High shear mixing equipment is essential for various industrial processes, ensuring efficiency and quality in operations such as homogenization, granulation, and powder mixing. At Arroyo Process Equipment, we offer a comprehensive range of high shear mixers, supported by our extensive experience and partnerships with leading manufacturers. Whether you’re in one of the many industries—like agricultural, chemical, or pharmaceutical—our high shear mixers can help you achieve optimal results.

High shear mixers are designed to handle the rigorous demands of mixing processes that require intense shear forces to break down particles and create uniform mixtures. These mixers are crucial for applications that involve blending powders, granulating materials, and homogenizing substances to achieve consistent and high-quality outputs.

Our Trusted Equipment Manufacturers

Arroyo Process Equipment partners with leading manufacturers to provide top-quality high shear mixers and related equipment. Our partnerships allow us to offer OEM repair services and source the best equipment in the industry. Some of our trusted partners include:

Sharpe Mixers

Sharpe Mixers is a subsidiary of Hayward Gordon and provide high-performance mixing solutions for various industries. Their innovative designs and robust construction ensure reliable and efficient mixing. Products include:

- Portable Mixers are ideal for small-scale industrial mixing applications, offering flexibility and mobility.

- Side-Entry Mixers are designed for large storage tanks and reactors, providing efficient mixing capabilities.

- Top-Entry Mixers are suitable for applications where the mixer needs to be mounted on top of the tank for thorough mixing.

Hayward Gordon

Hayward Gordon is known for their durable and efficient mixing equipment, Hayward Gordon’s products are ideal for demanding industrial applications, including high shear mixing. Key product:

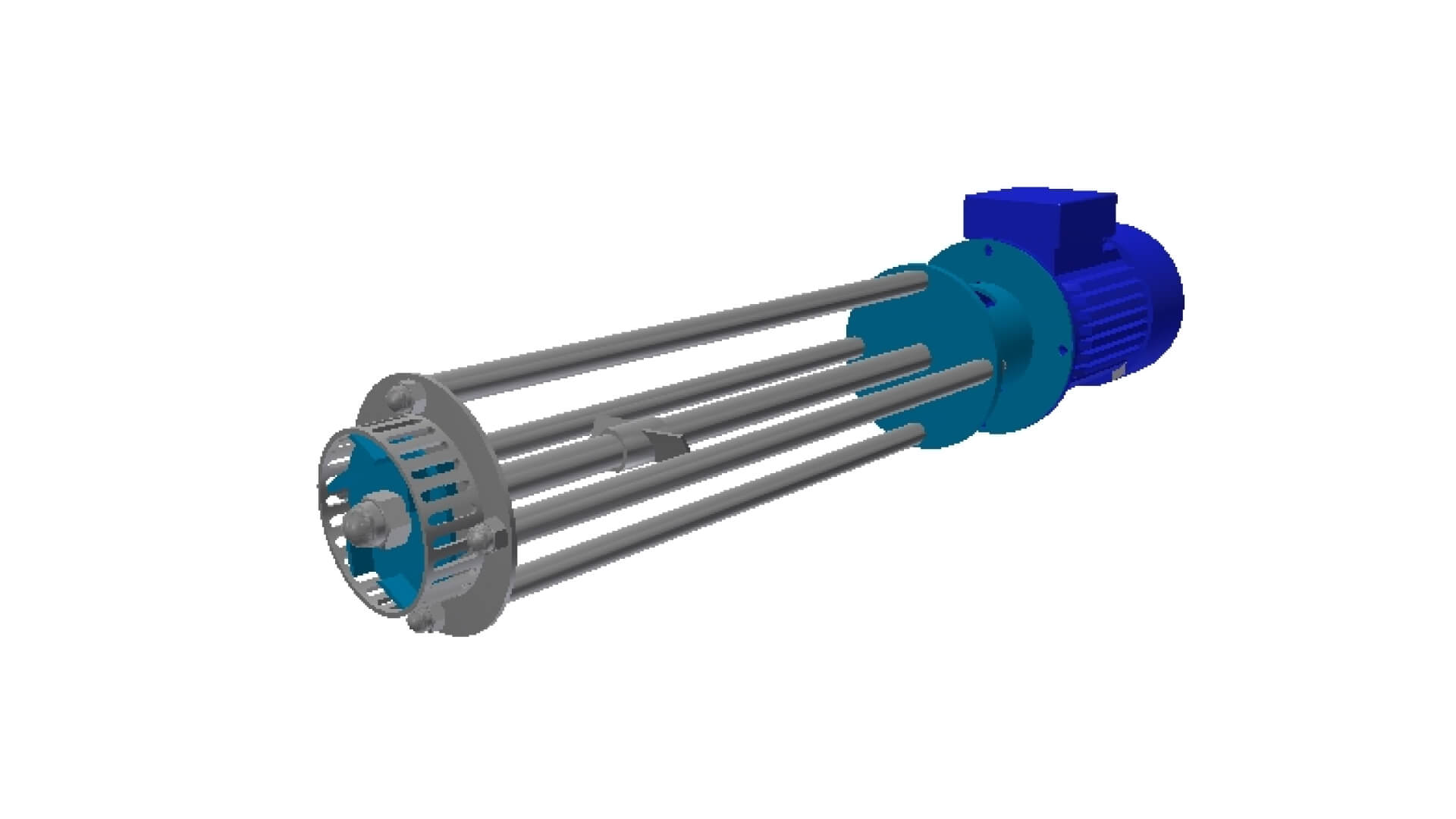

- Dynamic Inline Mixers: Efficient in-line mixing of various materials, ensuring consistent and high-quality results in industrial processes.

Sulzer

Sulzer offers a wide range of high shear mixers designed for optimal performance and reliability. Their mixers are used in various industrial processes, including homogenization and granulation. Key products include:

- Sulzer Salomix SLH Horizontal Agitator: Efficient mixing in large-scale industrial applications.

- Sulzer Salomix SLR Side-Entry Agitator: Ideal for large storage tanks, ensuring uniform blending.

- Sulzer Salomix SSA Agitator: Suitable for top-entry applications, providing robust mixing capabilities.

- Sulzer Salomix SSF Agitator: Designed for thorough mixing from the top of the tank.

- Sulzer SX Chemical Mixer: High-efficiency mixing for chemical processing applications.

Hansen Transmission

- Hansen Transmission provides robust and reliable mixing equipment for various industrial applications. Their products are known for their durability and performance. Key products include:

- Hansen M4 Air Cooled Condenser Drive: Ideal for cooling systems, providing efficient and reliable performance.

- Hansen P4 Multistage – Horizontal: Suitable for horizontal mounting, offering multi-stage mixing capabilities.

- Hansen P4 Multistage – Vertical: Designed for vertical mounting, providing robust multi-stage mixing.

- Hansen P4 Single Stage: Efficient single-stage mixing solution for various industrial applications.

- Hansen P4 UniMiner: Versatile and robust, ideal for mining and other demanding industrial environments.

Key Applications of High Shear Mixers

Shear Mixing involves using high-speed rotors to create shear forces that mix materials efficiently. This process is vital in industries where precise mixing is required to ensure product consistency and quality.

High Shear Homogenizers are used to break down particles and create uniform mixtures, especially in the pharmaceutical and food industries. These homogenizers ensure that ingredients are evenly distributed, resulting in stable and homogeneous products.

Powder Mixing use high shear mixers because of their ideal for ensuring that the particles are evenly distributed. This process is crucial in industries such as pharmaceuticals, where uniformity is essential for product efficacy.

Granulation involves forming powder particles into larger granules. High shear mixers are used in this process to ensure that the granules are uniform in size and consistency, which is essential for tablet formation in the pharmaceutical industry.

Types of High Shear Mixing Equipment

Arroyo Process Equipment offers a wide range of high shear mixers to meet the specific needs of various industries. Our ability to source includes:

Large Gear Box in Tank Mixers are ideal for large-scale operations that require powerful mixing capabilities. They are commonly used in the chemical and pharmaceutical industries.

Top Entry Mixers are versatile and can handle a variety of mixing tasks. They are suitable for applications where the mixer needs to be mounted on top of the tank.

Side Entry Mixers are designed for applications where the mixer needs to be mounted on the side of the tank. They are commonly used in large storage tanks and reactors.

Bottom Entry Mixers: Bottom entry mixers are ideal for applications that require thorough mixing from the bottom of the tank. They are often used in the food and beverage industry.

In-Line Mixers are used for continuous mixing processes, ensuring that materials are mixed as they flow through the mixer. They are ideal for high-throughput operations.

Static Mixers use stationary mixing elements to blend materials as they pass through the mixer. They are energy-efficient and require minimal maintenance.

Mixer Repair and Best Practices

Maintaining and repairing high shear mixing equipment is crucial to ensure long-term efficiency and reliability. Arroyo Process Equipment offers comprehensive repair services and best practices for equipment maintenance, focusing on leading brands like Sulzer, Sharpe Mixers, Hayward Gordon, Hansen Transmission, and Lightnin Mixers.

Best Practices for Maintaining High Shear Mixers:

Routine Inspections: Regularly inspect your mixing equipment to identify any signs of wear and tear, leaks, or unusual noises. Early detection of issues can prevent major problems.

Cleaning and Debris Removal: Keep mixers clean and free from debris that could cause blockages or reduce efficiency. This is especially important for mixers handling powders and viscous materials.

Lubrication: Proper lubrication of moving parts reduces friction and wear. Follow the manufacturer’s recommendations for the type and frequency of lubrication required.

Component Checks: Inspect critical components such as seals, bearings, and rotors. Replace any worn or damaged parts promptly to maintain optimal performance.

Professional Servicing: Engage professional services for comprehensive maintenance and repairs. Arroyo Process Equipment offers expert servicing for mixers from top brands like Lightnin Mixers, ensuring your equipment stays in top condition.

Benefits of Professional Repair Services:

Expertise and Experience: Our team has extensive experience in repairing high shear mixers, ensuring that your equipment receives the best possible care.

OEM Parts: We prioritize using original equipment manufacturer (OEM) parts to guarantee compatibility and longevity.

Comprehensive Diagnostics: Our repair services include thorough diagnostics to identify and address all potential issues, ensuring your mixer operates smoothly and efficiently.

How to Choose the Right High Shear Mixer

Selecting the right high shear mixer involves several important considerations:

Nature of the Materials: Understand the type of materials you need to mix. Different materials require specific mixing techniques to achieve the desired consistency and quality.

Mixing Volume: Determine the volume of materials that need to be processed. The mixer’s capacity must match your production requirements.

Shear Force Requirements: Consider the shear force needed to achieve the desired mixing results. High shear mixers are designed to provide the necessary force for efficient mixing.

Energy Efficiency: Look for mixers that offer high energy efficiency to reduce operational costs and environmental impact.

Maintenance and Servicing: Choose mixers that are easy to maintain and service. Arroyo Process Equipment offers comprehensive maintenance and repair services to ensure your equipment operates smoothly and efficiently.

Why Choose Arroyo Process Equipment?

Since 1968, we’ve offered a comprehensive range of high-quality high shear mixers and related services that support the industrial community. Our expertise and partnerships with leading manufacturers ensure that we can provide the best solutions for your mixing needs.

Benefits of Partnering With Us:

Wide Selection of Products: We offer a large selection of high shear mixers, ensuring the right solution for every need.

Quality Products and Equipment: We use only high-quality products and equipment from leading manufacturers, guaranteeing reliability and longevity.

Knowledgeable & Professional Team: Our team of experts is available to help you every step of the way, from selecting the right mixer to installation and maintenance.

Easy Quote Request: It’s simple to request a quote online, providing a hassle-free way to get the information you need.

Comprehensive Services: We offer installation, maintenance, and repair services to ensure your mixing equipment operates smoothly and efficiently.

High shear mixing equipment is vital for achieving efficient and consistent results in various industrial processes. By choosing reliable high shear mixers from Arroyo Process Equipment, you can ensure that your operations are efficient, reliable, and produce high-quality outcomes. Contact us today to learn more about our high shear mixing solutions and how we can help optimize your processes.