Industries / General Industry

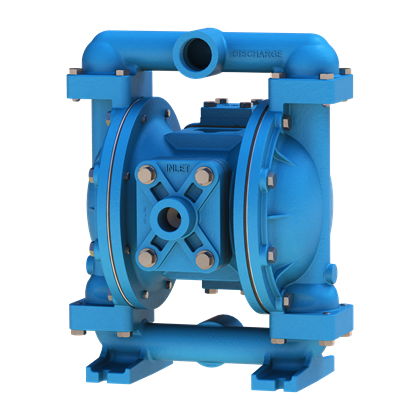

Assemble an adaptive, productive system

We know the ability to transfer liquids seamlessly is integral to many applications across industrial sectors like irrigation, air conditioning/heating, and construction. That’s why we partner with the best to provide reliable dewatering systems, rotating equipment services, and more.

Notable sectors we service

Unlock the potential of your specialized industry

Our decades of expertise partnering with industrial leaders allows us to guide better service and engineer systems and teams of all complexities and across many sectors.

The Power Behind Commercial Manufacturing Operations

The process of producing commercial goods involves several stages, including mixing, shaping, machining, assembly, and packaging. Each stage requires the use of rotating equipment, including mixers, grinders, lathes, mills, robots, and conveyors, to mix, process, and transport materials. Our team is responsible for providing the necessary equipment to shape, cut, and transport materials, as well as to assemble components and fill packaging containers.

How Equipment Drives Composite Manufacturing Efficiency

The process of producing composite materials involves several stages, including mixing, shaping, curing, and finishing. Each stage requires the use of rotating equipment, including mixers, pumps, molds, ovens, and grinders, to mix, process, and transport materials. Our team is responsible for providing the necessary equipment to mix and blend materials, shape and mold the composite, and grind and finish the final product.

The Role of Rotating Equipment in Insulation Operations

The process of producing insulation involves several stages, including mixing, shaping, curing, and finishing. Each stage requires the use of rotating equipment, including mixers, extruders, cutting machines, and packaging machines, to mix, process, and transport materials. Our team is responsible for providing the necessary equipment to mix and blend raw materials, shape and cut the insulation, and package and transport the final product.

Excel in your unique production applications

When we partner together, our team starts by understanding your system and individual key performance metrics, then we engineer a system that improves efficiencies and meets goals in the following applications:

- Septic tanks

- Slurry transfers

- Manure processing

- Hotel sewage management

- Campground sewage management

- Amusement park sewage management

- Industrial water treatment and plants

- Wastewater pump stations

- HVAC system chillers

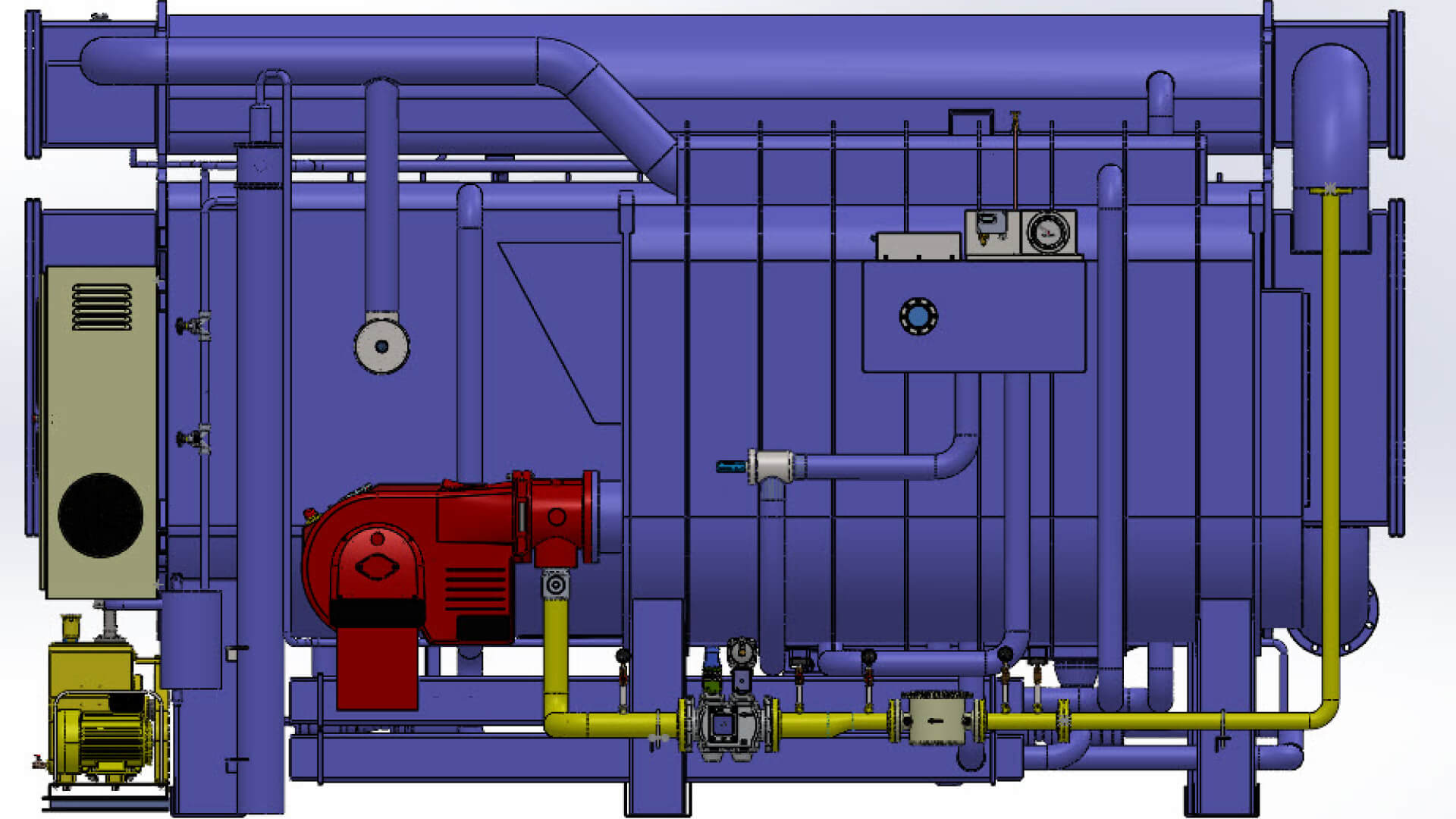

- HVAC boilers

- Cooling towers

- Hydronic distribution systems

- Water-based fire protection systems

- Livestock water transfer

- Small irrigation

- Domestic water

- Village water supplies

Ready to get started?

Let us know more about your specific needs, and a team member will contact you regarding the next steps.

Discover more about the industry

Use our resources to learn more about how the industrial industry changes through various applications, related products, and process improvements.

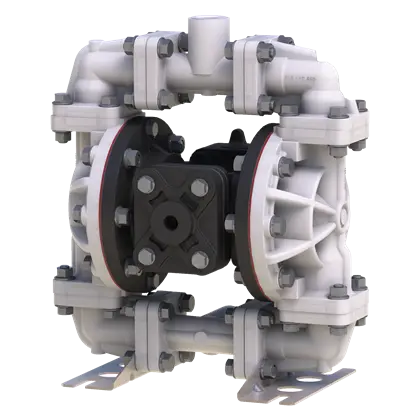

Water Pumps

Water pumps move water liquids from one point to another by increasing the pressure. They are used e

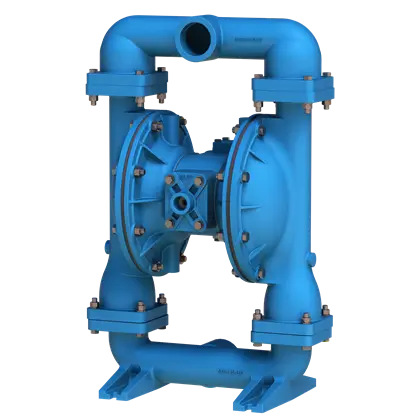

HVAC Pumps

HVAC pump systems generally use centrifugal pumps to move chilled water, heating hot water and conde

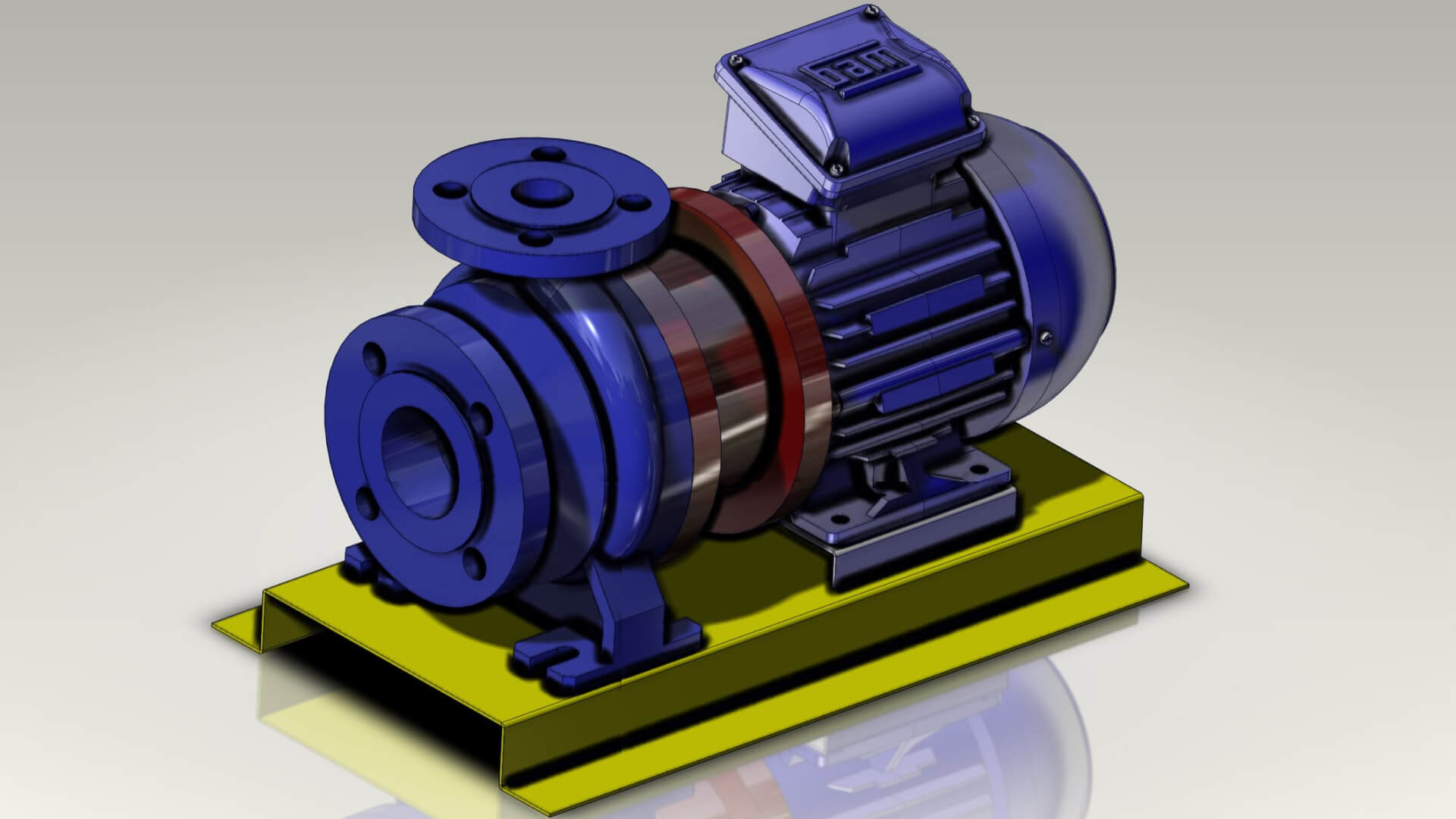

Centrifugal Pumps

Centrifugal pumps are a type of fluid transfer pump commonly used in a wide range of industrial appl

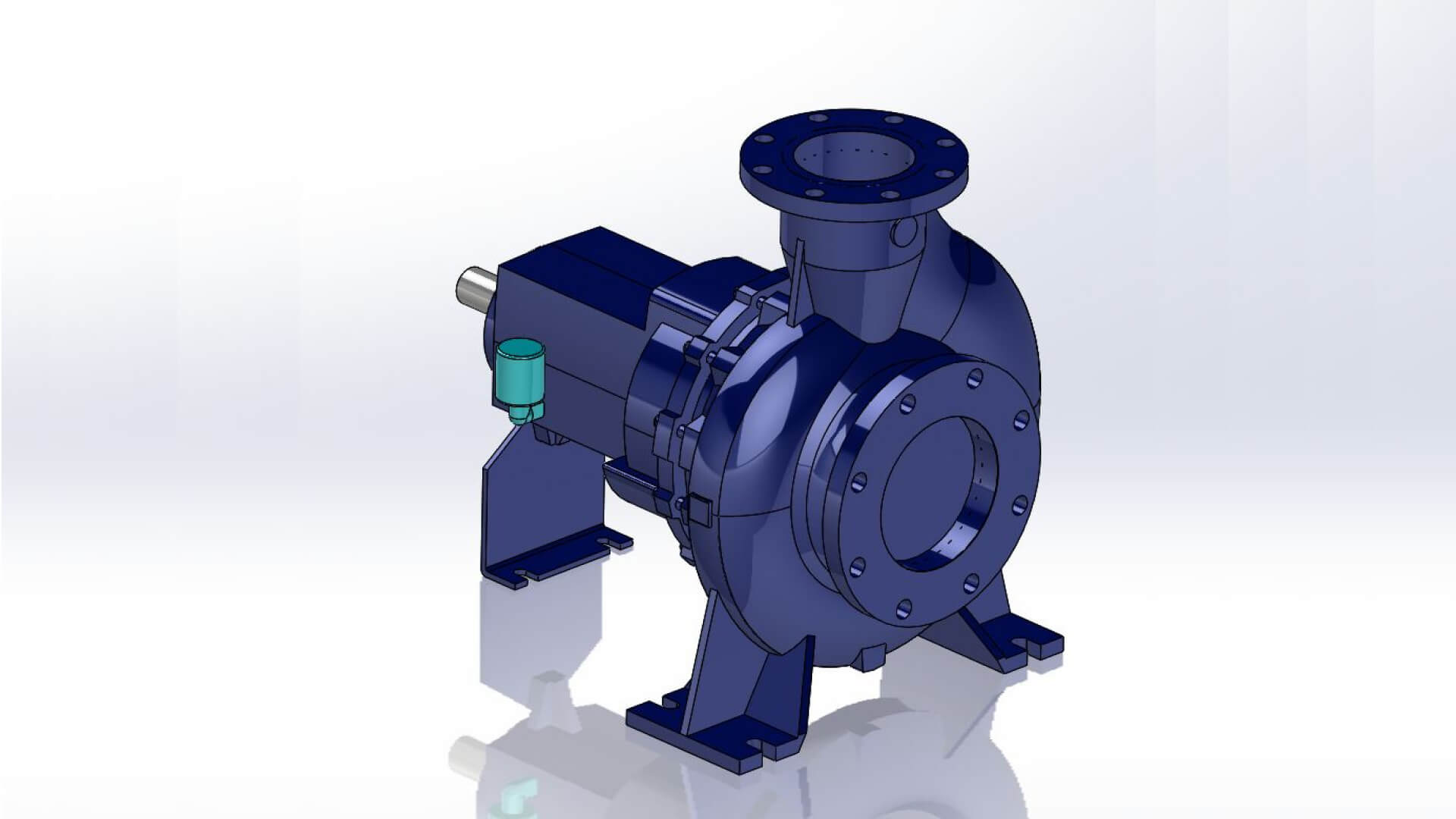

Making the Right Choice: End Suction Pumps

An end suction pump is a type of centrifugal pump that is usually single-stage with only one impelle

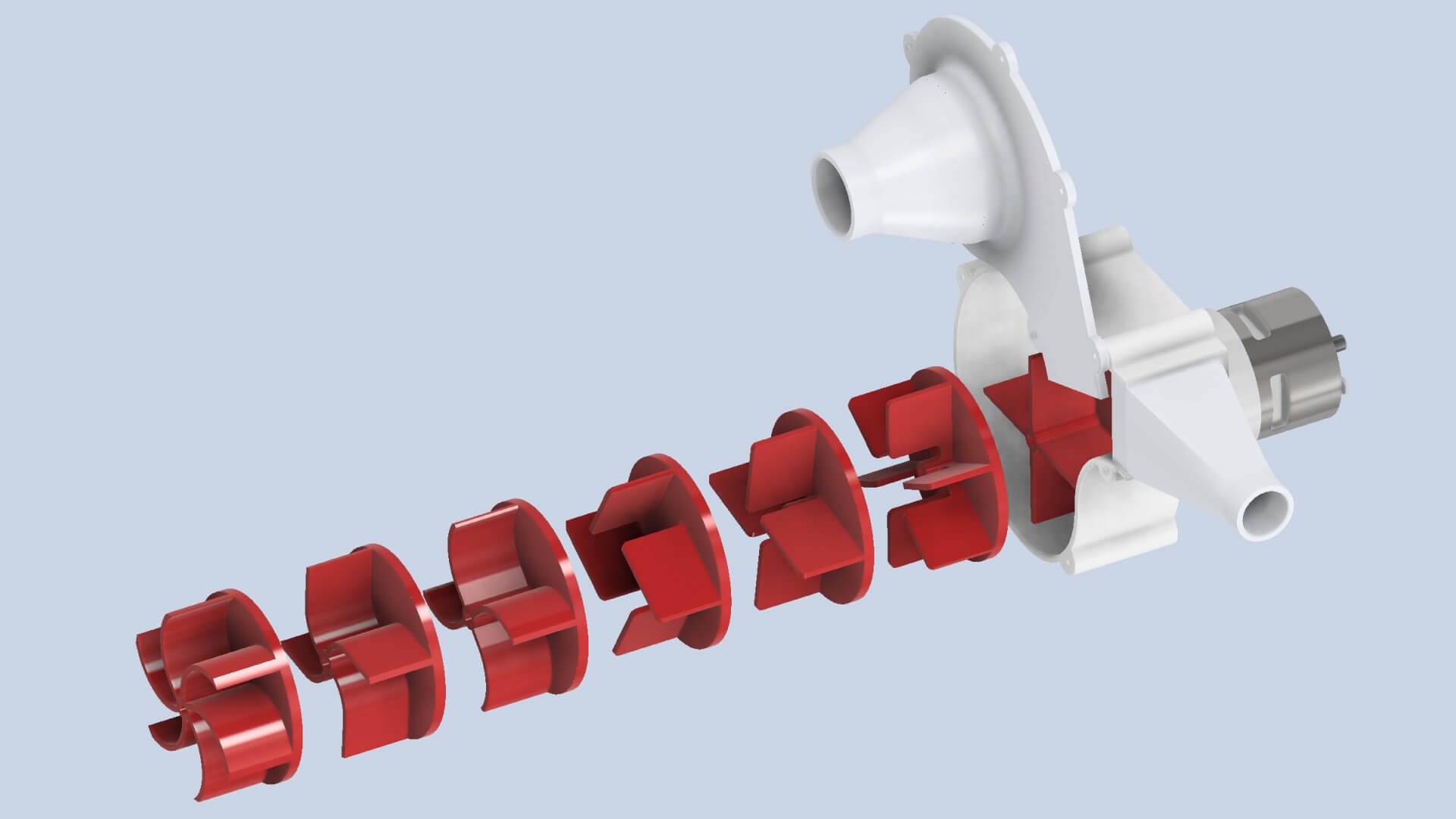

Centrifugal Pump Parts

Replacing parts in a centrifugal pump can be challenging. That's why Arroyo Process's engineers and