Sharpe Mixers Equipment We Distribute

Sharpe Mixers is a leading manufacturer of high-quality mixing equipment for a wide range of industrial applications. Their product line includes a variety of mixers, ranging from high-speed dispersers to static mixers, designed to meet the specific mixing requirements of their customers.

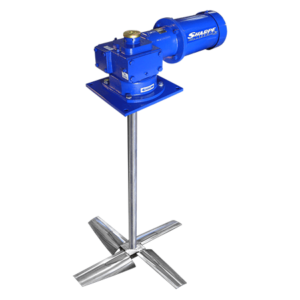

Portable Mixers

Sharpe Mixers offers a range of portable mixers that can be used for various mixing applications. These mixers are designed to provide flexibility and mobility, making them ideal for use in situations where the mixing process needs to be carried out in different locations. The portable mixers are available in different sizes and configurations, allowing users to choose the one that best suits their specific needs.

Sharpe Mixers’ portable mixers are used in a wide range of industries, including chemical processing, food and beverage, pharmaceuticals, and water and wastewater treatment. These mixers are ideal for applications that require mixing of small volumes of liquids or suspensions. The portable mixers are easy to move around and can be quickly set up for use, making them a convenient and cost-effective solution for small-scale mixing applications.

The portable mixers are available in different types, including clamp mount, fixed mount, and air-driven mixers. Each type is designed to meet different mixing requirements and is available in different sizes and configurations. The mixers are made from high-quality materials and are built to last, providing users with a reliable and durable mixing solution. With their versatility, mobility, and durability, Sharpe Mixers’ portable mixers are an ideal solution for many mixing applications.

These mixers are designed for use in a variety of industries, including chemical processing, food and beverage, pharmaceuticals, and wastewater treatment. They are ideal for mixing liquids with low to medium viscosity, and are available in a variety of sizes and configurations to meet the specific needs of each application.

One of the key benefits of Sharpe Mixers portable mixers is their versatility. These mixers are designed to be used in a variety of different applications, including blending, mixing, emulsifying, and dispersing. They can be used to mix a variety of different liquids, including water, oils, chemicals, and food products. In addition, they can be used in both batch and continuous processing applications.

Another key benefit of Sharpe Mixers portable mixers is their ease of use. These mixers are designed to be easy to operate, with intuitive controls and simple, user-friendly interfaces. They are also designed to be easy to clean and maintain, with simple, tool-free disassembly and reassembly. This makes them an ideal choice for applications where frequent cleaning and maintenance are required, such as in food processing and pharmaceutical manufacturing.

Top-Entry Mixers

Sharpe Mixers is a leading manufacturer of industrial mixers that offers a wide range of top entry mixers for various industries. Top entry mixers are generally used for mixing or blending of low-viscosity liquids with a high flow rate. Sharpe Mixers’ top entry mixers are designed to deliver superior mixing performance, high efficiency, and reliability, and are used in a variety of industries such as chemical processing, food and beverage, pharmaceutical, and water treatment.

Sharpe Mixers’ top entry mixers are available in different models, including the AFX series, the DFX series, and the Raptor series. The AFX series is designed for use in high viscosity mixing applications, while the DFX series is used for mixing of low viscosity fluids. The Raptor series is a high-performance mixer that features a modular design, which allows it to be easily customized for various applications.

Top entry mixers from Sharpe Mixers are used in a variety of applications, including mixing of chemicals, blending of food and beverage products, and agitation of water treatment chemicals. They are also used in the oil and gas industry for mixing of drilling fluids and in the pharmaceutical industry for mixing of pharmaceuticals. Sharpe Mixers’ top entry mixers are known for their high efficiency and reliability, which makes them ideal for use in critical applications where consistent and repeatable mixing is essential.

Top entry mixers are primarily used in large tanks and vessels for mixing and agitating liquids and fluids. These mixers are highly efficient and can provide excellent results in a range of applications. Sharpe Mixers offers a range of top entry mixers designed for specific applications, such as blending, solid suspension, and gas dispersion.

One of the main advantages of Sharpe Mixers top entry mixers is their ability to handle high volumes of fluid. These mixers are available in a range of sizes and can be customized to suit specific applications. They are ideal for mixing large volumes of fluids in the oil and gas, chemical, and water treatment industries. Top entry mixers can also be used in the food and beverage industry for blending liquids such as syrups, juices, and dairy products.

Sharpe Mixers top entry mixers are highly reliable and easy to maintain. They are designed to operate for extended periods without requiring any maintenance. The mixers are also easy to install and can be customized to meet specific requirements. Sharpe Mixers offers a range of top entry mixers, including the SE Series, TSS Series, and SBE Series, each designed for specific applications. These mixers are designed for high-performance and are built to last, making them ideal for a range of industries.

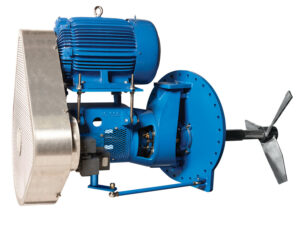

Side Entry Mixers

Sharpe Mixers manufactures a wide range of side entry mixers that are specifically designed for use in the oil and gas, petrochemical, and chemical processing industries. Side entry mixers are ideal for large tanks and vessels where a top-entry mixer would not be practical. These mixers are designed to be durable, reliable, and efficient, making them ideal for use in a range of applications.

One of the key advantages of side entry mixers is that they can be used to mix large volumes of fluid without the need for a lot of space. This makes them ideal for use in storage tanks, where they can be used to keep the contents of the tank homogeneous and prevent the formation of sediment or other types of buildup. They are also used in the production of chemicals, where they are used to mix raw materials and other ingredients together in large tanks.

Side entry mixers from Sharpe Mixers are designed to be highly customizable, which means that they can be adapted to meet the specific needs of each customer. They are available in a range of sizes and can be customized with a variety of impeller configurations and materials. This allows customers to choose the right mixer for their specific application, whether they need a high flow rate, high shear mixing, or a combination of both.

Sharpe Mixers’ side entry mixers are designed to provide efficient mixing in large storage tanks, with capacities ranging from 500 gallons to over 1,000,000 gallons. These mixers are commonly used in the chemical, petroleum, and water treatment industries, where the mixing of liquids and gases is crucial to the manufacturing process. The side entry mixers can also be used in applications that require high flow rates, such as in crude oil storage tanks or in large mixing tanks.

One of the key advantages of Sharpe Mixers’ side entry mixers is their ability to operate in large storage tanks with limited space for mixing equipment. The mixers are designed to be installed through the side of the tank, eliminating the need for costly and time-consuming modifications to the tank itself. They are also designed to operate at low speeds, which reduces the amount of wear and tear on the mixer and helps to extend its lifespan.

Sharpe Mixers’ side entry mixers can be customized to meet the specific needs of each application. They are available in a variety of materials, including stainless steel and exotic alloys, and can be equipped with a range of impeller designs to provide the desired mixing performance. The mixers can also be equipped with various seals and bearings to ensure reliable, long-lasting operation in harsh operating conditions.

Inline Mixing

These mixers are used in a wide range of industries, including chemical, pharmaceutical, food and beverage, and water treatment. The inline mixers offer a high level of efficiency, reliability, and accuracy in mixing a wide range of liquids, gases, and solids.

One of the key features of Sharpe Mixers’ inline mixing equipment is the precise mixing and dispersion of materials. This is achieved through the use of high shear and low shear mixing, which can be adjusted to meet the specific needs of the application. The inline mixers also offer the ability to mix at high volumes while maintaining a consistent flow rate.

The inline mixing equipment from Sharpe Mixers also offers easy maintenance and cleaning. The mixers are designed to be easily disassembled, and the parts can be quickly replaced, making maintenance a quick and simple process. This helps to reduce downtime and ensure that the equipment is always operating at peak performance. Additionally, the inline mixers can be cleaned in place, eliminating the need for disassembly and cleaning by hand.

The inline mixing equipment that is widely used in the chemical, pharmaceutical, food and beverage, and cosmetic industries. These inline mixers are specifically designed to be used in applications that require a high level of mixing intensity and product uniformity. Sharpe Mixers’ inline mixing equipment is known for its reliability, versatility, and ease of use, making it a popular choice for many different applications.

One of the most common applications of Sharpe Mixers’ inline mixing equipment is in the chemical industry. These mixers are often used for blending different chemicals and ensuring a consistent mixture. They are also used for emulsification, which is the process of creating a stable mixture of two immiscible liquids. Sharpe Mixers’ inline mixing equipment is also used in the pharmaceutical industry for mixing powders, granules, and liquids.

In the food and beverage industry, Sharpe Mixers’ inline mixing equipment is used for a variety of applications, including blending, emulsification, and homogenization. These mixers are used to create a uniform mixture of ingredients and to ensure that the final product is consistent in taste and texture. They are also used for the production of sauces, dressings, and other food products that require a high level of mixing intensity. Sharpe Mixers’ inline mixing equipment is also used in the cosmetic industry for mixing various ingredients and creating a consistent mixture for products like creams, lotions, and shampoos.

High Shear Mixers

One of the popular types of mixing equipment that Sharpe Mixers offers is the High Shear Mixers. High shear mixers use high-speed rotation to create a turbulent flow within the mixing chamber. This generates high shear rates that help to break down the ingredients and produce uniform mixing. The high shear mixers offered by Sharpe Mixers are suitable for a range of applications, including emulsifying, dispersing, and homogenizing.

Sharpe Mixers High Shear Mixers come in different designs, including inline and batch mixers. The inline mixers consist of a rotor and a stator, where the rotor rotates at high speeds, creating intense shear forces that mix the fluids. On the other hand, the batch mixers use an impeller that moves through the fluid, generating high shear forces. The mixers are designed with different impeller configurations to suit the specific application requirements.

The High Shear Mixers offered by Sharpe Mixers are ideal for a wide range of industries, including food and beverage, chemical processing, pharmaceuticals, cosmetics, and biotech. For instance, in the food and beverage industry, high shear mixers can be used to produce homogenized mixtures such as sauces, dips, dressings, and beverages. In the chemical industry, high shear mixers can be used to produce emulsions, dispersions, and other complex mixtures. Similarly, in the pharmaceutical industry, high shear mixers can be used to produce drug suspensions, creams, and ointments. Overall, Sharpe Mixers High Shear Mixers offer an efficient and reliable solution for high shear mixing applications across various industries.

The mixers are used for applications that require the emulsification, dispersion, and homogenization of liquids, as well as the incorporation of powders, solids, and liquids into a uniform mixture.

The high shear mixers feature a precision-engineered rotor/stator design, with the rotor spinning at high speeds to create a powerful hydraulic shear force that rapidly and effectively breaks down particles and droplets to create a fine, homogeneous mixture. The mixers are available in a range of sizes, from lab-scale models to large-scale industrial systems, to meet the needs of different applications.

Sharpe Mixers’ high shear mixers are ideal for use in a range of applications, including the production of pharmaceuticals, where they can be used to create emulsions, suspensions, and solutions. In the food and beverage industry, the mixers are used for the homogenization of dairy products, sauces, and dressings, as well as for the production of beverages, such as juices and smoothies. The mixers are also used in the chemical industry for the production of paints, adhesives, and other products that require uniform mixing of liquids, powders, and solids.

Overall, we offer a comprehensive range of Sharpe Mixers equipment to meet the specific needs of our customers. By selecting the appropriate mixer for their application, professionals can ensure efficient and reliable mixing performance, resulting in higher productivity and improved product quality.

Sharpe Mixers Applications

Sharpe Mixers equipment is widely used in a variety of industrial applications where efficient and reliable mixing is essential. Some of the industries that utilize Sharpe Mixers equipment include chemical processing, water treatment, food and beverage production, paint and coatings production, pharmaceuticals, and many others.

Chemical Processing

Sharpe Mixers has been providing mixing solutions for various industries, including the chemical processing industry, for over 65 years. They offer a range of mixing equipment that is designed to meet the specific needs of chemical processes. The chemical processing industry requires reliable, efficient, and safe mixing equipment to produce quality products, and Sharpe Mixers provide just that.

One of the primary applications of Sharpe Mixers in the chemical processing industry is in the mixing of chemicals. Chemical mixing is a crucial process in this industry as it helps to produce a uniform mixture of different chemicals. Sharpe Mixers offer various mixing equipment for chemical mixing, including turbine mixers, high shear mixers, and side entry mixers, which provide efficient and effective mixing.

Another application of Sharpe Mixers in the chemical processing industry is in the production of polymers. Polymer production involves mixing various chemicals, and Sharpe Mixers’ mixing equipment provides the required consistency and quality of mixing to produce high-quality polymers. The use of high-shear mixers in polymer production is particularly important, as it ensures that the final product is of the desired quality.

Sharpe Mixers also provide mixing solutions for the production of specialty chemicals, such as adhesives, coatings, and resins. These chemicals require precise mixing and uniformity to achieve the desired characteristics, and Sharpe Mixers’ equipment provides the necessary consistency and quality to achieve this. Their top entry and side entry mixers are particularly suitable for these applications, as they offer efficient mixing and are easy to maintain.

In conclusion, Sharpe Mixers’ mixing equipment plays a crucial role in the chemical processing industry, providing efficient, effective, and safe mixing solutions for various chemical processes. Their range of mixing equipment is designed to meet the specific needs of chemical processing, ensuring that the final product meets the required standards of quality and consistency.

Water Treatment

In the water treatment industry, Sharpe Mixers’ equipment is used to treat water to meet various regulatory standards and requirements. The equipment is designed to mix various chemicals and additives with the water to ensure the removal of impurities, bacteria, and other contaminants.

One of the applications of Sharpe Mixers’ equipment in the water treatment industry is in the mixing of coagulants and flocculants. Coagulants are added to the water to destabilize the impurities, while flocculants are added to clump the destabilized particles together, making them easier to remove. Sharpe Mixers’ top entry mixers are particularly effective in this application due to their ability to provide high intensity mixing and ensure that the chemicals are evenly distributed throughout the water.

Another application of Sharpe Mixers’ equipment in the water treatment industry is in the mixing of chemicals for disinfection purposes. Sharpe Mixers’ high shear mixers are particularly effective in this application, as they are designed to rapidly disperse chemicals into the water. This ensures that the chemicals are evenly distributed throughout the water, which is critical for effective disinfection.

In addition to coagulants, flocculants, and disinfectants, Sharpe Mixers’ equipment is also used in the water treatment industry for the mixing of other chemicals and additives, such as pH adjusters, anti-scaling agents, and corrosion inhibitors. The equipment is designed to handle a wide range of viscosities and densities, making it versatile and suitable for various applications in the water treatment industry.

Food and Beverage

The food and beverage industry requires high-quality mixing equipment to ensure that products are mixed uniformly and consistently. Sharpe Mixers has a range of mixers that can handle various applications, such as blending, emulsifying, and homogenizing.

One of the applications of Sharpe Mixers in the food and beverage industry is the mixing of liquid and solid ingredients. In the baking industry, mixers are used to combine ingredients such as flour, sugar, and water to make dough. In the beverage industry, mixers are used to blend ingredients such as fruit purees, juices, and syrups to make drinks. Sharpe Mixers’ high-quality mixing equipment ensures that ingredients are mixed uniformly, resulting in consistent and high-quality products.

Another application of Sharpe Mixers in the food and beverage industry is the homogenization of products. Homogenization is the process of breaking down and dispersing fat globules in products such as milk and cream to create a uniform product. Sharpe Mixers’ high-shear mixers are designed to handle this application, producing a smooth and uniform product.

In the food and beverage industry, hygiene is of utmost importance. Sharpe Mixers’ equipment is designed with ease of cleaning in mind, with features such as smooth surfaces and easy access to components. This makes their equipment ideal for use in the food and beverage industry, where hygiene is crucial.

In conclusion, Sharpe Mixers’ mixing equipment is essential in the food and beverage industry, where uniformity, consistency, and hygiene are crucial. Their range of mixers can handle various applications, ensuring high-quality products.

Painting and Coatings

Sharpe Mixers is a leading manufacturer of mixing equipment for various industries, including the painting and coating industry. Their equipment is designed to efficiently and effectively mix a variety of materials, including paints, coatings, adhesives, and sealants. Sharpe Mixers offers a range of mixing solutions for both small and large-scale operations, from laboratory-scale mixers to heavy-duty industrial mixers.

In the painting and coating industry, Sharpe Mixers’ equipment is essential for ensuring consistent and high-quality finishes. Their high shear mixers are particularly useful for dispersing pigments and other additives, resulting in a uniform and smooth coating. Sharpe Mixers also offers top entry mixers that are specifically designed for large-scale mixing operations, such as mixing tanks and reactors. These mixers are capable of handling high-viscosity materials and are built to withstand the demands of heavy-duty industrial use.

Sharpe Mixers’ side entry mixers are another popular choice for the painting and coating industry, as they can efficiently mix large volumes of materials without requiring extensive tank modifications. These mixers are also designed to prevent sedimentation and promote thorough mixing, resulting in a high-quality finished product.

Overall, Sharpe Mixers’ equipment plays a crucial role in the painting and coating industry, providing efficient and effective mixing solutions that help to ensure consistent and high-quality finishes. With their extensive experience and commitment to innovation, Sharpe Mixers is a trusted partner for companies in the painting and coating industry looking to improve their mixing processes.

Pharmaceutical

Pharmaceutical manufacturing requires high levels of accuracy and consistency to ensure that the final product meets the required standards. Mixing equipment plays a critical role in the production process, from mixing ingredients for tablets and capsules to creating homogenous suspensions for injectables. Sharpe Mixers offers a range of mixers that can meet the demanding requirements of the pharmaceutical industry, including sanitary designs that meet cGMP standards.

Sharpe Mixers’ side-entry mixers are ideal for blending large batches of pharmaceutical products, such as syrups, creams, and ointments. These mixers are designed to handle high viscosities and can efficiently disperse powders and other solids into liquids. Sharpe Mixers’ inline mixing equipment is suitable for blending and dispersing small quantities of ingredients accurately, making it an excellent choice for pharmaceutical formulations that require precision.

In addition to providing high-quality mixing solutions, Sharpe Mixers offers customized designs to meet specific needs. They can also help with the installation and commissioning of mixing equipment, as well as offer ongoing maintenance and support services. With their expertise in mixing technology and the pharmaceutical industry, Sharpe Mixers is a trusted partner for pharmaceutical manufacturers looking to optimize their production processes.

Overall, Sharpe Mixers equipment is used in a wide variety of industries and applications where efficient and reliable mixing is essential for production processes. By working with an expert to select the appropriate mixer for their specific application, professionals can ensure that they achieve the desired results and maintain high-quality product output.

Factors to Consider When Buying Sharpe Mixers

When considering purchasing equipment from Sharpe Mixers, there are several key factors that professionals should take into account.

Application Requirements

Before making a purchase, it is important to consider the specific application requirements of the equipment. This includes the type of material being mixed, the desired mixing speed, and the required mixing volume. Professionals should ensure that the equipment they choose is capable of meeting their specific application requirements to ensure optimal performance.

Mixer Type

There are several types of mixers available from Sharpe Mixers, including top entry, side entry, and portable mixers. Professionals should evaluate the advantages and disadvantages of each mixer type and choose the one that is best suited for their application.

Maintenance Requirements

Maintenance is an important consideration when purchasing equipment from Sharpe Mixers. Professionals should consider the maintenance requirements of the equipment and ensure that they have the necessary resources, such as spare parts and trained personnel, to maintain the equipment in good working condition.

Quality and Reliability

When investing in equipment from Sharpe Mixers, professionals should ensure that they are purchasing high-quality and reliable equipment that will meet their needs over the long term. It is important to choose equipment that is manufactured with high-quality materials and backed by strong warranties and support.

Cost

Cost is an important consideration when purchasing equipment from Sharpe Mixers. Professionals should ensure that they are selecting equipment that provides the best value for their investment. While cost is an important factor, it should not be the only factor considered when making a purchasing decision.

By taking these factors into account, professionals can make an informed decision when purchasing equipment from Sharpe Mixers and ensure that they select the equipment that best meets their specific needs and requirements.

About Sharpe Mixers

Sharpe Mixers is a leading manufacturer of high-quality mixing equipment for various industries. They offer a wide range of mixers, including portable mixers, top-entry mixers, and side-entry mixers, designed to meet the specific needs of each application. Sharpe Mixers has a reputation for producing reliable, durable, and efficient mixing equipment that can help improve productivity, reduce operating costs, and optimize performance.

Sharpe Mixers’ product line includes various types of mixers, such as high-speed dispersers, turbine mixers, propeller mixers, and static mixers. Each mixer is designed to handle a different range of viscosities and applications, from simple blending to complex emulsification processes. Sharpe Mixers also offers custom-designed mixing solutions to meet the unique requirements of specific industries or applications.

Sharpe Mixers’ equipment is used in a wide range of industries, including chemical processing, pharmaceuticals, food and beverage, water and wastewater treatment, pulp and paper, and mining. In chemical processing, Sharpe Mixers’ equipment can be used for chemical reactions, blending, and emulsification. In the pharmaceutical industry, Sharpe Mixers’ mixers can be used for the production of medicines, creams, and lotions. In the food and beverage industry, Sharpe Mixers’ equipment can be used for mixing, blending, and homogenization of products such as sauces, beverages, and dairy products.

The mixers produced by Sharpe Mixers are designed to meet specific application requirements, such as high shear, high flow, or low shear mixing. Sharpe Mixers’ top-entry and side-entry mixers are suitable for blending and mixing of viscous liquids and solids in large tanks, while their portable mixers are suitable for small tanks and applications that require frequent movement.

When considering purchasing equipment from Sharpe Mixers, professionals should consider the specific application requirements, including the viscosity and volume of the fluid being mixed, the type of mixing required, and any other specific requirements. Professionals should also consider the quality and durability of Sharpe Mixers’ equipment, as well as their customer service and support. Finally, professionals should consider the overall cost of ownership, including any maintenance and repair costs over the expected lifespan of the equipment. By considering these factors, professionals can make an informed decision when choosing mixing equipment from Sharpe Mixers that meets their specific needs and provides reliable and efficient performance for their application.

Affiliation with Hayward Gordon

Sharpe Mixers and Hayward Gordon are both leading manufacturers of industrial mixing equipment, each with their own unique expertise and product offerings. In 2019, the two companies announced their merger, forming a new company called Hayward Gordon Group.

Sharpe Mixers brings expertise in the design and manufacture of custom mixing solutions, with a focus on high-quality, efficient, and reliable equipment. Their product line includes a wide range of mixers, including high-speed dispersers, turbine mixers, propeller mixers, and static mixers, designed for a variety of applications.

Hayward Gordon, on the other hand, specializes in the design and manufacture of pumps and mixers for the most demanding applications. Their product line includes pumps for slurry and abrasive applications, as well as mixers for high-viscosity and high-solids applications.

Together, Sharpe Mixers and Hayward Gordon bring decades of experience and expertise in the mixing and pumping industry, providing customers with a comprehensive range of solutions for their specific needs. Their combined product offerings provide customers with a one-stop-shop for all their mixing and pumping needs, from custom mixing solutions to specialized pumps for demanding applications.