Industries / Pulp & Paper

Optimize your systems to enhance results

Our engineers improve systems by reducing the time between the initial placement of the fiber-water suspension on the sieve to the finished paper. We achieve this by focusing on the stock preparation, the paper machine, the finishing, and the equipment.

Notable Sectors We Service

Unlock the potential of your specialized industry

When we begin new projects, we always start by understanding the existing systems, then collaborate to engineer solutions that best fit and achieve individual key performance metrics, across industry sectors.

Maximizing Pulp Production with the Right Rotating Equipment

Pulp processing is a critical step in the production of paper and other related products. It involves breaking down raw materials, such as wood chips, into a fibrous pulp that can be used to create a wide range of paper products. We provide advanced machinery and specialized techniques to ensure that the pulp produced is of high quality and consistency.

How Rotating Equipment Drives Paper Processing

The process of turning wood into paper involves several steps, such as pulping, bleaching, refining, and drying. Our teams are experts at sourcing equipment that maximizes the quality and efficiency of breaking down wood fibers, mixing chemicals, circulating fluids, and providing the necessary energy to drive the process.

Excel in your unique production applications

Engineers from our team know that the right equipment depends on the medium, to ensure that pulp and fiber materials do not create clogs. This also applies to pulp materials across application areas, such as:

- Water delivery

- Stock preparation

- Coating production

- Caustic gasification

- De-inking

- Flocculation

- Paper bleaching

- Transporting wood chips for pulp making

- Pulp digester tanks

- Wet-end chemical preparation

- Pulp bleaching process

- Pulp slurry transfer

- Additives

- Dyes

- Recovered paper

- Wood chipping/debarking

- De-inking chemical application

- Containerboard

- Cartonboard

- Kraft paper and speciality

- Mechanical

- Stock preparation

- Starch preparation

- Wood-free

- Uncoated wood-free

- Coated wood-free

- Tissue

- Market-bleached hardwood kraft pulp

- Market-bleached softwood kraft pulp

- Wastewater treatment

Ready to get started?

Let us know more about your specific needs, and a team member will contact you regarding the next steps.

Discover more about the industry

Use our resources to learn more about how the industrial pulp and paper industry changes through various applications, related products, and process improvements.

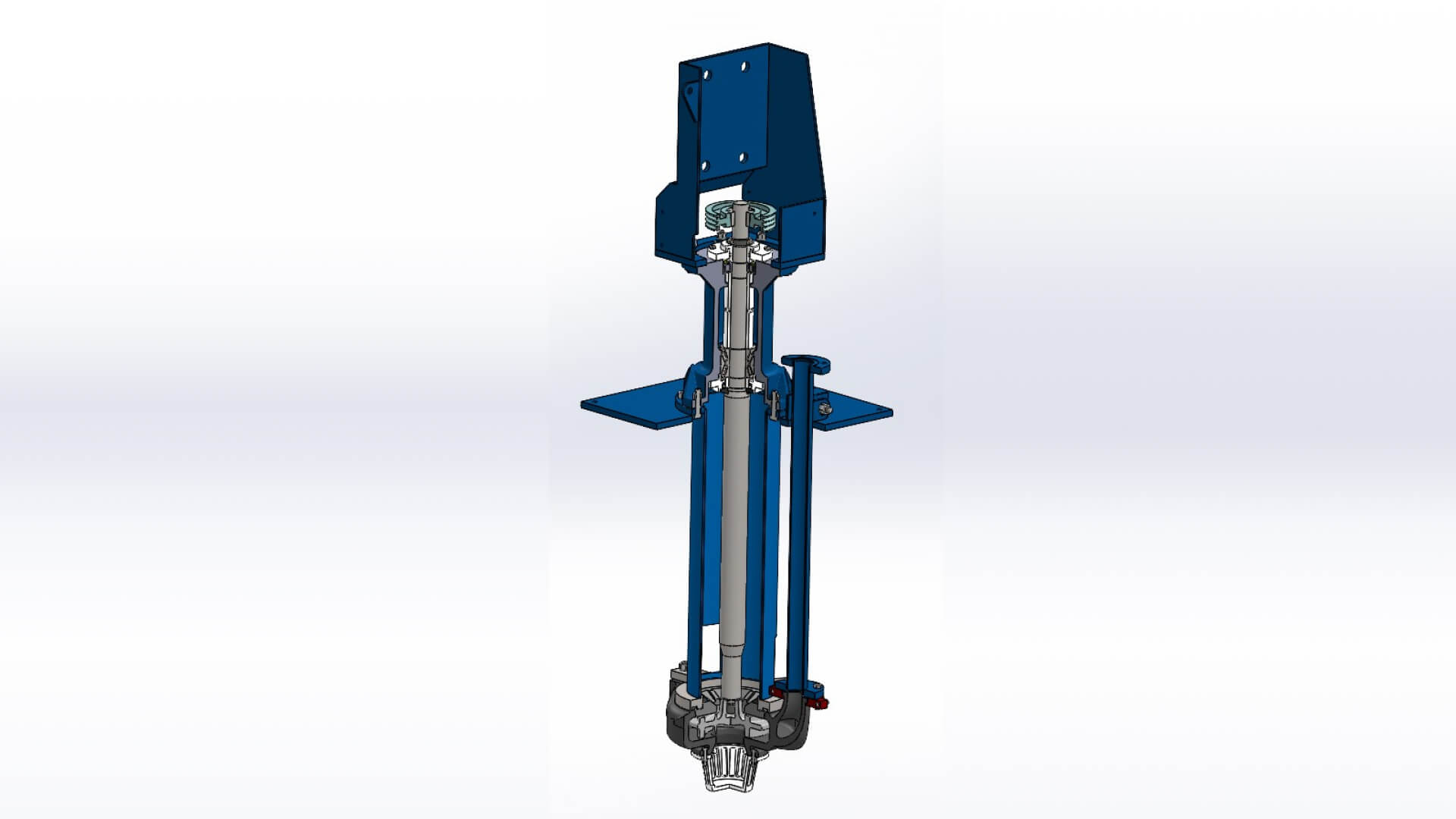

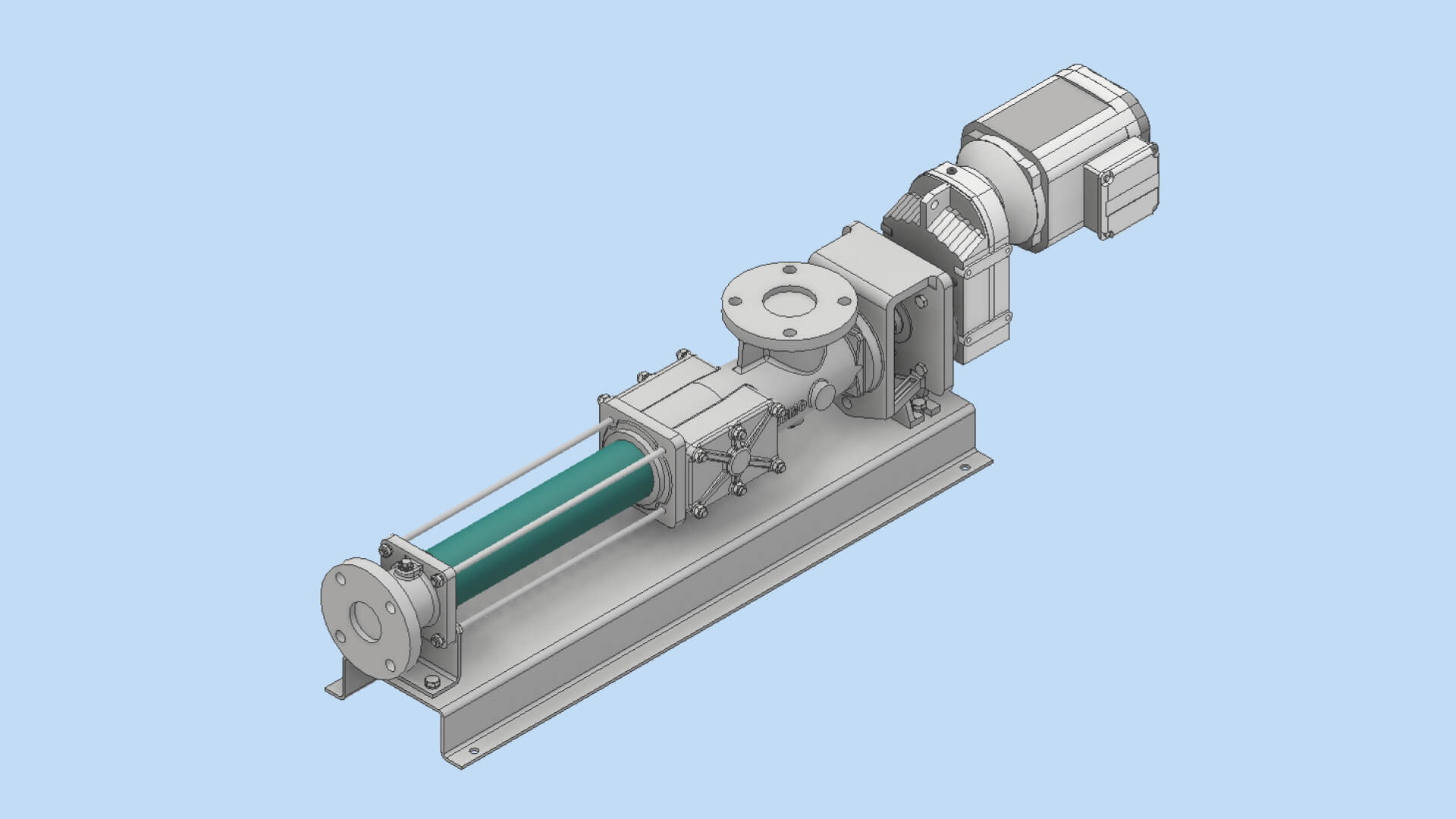

Vertical Sump Pumps

Industrial vertical sump pumps are designed to operate in sumps, pits, or tanks where liquids need t

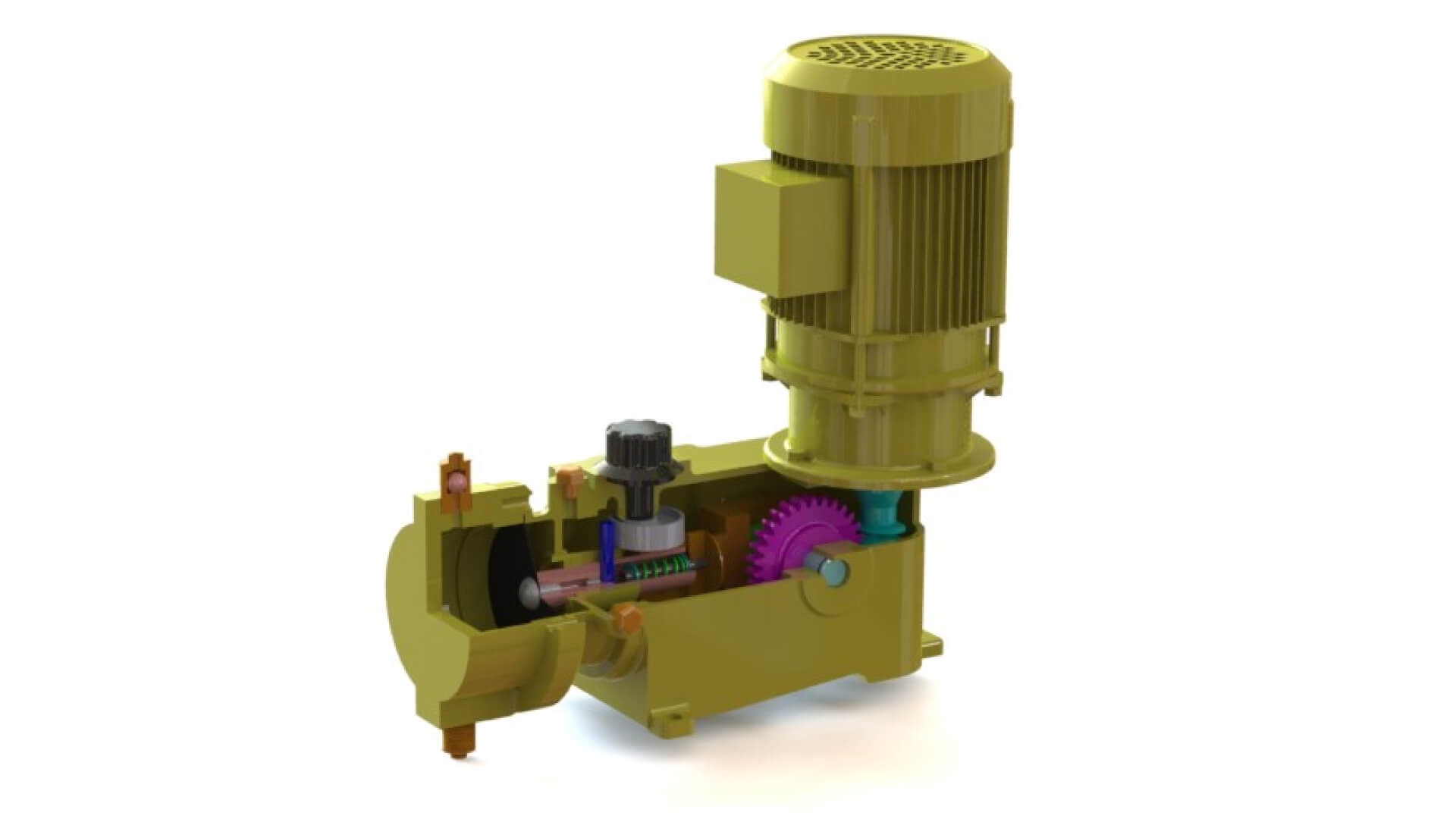

Metering Pumps

A metering pump, also called a dosing or proportioning pump, is used to add small, accurate volumes

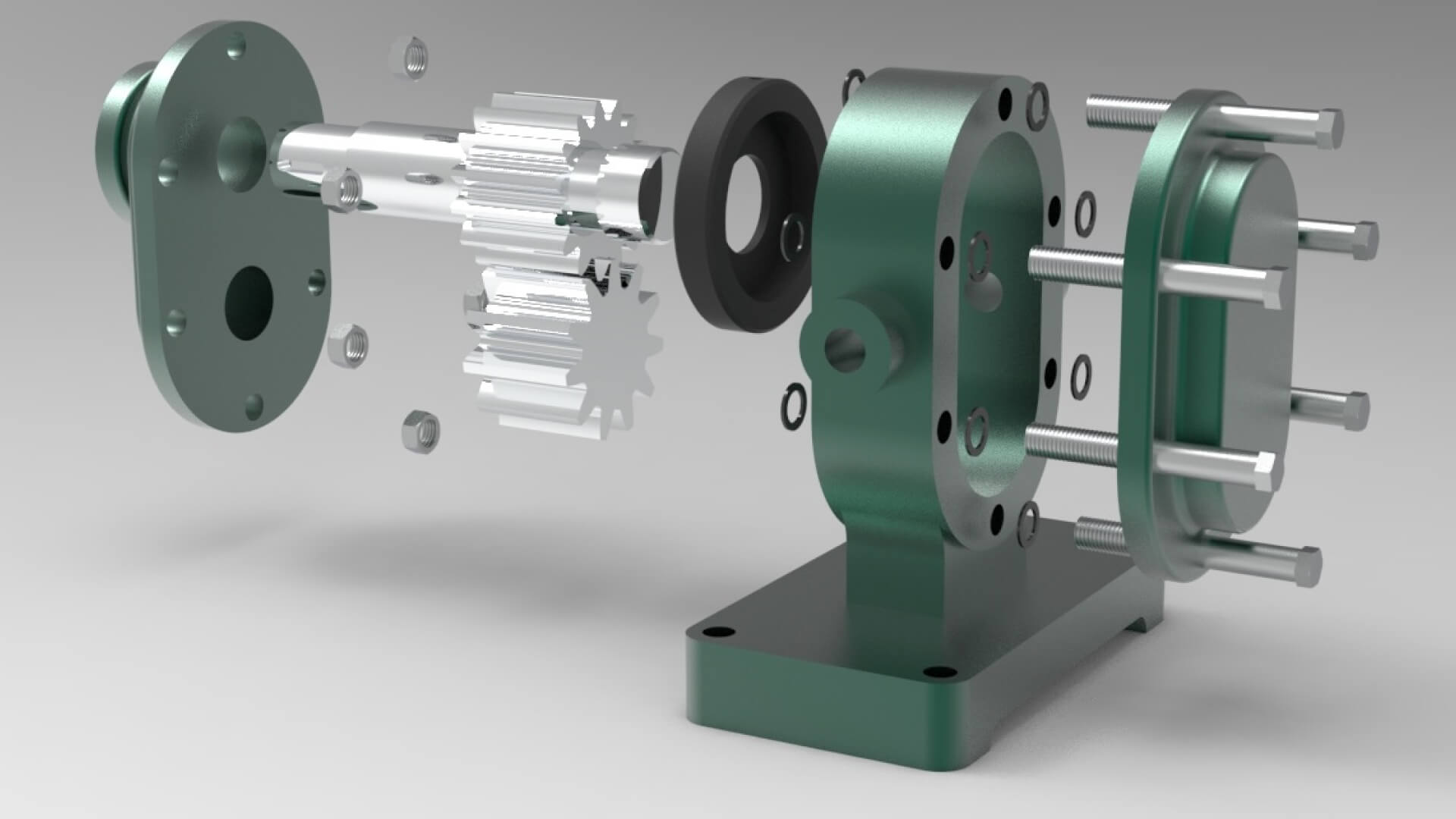

Gear Pumps

A Gear Pump is also called a positive displacement pump, or a spin pump. They consist of two inter-m

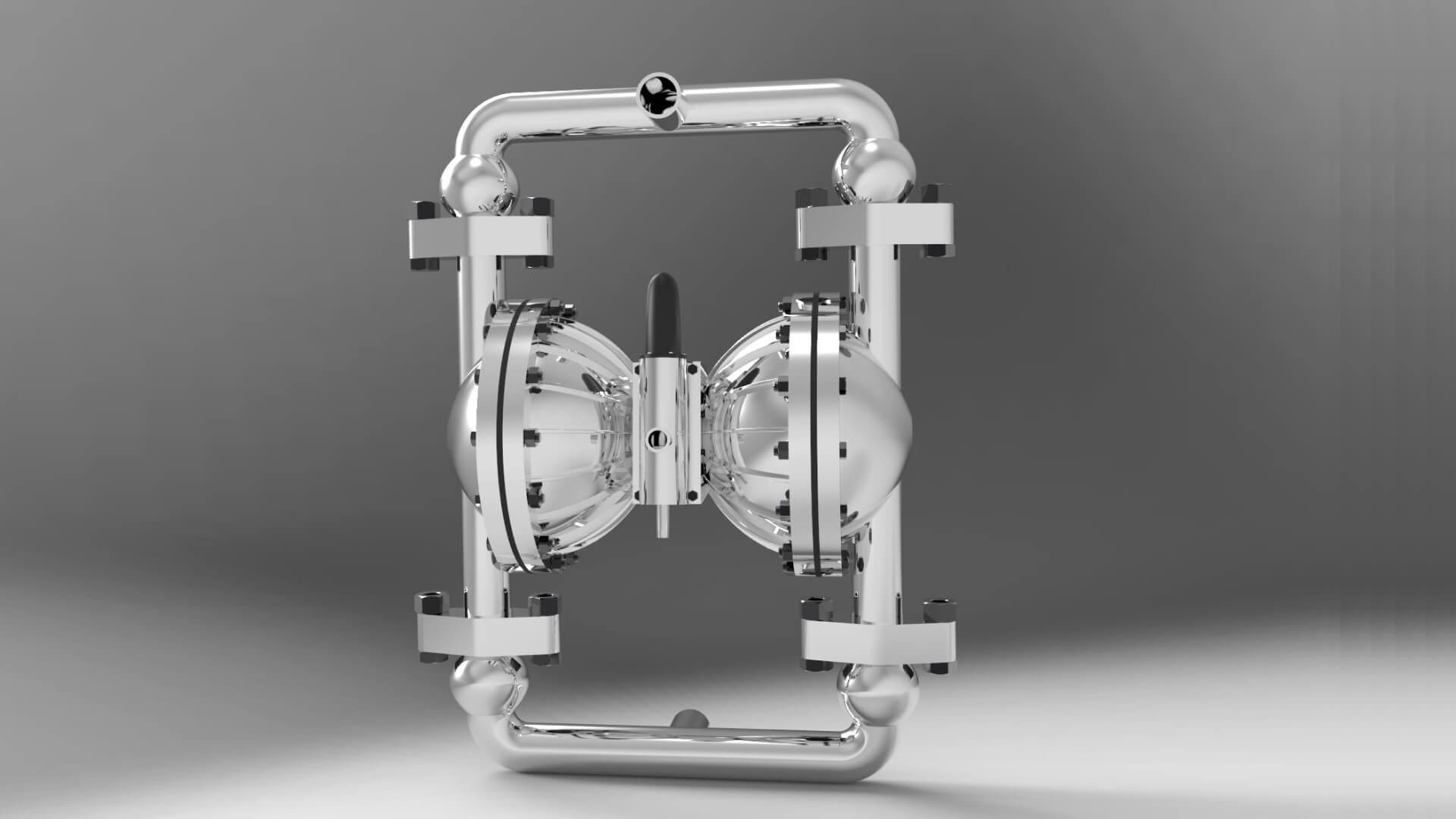

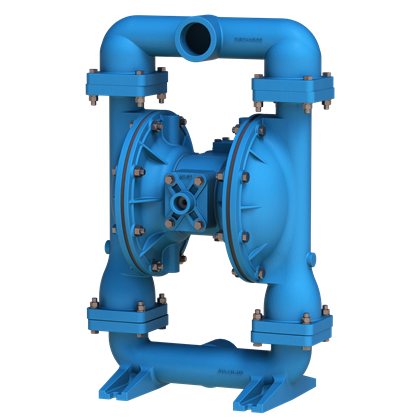

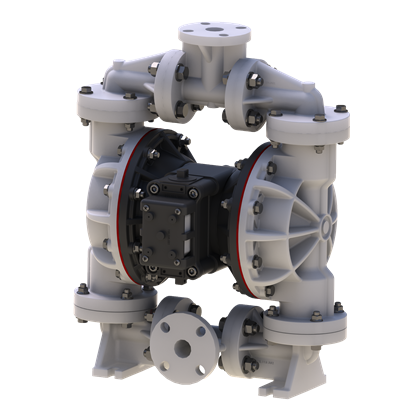

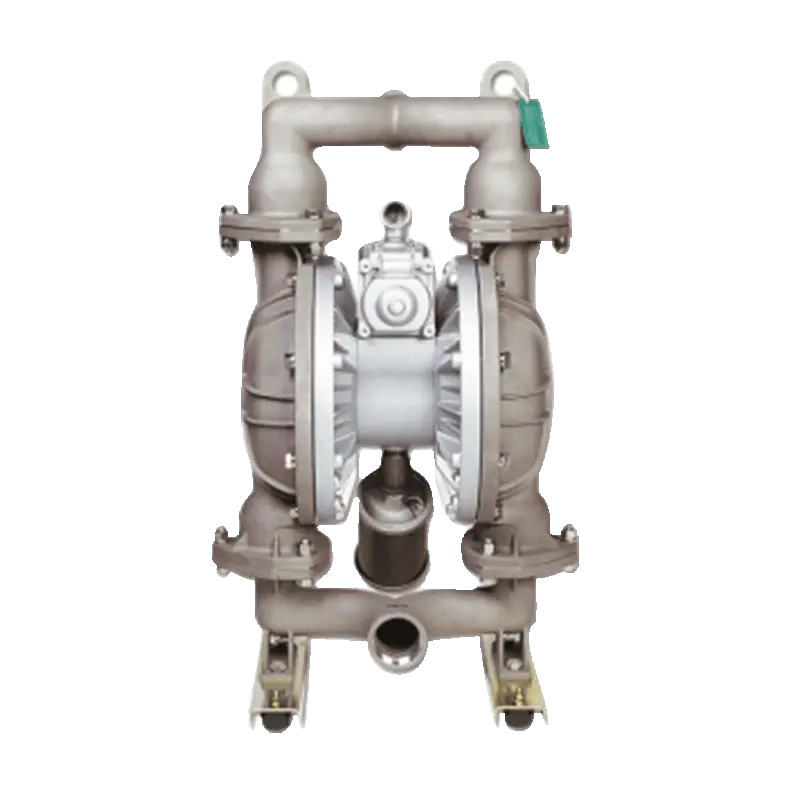

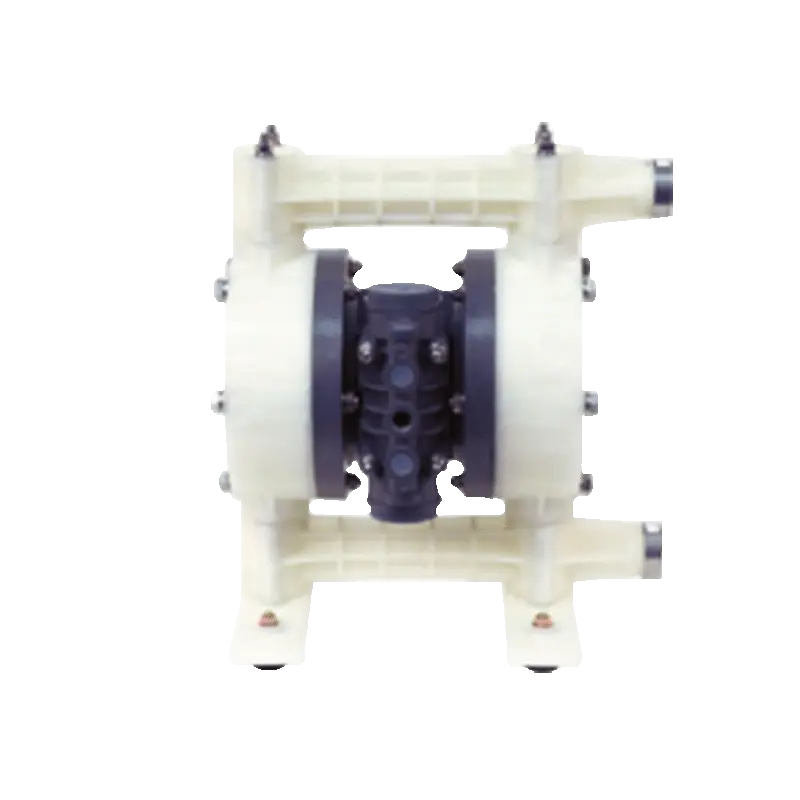

Air-Operated Diaphragm Pumps

Industrial air operated diaphragm pumps are designed to move liquids with high viscosity, solids, or

ANSI Pumps

Industrial pumps that meet the standards of the American National Standards Institute (ANSI) are des

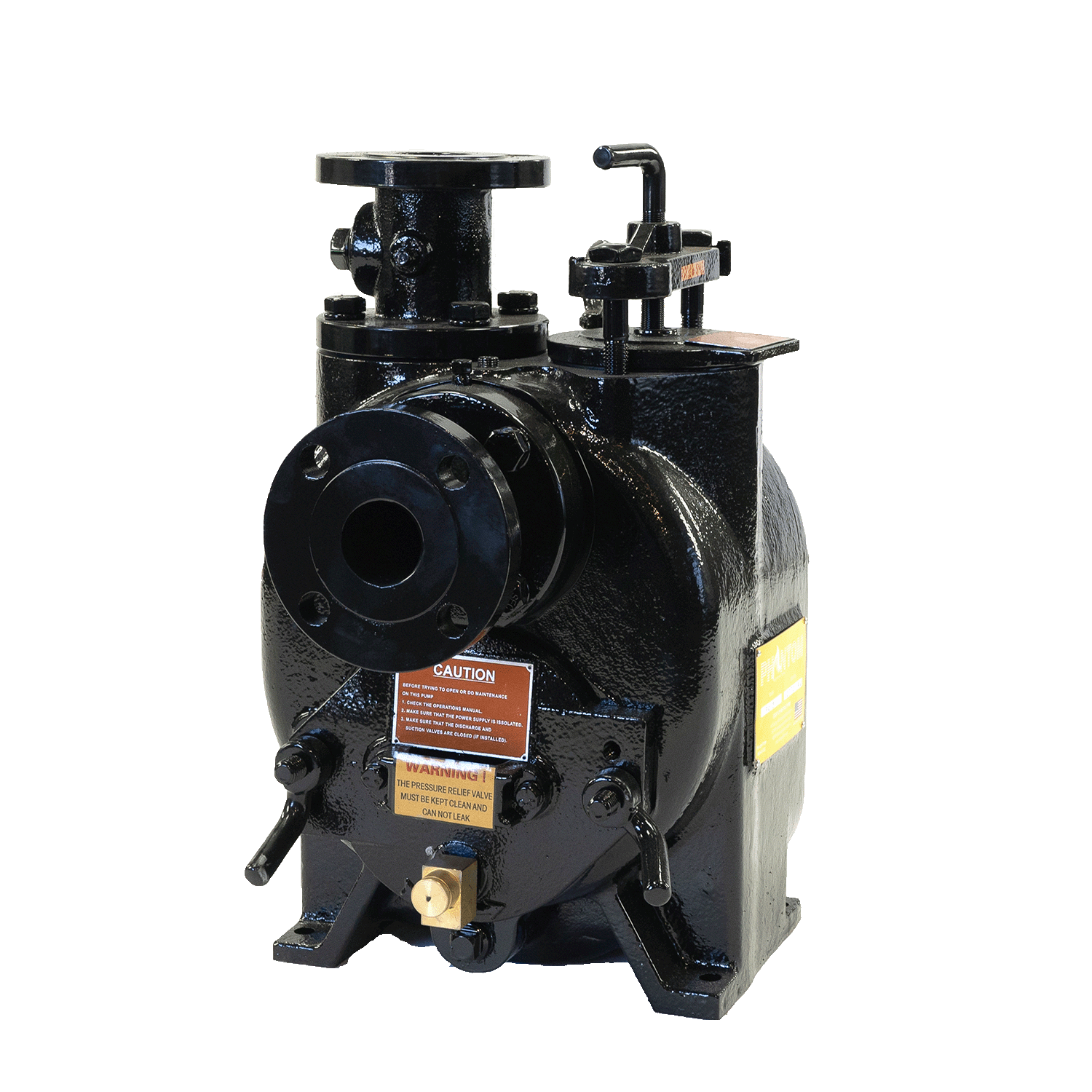

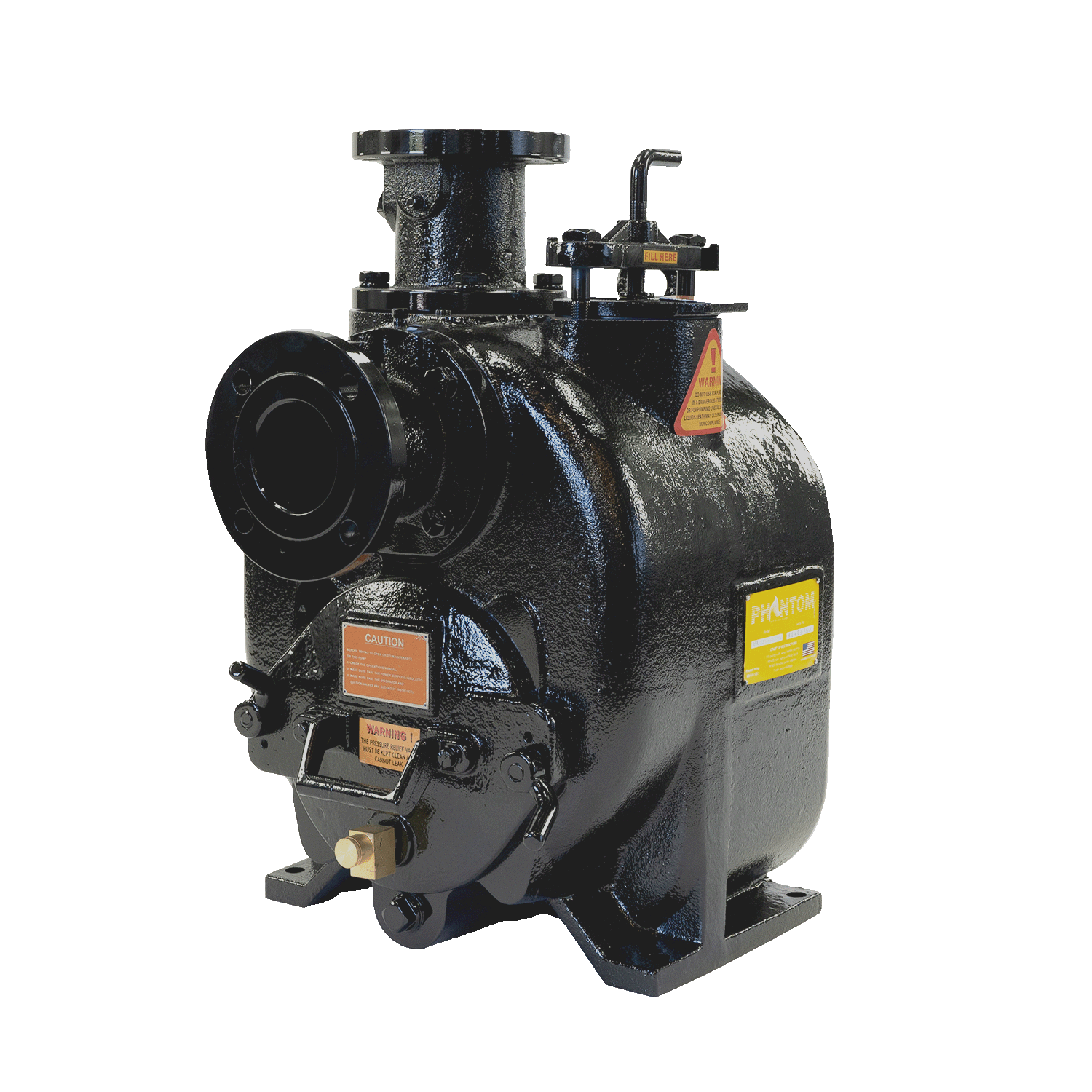

Self-Priming Pumps

Industrial self-priming pumps are designed to prime themselves automatically, meaning they can start