Industries / Refrigeration / Compressor Oil

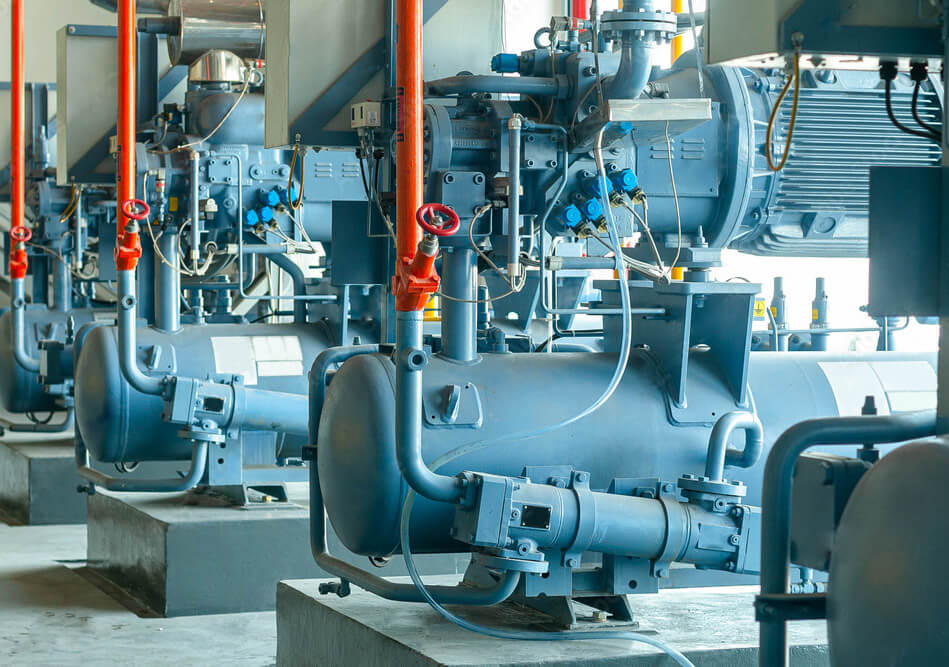

Streamline compressor oil handling with industrial equipment and services

Optimize oil handling and lubrication processes with equipment that ensures precise and consistent oil flow, efficient filtration, and controlled lubrication, resulting in improved compressor performance, reduced downtime, and enhanced overall system efficiency. By achieving optimal oil circulation and maintenance, refrigeration systems can operate at peak performance, maximizing energy efficiency and minimizing the risk of equipment failures.

The Manufacturing Process

Create economies of scale across your system

Each of these stages requires specific types of industrial rotating equipment, and proper operation and maintenance of this equipment is crucial for the efficiency and safety of the compressor oil manufacturing industry.

Mixing

The manufacture of compressor oil often involves blending various base oils with different additives. Rotating equipment such as agitators and mixers are used to ensure a homogeneous blend.

Pumping

Pumps are used to transfer raw materials, intermediates, and finished products between different stages of the manufacturing process.

Filtration

Rotary vacuum drum filters or centrifuges may be used to filter out any impurities or particulates that may be present in the oil, ensuring a clean final product.

Reaction

Certain types of compressor oil may require chemical reactions (such as hydrogenation) for their manufacture. These reactions often take place in reactors equipped with agitators or other rotating equipment to ensure proper mixing.

Heat Exchangers

These devices are often used to control the temperature during the oil production process, and they may involve rotating parts to improve heat transfer efficiency.

Separation

After the reaction process, it's important to separate the desired product from any byproducts or unreacted materials. This can be done using rotating equipment like centrifuges.

Quality Control

During the quality control process, rotating machinery like viscometers might be used to measure the viscosity of the compressor oil.

Packaging

When the compressor oil is ready for distribution, it is often filled into containers (like drums or bottles) for shipping. This process can involve rotating equipment like pumps and filling machines.

Maintenance & Cleaning

Rotating equipment like pressure washers and rotary brushes are used for the cleaning and maintenance of other manufacturing equipment.