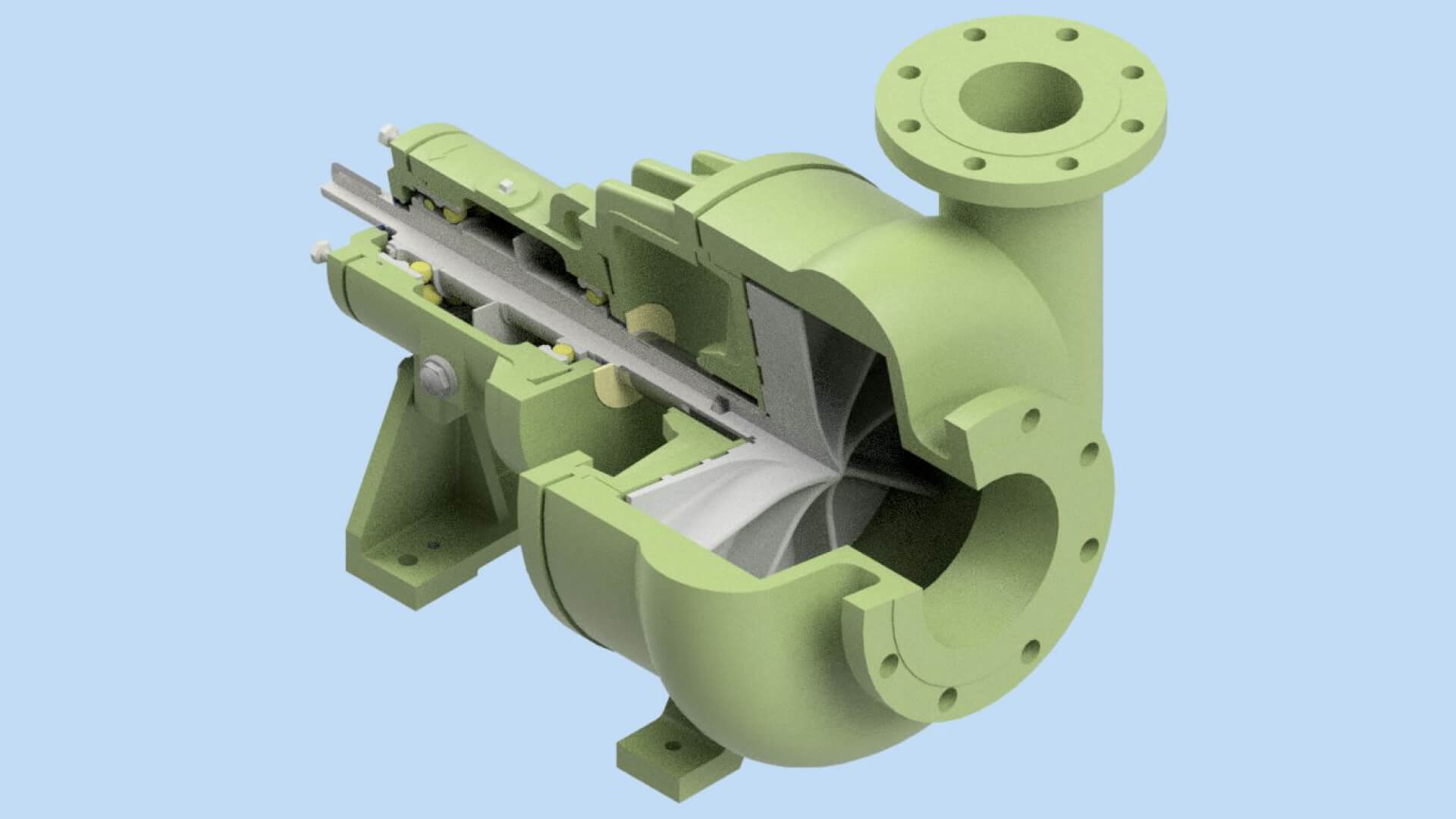

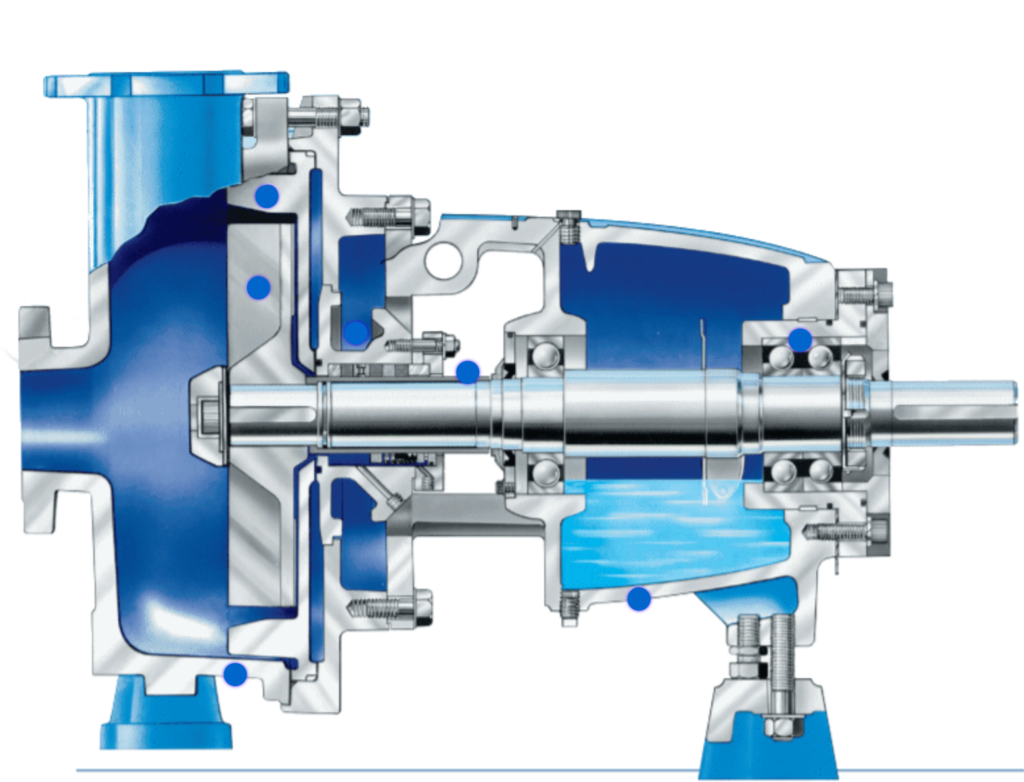

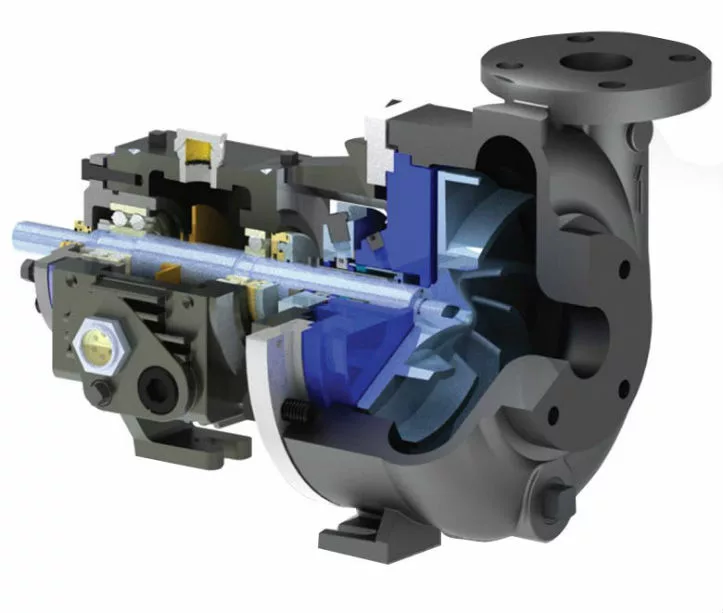

Recessed impeller pumps, including submersible and horizontal types, are designed for demanding applications. The unique design of these pumps, with the impeller recessed into the pump casing, allows for efficient handling of solids, reduced abrasive wear, and minimal maintenance. This design makes them ideal for pumping raw sewage, municipal wastewater, and other abrasive or corrosive liquids.

Key Features & Advantages

The key features of recessed impeller pumps, such as stainless steel shafts and easily replaceable top pullout designs, contribute to their longevity and reliability. These pumps are designed and manufactured to withstand tough conditions, assuring long-term, reliable performance. The impeller design, coupled with abrasion-resistant materials, ensures that these pumps can handle even the most challenging fluids efficiently.

Prominent Recessed Impeller Pump Brands

When selecting a recessed impeller pump, it’s important to consider the leading brands in the industry, each offering unique and advanced models that cater to various needs. Here are some notable manufacturers known for their high-quality recessed impeller pumps:

Hayward Gordon

XR Torus Recessed Impeller Pump: This pump is a true vortex pump, highly effective at handling abrasive slurries, stringy or fibrous materials, sludges, and fluids with high gas entrainment. Its robust design ensures durability and efficiency in challenging conditions.

PumpWorks

Model PWA-RC: Known for its reduced liquid velocities, this recessed impeller centrifugal pump minimizes casing and impeller wear rates. It is ideal for entrained gaseous or air-entrained liquids, featuring capacities up to 2,700 GPM and pressures up to 285 PSIG. This design enhances the pump’s longevity and operational efficiency.

Goulds Pumps

HSU and HSUL Recessed Impeller Submersible Pumps: These pumps are distinguished by their fully recessed impeller, allowing large, stringy, or fibrous material to pass through without binding or clogging. The concentric casing design enhances the flow of pumpage and solids, minimizing loads. The HSU and HSUL models offer mounting flexibility with flanged suction and horizontal discharge, and their bolt-on legs provide stability on the sump floor. An added advantage is the interchangeability of casing and optional wear ring with Goulds Model HS and VHS pumps, reducing inventory needs.

Applications in Industry

Recessed impeller pumps are particularly effective in challenging applications that involve pumping contaminated liquids with suspended solids and fibers. These pumps are ideal for handling a wide range of applications, including slurries, fibers, wastewater, and liquids with soft particles, such as those found in food processing. Their robust design and ability to create a liquid vortex in the open pump casing enable them to direct spherical solids, slurry, sludge, grit, and stringy or fibrous material through the pump without clogging.

Mining

In mining operations, recessed impeller pumps are used to handle abrasive slurries and materials containing solid particles. Their design minimizes wear and tear, ensuring prolonged operation and reducing the frequency of maintenance and replacements.

Oil & Gas

In the oil and gas industry, these pumps are crucial for handling drilling mud, crude oil, and other viscous fluids containing solids. Their ability to pump without clogging is essential for maintaining continuous operations in such harsh environments.

Wastewater Management

Wastewater treatment plants utilize recessed impeller pumps to manage raw sewage, sludge, and other contaminated liquids. These pumps are effective in handling fibrous materials and solids that can be present in wastewater, ensuring efficient processing and treatment.

Food Processing

In the food processing industry, these pumps are used to handle liquids containing soft particles, such as fruit pulp or vegetable pieces. Their gentle handling ensures that the integrity of the food particles is maintained while preventing clogging and downtime.

Agriculture

Agricultural applications benefit from recessed impeller pumps for tasks such as irrigation and slurry handling. These pumps can efficiently manage water containing organic matter and other solids, making them ideal for agricultural processes.

While recessed impeller pumps offer numerous advantages, it is important to note that they generally have decreased efficiency compared to other types of pumps. However, their ability to handle difficult fluids without clogging or excessive wear makes them invaluable in many industrial applications.

Regional Considerations in Pump Selection

Selecting the right recessed impeller pump requires an understanding of the unique environmental and industrial conditions in different regions. At Arroyo Process Equipment, we recognize these regional nuances, particularly in the American Southeast, the Caribbean, and Latin America.

The American Southeast (Florida, Georgia, etc.)

In this region, the focus is often on handling large volumes of water, particularly in flood-prone areas and in industries like agriculture and aquaculture. The high humidity and potential for corrosive environments, due to the proximity to the ocean, require pumps that are robust, corrosion-resistant, and capable of handling high flow rates. Pumps with high efficiency in energy usage are also preferred due to the warm climate and energy consumption concerns.

The Caribbean (Puerto Rico, the Dominican Republic)

Here, the key factors include resistance to corrosion from saltwater exposure and the ability to handle stormwater and flood conditions. The region’s vulnerability to hurricanes necessitates pumps that are reliable in extreme weather conditions. Additionally, the handling of wastewater and industrial effluents in small, isolated communities requires pumps that are efficient, easy to maintain, and capable of handling diverse types of solids.

Latin America (Colombia, Brazil)

The diverse industries in these countries, from mining in Colombia to agriculture in Brazil, require pumps that are versatile and durable. The handling of abrasive slurries in mining and the need for energy-efficient solutions in agriculture are critical considerations. Environmental concerns and regulatory standards in these regions also demand pumps that are eco-friendly and adhere to strict environmental regulations.

In each of these regions, Arroyo Process Equipment provides tailored solutions, ensuring that the chosen recessed impeller pumps not only meet the technical requirements but also address the environmental and economic challenges unique to each locale.

Choosing the Right Recessed Impeller Pump

Choosing the right recessed impeller pump can be challenging, but at Arroyo Process Equipment, we’re here to help. Our expertise in pump applications and our partnership with leading manufacturers like Hayward Gordon and PumpWorks enable us to provide the best possible solutions to our customers. We take into account factors like pump casing design, bearing and seal life, and specific application requirements to ensure you get a pump that not only meets but exceeds your expectations. Contact us today if you need assistance selecting, repairing, replacing, or maintaining an ammonia pump. Our team is ready to help you achieve optimal results in your ammonia handling processes.

Conclusion

Recessed impeller pumps are indispensable in various industrial applications, from handling abrasive slurries to managing corrosive liquids. Their unique design ensures efficiency, durability, and minimal maintenance, making them ideal for demanding environments. By partnering with leading manufacturers and leveraging our regional expertise, Arroyo Process Equipment provides comprehensive pumping solutions tailored to your specific needs. For more information on our services and to explore our range of recessed impeller pumps, contact us today.

To learn more about all the services we offer and manufacturers we represent, please check out our official line card.