Industries / Chemical / Soap

Discover advanced chemical pumps and equipment for soap manufacturing

The Manufacturing Process

Enhance efficiency in soap production and processing

We support soap manufacturers by providing state-of-the-art equipment. It’s designed to streamline production processes, ensuring consistent and high-quality results. Whether you’re producing kettle soap, soap stock, or liquid soap, our reliable solutions allow you to meet large-scale production demands efficiently.

-

Transfer and Handling of Raw Materials

-

Processing and Transformation

-

Waste Management

-

Blending and Finishing

-

Production and Blending

Efficiently handle oils and fats

The equipment we distribute, such as Viking pumps, facilitates the efficient transfer of natural oils and fats from storage tanks to processing vessels, ensuring a seamless production process. This is essential in soap manufacturing, where raw materials are transferred regularly. Our pumps handle a variety of raw materials, including viscous substances, with high efficiency and reliability.

Move oils and fats to saponification reactor

Our advanced pumps ensure the consistent and controlled transfer of oils and fats to the saponification reactor, where they are combined with alkali to produce soap. This step is critical for maintaining production efficiency and ensuring high-quality soap. By utilizing cutting-edge pump technology, we ensure precise temperature and pressure control throughout the process.

Transfer soap mixture from reactor to cooling tanks

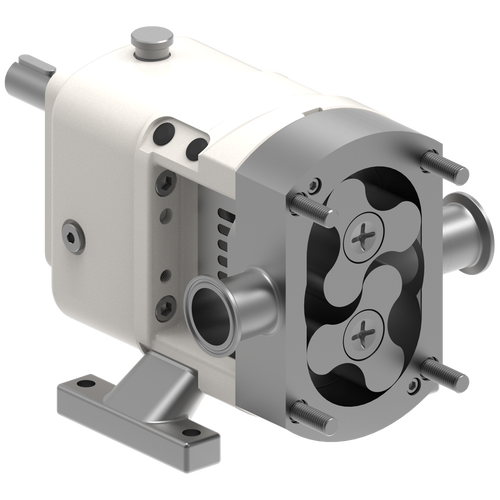

Our equipment, including Viking 327A Series and Viking 4127C Series internal gear pumps, facilitates the safe and efficient transfer of the soap mixture from the saponification reactor to cooling tanks. This application is essential in soap manufacturing facilities to maintain quality and control during the cooling process.

Move cooled soap to storage or cutting stations

Once the soap has been cooled, our pumps, such as the Viking Classic Plus and Viking 4127C Series, efficiently transfer it to storage or cutting stations, ensuring the proper handling of the material. Our pumps are designed to handle various soap types and compositions, providing reliability in demanding environments.

Move liquid waste to disposal systems

Our pumps effectively transfer liquid waste generated during the soap manufacturing process to disposal systems, ensuring safe and efficient waste management. This process is crucial in soap production facilities. Our equipment ensures even the most challenging waste materials are handled efficiently, minimizing environmental impact and ensuring compliance with regulatory standards.

Transfer liquid soap to blending tanks

Our advanced pumps ensure the smooth transfer of liquid soap to blending tanks, where fragrances, dyes, and other additives are incorporated. This step is vital for creating custom soap formulations. Our pumps are designed to handle delicate ingredients while maintaining precise flow rates and pressures.

Move product to plant day tank

Our pumps ensure the smooth transfer of blown asphalt or PMA (Polymer Modified Asphalt) to the plant day tank to ensure a consistent supply for the production process and precise control over the mixture composition. This step is critical in hot mix plants and roofing plants. By maintaining consistent flow rates and pressures, our pumps help optimize the mixing process, ensuring high-quality end products.

Transfer finished soap for packaging

With reliable equipment, including the Viking TRA-10 Series, efficiently transfer finished liquid soap to packaging lines, ensuring that the product is ready for distribution. Our pumps ensure smooth operation, maintaining product quality throughout the transfer process.

Featured Equipment

Our range of top-performing chemical pumps and rotating equipment

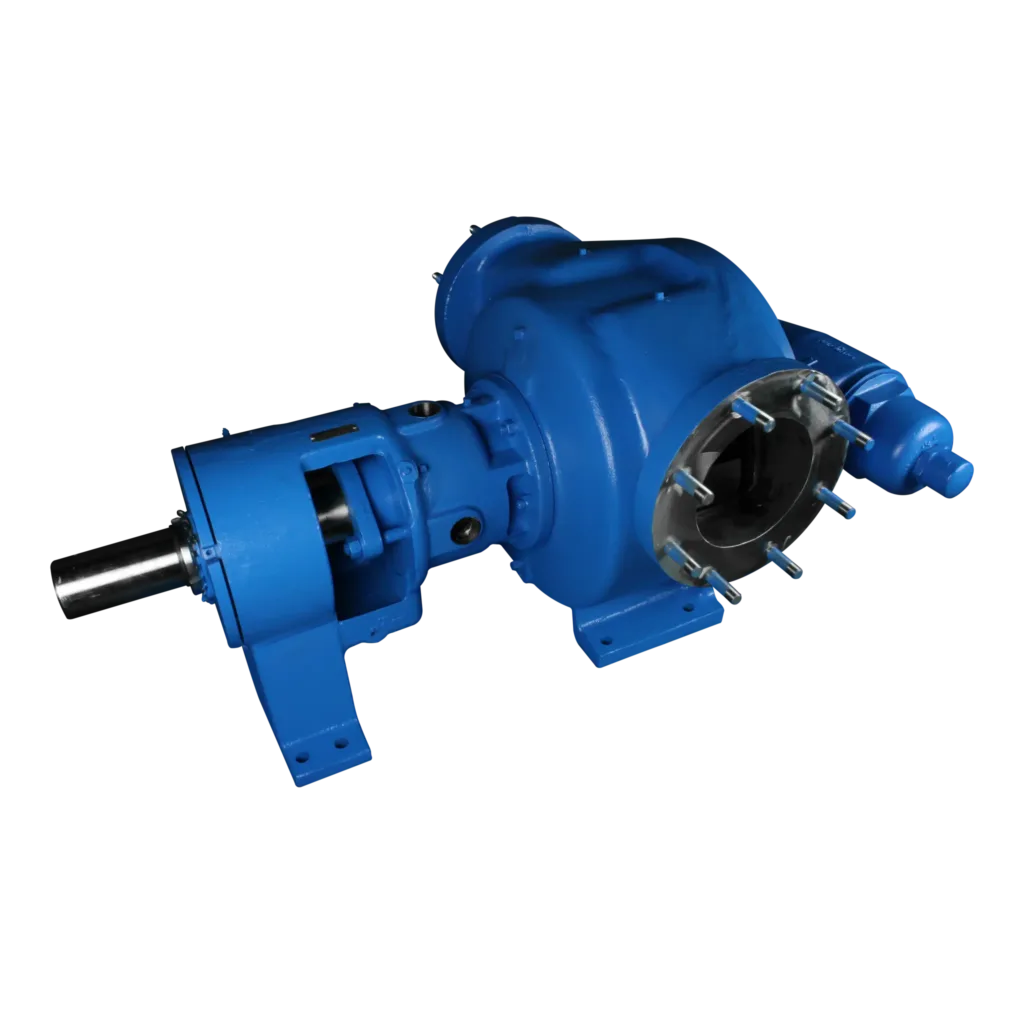

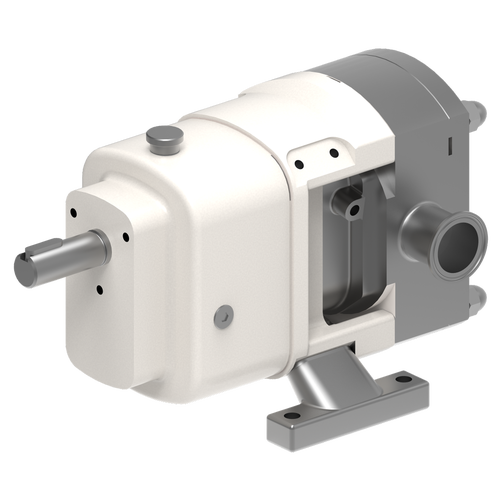

Viking Classic Plus MultiPump Series

Ideal for low-pressure applications throughout the soap manufacturing cycle.

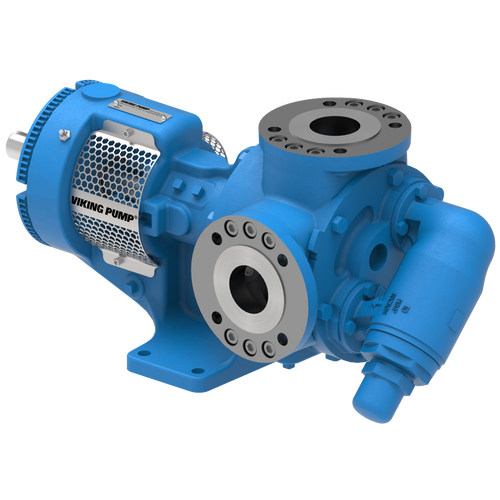

Viking 4127C Series

Heavy-duty pumps designed for handling viscous materials in demanding environments.

Applications Across the Industry

Chemical pumps and equipment for soap applications

Soap Manufacturing Plants

Ensuring efficient processing, handling, and production of soap raw materials and finished products while maintaining product quality.

Chemical Processing Facilities

Facilitating the large-scale production of various soap types with advanced equipment for precise control and high output.

Blending and Mixing Stations

Optimizing the incorporation of fragrances, dyes, and additives into soap products, ensuring uniform consistency and quality.

Packaging Lines

Enhancing the efficient transfer of finished soap products for packaging and distribution, ensuring speed, reliability, and product.

Looking for chemical pumps fast?

Shop our quick ship equipment catalog

MPN: S1FB1ABWANS000

Lead Time: Ready to Ship

MPN: NDP-25BST

Lead Time: Ready to Ship