What is a Regenerative Turbine Pump?

A regenerative turbine pump, also known as a peripheral pump, is a type of pump designed for applications requiring high-pressure output with low flow rates. Regenerative turbine pumps are different from other pump types. They use a special impeller design.

This design lets the fluid flow back through the pump several times. As a result, it increases discharge pressure. This also improves the pump’s overall performance.

These pumps are great for moving clean, non-abrasive liquids. Many industries, like chemical processing, water treatment, and general industrial work, use them. Their ability to reach high head and manage low NPSH conditions makes them a popular choice for many pump makers.

How Does a Regenerative Turbine Pump Work?

The regenerative turbine pump operates using a specialized impeller that features numerous small vanes or blades along its outer edge. As the impeller rotates, it creates a vortex that draws fluid into the pump. The fluid flows along a circular path within the pump casing, gaining kinetic energy with each pass through the impeller vanes. This repeated circulation process is what gives the pump its “regenerative” characteristic, allowing it to achieve higher pressures than traditional centrifugal pumps.

This impeller design is essential in achieving the high head and consistent discharge pressure required in certain fluid handling applications.

Key Features of Regenerative Turbine Pumps

- High Pressure at Low Flow Rates: Ideal for applications where maintaining a consistent pressure is critical.

- Compact Design: These pumps are typically smaller and lighter than other high-pressure pumps.

- Ability to Handle Low NPSH Conditions: They can perform well even in systems with low net positive suction head.

- Versatility: Suitable for multi-stage configurations, enhancing performance for more demanding applications.

Regenerative Turbine Pump vs. Centrifugal Pump: What's the Difference?

One common question is: What is the difference between a regenerative turbine pump and a centrifugal pump?

While both types of pumps are used to move liquids, there are significant differences between the two:

| Feature | Regenerative Turbine Pump | Centrifugal Pump |

|---|---|---|

| Flow Rate | Low | High |

| Pressure Output | High | Moderate |

| Fluid Recirculation | Yes | No |

| Impeller Design | Vane-style impeller | Radial or axial impeller |

| NPSH Requirements | Low | Higher |

In summary, regenerative turbine pumps are better suited for applications that require high pressure at low flow rates, while centrifugal pumps are ideal for handling large volumes of liquid at lower pressures. Understanding the difference between a regenerative turbine pump and a turbine pump can help you choose the right solution for your specific needs.

Applications of Regenerative Turbine Pumps

Due to their unique operating principles, regenerative turbine pumps are used in various industries, including:

- Chemical Processing: For transferring chemicals at high pressure without large flow rates.

- Water Treatment: For dosing chemicals and managing pressurized water systems.

- HVAC Systems: Used in refrigeration and air conditioning systems.

- Boiler Feed: Ideal for feeding water into boilers where high pressure is necessary.

- General Industrial Applications: Commonly used in manufacturing processes that require consistent and reliable pump performance.

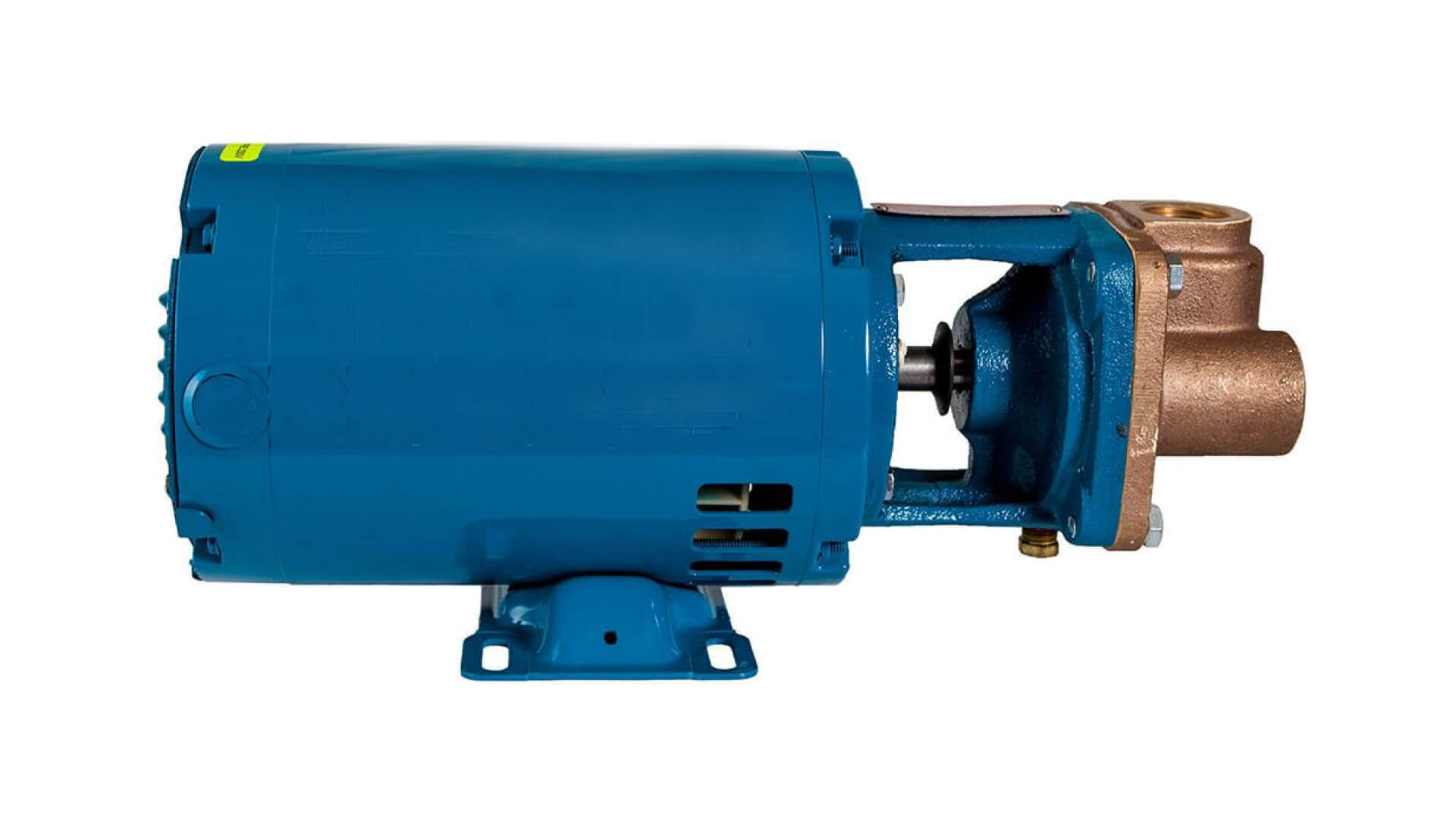

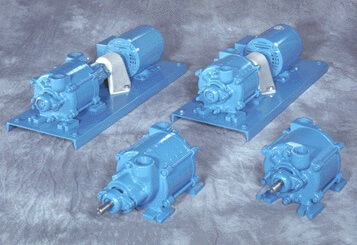

MTH Regenerative Turbine Pumps

MTH Pumps is one of the leading manufacturers of regenerative turbine pumps. At Arroyo Process Equipment, we proudly offer MTH regenerative turbine pumps. These pumps are designed to meet the needs of our clients in many industries. These pumps are known for their reliability, efficiency, and ability to handle challenging applications.

Why Choose Regenerative Turbine Pumps from Arroyo Process Equipment?

Arroyo Process Equipment has been a trusted provider of high-quality pumping solutions for decades. Our selection of regenerative turbine pumps includes models from top manufacturers like MTH. We provide expert guidance to ensure you choose the right pump for your specific needs.

Key Benefits of Choosing Arroyo Process Equipment:

- Access to industry-leading brands, including MTH.

- Expert support from a knowledgeable team.

- Customized solutions for unique applications.

- Guidance on selecting appropriate mechanical seals and ensuring optimal pump performance.

Conclusion

Regenerative turbine pumps offer a unique solution for applications requiring high-pressure output at low flow rates. If you need a pump for chemical processing, water treatment, or refrigeration, Arroyo Process Equipment can help. They have the knowledge and products to meet your needs.

Contact us today to learn more about our regenerative turbine pumps, including MTH models. Find out how the right impeller design can improve your fluid handling processes.