We understand the critical role that pumping systems play in industrial applications, especially when handling challenging fluids like liquid ammonia. With over 50 years of experience in the industry, we are experts in the design and procurement of top-quality pump solutions.

Overview of Liquid Ammonia Pumps

Liquid ammonia pumps are essential in many refrigeration systems and chemical processing plants. These pumps handle ammonia in its liquid state, requiring precision and reliability due to ammonia’s high vapor pressure and corrosive nature. Viking liquid ammonia pumps stand out for their efficiency and durability. Nonetheless, we offer mulitple product lines from various manufacturers that all work to excel within the desired application or system. These pumps are pivotal in applications ranging from agriculture to pharmaceuticals, ensuring operational continuity and safety.

Key Features of Ammonia Liquid Pumps

Another key point when it comes to ammonia liquid pumps, are the several features that must be considered when selecting the right piece of equipment for your application. High vapor pressure handling capabilities, robust stainless steel construction, and innovative pumping designs are paramount. Occasionally, technologies like centrifugal pumps and positive displacement pumping, including rotary vane and internal gear pumps, are employed. These features ensure that the pumps can handle the demanding conditions of ammonia transfer while maintaining efficiency and longevity.

Here several features that are non-negotiable when it comes to selecting an ammonial liquid application pump:

High Vapor Pressure Handling: These pumps must manage the high vapor pressure of liquid ammonia effectively to prevent leaks and ensure safe operation.

Robust Construction: Ammonia pumps are typically made from stainless steel to withstand the corrosive nature of ammonia and ensure longevity.

Innovative Pumping Designs: Technologies like centrifugal pumps and positive displacement pumps, including rotary vane and internal gear pumps, are commonly employed. These designs ensure efficiency and reliability under demanding conditions.

Choosing the Right Pump for Liquid Ammonia

Liquid ammonia pump selection can be challenging. Selecting the appropriate ammonia liquid pump requires careful consideration of several factors. The flow rate, type of pump, and specific application needs are critical in this decision-making process.

Flow Rate: The required flow rate for the application will determine the size and type of pump needed.

Pump Type: Different applications may require centrifugal, rotary vane, or internal gear pumps based on specific needs and operational conditions.

Application Needs: Consider the specific demands of your application, including environmental factors and operational pressures.

It’s essential to work with experienced pump experts who can provide guidance and solutions tailored to your unique requirements. At Arroyo Process Equipment, we help our customers select the perfect liquid ammonia pump, whether for a large-scale refrigeration system or a specialized application.

Prominent Liquid Ammonia Pump Manufacturers

We’re proud to represent some of the leading manufacturers in the industry, each bringing unique strengths to the realm of pumping ammonia liquid. Our partnerships with these manufacturers allow us to offer a diverse range of high-quality pumping solutions tailored to various industrial needs.

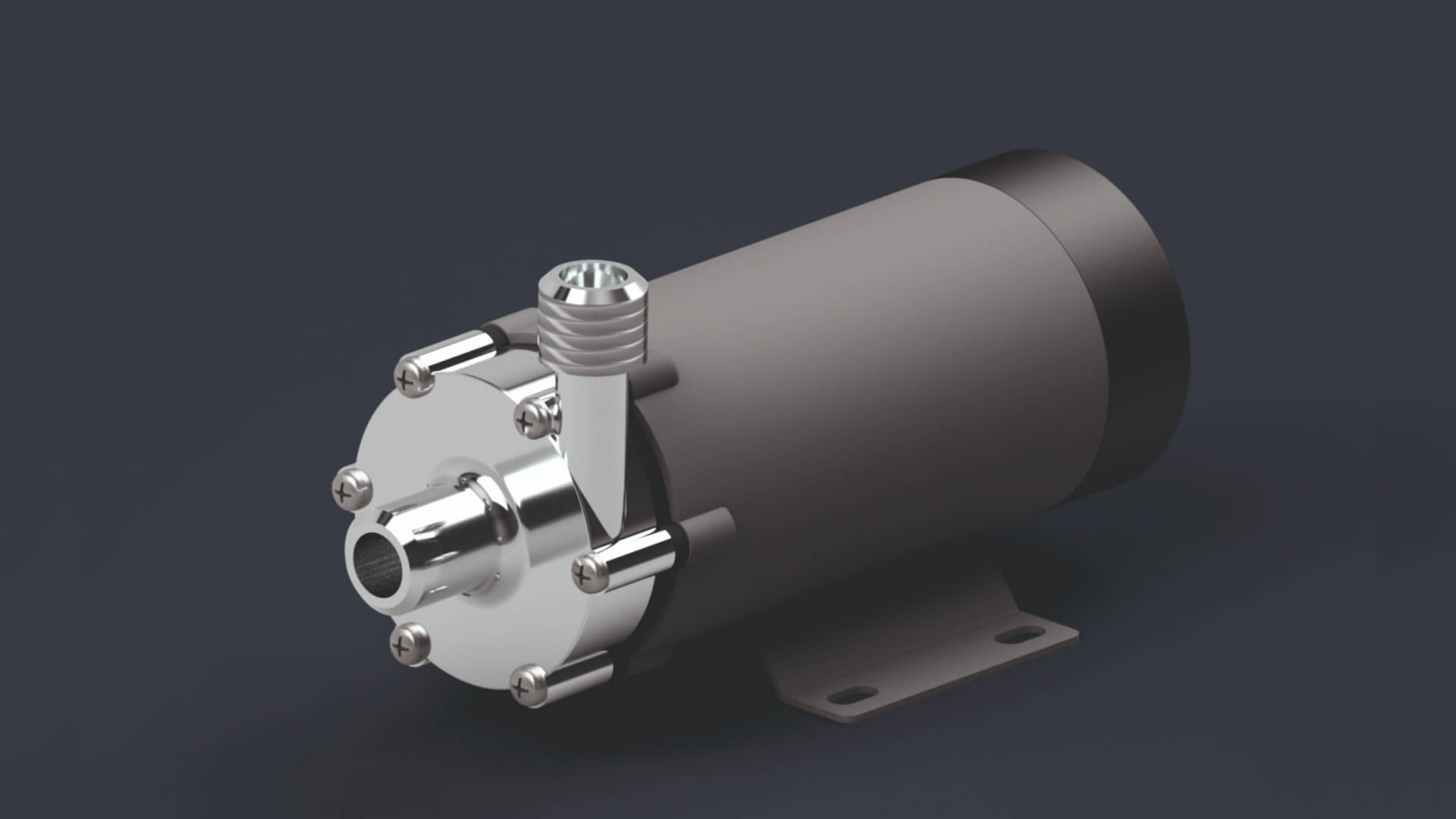

Viking Pump

Viking Pump offers robust and efficient liquid ammonia pumps known for their reliability and innovative design. Their pumps are ideal for demanding ammonia handling applications.

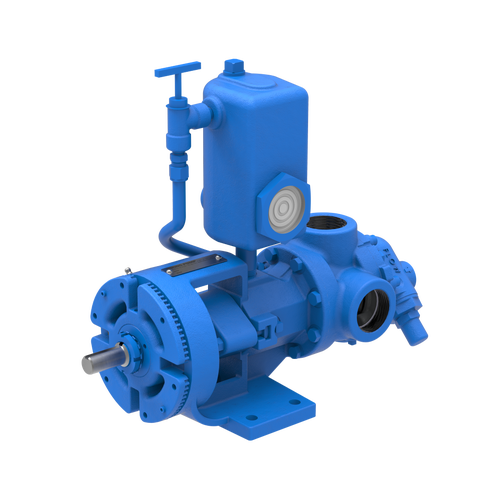

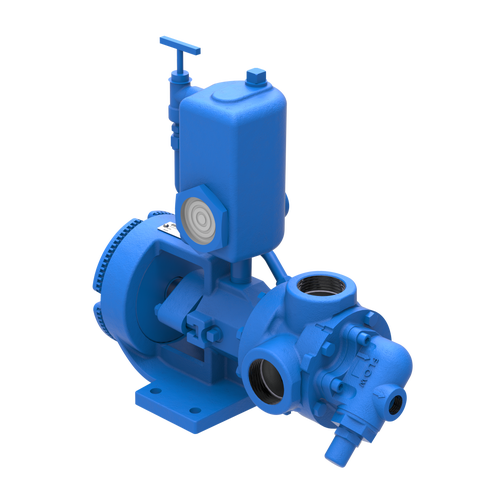

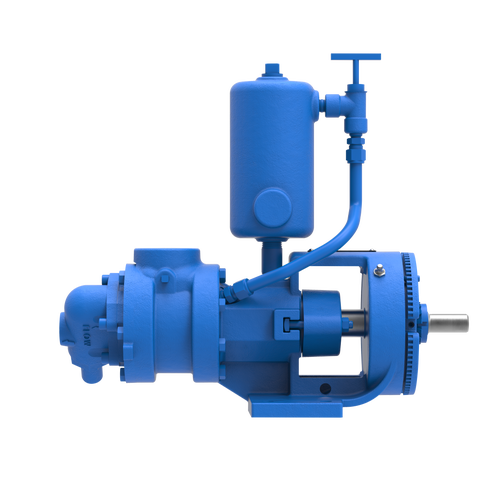

Corken

Standard Model Sliding Vane Pumps: High pressure applications.

Z-Model Sliding Vane Pumps: Available in 5 sizes, suitable for various ammonia transfer needs.

Regenerative Turbine Pump Series: Long-lasting pumps featuring free-floating impellers, perfect for continuous operation.

SC-Model Side Channel Pumps: Lastly, these pumps offer continuous duty and long service life, ideal for industrial applications.

Phantom Pumps

Self-Priming Centrifugal Pumps: Phantom Pumps provide self-priming centrifugal pumps with drop-in compatibility with Goulds and Gorman Rupp, ensuring versatility and ease of integration into existing systems. However, because these pumps are assembled and tested here in the USA, they offer cost-effective pricing and competitive lead times without foregoing quality.

There’s more than getting top-quality products when you decide to work with us. We offer comprehensive solutions that include after-sales support & repairs, maintenance, customization options, and fabrication. We ensure that our customers have access to the best possible solutions for their liquid ammonia pumping needs.

Specialized Applications

Generally, the demand for liquid ammonia pumps varies greatly across different regions and industries. In the Cayman Islands, for example, the focus might be on compact, efficient pumps for small-scale systems. In industrial hubs like South Carolina, larger, more robust pumps are often required. Our expertise extends to regions like Puerto Rico, the Turks and Caicos, Haiti, the Dominican Republic, North Carolina, and the Bahamas, where we have provided customized pumping solutions that cater to the unique environmental and industrial needs of each area.

Ammonia Liquid Pump Recirculation Systems

Ammonia liquid pump recirculation systems are vital in maintaining continuous and efficient flow in ammonia refrigeration and processing applications. These systems are designed to handle the specific challenges of ammonia recirculation, ensuring that the ammonia remains in the desired state and is efficiently moved through the system.

Design Considerations: Recirculation systems need to be carefully designed to manage ammonia’s high vapor pressure and corrosiveness. The choice of materials and pump design is crucial.

Efficiency: Recirculation systems must be energy-efficient to reduce operational costs. Using advanced pump technologies helps achieve this goal.

Maintenance: Regular maintenance of recirculation systems is essential to ensure long-term reliability and performance. Components such as seals, bearings, and impellers should be checked and replaced as needed.

Our Expertise

Finally, we don’t just sell pumps; we provide comprehensive pumping solutions. Our team of experts specializes in creating customized systems, including ammonia liquid pump recirculation systems, tailored to the specific needs of our clients. Whether it’s designing a new system from the ground up or retrofitting an existing one, our focus is on delivering efficiency, reliability, and value.

Choose the right ammonia liquid pump with confidence and ensure the success and safety of your industrial operations. With Arroyo Process Equipment, you gain not only a supplier but a partner dedicated to providing the best pumping solutions in the market. We invite you to experience the difference that expertise and quality can make in your ammonia handling processes. To learn more about all the services and industrial equipment manufacturers we work with, check out our official line card.