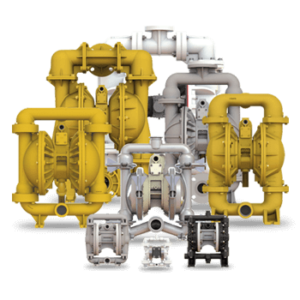

Warren Rupp Equipment We Distribute

Warren Rupp, a subsidiary of IDEX Corporation, is a leading manufacturer of air-operated double-diaphragm (AODD) pumps. They offer a wide range of pumps for various applications and industries.

Their standard AODD pumps come in various sizes and materials such as polypropylene, PVDF, aluminum, stainless steel, and hastelloy. These pumps have an innovative design that allows them to handle abrasive, viscous, and shear-sensitive fluids. They also have a self-priming capability, meaning they can handle liquids with high levels of gas or air.

Warren Rupp also offers specialized pumps for specific applications such as the Sandpiper HD, which is specifically designed for heavy-duty applications and the Versa-Matic Ultra-Matic, which is ideal for handling high-viscosity fluids. They also offer specialty pumps for sanitary applications, such as food and beverage processing, pharmaceuticals, and cosmetics.

In addition to AODD pumps, Warren Rupp also manufactures peristaltic hose pumps, which are ideal for pumping corrosive and abrasive fluids. Their peristaltic pumps feature a low-maintenance design and can handle fluids with high solid content.

Warren Rupp’s pumps are used in various industries, including chemical processing, mining, oil and gas, water and wastewater treatment, food and beverage, and pharmaceuticals.

Their pumps have a wide range of applications such as:

- Transferring and circulating chemicals and solvents

- Pumping slurry, sand, and mud

- Metering and dosing additives

- Handling high-viscosity fluids such as adhesives and paints

- Pumping abrasive fluids such as metal shavings and glass fibers

- Transferring and filling containers with various fluids

Warren Rupp’s pumps are known for their reliability, durability, and versatility, making them a popular choice for professionals in various industries.

When considering purchasing equipment from Warren Rupp, it is essential to consider the specific requirements of the application, the fluid being handled, and the environment in which the pump will be used. It is also crucial to consider the maintenance and repair requirements of the pump, as well as the level of support and service provided by the manufacturer.

Sandpiper

Sandpiper pumps are a line of air-operated double diaphragm (AODD) pumps manufactured by Warren Rupp. These pumps are designed to handle a wide range of liquids, including corrosive, abrasive, and viscous fluids, making them suitable for use in a variety of industries. Sandpiper pumps are known for their robust construction and reliable performance, making them a popular choice for many professionals.

One of the key features of Sandpiper pumps is their simple design. With no moving parts and a straightforward operating principle, these pumps are easy to use and maintain. They are also highly adaptable, with a range of materials available for wetted parts to suit specific applications. The pumps can be customized with a variety of options, such as porting configurations, elastomer types, and air distribution systems, to meet the specific needs of each application.

Sandpiper pumps are commonly used in industries such as mining, oil and gas, chemical processing, and wastewater treatment. They are ideal for applications where other types of pumps may be prone to clogging or wear, such as transferring slurries, handling acids and chemicals, and pumping abrasive liquids. With a range of sizes and flow rates available, Sandpiper pumps can be used for anything from small laboratory applications to large industrial processes, making them a versatile choice for professionals across many industries.

In the chemical processing industry, Sandpiper pumps are often used for handling chemicals, acids, and solvents. They are also used for metering, injecting, and transferring fluids. In the food and beverage industry, Sandpiper pumps are used for transferring products such as fruit juices, wine, beer, and syrup. The pumps can also be used for pumping viscous fluids like honey and molasses.

In the mining industry, Sandpiper pumps are used for slurry pumping, where they handle abrasive and corrosive materials. They are also used for tailings disposal, water supply, and chemical dosing. In the water treatment industry, Sandpiper pumps are used for wastewater treatment, effluent transfer, and chemical dosing. They are also used for handling industrial water, seawater, and fresh water.

Versamatic

Versamatic is a brand of air-operated double diaphragm pumps manufactured by Warren Rupp, Inc. These pumps are designed for use in a variety of industrial and commercial applications that require a reliable and efficient pumping solution. Versamatic pumps are available in a range of sizes and materials to meet the needs of various industries.

One of the key features of Versamatic pumps is their air valve system, which provides reliable and consistent performance. The pumps are also designed to handle a wide range of fluids, including abrasive and viscous materials. This makes them well-suited for use in the chemical, food and beverage, and mining industries, among others.

Versamatic pumps are also known for their ease of maintenance and repair. The pumps feature a simple, bolted design that allows for easy disassembly and reassembly, making it simple to replace parts and perform routine maintenance tasks. This helps to minimize downtime and keep operating costs low. Overall, Versamatic pumps are a versatile and reliable choice for a range of pumping applications.

One of the key applications of Versamatic pumps is in the chemical processing industry, where they are used to transfer and circulate a wide range of chemicals, such as acids, bases, solvents, and other corrosive materials. The pumps are designed to handle high-pressure applications and can operate at a range of temperatures, making them ideal for use in harsh and demanding environments.

Another application of Versamatic pumps is in the water and wastewater treatment industry, where they are used for a variety of functions, such as chemical dosing, sludge transfer, and filtration. The pumps are able to handle abrasive and viscous materials without clogging or causing damage to the system. They are also used in the food and beverage industry for applications such as transferring liquids, pumping viscous food products, and handling abrasive ingredients.

Overall, Versamatic pumps are known for their versatility and reliability, making them a popular choice for a wide range of applications in various industries. With a wide range of materials and configurations available, these pumps can be customized to suit specific application requirements, making them a cost-effective solution for various fluid-handling needs.

Warren Rupp Applications

These pumps are used in a variety of industries due to their versatility, durability, and ability to handle abrasive and viscous fluids. Warren Rupp pumps are used in many applications across industries such as chemical processing, food and beverage, mining, oil and gas, paint and coatings, pharmaceuticals, and wastewater treatment.

Chemical Processing

Warren Rupp, Inc. is a leading manufacturer of the air-operated double diaphragm (AODD) pumps that are widely used in the chemical processing industry. These pumps are highly versatile and can handle a wide range of fluids, including highly corrosive and abrasive ones. They are used in a variety of chemical processing applications such as transferring acids, solvents, and chemicals, as well as in wastewater treatment.

One of the key benefits of Warren Rupp pumps is their ability to handle a wide range of fluids, which makes them ideal for the chemical processing industry where different types of fluids are used. The pumps are also designed to handle high flow rates and pressures, which is essential in chemical processing applications where precise control of flow is important. They are also self-priming, meaning they can handle fluids that contain air or gases.

In addition to their versatility and durability, Warren Rupp pumps are also known for their ease of maintenance. They are designed to be easy to disassemble and clean, which is important in the chemical processing industry where contamination can be a major issue. This ease of maintenance also helps to reduce downtime and keep the pumps running smoothly, which is essential in a 24/7 production environment. Overall, Warren Rupp pumps are a trusted choice for chemical processing applications, providing reliable and efficient fluid transfer solutions.

Mining Industry

Warren Rupp, Inc. pumps are used extensively in the mining industry for a wide range of applications. One of the main benefits of these pumps is their ability to handle abrasive and corrosive fluids, which are commonly found in mining operations. They are used in many different areas of the mining process, including mineral processing, dewatering, and slurry transfer.

In mineral processing, Warren Rupp pumps are used for the transfer of minerals and chemicals from one location to another. They are also used in leaching and extraction processes where corrosive fluids are present. The pumps are designed to handle high flow rates and pressures, which is important in mineral processing applications where precise control of flow is critical to the efficiency of the process.

In dewatering applications, Warren Rupp pumps are used to remove water from mining pits, tunnels, and other underground areas. The pumps are designed to handle solids and slurries, which makes them ideal for removing water from areas where there is a lot of debris or sediment. The pumps are also used for tailings management, where they transfer the waste material from the processing plant to the tailings dam for storage.

Overall, Warren Rupp pumps are an essential part of many mining operations, providing reliable and efficient fluid transfer solutions for a wide range of applications. Their ability to handle abrasive and corrosive fluids, along with their durability and ease of maintenance, make them a trusted choice for the mining industry.

Pharmaceuticals

Warren Rupp, Inc. pumps are used in the pharmaceutical industry for a variety of applications. One of the main benefits of these pumps is their ability to handle a wide range of fluids, including highly viscous and sensitive ones. They are used in many different areas of the pharmaceutical process, including transferring and dosing of active ingredients, as well as in filtration and purification processes.

In the production of pharmaceuticals, Warren Rupp pumps are used to transfer active ingredients from one location to another. They are also used in dosing applications, where precise control of flow and pressure is essential for accurate dosing. The pumps are designed to be gentle on the fluid being transferred, which is important in pharmaceutical applications where the quality and purity of the product is critical.

Warren Rupp pumps are also used in filtration and purification processes in the pharmaceutical industry. They are used to pump fluids through filters and membranes, where they remove impurities and other contaminants. The pumps are designed to handle high pressures and flow rates, which is important in these applications where rapid filtration is required.

Painting and Coatings

Warren Rupp, Inc. pumps are used extensively in the painting and coatings industry for the transfer and circulation of paints, coatings, and other fluids. One of the main benefits of these pumps is their ability to handle high-viscosity fluids, such as paint and coatings, with ease. They are used in many different areas of the painting and coatings process, including fluid transfer, circulation, and spray applications.

In fluid transfer applications, Warren Rupp pumps are used to transfer paints and coatings from storage tanks to mixing tanks or directly to the application site. The pumps are designed to handle high flow rates and pressures, which is important in paint and coatings applications where a lot of fluid needs to be moved quickly and efficiently.

In circulation applications, Warren Rupp pumps are used to circulate fluids within the system, such as in paint mixing tanks. The pumps help to ensure that the fluid is properly mixed and maintained at the desired viscosity and temperature, which is important in achieving consistent and high-quality coatings.

Finally, Warren Rupp pumps are used in spray applications, where they are used to pump paint and coatings to spray guns. The pumps are designed to handle high pressure and low flow rates, which is important in achieving a fine and even spray pattern.

Overall, Warren Rupp pumps are an essential part of the painting and coatings industry, providing reliable and efficient fluid transfer solutions for a wide range of applications. Their ability to handle high-viscosity fluids, along with their durability and ease of maintenance, make them a trusted choice for this industry.

Water Treatment

Warren Rupp, Inc. pumps are used extensively in the water treatment industry for the transfer and treatment of water and wastewater. One of the main benefits of these pumps is their ability to handle a wide range of fluids, including those with high levels of solids and contaminants. They are used in many different areas of the water treatment process, including pumping and mixing of chemicals, filtration, and sludge dewatering.

In the treatment of water and wastewater, Warren Rupp pumps are used for the transfer of chemicals such as coagulants and flocculants, which help to remove impurities from the water. The pumps are also used in the mixing of chemicals, ensuring that they are properly distributed and mixed throughout the water. The pumps are designed to handle high flow rates and pressures, which is important in water treatment applications where a lot of fluid needs to be moved quickly and efficiently.

In filtration applications, Warren Rupp pumps are used to pump water through filters and membranes, where they remove impurities and other contaminants. The pumps are designed to handle high pressures and flow rates, which is important in these applications where rapid filtration is required.

Finally, Warren Rupp pumps are used in sludge dewatering applications, where they are used to transfer and dewater sludge from wastewater treatment plants. The pumps are designed to handle high solids and viscous materials, making them ideal for this application.

Overall, Warren Rupp pumps are an important part of the water treatment process, providing reliable and efficient fluid transfer solutions for a wide range of applications. Their ability to handle a variety of fluids, along with their durability and ease of maintenance, make them a trusted choice for the water treatment industry.

Overall, Warren Rupp pumps are versatile and reliable, making them ideal for a wide range of industries and applications. When selecting a Warren Rupp pump, it is important to consider the fluid being pumped, the flow rate and pressure requirements, and the specific application requirements to ensure the best performance and longevity of the pump.

Factors to Consider When Buying Warren Rupp

Before we select Warren Rupp products for our customers, our engineers start by considering several factors:

Fluid Compatibility

Fluid compatibility is an important consideration when purchasing Warren Rupp, Inc. equipment. Different fluids can have varying levels of corrosiveness and abrasiveness, which can impact the performance and lifespan of the pump. It is essential to ensure that the pump is compatible with the fluid being pumped to avoid any potential damage or failure.

To ensure fluid compatibility, Warren Rupp offers a wide range of materials for their pumps, including different types of plastics, metals, and elastomers. The choice of material will depend on the specific fluid being pumped and its properties. For example, if the fluid is highly corrosive, a material such as Hastelloy or PVDF may be necessary. If the fluid is highly abrasive, materials such as polyurethane or ceramic may be more suitable.

Fluid compatibility is essential not only for the performance and lifespan of the pump but also for the safety of the operator and the environment. If a pump is not compatible with the fluid being pumped, it can cause leaks or spills, which can be hazardous to the operator or the environment. Therefore, it is crucial to ensure that the pump is designed and constructed with the appropriate materials to handle the specific fluid being pumped.

Pump Size and Flow Rate

Pump size and flow rate are important considerations when purchasing Warren Rupp, Inc. equipment. The size of the pump will depend on the amount of fluid that needs to be pumped and the flow rate required for the application. Choosing the correct pump size and flow rate will ensure that the pump operates efficiently and meets the specific needs of the application.

The flow rate of the pump is the amount of fluid that can be pumped in a specific amount of time. The flow rate will depend on the size and speed of the pump, as well as the pressure and viscosity of the fluid being pumped. It is important to select a pump with a flow rate that matches the specific needs of the application. Choosing a pump with too low of a flow rate may result in inefficient operation, while a pump with too high of a flow rate may lead to excessive wear and tear on the pump.

The size of the pump is another important consideration. The size of the pump will determine the amount of fluid that can be pumped at one time. It is important to select a pump that is appropriately sized for the application to avoid any potential performance issues or pump failures. A pump that is too small may not be able to handle the required flow rate, while a pump that is too large may result in excess energy consumption and operating costs.

Pump Maintenance

Pump maintenance is an important consideration when purchasing Warren Rupp, Inc. equipment. Proper maintenance is essential for ensuring the pump operates efficiently and has a long lifespan. Before purchasing a pump, it is important to consider the maintenance requirements and ensure that they are compatible with the resources and capabilities of the user.

One of the main benefits of Warren Rupp pumps is their ease of maintenance. The pumps are designed to be easy to disassemble and clean, which is important in applications where contamination can be a major issue. It is important to consider the specific maintenance requirements of the pump and ensure that they are compatible with the resources and capabilities of the user. If a pump requires extensive maintenance, it may not be suitable for some applications.

Proper maintenance is essential for ensuring that the pump operates efficiently and has a long lifespan. Neglecting maintenance can lead to pump failure, decreased efficiency, and increased operating costs. Before purchasing a pump, it is important to consider the maintenance requirements and ensure that the user has the resources and capabilities to properly maintain the pump.

Environmental Considerations

Environmental considerations are an important consideration when purchasing Warren Rupp, Inc. equipment. The environmental impact of the equipment should be considered, as well as any regulations or standards that the equipment must comply with. It is essential to ensure that the equipment is environmentally friendly and complies with any relevant regulations or standards.

One of the main environmental considerations when purchasing Warren Rupp pumps is their energy efficiency. Choosing an energy-efficient pump can help to reduce energy consumption and operating costs, as well as reduce the environmental impact of the equipment. It is important to consider the energy efficiency of the pump and ensure that it meets any relevant efficiency standards or regulations.

Another environmental consideration is the materials used in the construction of the pump. Warren Rupp offers a range of materials for their pumps, including those that are environmentally friendly and can be recycled. It is important to consider the environmental impact of the materials used in the construction of the pump and ensure that they are compatible with any relevant regulations or standards.

Regulatory Compliance

Regulatory compliance is an important consideration when purchasing Warren Rupp, Inc. equipment. Different industries and applications may have specific regulations and standards that must be met, such as safety standards, environmental regulations, and material handling regulations. It is essential to ensure that the equipment being purchased meets any relevant regulations or standards.

One of the main reasons to consider regulatory compliance when purchasing Warren Rupp equipment is to ensure safety. Many industries, such as chemical processing and mining, have strict safety regulations that must be followed to protect workers and the environment. It is important to ensure that the equipment being purchased meets these safety standards to minimize the risk of accidents and injuries.

Another reason to consider regulatory compliance is to ensure that the equipment being purchased is compatible with any relevant environmental regulations. For example, pumps used in the water treatment industry must meet specific regulations to ensure that the water being treated is safe for human and animal consumption. It is essential to ensure that the equipment being purchased meets these environmental regulations to avoid any potential fines or penalties.

About Warren Rupp

Warren Rupp is a leading manufacturer of air-operated double diaphragm (AODD) pumps that offer versatile solutions for fluid handling applications across various industries. The company was founded in 1965 in Mansfield, Ohio, and has since become a part of the IDEX Corporation, a global leader in the development and manufacturing of fluid handling solutions.

Warren Rupp offers a wide range of AODD pumps that are designed for handling difficult fluids, including corrosive and abrasive materials, viscous liquids, and solids-laden slurries. The pumps are available in a variety of materials, including aluminum, stainless steel, and polypropylene, to suit different applications and process requirements.

The pumps are used in a range of industries, including chemical processing, food and beverage, oil and gas, pharmaceuticals, and water treatment. They are ideal for transferring and dosing a wide range of fluids, including acids, adhesives, paints, resins, solvents, and wastewater. The pumps are also suitable for handling high-viscosity fluids, shear-sensitive liquids, and abrasive slurries.

Warren Rupp’s AODD pumps are known for their reliability, ease of maintenance, and energy efficiency. They offer self-priming capabilities, dry running capabilities, and can operate with a wide range of pressures and flows. They are also designed for use in hazardous environments, as they are intrinsically safe and do not require electricity.

In addition to AODD pumps, Warren Rupp also offers a range of accessories, including air filters, regulators, and lubricators, as well as hoses and fittings that are designed for use with AODD pumps.

Overall, Warren Rupp is a trusted provider of fluid handling solutions that offers innovative and reliable products for a wide range of industries and applications.

Affiliation with IDEX Corporation

Warren Rupp is a leading manufacturer of air-operated double diaphragm pumps and a part of the Fluid & Metering Technologies (FMT) platform of IDEX Corporation. IDEX Corporation is a global company that designs, manufactures, and sells a wide range of engineered products and systems. IDEX Corporation has several platforms, including FMT, which is focused on fluid management solutions. Warren Rupp is one of the leading brands under FMT, offering innovative fluid handling solutions to a diverse range of industries.

Warren Rupp offers a wide range of air-operated double diaphragm pumps, including the SANDPIPER brand, which is a part of the FMT platform. These pumps are designed to handle a wide range of fluids, including corrosive and abrasive liquids, viscous liquids, and slurries. The pumps are also designed for a variety of applications, including chemical processing, mining, wastewater treatment, food and beverage processing, and more.

The affiliation with IDEX Corporation has provided Warren Rupp with the resources and support needed to continue to innovate and expand its product offerings. IDEX Corporation is committed to investing in research and development, which has allowed Warren Rupp to develop new products and technologies that meet the changing needs of its customers. The affiliation has also allowed Warren Rupp to expand its global reach, providing access to new markets and customers around the world.

In conclusion, Warren Rupp is a leading manufacturer of air-operated double diaphragm pumps and a part of the FMT platform of IDEX Corporation. The affiliation with IDEX Corporation has provided Warren Rupp with the resources and support needed to continue to grow and innovate. Warren Rupp is a trusted brand in the fluid handling industry, known for its high-quality products and exceptional customer service.