Understanding Liquid Ammonia Transfer Pumps

Handling and transferring liquid ammonia requires specialized equipment designed to manage the unique challenges posed by this harsh chemical. At Arroyo Process Equipment, we provide top-quality liquid ammonia transfer pumps to meet the needs of various industries, ensuring safety, efficiency, and reliability in your operations. Our extensive experience and partnerships with leading manufacturers allow us to deliver tailored solutions to clients across the American Southeast, the Caribbean, Central America, and South America.

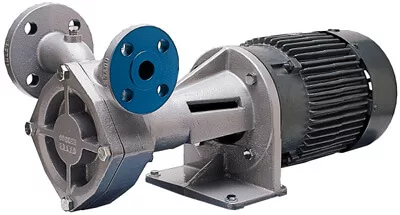

Liquid ammonia transfer pumps are specifically engineered to handle the rigorous demands of transferring ammonia and other harsh chemicals. These pumps must be robust, reliable, and efficient to ensure the safe and effective movement of ammonia in industrial settings. Magnetic drive pumps, in particular, are highly recommended for ammonia transfer due to their leak-free design and superior performance.

These pumps operate by using a magnetic coupling to drive the impeller, which eliminates the need for a mechanical seal. This design significantly reduces the risk of leaks and ensures a safer working environment. Additionally, magnetic drive pumps are known for their durability and low maintenance requirements, making them an excellent choice for continuous operation in demanding environments.

Top Manufacturers Today

These are some of the industry-leading manufacturers, which provide top-of-the-line liquid ammonia transfer pumps:

Viking Pump

Viking’s Universal Magnetic Drive Pumps are ideal for transferring liquid ammonia, offering reliability and efficiency in demanding applications. These pumps are designed to handle a wide range of viscosities and are known for their exceptional build quality.

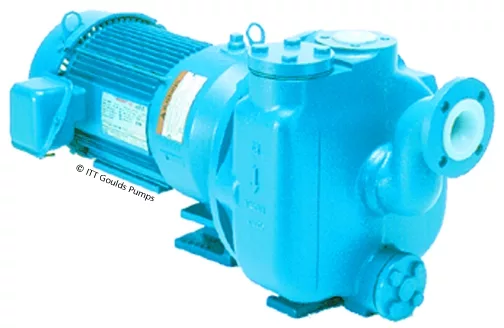

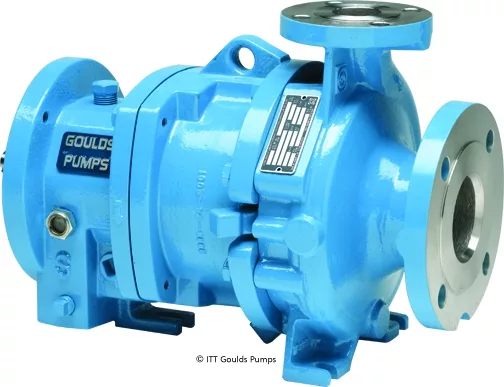

Goulds (ITT)

Goulds provides a range of chemical process pumps designed for ammonia transfer, including the ITT 3296 EZ MAG, ITT 3298, ITT 3299, ITT SP 3298, and ITT V 3298 series. These pumps are known for their durability and performance in harsh chemical environments. Each model offers specific features tailored to different aspects of chemical processing, ensuring optimal performance for your needs.

Liquiflo

Liquiflo Gear Pumps are designed to handle the transfer of ammonia and other corrosive chemicals, providing reliable and efficient operation in industrial applications. Their precision engineering and robust construction make them suitable for continuous use in the most demanding environments.

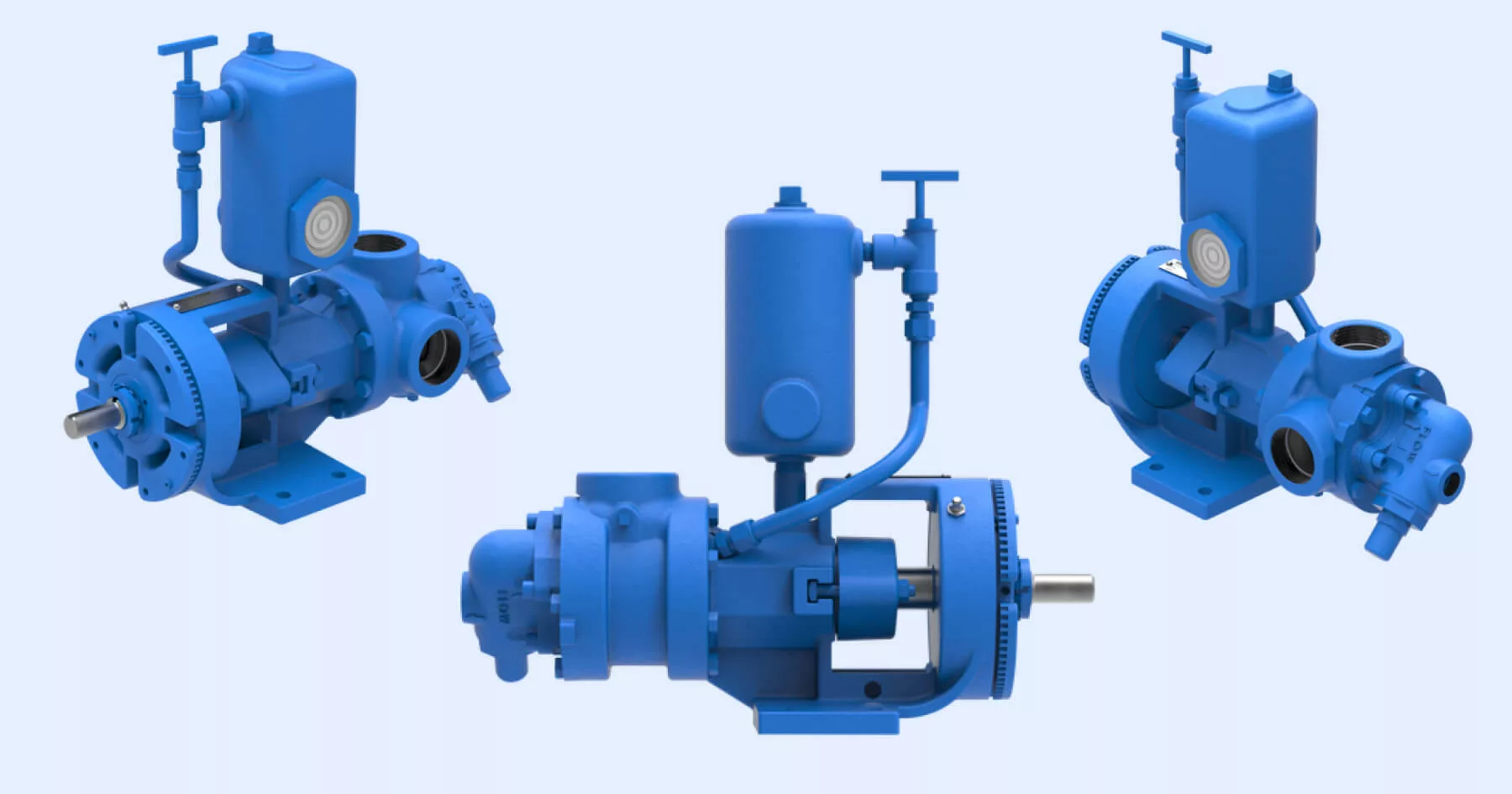

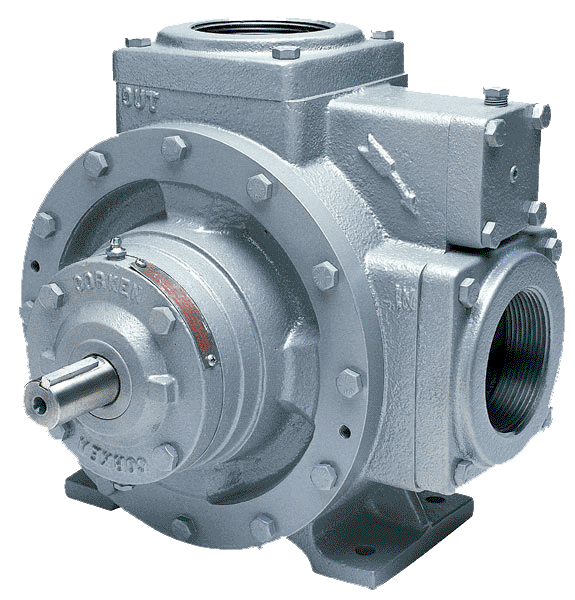

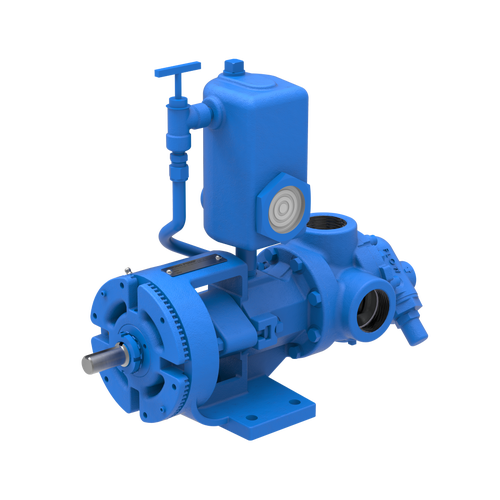

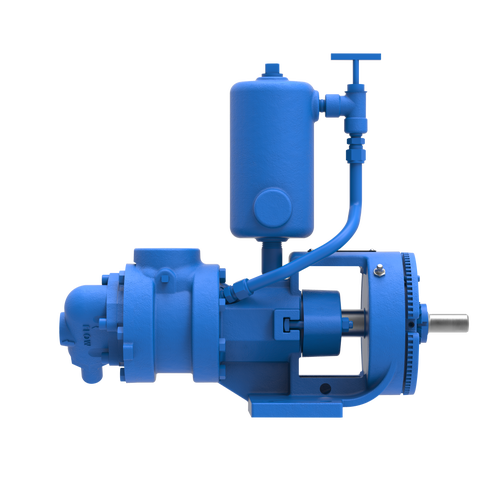

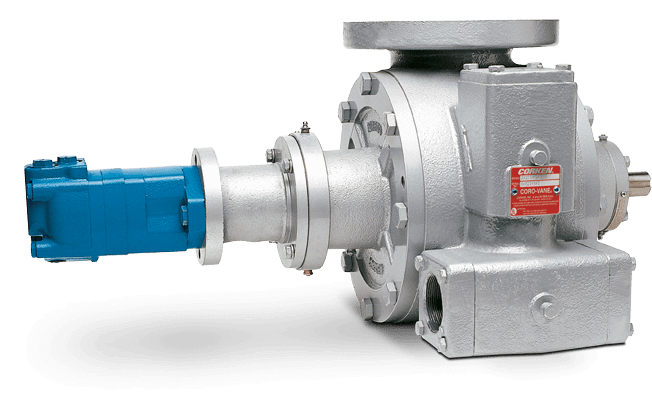

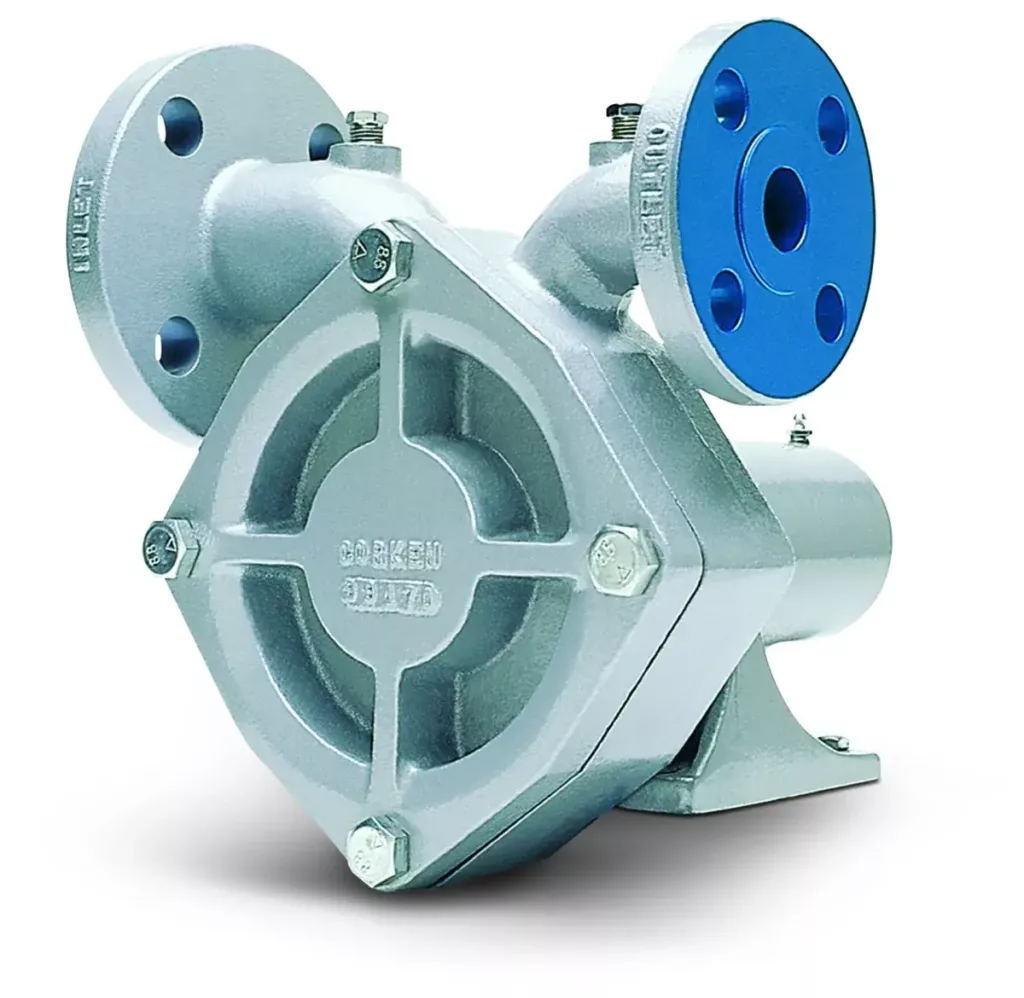

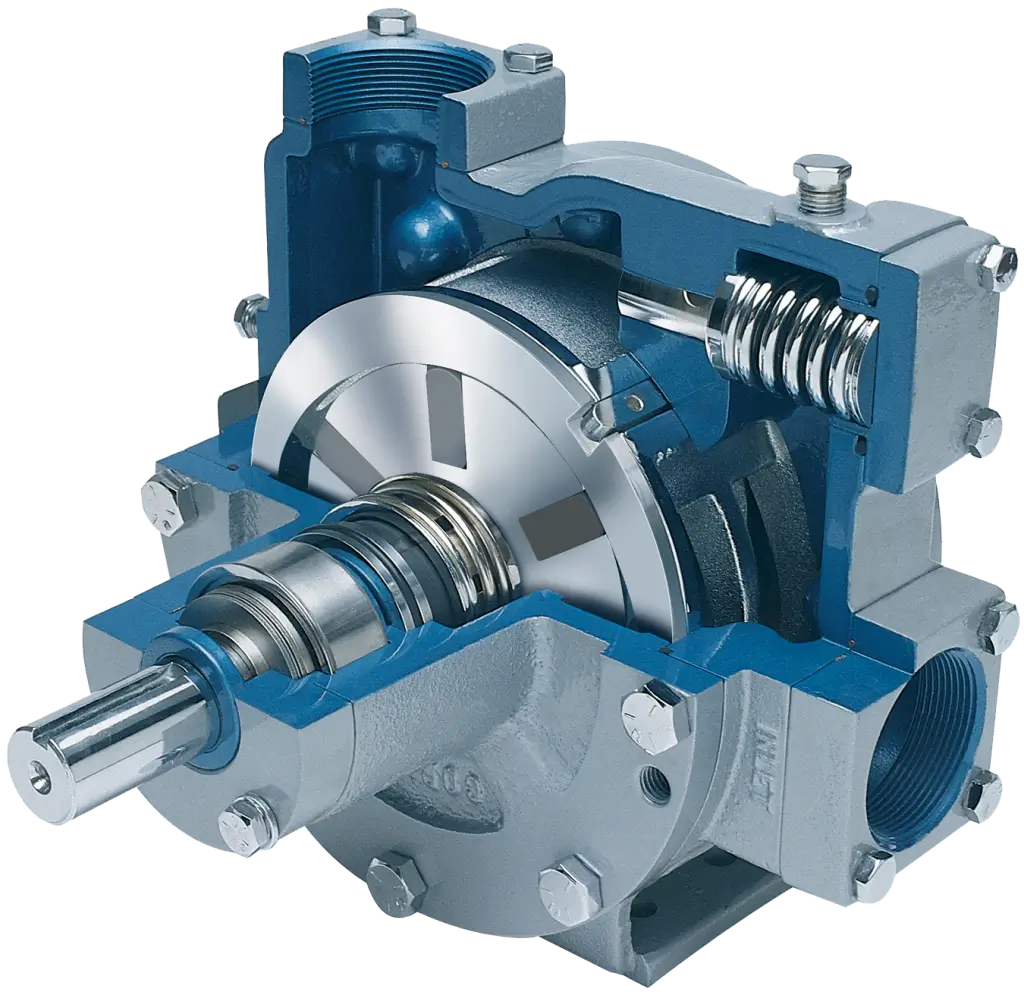

Corken Pumps

Corken offers a range of ammonia pumps, including sliding vane pumps, regenerative turbine pumps, and side channel pumps. These pumps are known for their durability and performance in high-pressure applications.

Phantom Pumps

Phantom Pumps offers self-priming centrifugal pumps that are compatible with Goulds and Gorman Rupp. These pumps are ideal for various industrial applications requiring self-priming capabilities.

Applications and Industries

Liquid ammonia transfer pumps are essential in various industries, including:

Chemical Processing

Efficiently transfer ammonia used in the production of chemicals and other industrial processes. These pumps ensure that the transfer process is smooth and controlled, minimizing the risk of spills and exposure to hazardous chemicals.

Refrigeration

Use ammonia as a refrigerant, requiring reliable pumps to manage the transfer and circulation of the chemical. Ammonia’s high efficiency as a refrigerant makes it a popular choice in industrial refrigeration, necessitating pumps that can handle its unique properties.

Fertilizer Production

Handle the transfer of ammonia used in the production of fertilizers, ensuring safe and efficient operations. The precise transfer of ammonia is crucial in maintaining the quality and consistency of fertilizer products.

Agricultural Applications

Utilize ammonia in various agricultural processes, requiring robust pumps to manage its transfer. These pumps ensure that ammonia is safely and efficiently delivered to its intended applications, supporting agricultural productivity.

Energy Sector →

Involved in the production and storage of energy, ammonia transfer pumps play a critical role in ensuring the safe and efficient handling of ammonia used in various energy-related applications.

Choosing the Right Liquid Ammonia Transfer Pump

Selecting the appropriate liquid ammonia transfer pump involves several key considerations:

Material Compatibility

Ensure the pump materials are compatible with ammonia to prevent corrosion and ensure long-term durability. Stainless steel and other corrosion-resistant materials are commonly used for this purpose.

Flow Rate Requirements

Determine the required flow rate for your application to select a pump that meets your operational needs. This ensures that your processes run smoothly and efficiently.

Pressure Requirements

Consider the pressure requirements of your system to ensure the pump can handle the necessary pressure levels. Proper pressure management is crucial for maintaining process integrity and safety.

Energy Efficiency

Choose pumps that offer high energy efficiency to reduce operational costs and environmental impact. Energy-efficient pumps not only save money but also contribute to sustainability efforts.

Maintenance Needs

Select pumps that are easy to maintain and service, ensuring minimal downtime and long-term reliability. Regular maintenance is essential for keeping your pumps in optimal condition.

Maintenance and Best Practices

Maintaining your liquid ammonia transfer pumps is crucial for ensuring their longevity and performance. Follow these best practices:

Regular Inspections

Conduct routine inspections to identify any signs of wear, leaks, or other issues that could affect performance. Early detection of problems can prevent costly repairs and downtime.

Cleaning and Debris Removal

Keep the pumps clean and free from debris to prevent blockages and ensure efficient operation. Regular cleaning helps maintain the efficiency and reliability of your pumps.

Proper Lubrication

Regularly lubricate moving parts to reduce friction and wear, following the manufacturer’s guidelines. Proper lubrication extends the lifespan of your pumps and reduces maintenance costs.

Component Checks

Inspect seals, bearings, and other critical components regularly and replace any worn or damaged parts promptly. Maintaining these components is essential for preventing leaks and ensuring optimal performance.

Professional Servicing

Engage professional services for comprehensive maintenance and repairs. Arroyo Process Equipment offers expert servicing for pumps from top manufacturers, ensuring your equipment stays in optimal condition. Our technicians are trained to handle a wide range of issues and provide reliable solutions.

Key Features and Benefits

Robust Construction

Liquid ammonia transfer pumps are built with materials that can withstand the corrosive nature of ammonia, ensuring long-term durability and performance. Common materials include stainless steel and specialized alloys that resist corrosion and wear.

Leak-Free Operation

Magnetic drive pumps eliminate the risk of leaks, providing a safe and environmentally friendly solution for ammonia transfer. This feature is particularly important in preventing hazardous spills and ensuring compliance with environmental regulations.

High Efficiency

These pumps are designed to operate efficiently, reducing energy consumption and operational costs. Their design allows for smooth and consistent flow, which is crucial for maintaining process integrity.

Versatility

Suitable for various applications, including chemical processing, refrigeration, and fertilizer production. This versatility makes them a valuable asset in any facility that handles ammonia or similar chemicals.

Key Locations We Serve

Our team is dedicated to providing exceptional service and support, ensuring that you have the right equipment for your specific needs. Whether you’re operating in a small facility or a large industrial plant, we can provide tailored solutions to meet your requirements.

Arroyo Process Equipment proudly serves clients across the American Southeast, the Caribbean, Central America, and South America. This includes:

- American Southeast: Florida, Georgia, Alabama, Louisiana, Tennessee, South Carolina, and other states.

- Caribbean: Puerto Rico, Trinidad & Tobago, Cayman Islands, Dominican Republic, Jamaica, Bahamas, Haiti, Saint Lucia, the U.S. Virgin Islands, and other locations.

- Central America: Mexico, Guatemala, Nicaragua, Costa Rica, Honduras, Panama and other countries.

- South America: Brazil, Colombia, Peru, Chile, Ecuador, Agrentina and other nations.

Advantages of Choosing Arroyo Process Equipment

Exceptional Customer Service

Our team is committed to providing personalized service and support, helping you find the best solutions for your operations. We take the time to understand your needs and offer recommendations that align with your goals.

Top-Quality Products

We offer a wide range of high-quality products from leading manufacturers, ensuring reliability and performance. Our partnerships with trusted brands mean you get access to the best equipment on the market.

Quick Order Turnarounds

With a well-stocked inventory and close relationships with the manufacturers, we can process orders quickly and deliver your equipment promptly. Our efficient order processing system ensures minimal downtime for your operations.

Comprehensive Services

In addition to supplying pumps, we offer equipment repairs, maintenance, and custom engineering solutions tailored to your needs. Our service team is equipped to handle any issues that arise, ensuring your equipment operates at peak performance.

Fully Engineered Solutions

Our experienced engineers can design and implement custom processing systems to meet your specific requirements. We work closely with you to develop solutions that enhance your operations and improve efficiency.

Conclusion

Liquid ammonia transfer pumps are essential for the safe and efficient handling of ammonia in various industrial applications. At Arroyo Process Equipment, we provide high-quality pumps and comprehensive services to meet your specific needs. Our partnerships with leading manufacturers like Viking Pump, Goulds, and Liquiflo ensure that we can deliver the best solutions for your operations.

Contact us today for more information about our liquid ammonia transfer pumps and how we can help optimize your processes. We proudly serve clients in the American Southeast, the Caribbean, Central America, and South America, and look forward to assisting you with your ammonia transfer needs.