Industries / Chemical

Overcome the challenges of chemical handling

We help producers work safely and effectively against many challenges when working with complicated chemicals—like transporting, conveying, and picking the right equipment.

Notable Sectors We Partner With

Unlock the potential of your specialized industry

We’re proud to partner with leaders across the chemical industry to always provide the best available equipment lead times, around the clock emergency services, and tailored preventative maintenance plans.

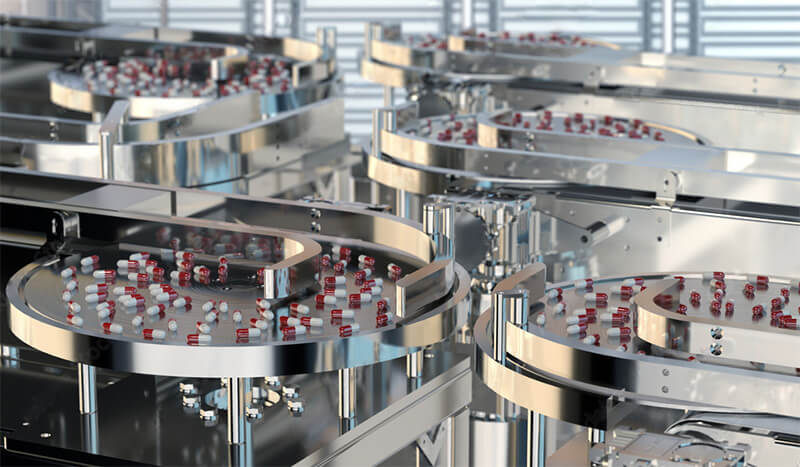

The Importance of Rotating Equipment in Pharmaceuticals

The production of high-quality pharmaceuticals requires precise and consistent processing of raw materials, and the use of rotating equipment such as mixers, mills, and granulators is essential to achieving this. In addition, the application of pharmaceutical products requires specialized equipment such as packaging machines and tablet presses, which ensure a consistent dosage and meet industry standards. Explore how our team assists leaders in the industry by sourcing and maintaining equipment.

Crafting the Perfect Scent to Optimize Fragrance Production

The production of high-quality fragrances requires precise and consistent processing of ingredients, and the use of rotating equipment such as mixers, reactors, and distillation columns is essential to achieving this. In addition, the application of fragrances to products requires specialized equipment such as spray drying machines and fillers, which ensure a consistent and even distribution of the fragrance. Explore how our team assists leaders in the industry by sourcing and maintaining equipment.

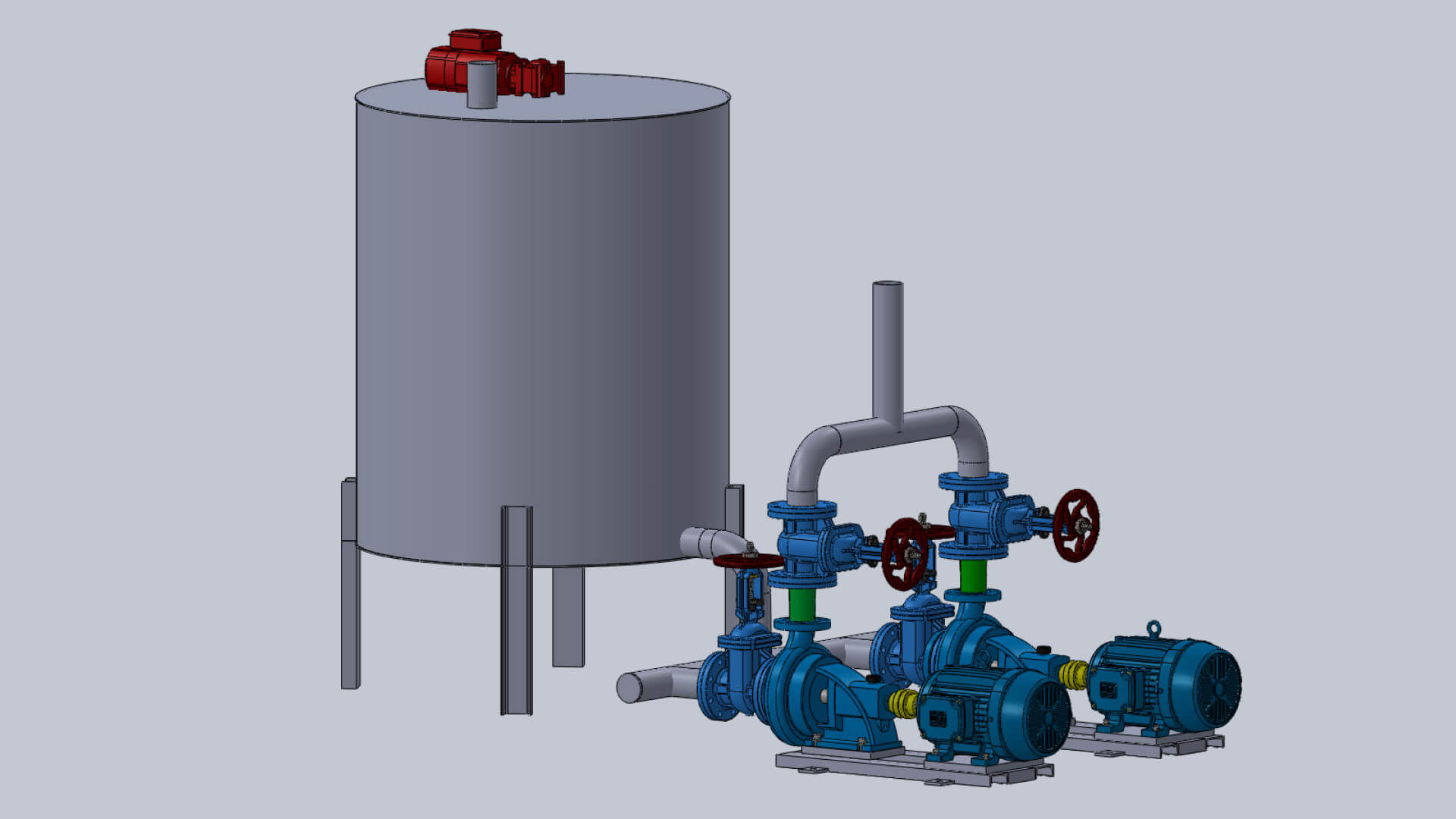

Advanced Equipment for Reliable Resins Production

The production of high-quality resins requires precise and consistent processing of raw materials, and the use of rotating equipment such as mixers, reactors, and pumps is essential to achieving this. In addition, the application of resins to products requires specialized equipment such as extruders and coating machines, which ensure a consistent and even distribution of the resin. Explore how our team assists leaders in the industry by sourcing and maintaining equipment.

The Power of Rotating Equipment in Paints & Pigments Production

The production of high-quality paints and pigments requires precise and consistent processing of raw materials, and the use of rotating equipment such as mixers, reactors, and mills is essential to achieving this. In addition, the application of paints and pigments requires specialized equipment such as sprayers and dispensers, which ensure a consistent and even distribution of the paint or pigment. Explore how our team assists leaders in the industry by sourcing and maintaining equipment.

Advantages of Quality Equipment in Flavorings Production

The production of high-quality flavorings requires precise and consistent processing of raw materials, and the use of rotating equipment such as mixers, blenders, and reactors is essential to achieving this. In addition, the application of flavorings requires specialized equipment such as spray dryers and fluid bed processors, which ensure a consistent and even distribution of the flavoring. Explore how our team assists leaders in the industry by sourcing and maintaining equipment.

How Rotating Equipment is Revolutionizing Cosmetics

Cosmetics are composed of a wide range of chemicals and require specialized equipment to blend, mix, and process these ingredients into a final product. From emulsifying creams and lotions to milling pigments and blending fragrances, rotating equipment is essential to achieving a consistent and high-quality product. Equipment such as mixers, blenders, and reactors are commonly used in the manufacturing process, along with more specialized equipment such as mills, homogenizers, and spray dryers. Explore how our team assists leaders in the industry by sourcing and maintaining equipment.

Excel in your unique production applications

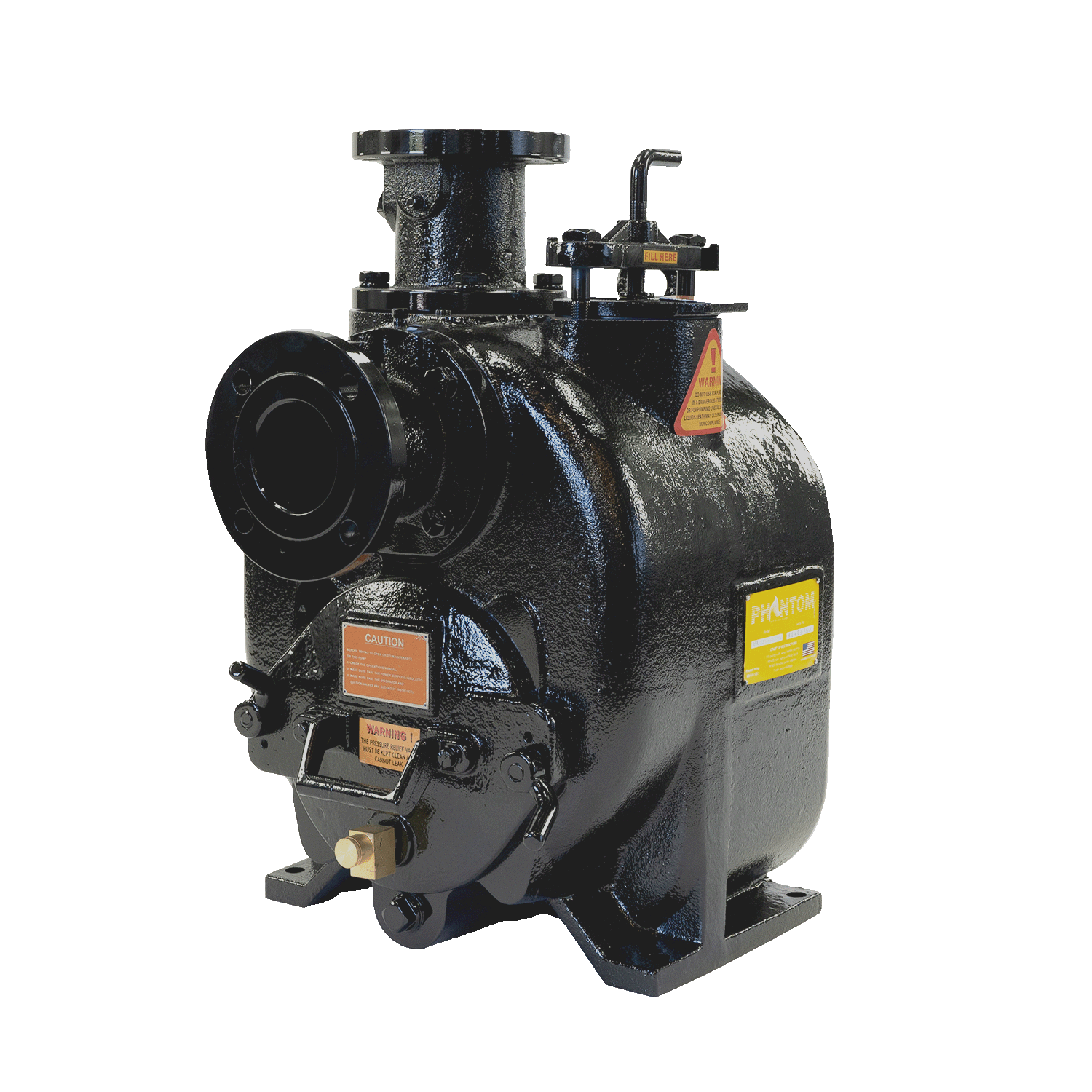

Our equipment has a safety-compliant design that improves productivity, reduces incidents, and is suited for applications with or without direct contact with the chemicals, such as:

- Fine chemicals

- Metals recovery

- Manufacturing of chemical intermediate & end products

- Production of sulphuric acid

- Production of fertilizers

- Large-scale electroplating

- Hazardous waste treatment

- Wastewater purification

- Acidity regulation

- Anodizing plants

- Chlorine chemistry

- Electrolytic processes

- Exhaust air scrubber

- Chemical flue-gas cleaning

- Steel and stainless steel pickling

Ready to get started?

Let us know more about your specific needs, and a team member will contact you regarding the next steps.

Discover more about the industry

Use our resources to learn more about how the industrial chemical industry changes through various applications, related products, and process improvements.

The Foundations of Acid-Resistant, Submersible Pumps

Acid-resistant pumps are a type of industrial pump designed specifically for handling corrosive chem

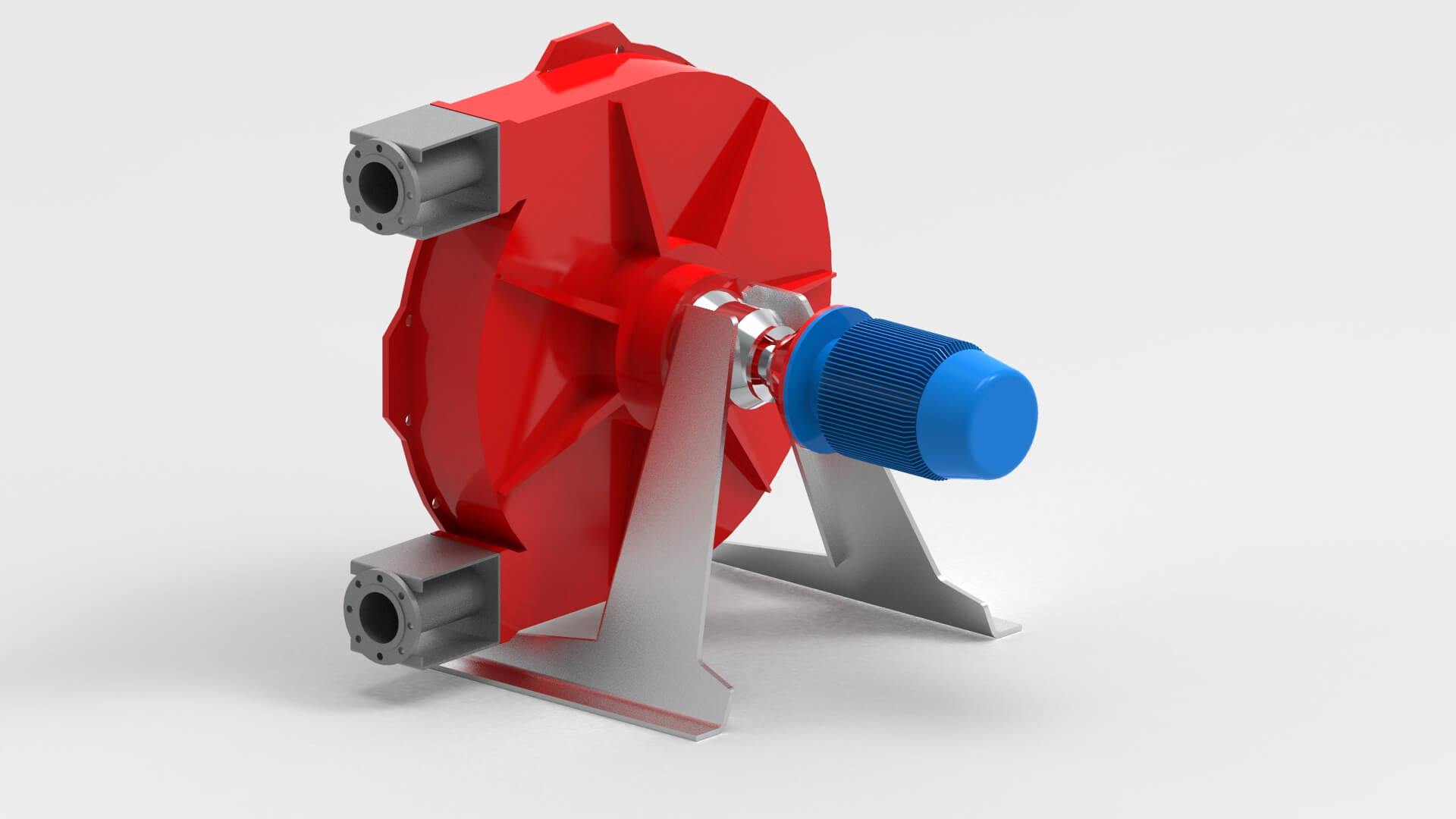

Bredel Hose Pump

Bredel Hose Pumps provide reliable and efficient self-priming pumping of highly viscous, abrasive an

Guide to Acid Pumps: Solutions for Corrosive Applications

Due to the nature of the abrasive media acid pumps must transfer and handle, like hydrofluoric and s

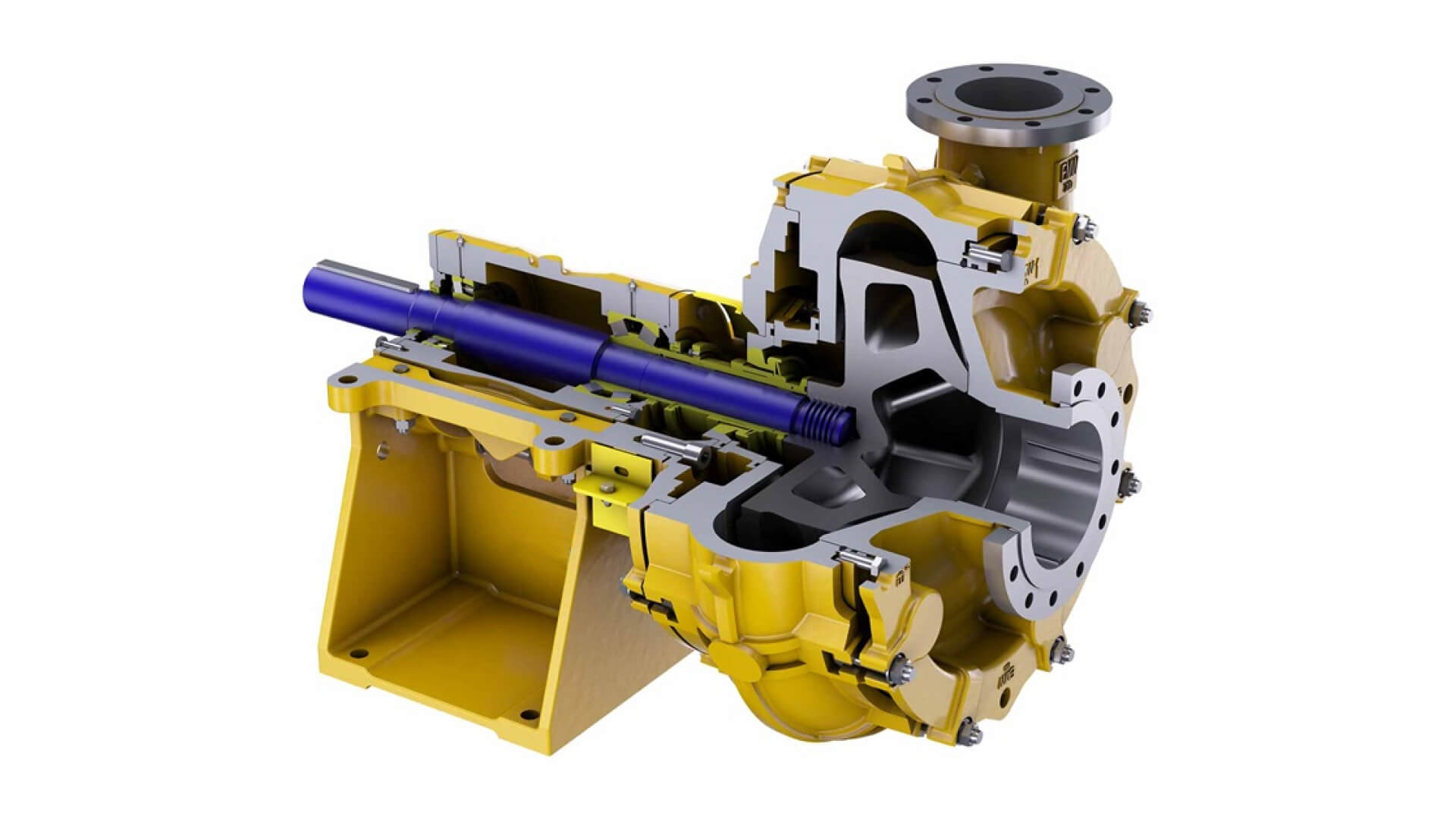

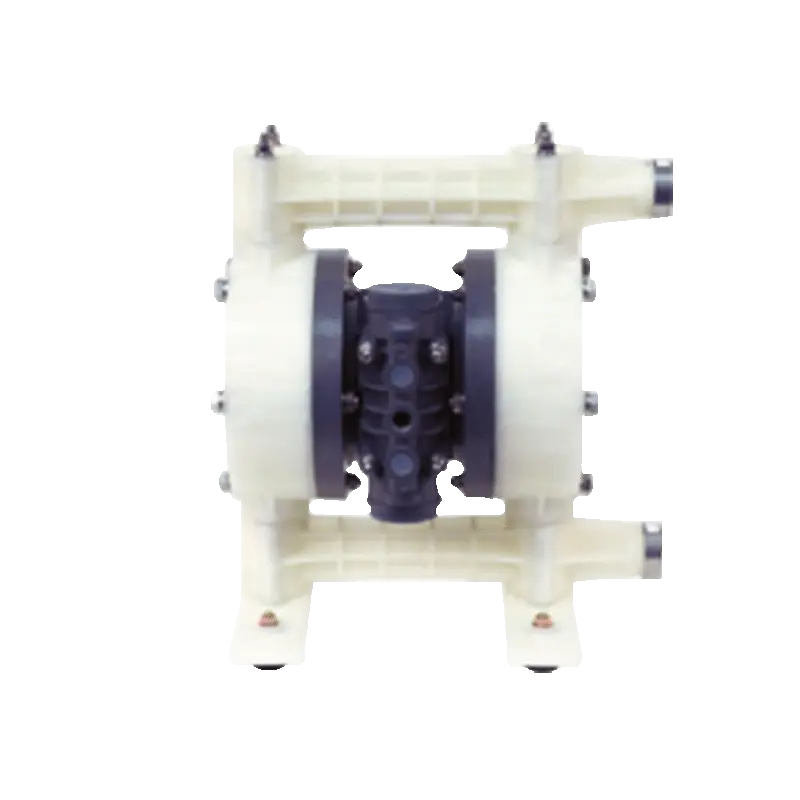

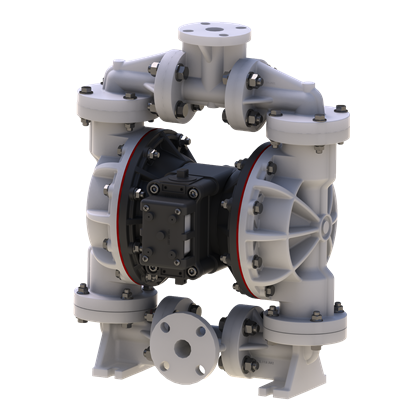

Introduction to Chemical Process Pumps

When picking the right industrial chemical process pump for your application, there is a lot to cons

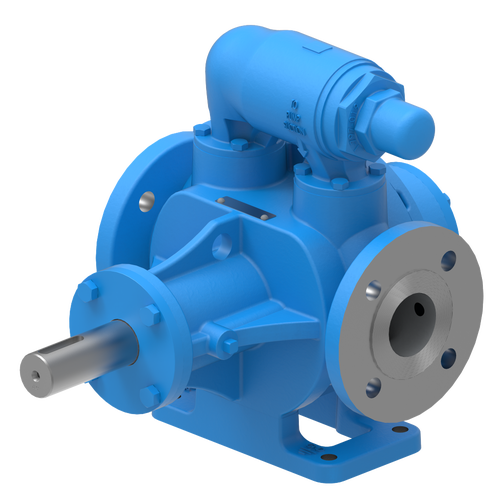

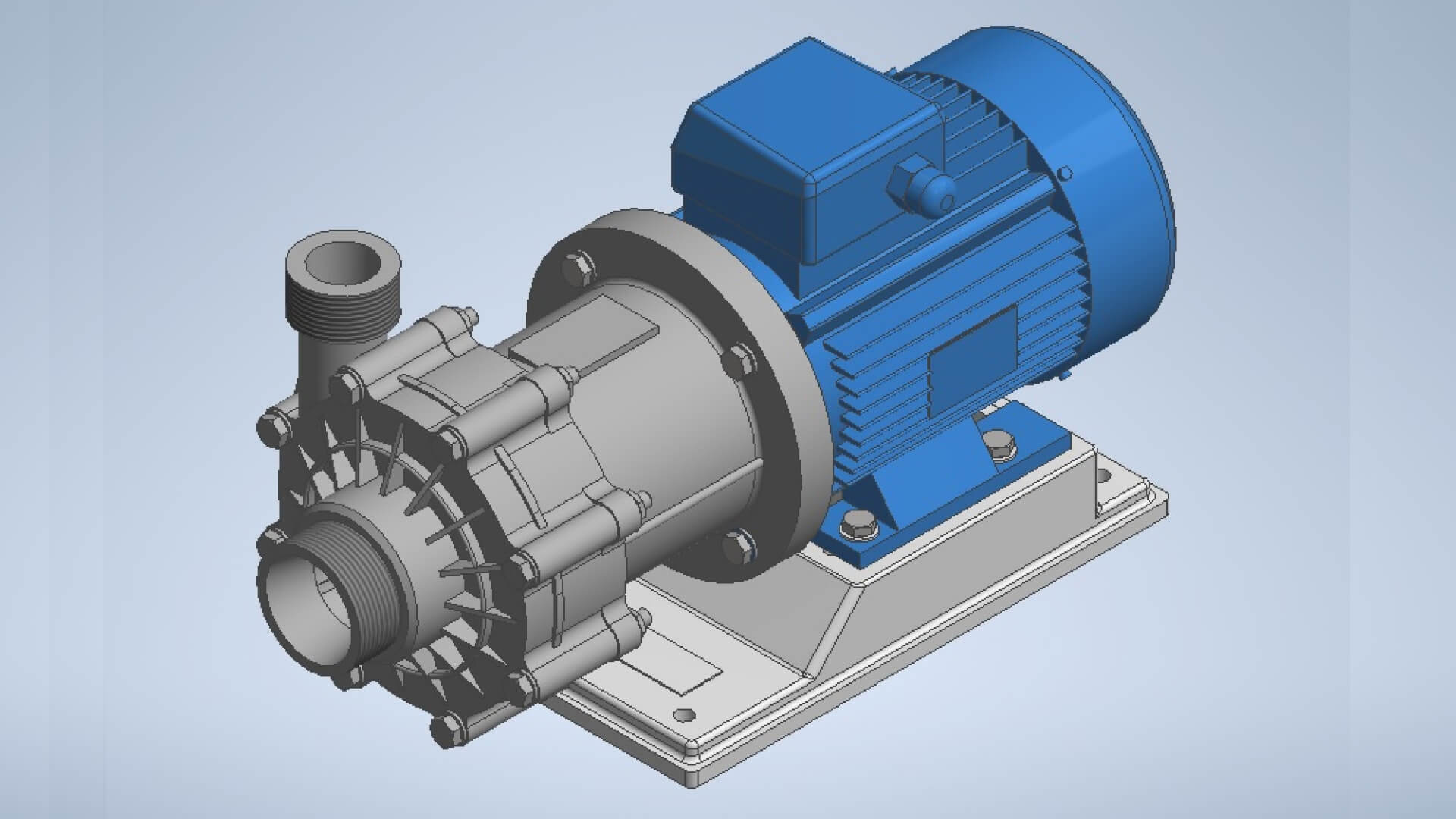

Close Coupled Pumps

Close-coupled pumps contain a common motor and pump shaft or a motor shaft and pump shaft that are c

Hot Oil Pumps

A hot oil pump, also referred to as a thermal oil pump, is designed for moving heat transfer fluids

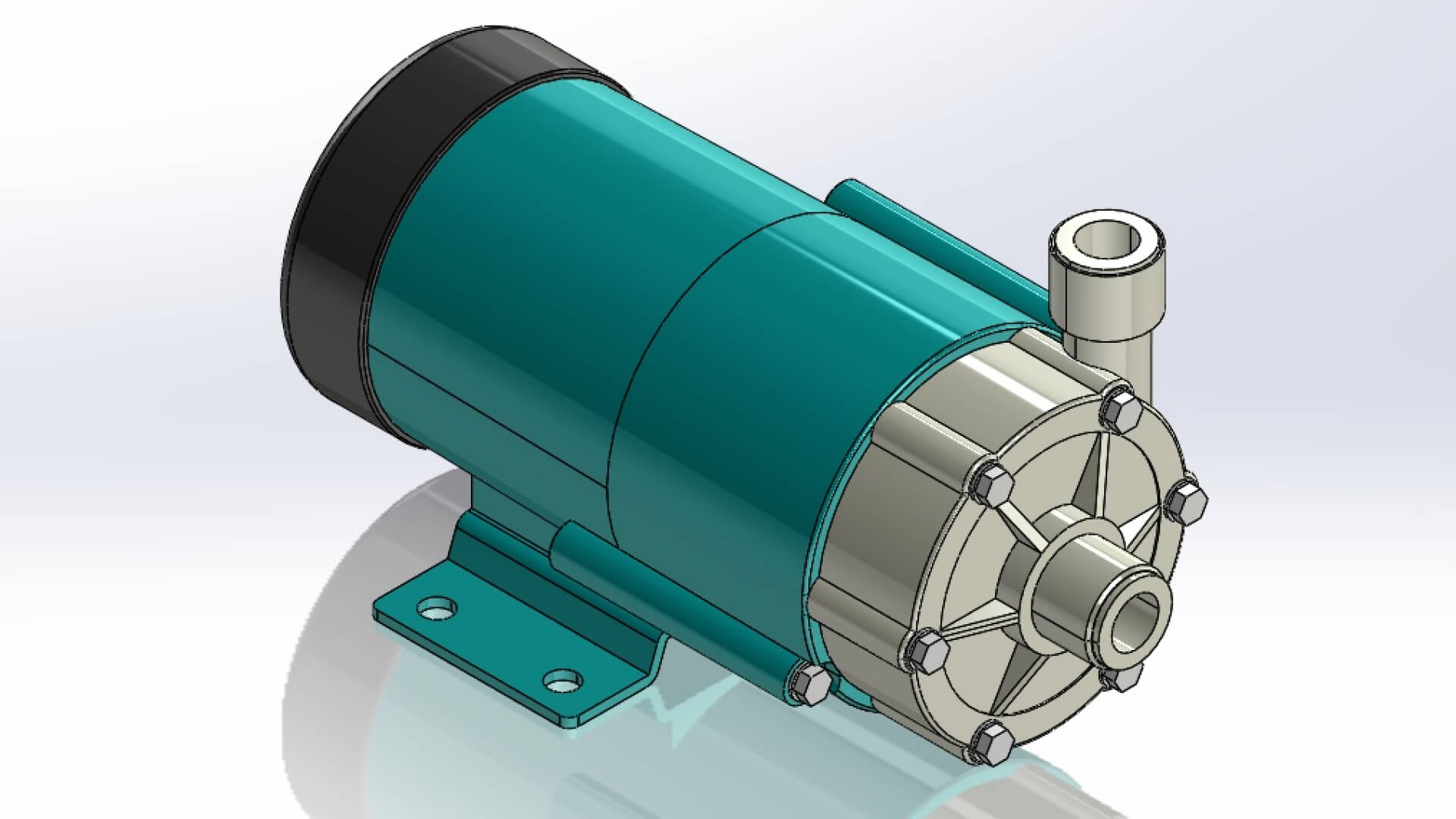

Sulfuric Acid Pumps

Sulfuric acid can dissolve most metals. Pumps that feature mag-drive technology offer seal-less oper

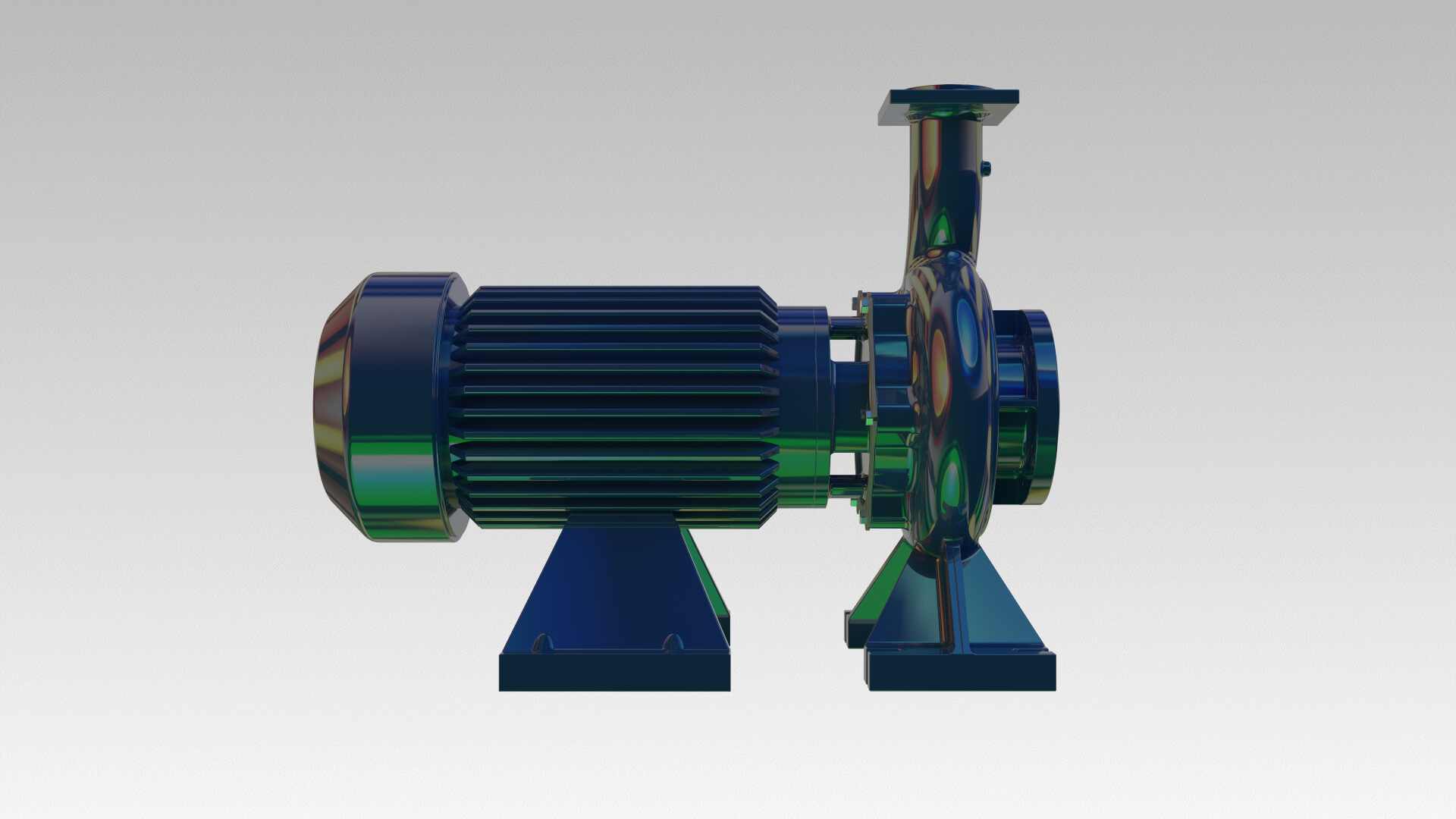

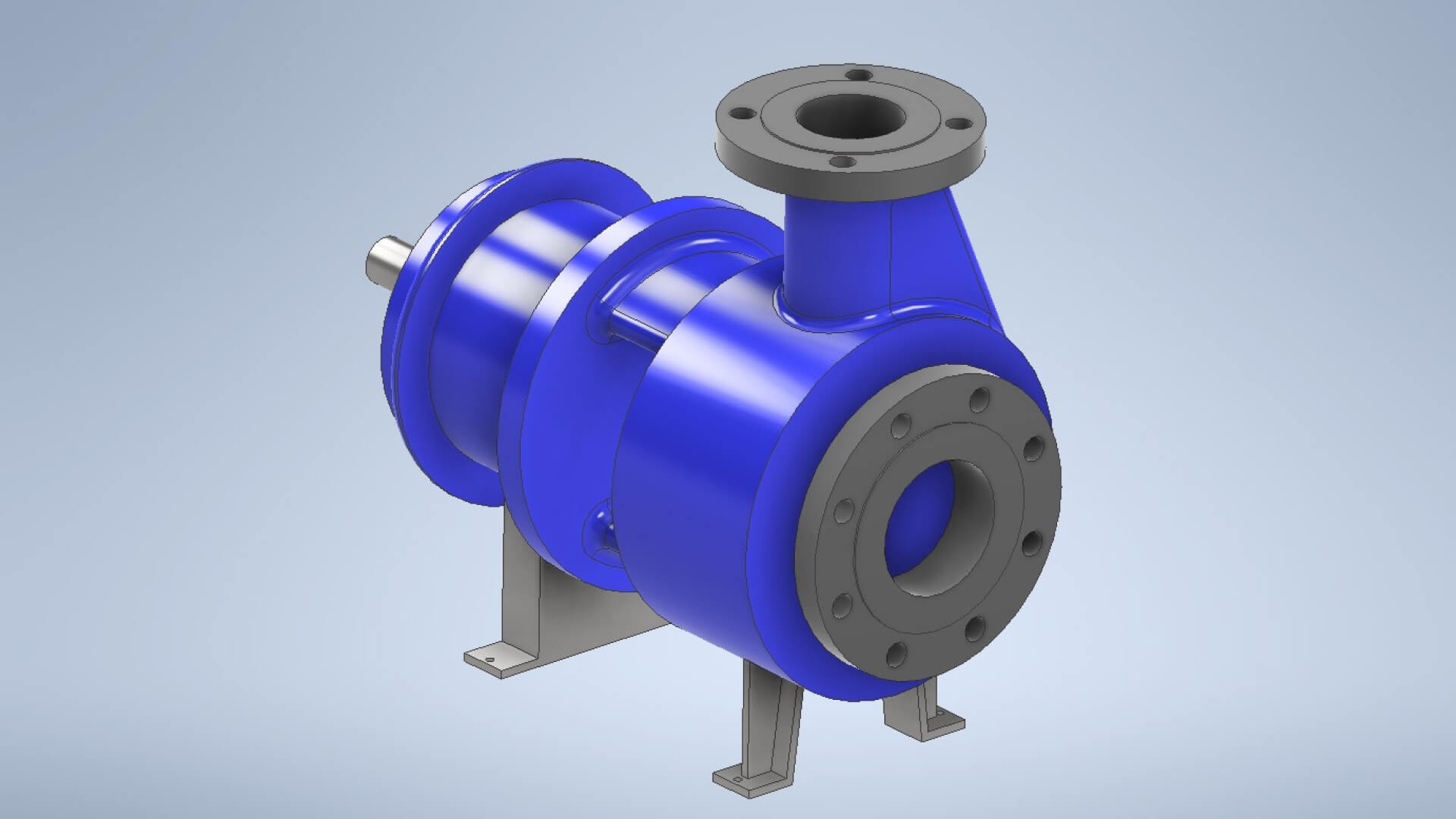

ANSI Chemical Process Pumps

ANSI pumps are centrifugal process pumps that meet the standards of the ANSI. These chemical pumps a

Fertilizer Pumps

Pumps are essential to phosphate fertilizer production. Hydraulic design, materials of construction,