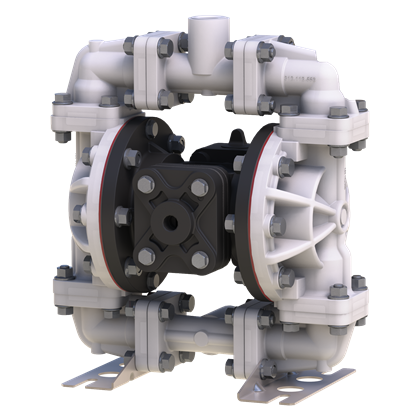

Dispersion

The dispersion of pigments into the paint medium is a critical step in paint manufacturing. This is typically achieved using a dispersion machine or a high-shear mixer, both of which use rotating elements to disperse the pigment evenly throughout the medium.

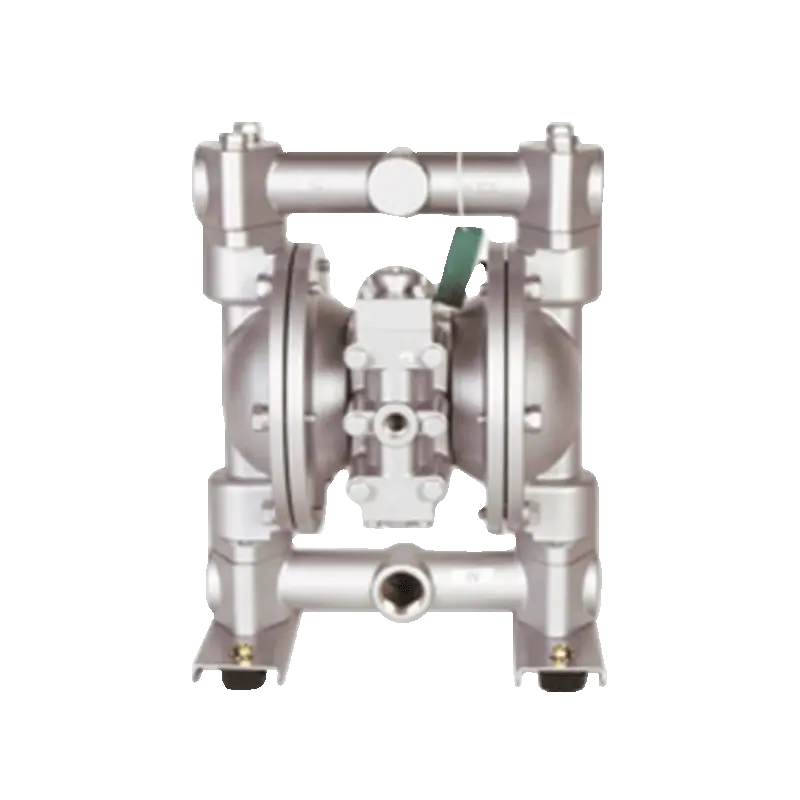

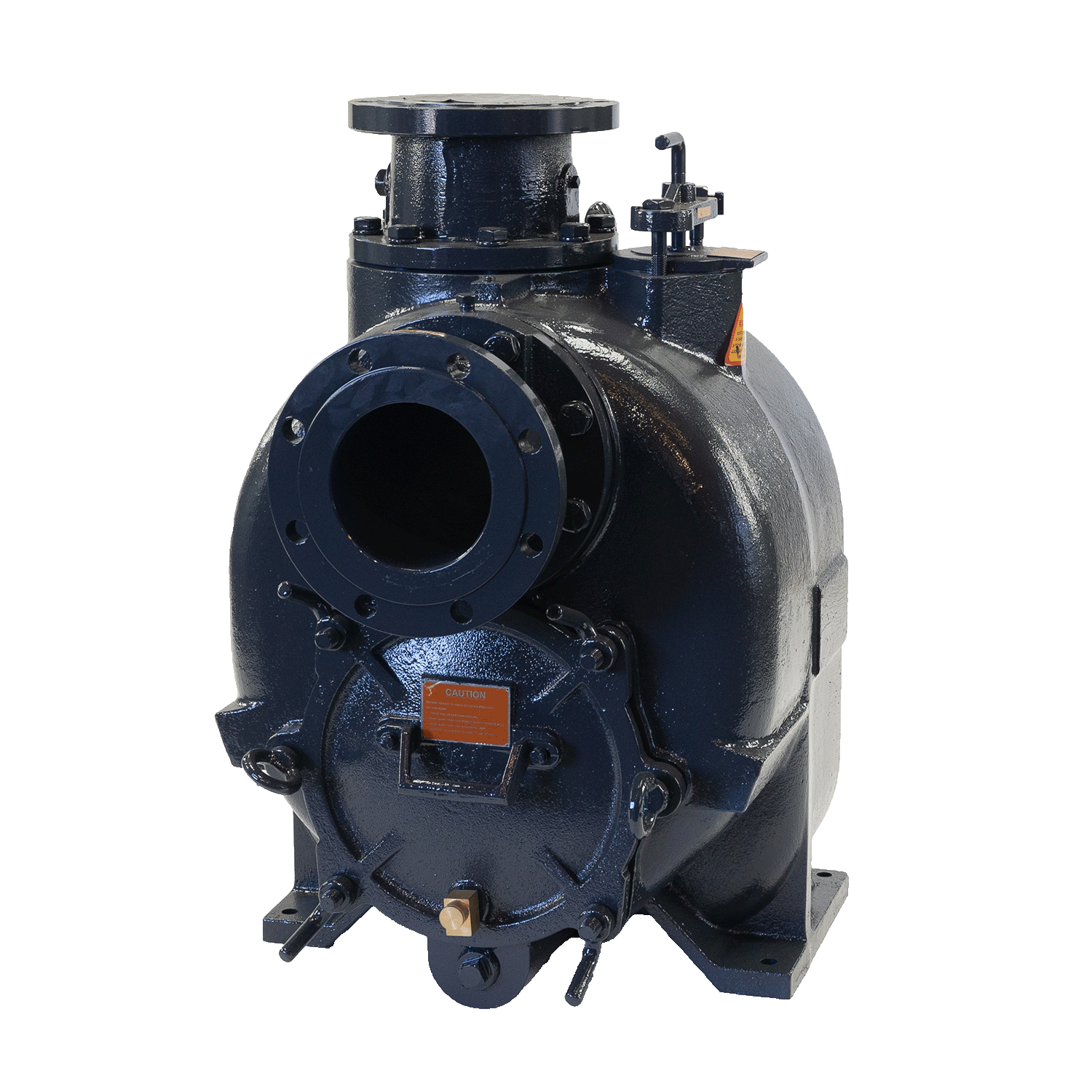

Filtration

After the paint has been mixed and dispersed, it is often filtered to remove any agglomerates or impurities. This process can involve rotating equipment such as centrifuges or rotary drum filters.

Filling & Packaging

Once the paint is ready, it needs to be packaged. This process often involves rotating machinery like filling machines, capping machines, and labeling machines.

Heat Transfer

In processes where heating or cooling is required, rotating equipment like agitators can be used in conjunction with a jacketed vessel to ensure even heat distribution.

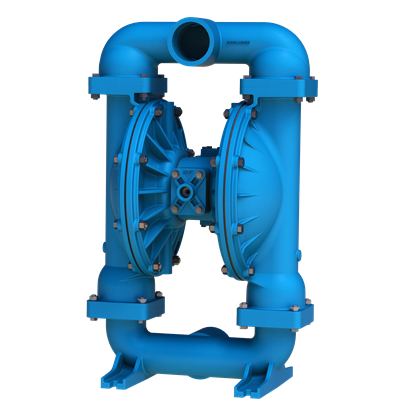

Waste Management

Any waste products from the production process need to be handled appropriately. This can involve the use of pumps or other rotating equipment to move the waste to the appropriate location for treatment or disposal.